ASTM D2442-75(2001)

(Specification)Standard Specification for Alumina Ceramics for Electrical and Electronic Applications

Standard Specification for Alumina Ceramics for Electrical and Electronic Applications

SCOPE

1.1 This specification covers the requirements for fabricated alumina parts suitable for electronic and electrical applications and ceramic-to-metal seals as used in electron devices. This standard specifies limits and methods of test for electrical, mechanical, thermal, and general properties of the bodies used for these fabricated parts, regardless of part geometry.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2442 – 75 (Reapproved 2001)

Standard Specification for

Alumina Ceramics for Electrical and Electronic

Applications

This standard is issued under the fixed designation D2442; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope mittivity (Dielectric Constant) of Solid Electrical Insula-

tion

1.1 Thisspecificationcoverstherequirementsforfabricated

D257 Test Methods for DC Resistance or Conductance of

alumina parts suitable for electronic and electrical applications

Insulating Materials

and ceramic-to-metal seals as used in electron devices. This

D618 Practice for Conditioning Plastics for Testing

standard specifies limits and methods of test for electrical,

D1711 Terminology Relating to Electrical Insulation

mechanical, thermal, and general properties of the bodies used

D1829 Test Method for Electrical Resistance of Ceramic

for these fabricated parts, regardless of part geometry.

Materials at Elevated Temperatures

1.2 The values stated in SI units are to be regarded as the

D2149 Test Method for Permittivity (Dielectric Constant)

standard. The values given in parentheses are for information

and Dissipation Factor of Solid Ceramic Dielectrics at

only.

Frequencies to 10 MHz and Temperatures to 500°C

2. Referenced Documents D2520 Test Method for Complex Permittivity (Dielectric

Constant) of Solid Electrical Insulating Materials at Mi-

2.1 ASTM Standards:

crowave Frequencies and Temperatures to 1650°C

C20 Test Methods for Apparent Porosity, Water Absorp-

E6 Terminology Relating to Methods of Mechanical Test-

tion, Apparent Specific Gravity, and Bulk Density of

ing

Burned Refractory Brick and Shapes by Boiling Water

E12 Terminology Relating to Density and Specific Gravity

C108 Symbols for Heat Transmission

of Solids, Liquids, and Gases

C242 Terminology of Ceramic Whitewares and Related

E122 Practice for Calculating Sample Size to Estimate,

Products

with a Specified Tolerable Error, the Average for a Char-

C408 Test Method forThermal Conductivity ofWhiteware

acteristic of a Lot or Process

Ceramics

E165 Practice for Liquid Penetrant Inspection Method

C573 Methods for Chemical Analysis of Fireclay and

E228 Test Method for Linear Thermal Expansion of Solid

High-Alumina Refractories

Materials with a Vitreous Silica Dilatometer

C623 Test Method for Young’s Modulus, Shear Modulus,

F19 Test Method for Tension and Vacuum Testing Metal-

and Poisson’s Ratio for Glass and Glass-Ceramics by

ized Ceramic Seals

Resonance

F77 Test Method for Apparent Density of Ceramics for

D116 Methods of Testing Vitrified Ceramic Materials for

Electron Device and Semiconductor Application

Electrical Applications

F109 Terminology Relating to Surface Imperfections on

D149 Test Methods for Dielectric Breakdown Voltage and

Ceramics

Dielectric Strength of Electrical Insulating Materials at

F134 Test Methods for Determining Hermeticity of Elec-

Commercial Power Frequencies

tron Devices with a Helium Mass Spectrometer Leak

D150 Test Methods for AC Loss Characteristics and Per-

Detector

F417 Test Method for Flexural Strength (Modulus of Rup-

ture) of Electronic-Grade Ceramics

This specification is under the jurisdiction of Committee C-21 on Ceramic

2.2 Other Standards:

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.03 on Fundamental Properties.

This specification also includes material and suggestions provided by ASTM

Committee D-9 on Electrical and Electronic Insulating Materials. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved June 30, 1975. Published August 1975. Originally Annual Book of ASTM Standards, Vol 10.02.

published as D2442–65T. Last previous edition D2442–72. Annual Book of ASTM Standards, Vol 03.01.

2 9

Annual Book of ASTM Standards, Vol 15.01. Annual Book of ASTM Standards, Vol 15.05.

3 10

Annual Book of ASTM Standards, Vol 15.02. Annual Book of ASTM Standards, Vol 14.02.

4 11

Annual Book of ASTM Standards, Vol 03.05. Annual Book of ASTM Standards, Vol 03.03.

5 12

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2442

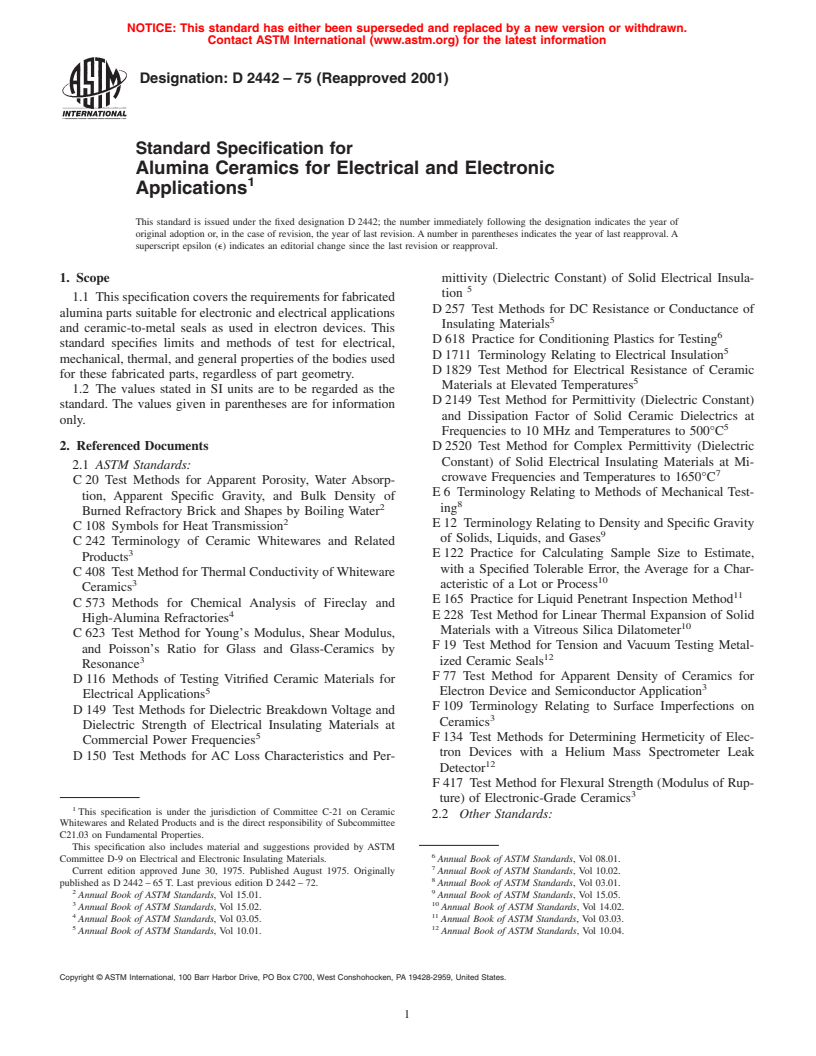

TABLE 1 Electrical Requirements

MIL-STD-105 Sampling Procedures and Tables for Inspec-

tion by Attributes Property Type I Type II Type III Type IV

MIL-STD-883 TestMethodsandProceduresforMicroelec-

Dielectric constant,

max 25°C:

tronics

at 1 MHz 8.8 9.6 9.8 10.1

ANSIB46.1 Surface Texture

at 10 GHz 8.7 9.6 9.8 10.1

Dissipation factor,

3. Terminology max 25°C:

at 1 MHz 0.002 0.001 0.0005 0.0002

3.1 Definitions:

at 10 GHz 0.002 0.001 0.0005 0.0002

3.1.1 The applicable definitions of terms in the following Volume resistivity,

min V·cm:

documentsshallapplytothisspecification:SymbolsC108,and

14 14 14 14

at 25°C 10 10 10 10

Definitions C242, D1711, E6, E12, and F109. 10 10 10 10

at 300°C 1 3 10 1 3 10 1 3 10 7 3 10

7 7 7 8

at 500°C 4 3 10 2 3 10 8 3 10 1 3 10

6 6 6 7

4. Classification at 700°C 4 3 10 2 3 10 6 3 10 1 3 10

5 5 5 6

at 900°C 4 3 10 2 3 10 8 3 10 1 3 10

4.1 Ceramics covered by this specification shall be classi-

Dielectric

strength:

fied by alumina content as follows:

3.175 mm 9.85 9.85 9.85 9.85

Alumina Content

(0.125 in.) (250 V/mil) (250 V/mil) (250 V/mil) (250 V/mil)

Type Weight percent, min

min kV/mm

I82

II 93

III 97

IV 99

TABLE 2 Mechanical Requirements

Property Type I Type II Type III Type IV

5. Basis of Purchase

Flexural strength, 240 275 275 275

5.1 Purchase orders for ceramic parts furnished to this A

min avg, (35 000) (40 000) (40 000) (40 000)

specification shall include the following information: MPa (psi)

Modulus of 215 275 310 345

5.1.1 Type designation (see 3.1),

6 6 6 6

elasticity, min, (31 3 10 ) (40 3 10 ) (45 3 10 ) (50 3 10 )

5.1.2 Surface finish and allowable defect limits (if required)

GPa (psi)

Poisson’s ratio, 0.20 to 0.25 0.20 to 0.25 0.20 to 0.25 0.20 to 0.25

(Definitions F109, ANSI B46.1, and Appendix X1),

average

5.1.3 Part drawing with dimensional tolerances (Appendix

A

Maximum permissible coefficient of variation is 10 percent.

X1),

5.1.4 Specific tests (if required),

5.1.5 Certification (if required), and

6.3.2 For hermetic seal applications at least ⁄4 of the width

5.1.6 Packing and marking.

of the seal surface shall remain intact at the location of any

defect.

6. Requirements

6.3.3 On other surfaces the limits for defects are such that

6.1 This material shall conform to the electrical, mechani-

the dimensional tolerances of the part are not affected at the

cal, thermal, and general property requirements specified in

location of the defect.

Table 1, Table 2, Table 3, and Table 4.

7. Test Specimens

6.2 Dimensionalandsurfacefinishrequirementsoftheparts

shall be as agreed between the supplier and the purchaser;

7.1 Thepreferredspecimensfortestare,wherepossible,the

however, guidance for establishing such an agreement is

actual part. When necessary, however, specific test specimens

provided in Appendix X1.

shall be prepared from the same batch of material and by the

6.3 Visual Requirements:

same processes as those employed in fabricating the ceramic

6.3.1 Parts shall be uniform in color and texture. Cracks,

part insofar as possible.

blisters, holes, porous areas, inclusions, and adherent foreign

8. Specimen Preparation

particles shall not be permitted. The limits of surface imper-

fections such as pits, pocks, chips (open or closed), surface

8.1 The specimens for tests described in 9.1-9.3 shall be

marks, fins, ridges, and flow lines shall be set by mutual

preconditioned in accordance with Procedure A of Test Meth-

agreement between the supplier and the purchaser. Limiting

ods D618.

dimensions for these defects, when required for clarification,

will be listed in the parts drawing or purchase description. For 9. Test Methods

definitions of the surface imperfections enumerated above, see

9.1 Dielectric Constant and Dissipation Factor—

Definitions F109.

Determine in accordance withTest Methods D150. Determine

values at higher frequencies in accordance with Test Methods

D2520. Determine values at higher temperatures in accor-

AvailablefromtheSuperintendentofDocuments,GovernmentPrintingOffice,

dance with Test Method D2149.

Washington, D.C. 20402.

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

15 16

Available from American National Standards Institute, 11 West 42nd Street, For another suitable method see Dielectric Materials and Applications, edited

13th Floor, New York, NY 10036. by Von Hippel, A., John Wiley and Sons, Inc., New York, N.Y., 1954.

D 2442

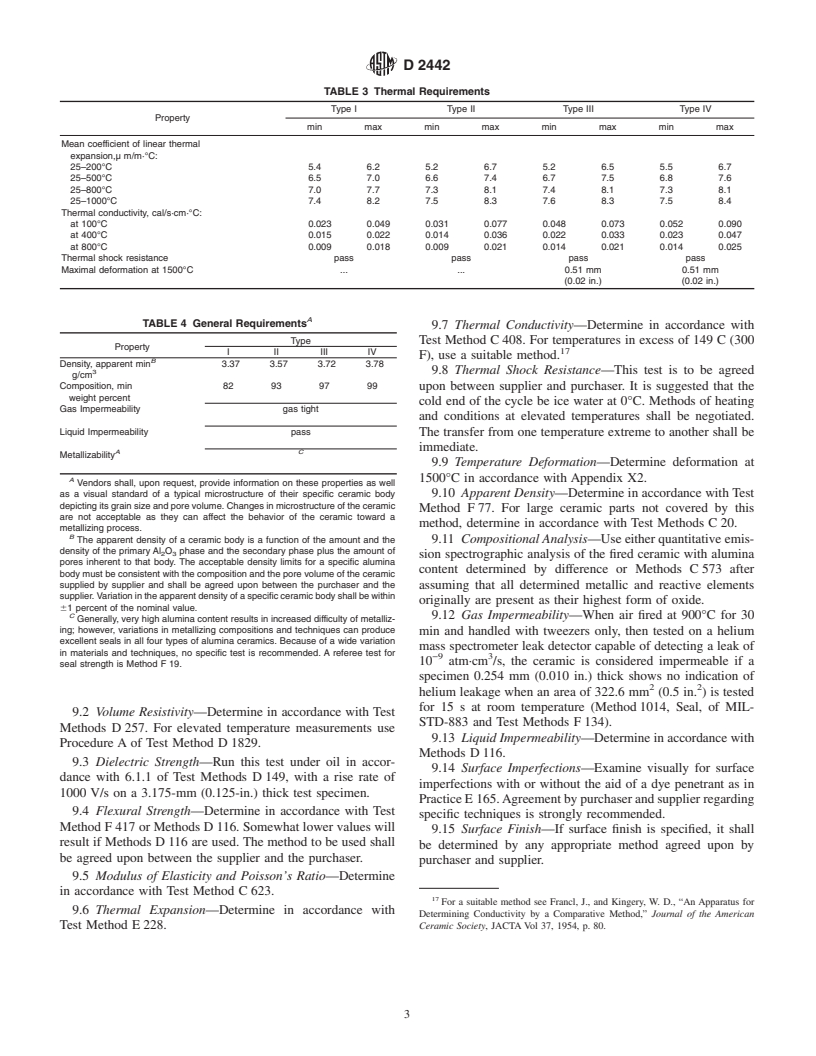

TABLE 3 Thermal Requirements

Type I Type II Type III Type IV

Property

min max min max min max min max

Mean coefficient of linear thermal

expansion,µ m/m·°C:

25–200°C 5.4 6.2 5.2 6.7 5.2 6.5 5.5 6.7

25–500°C 6.5 7.0 6.6 7.4 6.7 7.5 6.8 7.6

25–800°C 7.0 7.7 7.3 8.1 7.4 8.1 7.3 8.1

25–1000°C 7.4 8.2 7.5 8.3 7.6 8.3 7.5 8.4

Thermal conductivity, cal/s·cm·°C:

at 100°C 0.023 0.049 0.031 0.077 0.048 0.073 0.052 0.090

at 400°C 0.015 0.022 0.014 0.036 0.022 0.033 0.023 0.047

at 800°C 0.009 0.018 0.009 0.021 0.014 0.021 0.014 0.025

Thermal shock resistance pass pass pass pass

Maximal deformation at 1500°C . . 0.51 mm 0.51 mm

(0.02 in.) (0.02 in.)

A

TABLE 4 General Requirements

9.7 Thermal Conductivity—Determine in accordance with

Type Test Method C408. For temperatures in excess of 149 C (300

Property

I II III IV

F), use a suitable method.

B

Density, apparent min 3.37 3.57 3.72 3.78

3 9.8 Thermal Shock Resistance—This test is to be agreed

g/cm

Composition, min 82 93 97 99 upon between supplier and purchaser. It is suggested that the

weight percent

cold end of the cycle be ice water at 0°C. Methods of heating

Gas Impermeability gas tight

and conditions at elevated temperatures shall be negotiated.

Liquid Impermeability pass The transfer from one temperature extreme to another shall be

immediate.

AC

Metallizability

9.9 Temperature Deformation—Determine deformation at

A 1500°C in accordance with Appendix X2.

Vendors shall, upon request, provide information on these properties as well

9.10 Apparent Density—Determine in accordance withTest

as a visual standard of a typical microstructure of their specific ceramic body

depicting its grain size and pore volume. Changes in microstructure of the ceramic

Method F77. For large ceramic parts not covered by this

are not acceptable as they can affect the behavior of the ceramic toward a

method, determine in accordance with Test Methods C20.

metallizing process.

B

The apparent density of a ceramic body is a function of the amount and the 9.11 Compositional Analysis—Useeitherquantitativeemis-

density of the primary Al O phase and the secondary phase plus the amount of

2 3

sion spectrographic analysis of the fired ceramic with alumina

pores inherent to that body. The acceptable density limits for a specific alumina

content determined by difference or Methods C573 after

body must be consistent with the composition and the pore volume of the ceramic

supplied by supplier and shall be agreed upon between the purchaser and the

assuming that all determined metallic and reactive elements

supplier. Variation in the apparent density of a specific ceramic body shall be within

originally are present as their highest form of oxide.

61 percent of the nominal value.

C

9.12 Gas Impermeability—When air fired at 900°C for 30

Generally, very high alumina content results in increased difficulty of metalliz-

ing; however, variations in metallizing compositions and techniques can produce

min and handled with tweezers only, then tested on a helium

excellent seals in all four types of alumina ceramics. Because of a wide variation

mass spectrometer leak detector capable of detecting a leak of

in materials and techniques, no specific test is recommended. A referee test for

−9 3

10 atm·cm /s, the ceramic is considered impermeable if a

seal strength is Method F 19.

specimen 0.254 mm (0.010 in.) thick shows no indication of

2 2

helium leakage when an area of 322.6 mm (0.5 in. ) is tested

for 15 s at room temperature (Method1014, Seal, of MIL-

9.2 Volume Resistivity—Determine in accordance with Test

STD-883 and Test Methods F134).

Methods D257. For elevated temperature measurements use

9.13 Liquid Impermeability—Determineinaccordancewith

Procedure A of Test Method D1829.

Methods D116.

9.3 Dielectric Strength—Run this test under oil in accor-

9.14 Surface Imperfections—Examine visually for surface

dance with 6.1.1 of Test Methods D149, with a rise rate of

imperfections with or without the aid of a dye penetrant as in

1000 V/s on a 3.175-mm (0.125-in.) thick test specimen.

PracticeE165.Agreementbypurchaserandsupplierregarding

9.4 Flexural Strength—Determine in accordance with Test

specific techniques is strongly recommended.

Method F417 or Methods D116. Somewhat lower values will

9.15 Surface Finish—If surface finish is specified, it shall

result if Methods D116 are used. The method to be used shall

be determined by any appropriate method agreed upon by

be agreed upon between the supplier and the purchaser.

purchaser and supplier.

9.5 Modulus of Elasticity and Poisson’s Ratio—Determine

in accordance with Test Method C623.

For a suitable method see Francl, J., and Kingery, W. D., “An Apparatus for

9.6 Thermal Expansion—Determine in accordance with

Determining Conductivity by a Comparative Method,” Journal of the American

Test Method E228. Ceramic Society, JACTA Vol 37, 1954, p. 80.

D 2442

10. Inspection 12. Certification

10.1 When agreed upon between the manufacturer and the

12.1 Any test results requiring certification shall be explic-

purchaser, the purchaser may inspect the ceramic parts and

itly agreed upon, in writing, between the purchaser and the

verify the test results at the manufacturer’s facility. Otherwise

manufacturer.

thepurchasershallinspectandtesttheceramicpartswithinone

month of the date of receipt by the purchaser or at such other

13. Packing and Marking

times as may be agreed upon between the purchaser and the

13.1 Special packing techniques shall be subject to agree-

manufacturer.

ment between the purchaser and the manufacturer. Otherwise

10.2 When agreed upon between the manufacturer and the

all parts shall be handled, inspected, and packed in such a

purchaser, the manufacturer shall supply, pri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.