ASTM E1182-01

(Test Method)Standard Test Method for Measurement of Surface Layer Thickness by Radial Sectioning (Withdrawn 2002)

Standard Test Method for Measurement of Surface Layer Thickness by Radial Sectioning (Withdrawn 2002)

SCOPE

1.1 This test method covers the radial sectioning technique 2,3,4 for measurement of the thickness of thin surface layers, made by a wide variety of processes, on metals, alloys, carbides, and oxides.

1.2 This test method is applicable to measurement of a wide variety of surface layer types where the interface between the layer and substrate is discernible by natural color or reflectivity differences or by means of color or reflectivity differences due to etching or staining.

1.3 This test method does not pertain to layer thickness measurements made by analysis of compositional variations.

1.4 This test method deals only with the recommended test method and nothing in it should be construed as defining or establishing limits of acceptability for any coating method.

1.5 The measurement values stated are in the metric system, as defined in Standard E380.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: E 1182 – 01

Standard Test Method for

Measurement of Surface Layer Thickness by Radial

1

Sectioning

This standard is issued under the fixed designation E1182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

6

1. Scope E7 Terminology Relating to Metallography

6

E407 Practice for Microetching Metals and Alloys

1.1 This test method covers the radial sectioning tech-

2,3,4

E691 Practice for Conducting an Interlaboratory Study to

nique for measurement of the thickness of thin surface

7

Determine the Precision of a Test Method

layers, made by a wide variety of processes, on metals, alloys,

F110 Test Method for Thickness of Epitaxial or Diffused

carbides, and oxides.

Layers in Silicon by the Angle Lapping and Staining

1.2 Thistestmethodisapplicabletomeasurementofawide

8

Technique

variety of surface layer types where the interface between the

IEEE/ASTM SI 10 Standard for Use of the International

layerandsubstrateisdiscerniblebynaturalcolororreflectivity

7

System of Units (SI): The Modern Metric System

differences or by means of color or reflectivity differences due

to etching or staining.

3. Terminology

1.3 This test method does not pertain to layer thickness

3.1 Definitions:

measurements made by analysis of compositional variations.

3.1.1 For definitions of terms used in this test method, see

1.4 This test method deals only with the recommended test

TerminologyE7.

method and nothing in it should be construed as defining or

3.2 Definitions of Terms Specific to This Standard:

establishing limits of acceptability for any coating method.

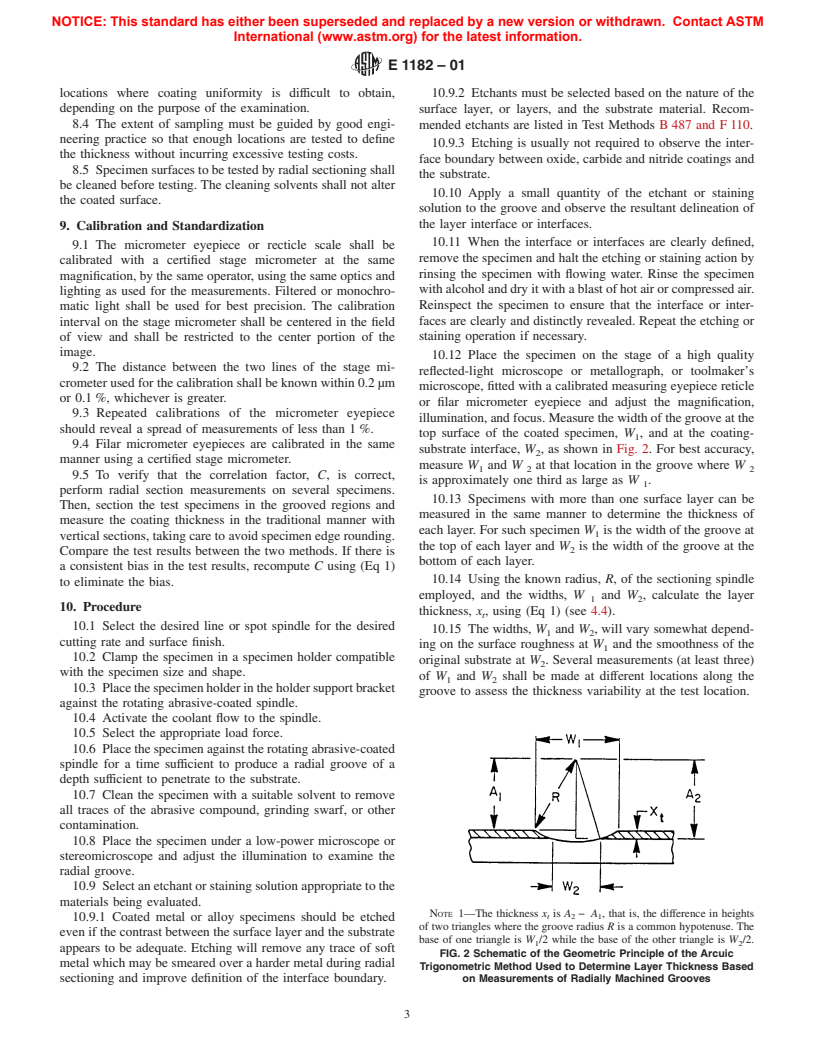

3.2.1 arcuic trigonometric measurement—method for mea-

1.5 Themeasurementvaluesstatedareinthemetricsystem,

suring the thickness of a surface layer using a radial cut of

as defined in Practice E380.

radius R through the layer into the substrate and measurement

1.6 This standard does not purport to address all of the

of the widths of the cut at the top of the layer and at the

safety concerns associated with its use. It is the responsibility

layer-substrate interface.

of the user of this standard to establish appropriate safety and

3.2.2 radial sectioning—amachiningprocedureforproduc-

health practices and determine the applicability of regulatory

ing a precise groove on the surface of a sample to a depth

limitations prior to use. For specific precautionary statements,

below the layer interface, that is, through a surface layer into

see Section 7.

the substrate, using a line or spot spindle of known radius.

2. Referenced Documents 3.3 Symbols:

3.3.1 x—thickness of the surface layer.

2.1 ASTM Standards: t

3.3.2 R—radius of the machined groove.

B487 Test Method for Measurement of Metal and Oxide

3.3.3 W — width of the groove at the layer-substrate

Coating Thickness by Microscopical Examination of a 2

5

interface.

Cross Section

3.3.4 C—correlation factor to correct for the deflection of

the spindle when the spindle contacts the specimen.

1

3.3.5 W — width of the groove at the top surface.

This test method is under the jurisdiction of ASTM Committee E04 on 1

Metallography and is the direct responsibility of Subcommittee E04.14 on Quanti-

3.3.6 n—number of fields measured

tative Metallography.

3.3.7 s—standard deviation

Current edition approved Dec. 10, 2001. Published January 2002. Originally

3.3.8 95%CI—confidence interval

published as E1182–87. Last previous edition E1182–93 (1998).

2

3.3.9 t—a multiplier related to the number of fields exam-

Happ, W. W., and Shockley, W., “Diffusion Depths in Silicon Measured by

Using Cylindrical Grooves,” Bulletin of the American Physical Society, Series II,

inedandusedinconjunctionwiththestandarddeviationofthe

Vol 1, 1956, p. 382.

measurements to determine the 95% CI.

3

McDonald, B., and Goetzuberger,A., “Measurement of the Depth of Diffused

LayersinSiliconbytheGroovingMethod,” Journal of the Electrochemical Society,

Vol 109, February 1962, pp. 141–144.

4 6

Whitelam, F. E., “Using Radial Sectioning to Measure Thin Layers,” Metal Annual Book of ASTM Standards, Vol 03.01.

7

Progress, Vol 127, March 1985, pp. 45, 46, 49, and 50. Annual Book of ASTM Standards, Vol 14.02.

5 8

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 10.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.