ASTM E837-13

(Test Method)Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method

Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method

SIGNIFICANCE AND USE

5.1 Summary:

5.1.1 Residual stresses are present in almost all materials. They may be created during the manufacture or during the life of the material. If not recognized and accounted for in the design process, residual stresses can be a major factor in the failure of a material, particularly one subjected to alternating service loads or corrosive environments. Residual stress may also be beneficial, for example, the compressive stresses produced by shot peening. The hole-drilling strain-gage technique is a practical method for determining residual stresses.

SCOPE

1.1 Residual Stress Determination :

1.1.1 This test method specifies a hole-drilling procedure for determining residual stress profiles near the surface of an isotropic linearly elastic material. The test method is applicable to residual stress profile determinations where in-plane stress gradients are small. The stresses may remain approximately constant with depth (“uniform” stresses) or they may vary significantly with depth (“non-uniform” stresses). The measured workpiece may be “thin” with thickness much less than the diameter of the drilled hole or “thick” with thickness much greater than the diameter of the drilled hole. Only uniform stress measurements are specified for thin workpieces, while both uniform and non-uniform stress measurements are specified for thick workpieces.

1.2 Stress Measurement Range:

1.2.1 The hole-drilling method can identify in-plane residual stresses near the measured surface of the workpiece material. The method gives localized measurements that indicate the residual stresses within the boundaries of the drilled hole.

1.2.2 This test method applies in cases where material behavior is linear-elastic. In theory, it is possible for local yielding to occur due to the stress concentration around the drilled hole. Satisfactory measurement results can be achieved providing the residual stresses do not exceed about 80 % of the material yield stress for hole drilling in a “thick” material and about 50% of the material yield stress in a “thin” material.

1.3 Workpiece Damage:

1.3.1 The hole-drilling method is often described as “semi-destructive” because the damage that it causes is localized and often does not significantly affect the usefulness of the workpiece. In contrast, most other mechanical methods for measuring residual stresses substantially destroy the workpiece. Since hole drilling does cause some damage, this test method should be applied only in those cases either where the workpiece is expendable, or where the introduction of a small shallow hole will not significantly affect the usefulness of the workpiece.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E837 − 13

StandardTest Method for

Determining Residual Stresses by the Hole-Drilling Strain-

1

Gage Method

This standard is issued under the fixed designation E837; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

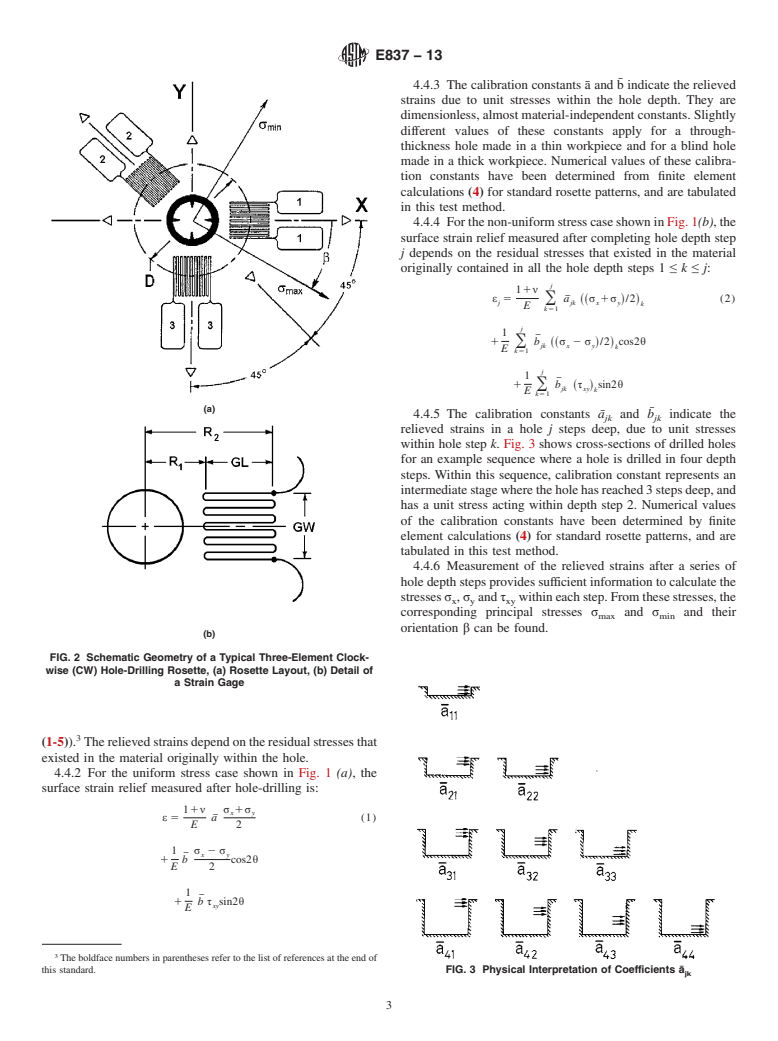

The hole-drilling strain-gage method determines residual stresses near the surface of an isotropic

linear-elastic material. It involves attaching a strain rosette to the surface, drilling a hole at the

geometric center of the rosette, and measuring the resulting relieved strains. The residual stresses

withintheremovedmaterialarethendeterminedfromthemeasuredstrainsusingaseriesofequations.

1. Scope 1.3 Workpiece Damage:

1.3.1 The hole-drilling method is often described as “semi-

1.1 Residual Stress Determination:

destructive” because the damage that it causes is localized and

1.1.1 This test method specifies a hole-drilling procedure

often does not significantly affect the usefulness of the work-

for determining residual stress profiles near the surface of an

piece. In contrast, most other mechanical methods for measur-

isotropiclinearlyelasticmaterial.Thetestmethodisapplicable

ing residual stresses substantially destroy the workpiece. Since

to residual stress profile determinations where in-plane stress

hole drilling does cause some damage, this test method should

gradients are small. The stresses may remain approximately

be applied only in those cases either where the workpiece is

constant with depth (“uniform” stresses) or they may vary

expendable, or where the introduction of a small shallow hole

significantly with depth (“non-uniform” stresses). The mea-

will not significantly affect the usefulness of the workpiece.

sured workpiece may be “thin” with thickness much less than

1.4 This standard does not purport to address all of the

the diameter of the drilled hole or “thick” with thickness much

safety concerns, if any, associated with its use. It is the

greater than the diameter of the drilled hole. Only uniform

responsibility of the user of this standard to establish appro-

stress measurements are specified for thin workpieces, while

priate safety and health practices and determine the applica-

both uniform and non-uniform stress measurements are speci-

bility of regulatory limitations prior to use.

fied for thick workpieces.

1.2 Stress Measurement Range:

2. Referenced Documents

1.2.1 The hole-drilling method can identify in-plane re-

2

2.1 ASTM Standards:

sidual stresses near the measured surface of the workpiece

E251Test Methods for Performance Characteristics of Me-

material. The method gives localized measurements that indi-

tallic Bonded Resistance Strain Gauges

cate the residual stresses within the boundaries of the drilled

hole.

3. Terminology

1.2.2 This test method applies in cases where material

3.1 Symbols:

behavior is linear-elastic. In theory, it is possible for local

yielding to occur due to the stress concentration around the

a¯ = calibration constant for isotropic stresses

drilled hole. Satisfactory measurement results can be achieved

¯

b = calibration constant for shear stresses

providingtheresidualstressesdonotexceedabout80%ofthe

a¯ = calibration matrix for isotropic stresses

jk

material yield stress for hole drilling in a “thick” material and

¯

b = calibration matrix for shear stresses

jk

about 50% of the material yield stress in a “thin” material.

D = diameter of the gage circle, see Table1.

D = diameter of the drilled hole

0

E = Young’s modulus

1

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.13 on

2

Residual Stress Measurement. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2013. Published October 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 1981. Last previous edition approved in 2001 as E837–08 . DOI: Standards volumeinformation,refertothestandard’sDocumentSummarypageon

10.1520/E0837-13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E837 − 13

j = number of hole depth steps so far

k = sequence number for hole depth steps

P = uniform isotropic (equi-biaxial) stress

P = isotropic stress within hole depth step k

k

p = uniform isotropic (equi-biaxial) strain

p = isotropic strain after hole depth step k

k

Q = uniform 45° shear stress

Q = 45° shear stress within hole depth step k

k

q = uniform 45° she

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2

Designation: E837 − 08 E837 − 13

Standard Test Method for

Determining Residual Stresses by the Hole-Drilling Strain-

1

Gage Method

This standard is issued under the fixed designation E837; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Eq 27 was editorially corrected in July 2009.

2

ε NOTE—Eq 21 was editorially corrected in March 2013.

INTRODUCTION

The hole-drilling strain-gage method determines residual stresses near the surface of an isotropic

linear-elastic material. It involves attaching a strain rosette to the surface, drilling a hole at the

geometric center of the rosette, and measuring the resulting relieved strains. The residual stresses

within the removed material are then determined from the measured strains using a series of equations.

1. Scope

1.1 Residual Stress Determination:

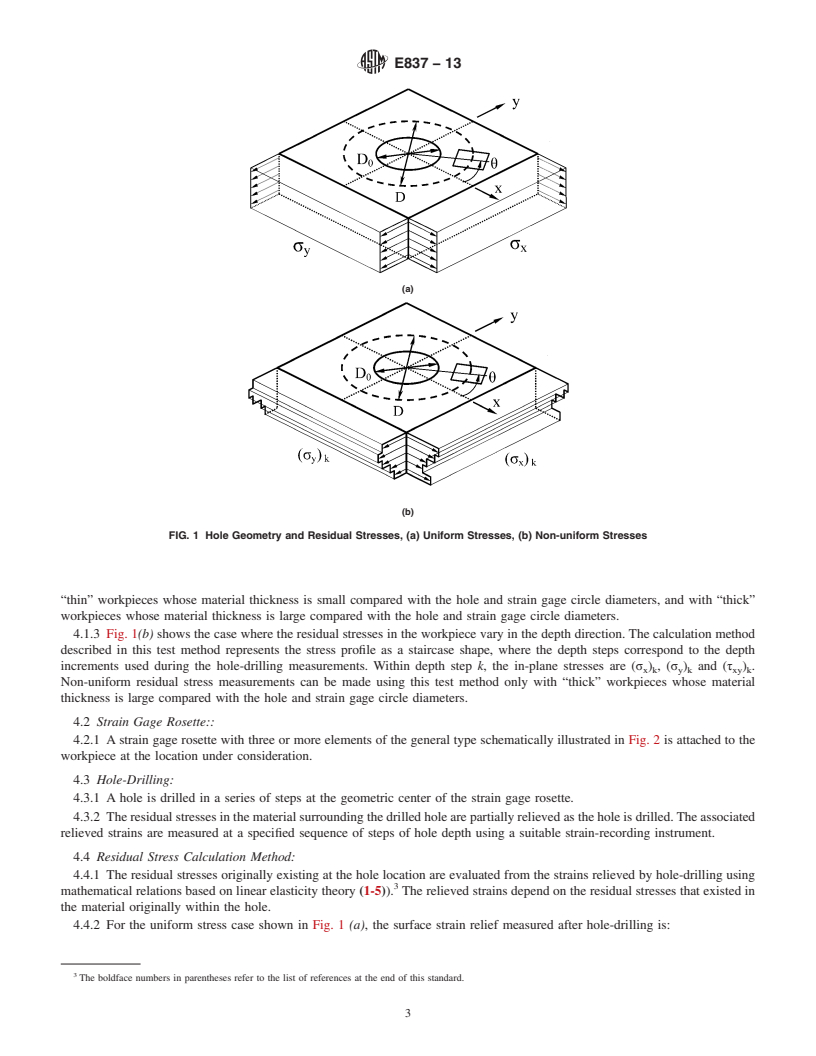

1.1.1 This test method specifies a hole-drilling procedure for determining residual stress profiles near the surface of an isotropic

linearly elastic material. The test method is applicable to residual stress profile determinations where in-plane stress gradients are

small. The stresses may remain approximately constant with depth (“uniform” stresses) or they may vary significantly with depth

(“non-uniform” stresses). The measured workpiece may be “thin” with thickness much less than the diameter of the drilled hole

or “thick” with thickness much greater than the diameter of the drilled hole. Only uniform stress measurements are specified for

thin workpieces, while both uniform and non-uniform stress measurements are specified for thick workpieces.

1.2 Stress Measurement Range:

1.2.1 The hole-drilling method can identify in-plane residual stresses near the measured surface of the workpiece material. The

method gives localized measurements that indicate the residual stresses within the boundaries of the drilled hole.

1.2.2 This test method applies in cases where material behavior is linear-elastic. In theory, it is possible for local yielding to

occur due to the stress concentration around the drilled hole, for isotropic (equi-biaxial) residual stresses exceeding 50 % of the

yield stress, or for shear stresses in any direction exceeding 25 % of the yield stress. However, in practice it is found that

satisfactory results can be achieved providing the residual stresses do not exceed about 60 % of the material yield stress.hole.

Satisfactory measurement results can be achieved providing the residual stresses do not exceed about 80 % of the material yield

stress for hole drilling in a “thick” material and about 50% of the material yield stress in a “thin” material.

1.3 Workpiece Damage:

1.3.1 The hole-drilling method is often described as “semi-destructive” because the damage that it causes is localized and often

does not significantly affect the usefulness of the workpiece. In contrast, most other mechanical methods for measuring residual

stresses substantially destroy the workpiece. Since hole drilling does cause some damage, this test method should be applied only

in those cases either where the workpiece is expendable, or where the introduction of a small shallow hole will not significantly

affect the usefulness of the workpiece.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.13 on Residual Stress

Measurement.

Current edition approved July 23, 2009April 1, 2013. Published April 2008October 2013. Originally approved in 1981. Last previous edition approved in 2001 as

ε1

E837 – 01E837 – 08 . DOI: 10.1520/E0837-08E01.10.1520/E0837-13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E837 − 13

2. Referenced Documents

2

2.1 ASTM Standards:

E251 Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gauges

3. Terminology

3.1 Symbols:

a¯ = calibration constant for isotropic stresses

b¯ = calibration constant for shear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.