ASTM F2787-09

(Practice)Standard Practice for Structural Design of Thermoplastic Corrugated Wall Stormwater Collection Chambers

Standard Practice for Structural Design of Thermoplastic Corrugated Wall Stormwater Collection Chambers

SIGNIFICANCE AND USE

This practice provides a rational method for structural design of thermoplastic stormwater chambers. The loads, capacities, and limit states are based on accepted load and resistance factor design for thermoplastic pipes; however, existing design specifications for thermoplastic pipes do not adequately address the design of chambers due to (1) open-bottom geometry, (2) support on integral foot, (3) varying circumferential corrugation geometry, and (4) manufacture with alternative thermoplastic resin. This practice standardizes recommendations for designers to adequately address these aspects of chamber design.

This practice is written to allow chamber manufacturers to evaluate chambers meeting existing classifications and to design chambers for new classifications as they are developed.

SCOPE

1.1 This practice standardizes structural design of thermoplastic corrugated wall arch-shaped chambers used for collection, detention, and retention of stormwater runoff. The practice is for chambers installed in a trench or bed and subjected to earth and live loads. Structural design includes the composite system made up of the chamber arch, the chamber foot, and the soil envelope. Relevant recognized practices include design of thermoplastic culvert pipes and design of foundations.

1.2 This practice standardizes methods for manufacturers of buried thermoplastic structures to design for the time dependent behavior of plastics using soil support as an integral part of the structural system. This practice is not applicable to thermoplastic structures that do not include soil support as a component of the structural system.

1.3 This practice is limited to structural design and does not provide guidance on hydraulic, hydrologic, or environmental design considerations that may need to be addressed for functional use of stormwater collection chambers.

1.4 Stormwater chambers are most commonly embedded in open graded, angular aggregate which provide both structural support and open porosity for water storage. Should soils other than open graded, angular aggregate be specified for embedment, other installation and functional concerns may need to be addressed that are outside the scope of this practice.

1.5 Chambers are produced in arch shapes to meet classifications that specify chamber rise, chamber span, minimum foot width, minimum wall thickness, and minimum arch stiffness constant. Chambers are manufactured with integral footings.

1.6 Polypropylene chamber classifications are found in Specification F 2418. Specification F 2418 also specifies chamber manufacture and qualification.

1.7 This practice is applicable to design in inch-pound units. The SI units in parenthesis are given for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2787 – 09

Standard Practice for

Structural Design of Thermoplastic Corrugated Wall

Stormwater Collection Chambers

This standard is issued under the fixed designation F2787; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice standardizes structural design of thermo-

bility of regulatory limitations prior to use.

plastic corrugated wall arch-shaped chambers used for collec-

tion, detention, and retention of stormwater runoff. The prac-

2. Referenced Documents

tice is for chambers installed in a trench or bed and subjected

2.1 ASTM Standards:

to earth and live loads. Structural design includes the compos-

D2487 Practice for Classification of Soils for Engineering

ite system made up of the chamber arch, the chamber foot, and

Purposes (Unified Soil Classification System)

thesoilenvelope.Relevantrecognizedpracticesincludedesign

D2990 Test Methods for Tensile, Compressive, and Flex-

of thermoplastic culvert pipes and design of foundations.

ural Creep and Creep-Rupture of Plastics

1.2 This practice standardizes methods for manufacturers of

D6992 Test Method for Accelerated Tensile Creep and

buried thermoplastic structures to design for the time depen-

Creep-Rupture of Geosynthetic Materials Based on Time-

dent behavior of plastics using soil support as an integral part

Temperature Superposition Using the Stepped Isothermal

of the structural system. This practice is not applicable to

Method

thermoplastic structures that do not include soil support as a

F2418 Specification for Polypropylene (PP) Corrugated

component of the structural system.

Wall Stormwater Collection Chambers

1.3 This practice is limited to structural design and does not

2.2 AASHTO LRFD Bridge Design Specifications:

provide guidance on hydraulic, hydrologic, or environmental

Section 3 Loads and Load Factors, 3.5 Permanent Loads;

design considerations that may need to be addressed for

3.6 Live Loads

functional use of stormwater collection chambers.

Section 10 Foundations, 10.6 Spread Footings

1.4 Stormwater chambers are most commonly embedded in

Section 12 Buried Structures and Tunnel Liners, 12.12

open graded, angular aggregate which provide both structural

Thermoplastic Pipes

support and open porosity for water storage. Should soils other

2.3 AASHTO Standard Specifications:

than open graded, angular aggregate be specified for embed-

M43 Standard Specification for Size ofAggregate for Road

ment,otherinstallationandfunctionalconcernsmayneedtobe

and Bridge Construction

addressed that are outside the scope of this practice.

M 145 Standard Specification for Classification of Soils and

1.5 Chambers are produced in arch shapes to meet classifi-

Soil-Aggregate Mixtures for Highway Construction Pur-

cationsthatspecifychamberrise,chamberspan,minimumfoot

poses

width, minimum wall thickness, and minimum arch stiffness

T99 Standard Method of Test for Moisture-Density Rela-

constant. Chambers are manufactured with integral footings.

tions of Soils Using a 2.5-kg (5.5-lb) Rammer and a

1.6 Polypropylene chamber classifications are found in

305-mm (12-in.) Drop

Specification F2418. Specification F2418 also specifies cham-

ber manufacture and qualification.

1.7 Thispracticeisapplicabletodesignininch-poundunits.

The SI units in parenthesis are given for information only.

1.8 This standard does not purport to address all of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

safety concerns, if any, associated with its use. It is the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This practice is under the jurisdiction of ASTM Committee F17 on Plastic AASHTO LRFD Bridge Design Specifications-Dual Units, 4th Edition, 2007

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land and AASHTO Standard Specifications for Transportation Materials and Sampling,

Drainage. 28th edition, 2008. Available from American Association of State Highway and

Current edition approved Aug. 1, 2009. Published September 2009. DOI: Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washing-

10.1520/F2787-09. ton, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2787 – 09

2.4 AWWA Manual: 3.1.9 foot area—the actual contact area of the foot with the

M 45 Manual of Water Supply Practices: Fiberglass Pipe foundation.

Design

3.1.10 local buckling—compressionfailureofbuilt-upplate

sections with high width-to-thickness ratios.

3. Terminology

3.1.11 nominal height—a designation describing the ap-

3.1 Definitions—Definitions used in this specification are in

proximate outside vertical dimension of the chamber at its

accordance with the definitions in Terminology F412, and

crown (see Fig. 1).

abbreviations are in accordance with Terminology D1600,

3.1.12 nominal width—a designation describing the ap-

unless otherwise indicated.

proximate outside horizontal dimension of the chamber at its

3.1.1 chamber—an arch-shaped structure manufactured of

feet (see Fig. 1).

thermoplastic with an open-bottom that is supported on feet

3.1.13 rise—the vertical distance from the chamber base

and may be joined into rows that begin with, and are termi-

(bottom of the chamber foot) to the inside of a chamber wall

nated by, end caps (see Fig. 1).

valley element at the crown as depicted in Fig. 1.

3.1.2 classification—the chamber model specification that

identifies nominal height, nominal width, rise, span, minimum

3.1.14 span—the horizontal distance from the interior of

foot width, wall thickness, and arch stiffness constant.

one sidewall valley element to the interior of the other sidewall

3.1.3 corrugated wall—awallprofileconsistingofaregular

valley element as depicted in Fig. 1.

pattern of alternating crests and valleys connected by web

3.1.15 valley—the element of a corrugation located at the

elements (see Fig. 2).

interior surface of a chamber wall, spanning between two web

3.1.4 crest—the element of a corrugation located at the

elements (see Fig. 2).

exterior surface of the chamber wall, spanning between two

3.1.16 viscoelasticity—the response of a material to load

web elements (see Fig. 2).

thatisdependentbothonloadmagnitude(elastic)andloadrate

3.1.5 crown—the center section of a chamber typically

(viscous).

located at the highest point as the chamber is traversed

3.1.17 web—the element of a corrugated wall that connects

circumferentially.

a crest element to a valley element (see Fig. 2).

3.1.6 embedment—backfill material against the sides of

chambers and end caps and in between rows of chambers from

4. Significance and Use

the foundation stone below to a specified dimension over the

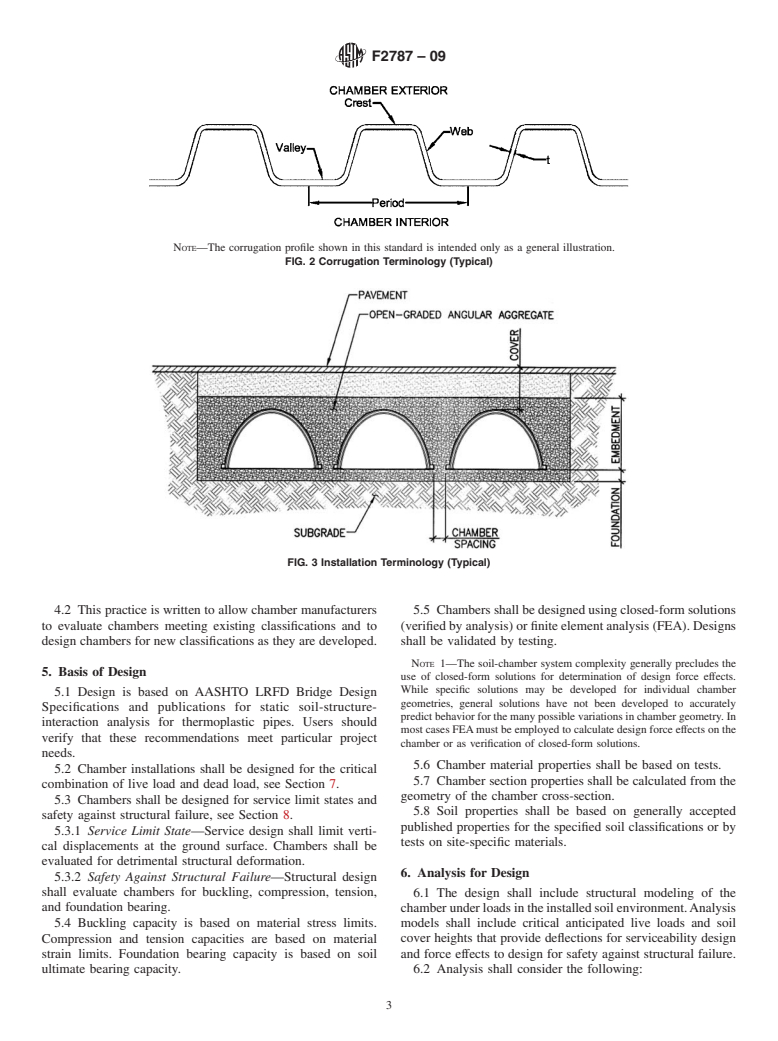

top of the chambers (see Fig. 3).

4.1 This practice provides a rational method for structural

3.1.7 end cap—a bulkhead provided to begin and terminate

design of thermoplastic stormwater chambers. The loads,

a chamber, or row of chambers, and prevent intrusion of

capacities, and limit states are based on accepted load and

surrounding embedment materials.

resistance factor design for thermoplastic pipes; however,

3.1.8 foot—a flat, turned out section that is manufactured

existing design specifications for thermoplastic pipes do not

with the chamber to provide a bearing surface for transfer of

adequately address the design of chambers due to (1) open-

vertical loads to the foundation (see Fig. 1).

bottom geometry, (2) support on integral foot, (3) varying

circumferential corrugation geometry, and (4) manufacture

with alternative thermoplastic resin. This practice standardizes

AWWA Manual of Water Supply Practices M45: Fiberglass Pipe Design, 2nd

recommendations for designers to adequately address these

Edition, 2005. Available from the American Water Works Association (AWWA),

aspects of chamber design.

6666 W. Quincy Ave., Denver, CO 80235.

NOTE—The model chamber shown in this standard is intended only as a general illustration.

FIG. 1 Chamber Terminology (Typical)

F2787 – 09

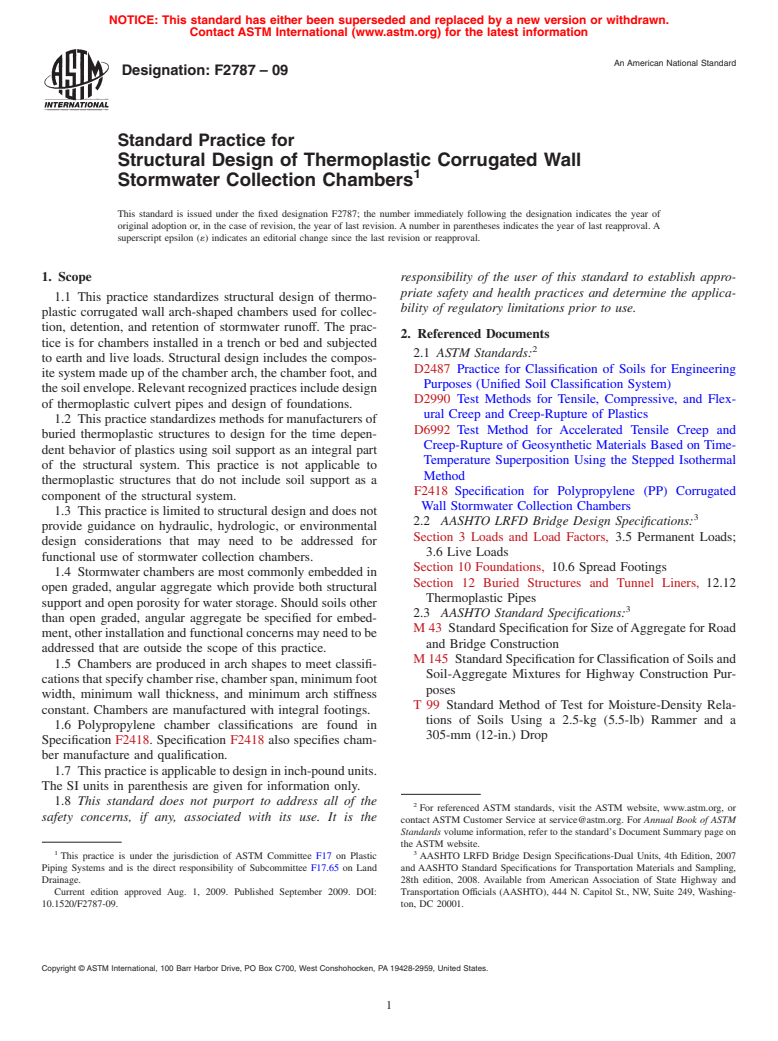

NOTE—The corrugation profile shown in this standard is intended only as a general illustration.

FIG. 2 Corrugation Terminology (Typical)

FIG. 3 Installation Terminology (Typical)

4.2 This practice is written to allow chamber manufacturers 5.5 Chambers shall be designed using closed-form solutions

to evaluate chambers meeting existing classifications and to (verified by analysis) or finite element analysis (FEA). Designs

design chambers for new classifications as they are developed. shall be validated by testing.

NOTE 1—The soil-chamber system complexity generally precludes the

5. Basis of Design

use of closed-form solutions for determination of design force effects.

While specific solutions may be developed for individual chamber

5.1 Design is based on AASHTO LRFD Bridge Design

geometries, general solutions have not been developed to accurately

Specifications and publications for static soil-structure-

predict behavior for the many possible variations in chamber geometry. In

interaction analysis for thermoplastic pipes. Users should

most cases FEAmust be employed to calculate design force effects on the

verify that these recommendations meet particular project

chamber or as verification of closed-form solutions.

needs.

5.6 Chamber material properties shall be based on tests.

5.2 Chamber installations shall be designed for the critical

5.7 Chamber section properties shall be calculated from the

combination of live load and dead load, see Section 7.

geometry of the chamber cross-section.

5.3 Chambers shall be designed for service limit states and

5.8 Soil properties shall be based on generally accepted

safety against structural failure, see Section 8.

published properties for the specified soil classifications or by

5.3.1 Service Limit State—Service design shall limit verti-

tests on site-specific materials.

cal displacements at the ground surface. Chambers shall be

evaluated for detrimental structural deformation.

6. Analysis for Design

5.3.2 Safety Against Structural Failure—Structural design

shall evaluate chambers for buckling, compression, tension,

6.1 The design shall include structural modeling of the

and foundation bearing. chamberunderloadsintheinstalledsoilenvironment.Analysis

5.4 Buckling capacity is based on material stress limits. models shall include critical anticipated live loads and soil

Compression and tension capacities are based on material cover heights that provide deflections for serviceability design

strain limits. Foundation bearing capacity is based on soil and force effects to design for safety against structural failure.

ultimate bearing capacity. 6.2 Analysis shall consider the following:

F2787 – 09

6.2.1 Chamber Structure—Two-dimensional FEA shall use 7.4.1 HL-93—The HL-93 load is a combination of the

beam elements with effective section properties to model the design truck or design tandem, whichever is critical, applied

chamber wall. Each beam element shall represent not more with the design lane load.

than 10 degrees of the chamber circumference. Nodes at beam 7.4.2 Design Truck—The design truck shall be the

ends shall be located at the center of the gravity (cg) of the

AASHTO Design Truck as specified in AASHTO LRFD

corrugated chamber wall cross-section. Three-dimensional Bridge Design Specifications, Section 3.6.1.2.2.

FEA shall employ shell elements.

7.4.3 Design Tandem—The design tandem shall be the

6.2.2 FEAProgram—AcceptableFEAprogramsinclude (1)

AASHTO Design Tandem as specified in AASHTO LRFD

CANDE (Culvert Analysis and Design), (2) similarly featured

Bridge Design Specifications, Section 3.6.1.2.3.

and verified culvert design software, or (3) general purpose

7.4.4 Thermoplastic chamber structures have a structural

finite element analysis software with capability to model

response that is dependent on load duration. Chamber response

nonlinear static soil-structure-interaction.

to live load is computed using appropriate creep moduli for

6.2.3 Creep—The time-dependent response (creep) of ther-

instantaneous response (transient loads) and longer-duration

moplastic chamber materials shall be included in the analysis.

response (sustained loads).As a minimum, design for live load

Acceptable methods are (1) multiple linear-elastic models with

shall include evaluation of instantaneous response (due to

successive stiffness reductions for creep effects, and (2) non-

moving vehicles), using a short duration (# 1 min) creep

linear chamber models that include the creep response. Values

modulus, with multiple presence and impact factors in the live

of creep modulus shall be determined by test in accordance

loadcomputation,andasustainedloadresponse(duetoparked

with Test Methods D2990 or Test Method D6992.

vehicle) using a 1 week creep modulus with no multiple

6.2.4 Soil—Models shall include accurate representation of

presence or impact factors included in the live load computa-

the structural backfill envelope and boundary conditions. The

tion.

backfill envelope includes foundation, embedment, and cover.

7.5 Live Load Factor (g )—The live load factor shall be

LL

Boundary conditions typically include the size of the soil

1.75.

embedment zone, distance to trench walls, subgrade under the

backfill envelope, weight and stiffness of soils above the

8. Structural Design

backfill envelope, and boundary for application of live loads.

8.1 The resistance of a chamber to design loads shall be

Structural backfill soils shall be modeled with nonlinear

based on the critical limit state for (1) serviceability require-

properties that incorporate the effects of confinement. Accept-

ments, (2) stability of the chamber to global buckling, (3)

ablesoilmodelsinclude(1)soilhardeningmodelsthatincrease

strength of the chamber to local buckling, (4) strength of the

soil stiffness for confinement, (2) elastic-plastic models that

chambermaterialrelativetotensilestrainlimits,(5)capacityof

allow failure in shear, or (3) large-deformation models. Soils

the foundation material to bearing from the chamber foot, and

outside the backfill envelope and further than two times the

(6) capacity of the subgrade material to bearing from the

chamber span from the chamber may be modeled as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.