ASTM F2063-05

(Specification)Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants

Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants

ABSTRACT

This specification covers the chemical, physical, mechanical, and metallurgical requirements for wrought nickel-titanium bar, flat rolled products, and tubing containing nominally 54.5 % to 57.0 % nickel and used for the manufacture of medical devices and surgical implants. The material shall be made from ingot made from nickel and titanium with no other intentional alloy additions. The material shall be vacuum or inert atmosphere melted to control metallurgical cleanliness and alloy chemistry. Bar, plate, and tubing shall be supplied as hot finished or cold finished and annealed or heat treated. Surface condition may be oxidized, descaled, pickled, blasted, machined, ground, mechanically polished, or electropolished. Major elements shall be analyzed by direct current plasma spectrometry, atomic absorption, inductively coupled plasma spectrometry, X-ray spectrometer, glow discharge mass spectrometry, or an equivalent method. Carbon shall be measured by combustion and hydrogen shall be measured by inert gas fusion or vacuum hot extraction. Nitrogen and oxygen shall be measured by inert gas fusion. The nickel and titanium contents of nickel-titanium shape memory alloys cannot be measured to a precision required to guarantee shape memory or superelastic properties. Calorimetry or an equivalent thermomechanical test method must be used to assure the alloy formulation in terms of transformation temperature. Mechanical properties of the samples such as tensile strength and elongation shall be determined after annealing.

SCOPE

1.1 This specification covers the chemical, physical, mechanical, and metallurgical requirements for wrought nickel-titanium bar, flat rolled products, and tubing containing nominally 54.5 % to 57.0 % nickel and used for the manufacture of medical devices and surgical implants.

1.2 Requirements are for mill product, measuring 6 to 130 mm (0.24 to 5.12 in.) diameter or thickness, in its annealed condition.

1.3 The values stated in SI units are to be regarded as the standard. The values given in inch-pound units are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2063 −05

StandardSpecification for

Wrought Nickel-Titanium Shape Memory Alloys for Medical

1

Devices and Surgical Implants

This standard is issued under the fixed designation F2063; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* nium and Titanium Alloys by Inert Gas Fusion Thermal

Conductivity/Infrared Detection Method

1.1 This specification covers the chemical, physical,

E1479Practice for Describing and Specifying Inductively-

mechanical, and metallurgical requirements for wrought

Coupled Plasma Atomic Emission Spectrometers

nickel-titanium bar, flat rolled products, and tubing containing

E1941Test Method for Determination of Carbon in Refrac-

nominally 54.5% to 57.0% nickel and used for the manufac-

toryandReactiveMetalsandTheirAlloysbyCombustion

ture of medical devices and surgical implants.

Analysis

1.2 Requirements are for mill product, measuring 6 to 130

F1710Test Method for Trace Metallic Impurities in Elec-

mm (0.24 to 5.12 in.) diameter or thickness, in its annealed

tronic Grade Titanium by High Mass-Resolution Glow

condition.

Discharge Mass Spectrometer

1.3 The values stated in SI units are to be regarded as the F2004Test Method for Transformation Temperature of

Nickel-Titanium Alloys by Thermal Analysis

standard. The values given in inch-pound units are for infor-

mation only. F2005Terminology for Nickel-Titanium Shape Memory

Alloys

2. Referenced Documents

F2082Test Method for Determination of Transformation

2

Temperature of Nickel-Titanium Shape Memory Alloys

2.1 ASTM Standards:

by Bend and Free Recovery

E4Practices for Force Verification of Testing Machines

E8Test Methods for Tension Testing of Metallic Materials

2.2 ASQ Standard:

3

E112Test Methods for Determining Average Grain Size C1General Requirements for a Quality Program

E1019Test Methods for Determination of Carbon, Sulfur,

3. Terminology

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Fusion Techniques

3.1 The terminology describing the physical and thermal

E1097Guide for Determination of Various Elements by

properties of these alloys shall be as defined in Terminology

Direct Current Plasma Atomic Emission Spectrometry

F2005.

E1172PracticeforDescribingandSpecifyingaWavelength-

3.2 See also Practice E4: General Terminology.

Dispersive X-Ray Spectrometer

E1245Practice for Determining the Inclusion or Second-

4. Product Classification

Phase Constituent Content of Metals byAutomatic Image

4.1 Bar—Round bars and flats (other sizes or shapes by

Analysis

special order).

E1409TestMethodforDeterminationofOxygenandNitro-

gen in Titanium and Titanium Alloys by the Inert Gas

4.2 Plate—Any product with width equal to or greater than

Fusion Technique

five times the thickness.

E1447Test Method for Determination of Hydrogen in Tita-

4.3 Tubing—Hollow cylindrical shapes.

1

5. Ordering Information

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

5.1 Inquiriesandordersformaterialunderthisspecification

Subcommittee F04.12 on Metallurgical Materials.

shall include the following information:

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 2000. Last previous edition approved in 2000 as F2063–00. DOI:

5.1.1 Quantity: weight, length, or number of pieces.

10.1520/D2063–05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

the ASTM website. Milwaukee, WI 53203.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

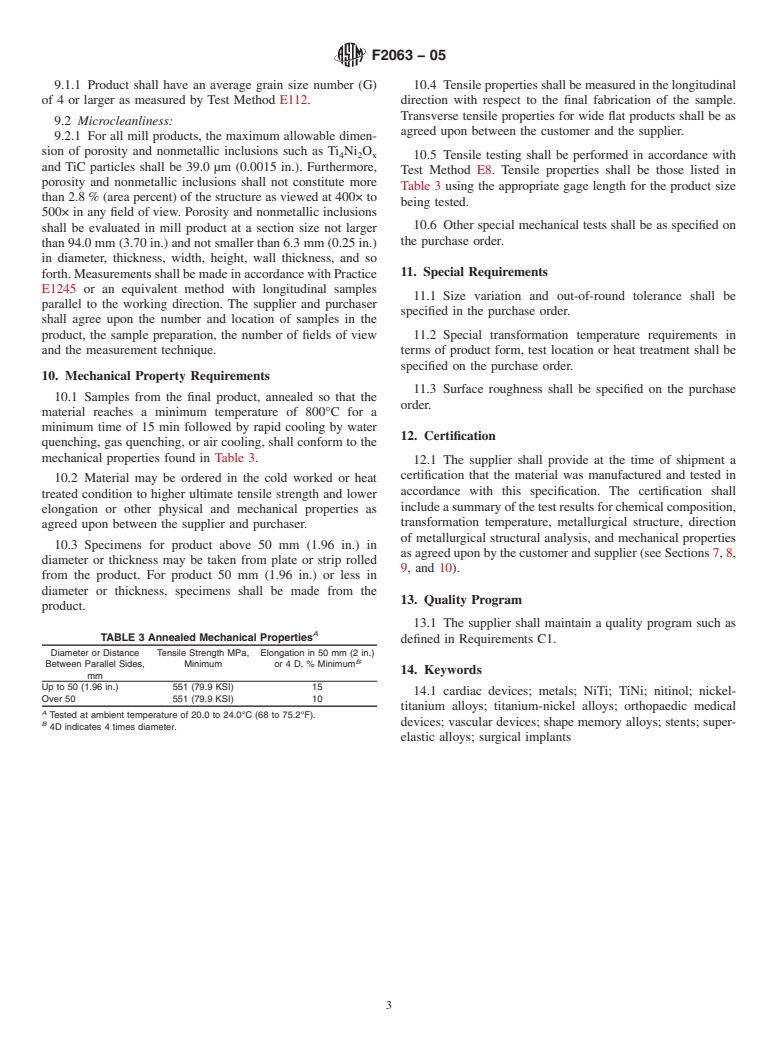

F2063−05

5.1.2 Alloyformulation,intermsoftransformationtempera- Carbon shall be measured by combustion according to Test

ture parameter (see Section 8). Methods E1019 or E1941. Hydrogen shall be measured by

5.1.3 Form: bar, plate, or tubing (see Section 4). inert gas fusion or vacuum hot extraction according to Test

5.1.4 Condition (see Sections 6.3 and 10.1). Method E1447. Nitrogen and oxygen shall be measured by

5.1.5 Mechanical Properties, if applicable for special con- inert gas fusion according to Test Method E1409.

ditions (see Section 10).

7.3 Thetitaniumcontentofthesealloysshallbedetermined

5.1.6 Surface Conditio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.