ASTM F3181-16(2023)

(Test Method)Standard Test Method for The Un-notched, Constant Ligament Stress Crack Test (UCLS) for HDPE Materials Containing Post- Consumer Recycled HDPE

Standard Test Method for The Un-notched, Constant Ligament Stress Crack Test (UCLS) for HDPE Materials Containing Post- Consumer Recycled HDPE

SIGNIFICANCE AND USE

4.1 This test method is a way to evaluate the effects of contaminant particles found in HDPE products containing PCR-HDPE, primarily corrugated pipe. Particles of significant number, size and shape can reduce the slow crack growth resistance of the products. This test is performed in water without a controlled defect such as a notch. Since there is no notch, it is not necessary to use a surfactant in the water bath. It is a constant load test.

4.2 This test may be used to evaluate various blends of recycled and virgin materials. For example, a material with high stress crack resistance and few contaminants can be blended with materials that are less resistant to cracking to enhance the overall stress crack resistance of the blend.

4.3 The test can be conducted at various temperature and stress conditions. If at least three (3) different temperature/stress conditions are evaluated, an estimate of the service lifetime of the material can be predicted with the use of bi-directional shifting or the rate process method.

4.4 The test can also be performed under a single applied load and a single temperature to create a single point test useful for comparative purposes as well as for quality control.

SCOPE

1.1 This test method covers an un-notched constant ligament stress (UCLS) test for use with HDPE materials that contain post-consumer recycled HDPE (PCR-HDPE). Contaminants in the PCR-HDPE can initiate stress cracks at elevated temperatures, and this test method evaluates the response of these materials to a constant applied stress.

1.2 The test method is focused on HDPE corrugated pipe containing PCR-HDPE, but can be used in other applications where PCR-HDPE is used.

1.3 The test utilizes the same devices used to perform the NCTL test (Test Method D5397) and the NCLS test (Test Method F2136), but the test is conducted with different specimens and with the use of water instead of a surfactant solution. The test specimen is larger than standard NCLS and NCTL specimens to increase the number of contaminant particles in the specimen that might grow cracks.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3181 − 16 (Reapproved 2023)

Standard Test Method for

The Un-notched, Constant Ligament Stress Crack Test

(UCLS) for HDPE Materials Containing Post- Consumer

Recycled HDPE

This standard is issued under the fixed designation F3181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers an un-notched constant liga-

D1600 Terminology for Abbreviated Terms Relating to Plas-

ment stress (UCLS) test for use with HDPE materials that

tics

contain post-consumer recycled HDPE (PCR-HDPE). Con-

D2837 Test Method for Obtaining Hydrostatic Design Basis

taminants in the PCR-HDPE can initiate stress cracks at

for Thermoplastic Pipe Materials or Pressure Design Basis

elevated temperatures, and this test method evaluates the

for Thermoplastic Pipe Products

response of these materials to a constant applied stress.

D4703 Practice for Compression Molding Thermoplastic

1.2 The test method is focused on HDPE corrugated pipe

Materials into Test Specimens, Plaques, or Sheets

containing PCR-HDPE, but can be used in other applications

D5397 Test Method for Evaluation of Stress Crack Resis-

where PCR-HDPE is used.

tance of Polyolefin Geomembranes Using Notched Con-

stant Tensile Load Test

1.3 The test utilizes the same devices used to perform the

D638 Test Method for Tensile Properties of Plastics

NCTL test (Test Method D5397) and the NCLS test (Test

F412 Terminology Relating to Plastic Piping Systems

Method F2136), but the test is conducted with different

F2136 Test Method for Notched, Constant Ligament-Stress

specimens and with the use of water instead of a surfactant

(NCLS) Test to Determine Slow-Crack-Growth Resis-

solution. The test specimen is larger than standard NCLS and

tance of HDPE Resins or HDPE Corrugated Pipe

NCTL specimens to increase the number of contaminant

2.2 AASHTO Documents:

particles in the specimen that might grow cracks.

Report 696 National Cooperative Highway Research Pro-

1.4 The values stated in inch-pound units are to be regarded

gram (NCHRP)

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Terminology

and are not considered standard.

3.1 Definitions: Definitions are in accordance with Termi-

1.5 This standard does not purport to address all of the

nology F412, and abbreviations are in accordance with Termi-

safety concerns, if any, associated with its use. It is the

nology D1600, unless otherwise specified.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 bi-directional shift constants, n—Constants used to

mine the applicability of regulatory limitations prior to use.

shift elevated temperature and stress data to service conditions;

1.6 This international standard was developed in accor-

e.g. Popelar shift constants for HDPE.

dance with internationally recognized principles on standard-

3.2.2 contaminant, n—inorganic particulate matter or other

ization established in the Decision on Principles for the

non-HDPE material that creates inclusions or stress risers in

Development of International Standards, Guides and Recom-

the crystalline structure of HDPE.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test the ASTM website.

Methods. Available from American Association of State Highway and Transportation

Current edition approved July 1, 2023. Published July 2023. Originally approved Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

2016 F3181-16. DOI: 10.1520/F3181–16R23 http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3181 − 16 (2023)

3.2.3 post-consumer recycled HDPE (PCR-HDPE), 5. Apparatus

n—HDPE materials from products that have served a previous

5.1 Blanking Die—A die suitable of cutting Test Method

consumer purpose (for example, laundry detergent bottles,

D638, Type I tensile specimens. Alternatively, specimens may

milk bottles and other consumer goods).

be prepared by machining.

5.2 Stress-Crack Testing Device—A lever-loading machine

4. Significance and Use

with a mechanical advantage of up to 10:1. The most common

4.1 This test method is a way to evaluate the effects of

devices used for corrugated pipe resins have a maximum

contaminant particles found in HDPE products containing

mechanical advantage of 5:1, but higher ratios would allow for

PCR-HDPE, primarily corrugated pipe. Particles of significant

testing of thicker specimens. The device is similar or identical

number, size and shape can reduce the slow crack growth

to those used for Test Methods D5397 and F2136. The device

resistance of the products. This test is performed in water

shall have a timer capable of recording failures within the

without a controlled defect such as a notch. Since there is no

nearest 0.1 hr. for each individual lever arm. The timer must

notch, it is not necessary to use a surfactant in the water bath.

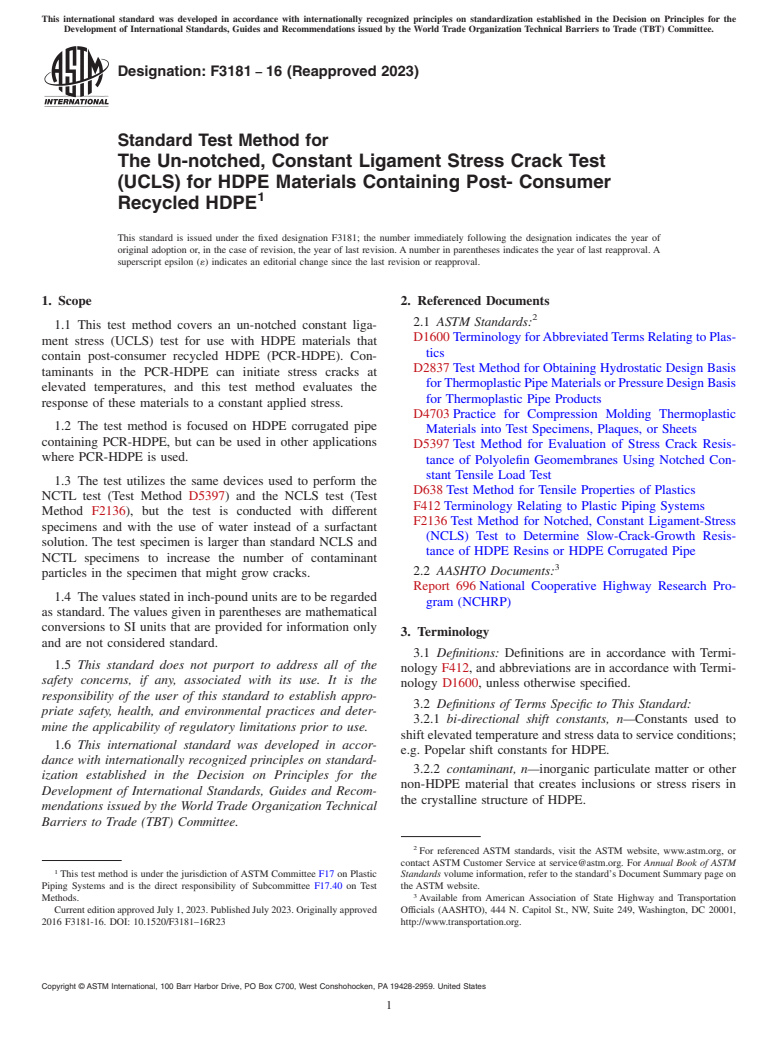

stop when a test specimen fails. An example of an acceptable

It is a constant load test. device is shown in Fig. 1 and Fig. 2. Fig. 1 shows some test

specimens mounted in the testing frame. Fig. 2 shows the

4.2 This test may be used to evaluate various blends of

frame mounted in a water bath with the weights hung on the

recycled and virgin materials. For example, a material with

lever arms.

high stress crack resistance and few contaminants can be

5.3 Water Bath—A heated and stirred water bath deep

blended with materials that are less resistant to cracking to

enough to cover the test specimens mounted in the frame to a

enhance the overall stress crack resistance of the blend.

point above the reduced section and into the top tab. The bath

4.3 The test can be conducted at various temperature and

must be capable of heating to a constant temperature of 80 °C

stress conditions. If at least three (3) different temperature/

6 1 °C.

stress conditions are evaluated, an estimate of the service

NOTE 1—Baths that once contained surfactant solutions for other stress

lifetime of the material can be predicted with the use of

crack tests are extremely difficult to clean. Residual surfactant will reduce

bi-directional shifting or the rate process method.

the failure times of this test and may stay present for many months and

after many cleanings.

4.4 The test can also be performed under a single applied

load and a single temperature to create a single point test useful 5.4 Compression Molding Press and Mold—A set-up for

for comparative purposes as well as for quality control. compression molding a plaque at least 7 in. (178 mm) by 7 in.

FIG. 1 Test Apparatus

F3181 − 16 (2023)

FIG. 2 Hanging Weights

(178 mm) and cooling it at 15°C per minute in accordance with in. (5.6 mm) is placed in each tab with the use of a ⁄32 in. drill

Practice D4703. The mold shall be designed in a way to allow bit. The finished specimen and associated dimensions are

the removal of at least five Test method D638, Type I tensile

shown in Fig. 3 and Table 1. At least five (5) specimens are

specimens with the geometry described in Section 6. recommended for each material tested.

6. Test Specimen

7. Procedure

6.1 Plaque

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.