ASTM D6616-01a(2006)

(Test Method)Standard Test Method for Measuring Viscosity at High Shear Rate by Tapered Bearing Simulator Viscometer At 100°C

Standard Test Method for Measuring Viscosity at High Shear Rate by Tapered Bearing Simulator Viscometer At 100°C

SIGNIFICANCE AND USE

Viscosity at the shear rate and temperature of this test method is thought to be particularly representative of bearing conditions in large medium speed reciprocating engines as well as automotive and heavy duty engines operating in this temperature regime.

The importance of viscosity under these conditions has been stressed in railroad specifications.

SCOPE

1.1 This test method covers the laboratory determination of the viscosity of engine oils at 100C and 1106s -1 using the Tapered Bearing Simulator (TBS) viscometer.This test method is similar to Test Method D 4683 which uses the same TBS viscometer to measure high shear viscosity at 150C.

1.2 The Newtonian calibration oils used to establish this test method range from approximately 5 to 12 mPas (cP) at 100C and either the manual or automated protocol was used by each participant in developing the precision statement. The viscosity range of the test method at this temperature is from 1 mPas (cP) to above 25 mPas (cP), depending on the model of TBS.

1.3 The non-Newtonian reference oil used to establish the shear rate of 1106s-1 for this test method has a viscosity of approximately 10 mPas at 100C.

1.4 Application to petroleum products other than engine oil has not been determined in preparing the viscometric information for this test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. This test method uses the milliPascal second (mPas) as the unit of viscosity. This unit is equivalent to the centiPoise (cP), which is shown in parentheses.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6616 – 01a (Reapproved 2006)

Standard Test Method for

Measuring Viscosity at High Shear Rate by Tapered Bearing

Simulator Viscometer at 100°C

This standard is issued under the fixed designation D 6616; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the laboratory determination of 2.1 ASTM Standards:

6 –1

the viscosity of engine oils at 100°C and 1·10 s using the D 4683 Test Method for Measuring Viscosity at High Shear

Tapered Bearing Simulator (TBS) viscometer. Rate and High Temperature by Tapered Bearing Simulator

NOTE 1—This test method is similar toTest Method D 4683 which uses

3. Terminology

the same TBS viscometer to measure high shear viscosity at 150°C.

3.1 Definitions:

1.2 The Newtonian calibration oils used to establish this test

3.1.1 density—the mass per unit volume. In the SI, the unit

method range from approximately 5 to 12 mPa·s (cP) at 100°C

ofdensityisthekilogrampercubicmetre,butforpracticaluse,

and either the manual or automated protocol was used by each

a submultiple is more convenient. The gram per cubic centi-

participantindevelopingtheprecisionstatement.Theviscosity 3 3

metre is equivalent to 10 kg/m and is customarily used.

range of the test method at this temperature is from 1 mPa·s

3.1.2 Newtonian oil or fluid—an oil or fluid that at a given

(cP) to above 25 mPa·s (cP), depending on the model of TBS.

temperature exhibits a constant viscosity at all shear rates or

1.3 The non-Newtonian reference oil used to establish the

shear stresses.

6 –1

shear rate of 1·10 s for this test method has a viscosity of

3.1.3 non-Newtonian oil or fluid—an oil or fluid that exhib-

approximately 10 mPa·s at 100°C.

its a viscosity that varies with changing shear stress or shear

1.4 Application to petroleum products other than engine oil

rate.

has not been determined in preparing the viscometric informa-

3.1.4 shear rate—the velocity gradient in fluid flow. The SI

tion for this test method. –1

unit for shear rate is s .

1.5 The values stated in SI units are to be regarded as

3.1.5 shear stress—the motivating force per unit area for

standard. No other units of measurement are included in this

fluid flow. The area is the area under shear.

standard. This test method uses the milliPascal second (mPa·s)

3.1.6 viscosity—the ratio between the applied shear stress

as the unit of viscosity.This unit is equivalent to the centiPoise

and the rate of shear. It is sometimes called the coefficient of

(cP), which is shown in parentheses.

dynamic viscosity. This coefficient is a measure of the resis-

1.6 This standard does not purport to address all of the

tance to flow of the liquid. In the SI, the unit of viscosity is the

safety concerns, if any, associated with its use. It is the

Pascal·second; often the milliPascal·second or its equivalent

responsibility of the user of this standard to establish appro-

the centiPoise is found more convenient.

priate safety and health practices and to determine the

3.1.6.1 apparent viscosity—the viscosity of a non-

applicability of regulatory limitations prior to use.

Newtonianfluidatagivenshearrateorshearstressdetermined

by this test method.

3.2 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction of ASTM Committee D02 on 2

3.2.1 idling oil —an oxidatively stable Newtonian oil in-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

jected into the operating viscometer stator when the instrument

D02.07.0B on High Temperature Rheology of Non-Newtonian Fluids.

Current edition approved May 1, 2006. Published June 2006. Originally is likely to be held for periods of time greater than 30 min and

approved in 2001. Last previous edition approved in 2001 as D 6616 – 01a.

Available from Tannas Co., 4800 James Savage Rd., Midland, MI 48642. This

viscometer and associated equipment as listed in the research report was used to For referenced ASTM standards, visit the ASTM website, www.astm.org, or

develop the precision statement. To date, no other equipment has demonstrated, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

through ASTM interlaboratory testing, the ability to meet the precision of this test. Standards volume information, refer to the standard’s Document Summary page on

This is not an endorsement or certification by ASTM. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6616 – 01a (2006)

up to two weeks at 100°C. Use of this oil prevents stator 6. Apparatus

deposits from additives, which may decompose after longer

6.1 Tapered Bearing Simulator Viscometers (TBS)—a vis-

exposure times in the operating viscometer and permits con-

cometer consisting of a motor connected to a slightly tapered

tinuous operation of the viscometer without need to shut the

rotor that fits into a matched stator. Several models of the TBS

instrument off.

are in use. All of these are capable of analyzing test oils at

3.2.2 Newtonian Reference Oil —a specially blended New-

100°C but earlier models are more limited in their upper

tonian oil that has the same viscosity at 100°C as the

viscosity range.

non-Newtonian reference oil of 3.2.3.

6.2 Different models of the tapered bearing simulator (TBS)

3.2.3 non-Newtonian reference oil —a specially formulated

have the following upper levels of operating viscosities at

non-Newtonian oil, identified as NNR-10, having a selected

6 –1

1·10 s shear rate:

6 –1

apparent viscosity at 1·10 s shear rate. The oil is used to

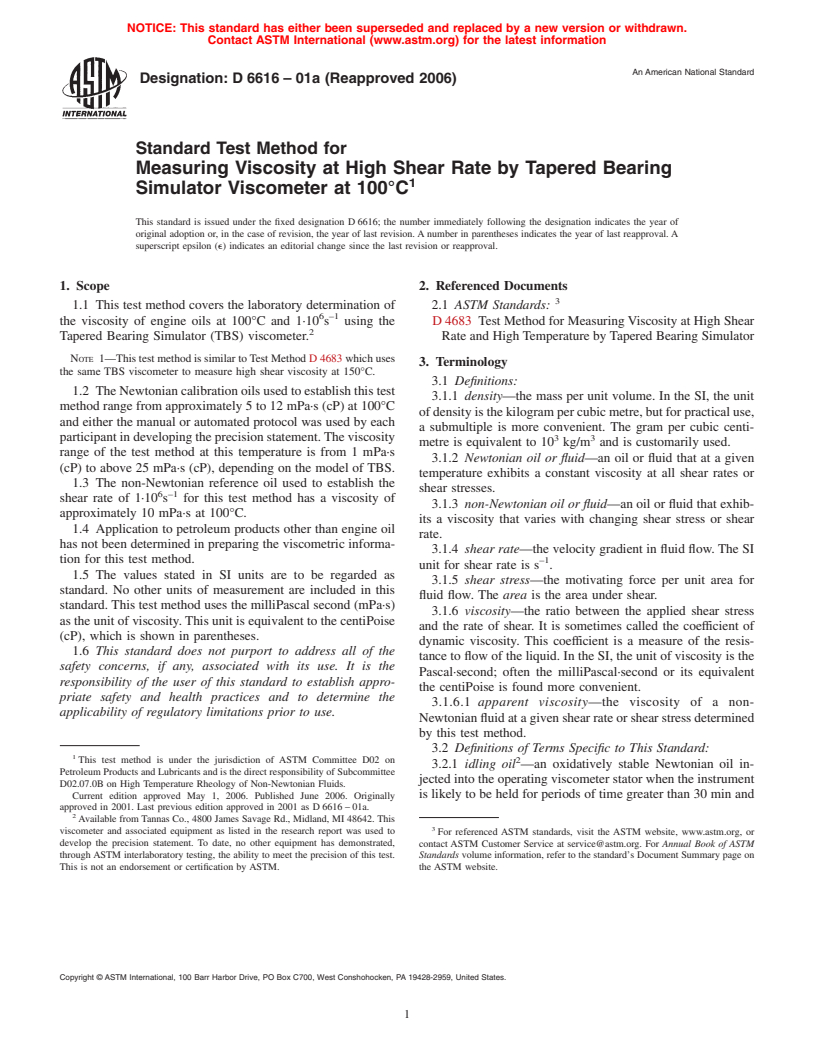

6.2.1 Model Series 400 (similar to Fig. 1)—;14 mPa·s

establish an operating gap between the rotor and stator which

6 –1

(cP), dual speed.

will produce 1·10 s shear rate when the rotor height is

6.2.2 Model Series 500 (Fig. 1)—; 16 mPa·s (cP) single

adjustedtogiveatorqueoutputequivalenttothatofthespecial

speed.

reference oil described in 3.2.2.

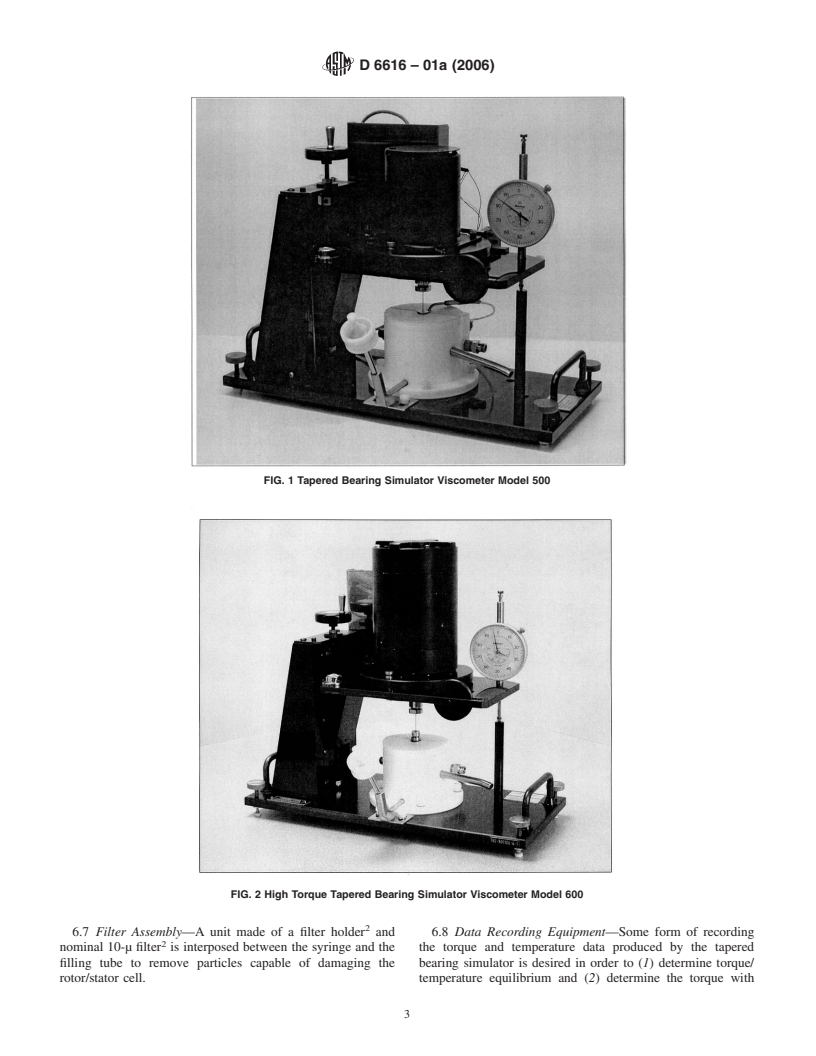

6.2.3 Model Series 600 (Fig. 2)—;100 mPa·s (cP) (usually

3.2.4 reciprocal torque intersection, 1/T—the rotor position

i

liquid cooled), dual speed.

on the micrometer defined by the intersection of two straight

lines generated by the reciprocal torque method using the

6.2.4 Model Series SS (SuperShear) (similar to Fig. 1)—

Newtonian reference oil of 3.2.2 and non-Newtonian reference

;20 mPa·s (cP), multi-speed.

oil of 3.2.3. Reciprocal torque versus rotor height measure-

6.2.5 Model Series 2100 E (Fig. 3)—;20 mPa·s (cP) (see

ments on both oils gives straight lines whose intersection, 1/T,

i

Note 2), multi-speed.

6 –1

establishes the desired rotor position for operation at 1·10 s

NOTE 2—TBS Models 500, 600, and SS use a so-called bouncer to

shear rate.

2 automate unloading and reloading the load cell just before taking a torque

3.2.5 reference Newtonian calibration oils —specially cho-

reading. (All automated units apply the bouncer at the appropriate point of

sen Newtonian oils used to determine the viscosity-torque

operation as part of their program.) If a bouncer is not on the TBS model

relationship of the TBS viscometer at 100°C from which the

used (Model 400), the effect is generated by placing the thumb on the

viscosity of an unknown oil is calculated.

brass weight pin and turning the turntable slightly in a clockwise direction

and quickly releasing the turntable.The bearingless Models 2100 E do not

3.2.6 rotor height (rotor position)—the vertical position of

require unloading the cell since there is no turntable bearing.

the rotor relative to the stator and measured by the platform

micrometer.

6.3 Automated System for Calibration, Injection, and Data

3.2.6.1 stored rotor height (rotor position)—the rotor posi-

Analysis Programs—An automated program for the Tapered

tion with the rotor 0.50 mm above the rubbing contact position

Bearing Simulator, simulating the manual method has been

(see 3.2.7) when the instrument is shut down.

used.

3.2.7 rubbing contact position—the rotor height determined

6.4 Console—The console shown in Fig. 4 is similar in

when the tapered rotor is lightly brought into contact with the

Models 400, 500, and 600. Consoles for Series SS and 2100 E

similarly tapered stator.

haveprovisionsforchangingmotorspeed.Allconsolescontain

3.2.8 test oil—any oil for which the apparent viscosity is to

the power source for the load cell, thermoregulator circuit,

be determined by this test method.

stator-heating element, and motor. They also contain the

circuitry for regulating and monitoring the temperature of the

4. Summary of Test Method

oil in the stator as well as the amplifier and digital readout of

the load cell.

4.1 A motor drives a tapered rotor closely fitted inside a

matched tapered stator. Appropriate technique establishes op-

NOTE 3—The thermoregulator circuit of the TBS viscometers has

6 –1

eration of the viscometer to yield 1·10 s at a temperature of

evolved as improvements have been made in the solid-state temperature

100°C at which point test oils are introduced into the gap

controller and heater. To achieve the 5 min analysis time specified in this

between the spinning rotor and stationary stator. The rotor

test method requires a late model solid-state controller with automatic

reset coupled to a thermo-foil stator heater with small heat inertia or a

exhibits a reactive torque to the viscous resistance of each test

fast-responding thermoregulated liquid bath.

oil and the value of this torque response is used to determine

the apparent viscosity of the test oil at 100°C.

6.5 Cooling Systems—Two cooling systems are available

for TBS viscometer work at 100°C: forced air cooling and

5. Significance and Use

liquid bath cooling. The stator housing is prepared for the

former but must be modified for the latter according to

5.1 Viscosity at the shear rate and temperature of this test

method is thought to be particularly representative of bearing directions from the manufacturer.

conditionsinlargemediumspeedreciprocatingenginesaswell

6.6 Glass Syringe—A50-mL glass syringe equipped with a

as automotive and heavy duty engines operating in this

Luer needle lock fits the tip of the filling tube for injection of

temperature regime.

test oil into the test cell. Smaller glass and plastic syringes can

5.2 The importance of viscosity under these conditions has beusedifanyairbubbleinthefilltubecausedbytheexchange

been stressed in railroad specifications. of syringes is first pulled up into the next syringe to be used.

D 6616 – 01a (2006)

FIG. 1 Tapered Bearing Simulator Viscometer Model 500

FIG. 2 High Torque Tapered Bearing Simulator Viscometer Model 600

6.7 Filter Assembly—A unit made of a filter holder and 6.8 Data Recording Equipment—Some form of recording

nominal 10-µ filter is interposed between the syringe and the the torque and temperature data produced by the tapered

filling tube to remove particles capable of damaging the bearing simulator is desired in order to (1) determine torque/

rotor/stator cell. temperature equilibrium and (2) determine the torque with

D 6616 – 01a (2006)

FIG. 3 Multi-Speed Tapered Bearing Simulator Viscometer Model 2100E

FIG. 4 Control Console for Tapered Bearing Simulator Viscometer Models 400, 500, and 600

variation of torque with time makes desirable the recording and analysis

sufficient precision to calculate viscosity to the second decimal

of the torque output more precise, particularly when determining torque

place. Early in the use of the TBS viscometer, a strip-chart

equilibrium.

recorder was used, later an automated, computer-based record-

ing system was developed with both a computer-simulated

6.8.1 Strip-chart Recorder:

strip chart and with data digitally recorded.

6.8.1.1 If a strip-chart recorder is used to record the torque

and temperature output signals, use the manufacturer’s direc-

NOTE 4—Although the console has a torque indicator that can be used

for determining viscosity, it has been found that the small oscillatory tions for calibrating and setting up the strip chart for recording

D 6616 – 01a (2006)

NOTE 7—It is important to always use a filter and filter disk to prevent

torque/temperature data (see Note 5). The torque reading must

larger particles from entering the rotor-stator gap. However, it is also

be in milliVolts and the temperature in °C with a full-scale

important to note that the TBS viscometer will work with heavily particle

chart range of 20° to 120°C.

laden used oils as long as they are passed through the 10-µ filter.

6.8.1.2 Use a chart speed of 1 cm/min for recording.

6.8.1.3 Set and, when necessary, reset, the strip chart torque

9. Preparation of Apparatus

voltage to that which will permit recording the torque as much

9.1 Set up stator cooling method, air or liquid, according to

as possible on the upper two-thirds of the chart paper for

the manufacturer’s directions.

maximum sensitivity.

NOTE 8—When analyzing relatively viscous oils, stator cooling is

6.8.1.4 Factor the resulting voltage values to calculate the

necessary. This is particularly the case at lower operating temperatures

correct values of torque.

such as 100°C where simple radiation from the stator through the stator

NOTE 5—Althoughthedigitalinformationfromthetorqueoutputmeter

housing is not sufficient to carry away the heat generated by viscous

on the viscometer console can be, and is, used for recording additional test

resistance to shear.

information, it is desirable to use a two-pen, strip-chart recorder or its

9.1.1 Air Cooling—Connect cooling air tubing to the ports

computer equivalent since this provides a continuous torque/temperature

on the stator housing and the back of the console following

record of torque/temperature equilibrium necessary for precision in

directions given by the manufacturer in the Owner’s Manual.

calibration and in calculating viscosity.

This will permit use of the flow meter on the left side of the

6.8.2 Computer Accumulation of Torque and Temperature

console to adjust the cooling-air flow rate.

Data—Computer recording of digital data can also be used for

9.1.1.1 Set the airflow rate at 100 SCFH.

the test method. Such programs should show data for both

torque and stator temperature. Torque information should be NOTE 9—Once airflow rate has been set, it is important that this level

bemaintainedthroughoutcalibrationandoperation.Ifdesired,theai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.