ASTM D4501-01(2009)e1

(Test Method)Standard Test Method for Shear Strength of Adhesive Bonds Between Rigid Substrates by the Block-Shear Method

Standard Test Method for Shear Strength of Adhesive Bonds Between Rigid Substrates by the Block-Shear Method

SIGNIFICANCE AND USE

This test method provides an estimate of the shear strength of an adhesive on various machinable and nonmachinable substrate materials. It is particularly applicable for testing bonds between ceramic, glass, magnet moldings, and plastic parts with one flat face where machining would be difficult or impractical.

SCOPE

1.1 This test method describes a procedure and fixture used to determine shear strengths of adhesives used to bond materials with moduli higher than the modulus of the adhesive. The size and shape of the specimens are variable within the physical restraints of the fixture.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4501 − 01 (Reapproved2009)

Standard Test Method for

Shear Strength of Adhesive Bonds Between Rigid

Substrates by the Block-Shear Method

This standard is issued under the fixed designation D4501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Paragraph 11.1 was corrected editorially in September 2009.

1. Scope 5. Significance and Use

1.1 This test method describes a procedure and fixture used

5.1 This test method provides an estimate of the shear

to determine shear strengths of adhesives used to bond mate-

strength of an adhesive on various machinable and nonmachin-

rials with moduli higher than the modulus of the adhesive. The

able substrate materials. It is particularly applicable for testing

size and shape of the specimens are variable within the

bonds between ceramic, glass, magnet moldings, and plastic

physical restraints of the fixture.

parts with one flat face where machining would be difficult or

impractical.

1.2 The values stated in SI units are to be regarded as the

standard.

6. Apparatus

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 6.1 Testing Machine, conforming to the requirements of

responsibility of the user of this standard to establish appro- Practices E4, with a capacity of not less than 44 kN (10 000

priate safety and health practices and determine the applica- lbf) in tension.

bility of regulatory limitations prior to use.

6.2 ShearingFixture—Performthetestsbyusingashearing

fixture consisting of a holding block and a shearing tool (Figs.

2. Referenced Documents

1 and 2).The holding block can accommodate specimens up to

2.1 ASTM Standards:

80 by 80 by 13 mm (3 by 3 by ⁄2 in.). For small specimens as

D907 Terminology of Adhesives

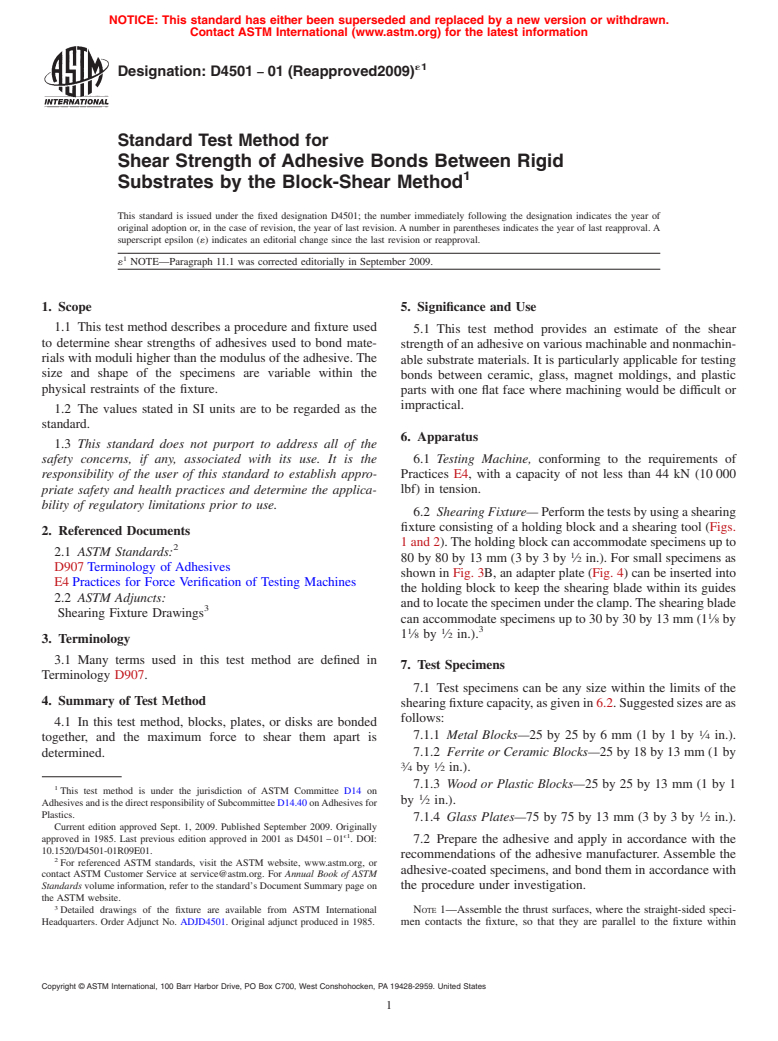

shown in Fig. 3B, an adapter plate (Fig. 4) can be inserted into

E4 Practices for Force Verification of Testing Machines

the holding block to keep the shearing blade within its guides

2.2 ASTM Adjuncts:

and to locate the specimen under the clamp.The shearing blade

Shearing Fixture Drawings

can accommodate specimens up to 30 by 30 by 13 mm (1 ⁄8 by

1 1

1 ⁄8 by ⁄2 in.).

3. Terminology

3.1 Many terms used in this test method are defined in

7. Test Specimens

Terminology D907.

7.1 Test specimens can be any size within the limits of the

4. Summary of Test Method

shearingfixturecapacity,asgivenin6.2.Suggestedsizesareas

follows:

4.1 In this test method, blocks, plates, or disks are bonded

7.1.1 Metal Blocks—25by25by6mm(1by1by ⁄4 in.).

together, and the maximum force to shear them apart is

7.1.2 Ferrite or Ceramic Blocks—25 by 18 by 13 mm (1 by

determined.

3 1

⁄4 by ⁄2 in.).

7.1.3 Wood or Plastic Blocks—25 by 25 by 13 mm (1 by 1

This test method is under the jurisdiction of ASTM Committee D14 on

by ⁄2 in.).

AdhesivesandisthedirectresponsibilityofSubcommitteeD14.40onAdhesivesfor

Plastics. 1

7.1.4 Glass Plates—75 by 75 by 13 mm (3 by 3 by ⁄2 in.).

Current edition approved Sept. 1, 2009. Published September 2009. Originally

ϵ1

approved in 1985. Last previous edition approved in 2001 as D4501 – 01 . DOI:

7.2 Prepare the adhesive and apply in accordance with the

10.1520/D4501-01R09E01.

recommendations of the adhesive manufacturer. Assemble the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

adhesive-coated specimens, and bond them in accordance with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on the procedure under investigation.

the ASTM website.

Detailed drawings of the fixture are available from ASTM International NOTE 1—Assemble the thrust surfaces, where the straight-sided speci-

Headquarters. Order Adjunct No. ADJD4501. Original adjunct produced in 1985. men contacts the fixture, so that they are parallel to the fixture within

Copyright © ASTM Inte

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D4501 – 95 Designation:D4501 –01(Reapproved2009)

Standard Test Method for

Shear Strength of Adhesive Bonds Between Rigid

Substrates by the Block-Shear Method

This standard is issued under the fixed designation D 4501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Paragraph 11.1 was corrected editorially in September 2009.

1. Scope

1.1 This test method describes a procedure and fixture used to determine shear strengths of adhesives used to bond materials

with moduli higher than the modulus of the adhesive. The size and shape of the specimens are variable within the physical

restraints of the fixture.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 907 Terminology of Adhesives

E4 Practices for Force Verification of Testing Machines Practices for Force Verification of Testing Machines

2.2 ASTM Adjuncts:

Shearing Fixture Drawings

3. Terminology

3.1 Many terms used in this test method are defined in Terminology D 907.

4. Summary of Test Method

4.1 In this test method, blocks, plates, or disks are bonded together, and the maximum force to shear them apart is determined.

5. Significance and Use

5.1 This test method provides an estimate of the shear strength of an adhesive on various machinable and nonmachinable

substrate materials. It is particularly applicable for testing bonds between ceramic, glass, magnet moldings, and plastic parts with

one flat face where machining would be difficult or impractical.

6. Apparatus

6.1 Testing Machine, with a capacity of not less than 44 kN (10000 lbf) in tension. Testing machine shall conform to the

requirements of Practices E4.

6.2, conforming to the requirements of Practices E 4, with a capacity of not less than 44 kN (10 000 lbf) in tension.

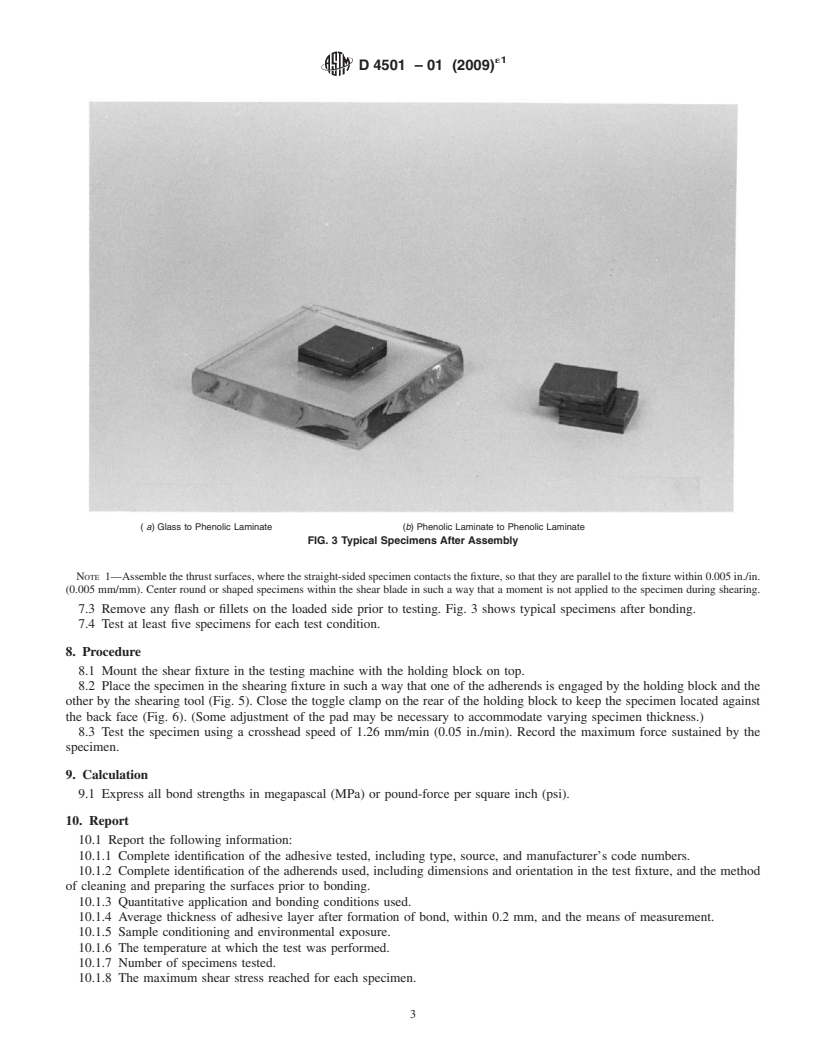

6.2 Shearing Fixture— Perform the tests by using a shearing fixture consisting of a holding block and a shearing tool (Figs. 1

and 2). The holding block can accommodate specimens up to 80 by 80 by 13 mm (3 by 3 by ⁄2 in.). For small specimens as shown

in Fig. 3B, an adapter plate (Fig. 4) can be inserted into the holding block to keep the shearing blade within its guides and to locate

1 1 1

the specimen under the clamp. The shearing blade can accommodate specimens up to 30 by 30 by 13 mm (1 ⁄8 by 1 ⁄8 by ⁄2 in.).

ThistestmethodisunderthejurisdictionofASTMCommitteeD-14D14onAdhesivesandisthedirectresponsibilityofSubcommitteeD14.40onAdhesivesforPlastics.

Current edition approved Sept. 10, 1995. Published November 1995. Originally published as D4501–85. Last previous edition D4501–91.

´1

Current edition approved Sept. 1, 2009. Published September 2009. Originally approved in 1985. Last previous edition approved in 2001 as D 4501 – 01 .

Annual Book of ASTM Standards, Vol 15.06.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.01.

Detailed drawings of the fixture are available from ASTM International Headquarters. Order Adjunct No. . Original adjunct produced in 1985.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4501 –01 (2009)

FIG. 1 Shearing Tool

FIG. 2 Holding Block

7. Test Specimens

7.1 Test specimens can be any size within the limits of the shearing fixture capacity, as given in 6.2. Suggested sizes are as

follows:

7.1.1 Metal Blocks—25by25by6mm(1by1by ⁄4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.