ASTM D4823-95(2003)e1

(Guide)Standard Guide for Core Sampling Submerged, Unconsolidated Sediments

Standard Guide for Core Sampling Submerged, Unconsolidated Sediments

ABSTRACT

This guide covers core-sampling submerged, unconsolidated sediments. It also covers terminology, advantages and disadvantages of different types of core samplers, core-distortions that may occur during sampling, techniques for detecting and minimizing core distortions, and methods for dissecting and preserving sediment cores. Sampling procedures and equipment are divided into categories based on water depth. Critical dimensions and properties of open-barrel and piston samplers like the cutting-bit angle, core-liner diameter, inside friction factor, outside friction factor, area factor, core-barrel length, barrel surfaces, and chemical composition of sampler parts shall conform to this standard guide. The following factors shall be considered for decisions in choosing between an open-barrel sampler and a piston sampler: depth of penetration, core compaction, flow-in distortion, surface disturbance, and repenetration. Driving techniques included in this guide are free core samplers, implosive and explosive samplers, punch-corer samplers, vibratory-driven samplers and impact-driven samplers. Guides are also included for collecting short cores in shallow water, collecting long cores in shallow water, and collecting short and long cores for a range of water depth. Field record shall be provided for every sampling operation. Guides are also provided for core extrusion for samplers with no liners, slitting core and core liners, sectioning cores, sampling through liner walls, preserving cores, and displaying cores.

SCOPE

1.1 This guide covers core-sampling terminology, advantages and disadvantages of different types of core samplers, core-distortions that may occur during sampling, techniques for detecting and minimizing core distortions, and methods for dissecting and preserving sediment cores.

1.2 In this guide, sampling procedures and equipment are divided into the following categories based on water depth: sampling in depths shallower than 0.5 m, sampling in depths between 0.5 m and 10 m, and sampling in depths exceeding 10 m. Each category is divided into two sections: equipment for collecting short cores and equipment for collecting long cores.

1.3 This guide emphasizes general principles. Only in a few instances are step-by-step instructions given. Because core sampling is a field-based operation, methods and equipment must usually be modified to suit local conditions. This modification process requires two essential ingredients:operator skill and judgment. Neither can be replaced by written rules.

1.4 Drawings of samplers are included to show sizes and proportions. These samplers are offered primarily as examples (or generic representations) of equipment that can be purchased commercially or built from plans in technical journals.

1.5 This guide is a brief summary of published scientific articles and engineering reports. These references are listed in this guide. These documents provide operational details that are not given in this guide but are nevertheless essential to the successful planning and completion of core sampling projects.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Notes 1 and 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 4823 – 95 (Reapproved 2003)

Standard Guide for

Core Sampling Submerged, Unconsolidated Sediments

This standard is issued under the fixed designation D4823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were editorially moved into the standard text in August 2003.

1. Scope sign, and Construction Purposes

D1129 Terminology Relating to Water

1.1 This guide covers core-sampling terminology, advan-

D1452 Practice for Soil Investigation and Sampling by

tages and disadvantages of different types of core samplers,

Auger Borings

core-distortions that may occur during sampling, techniques

D1586 Test Method for Penetration Test and Split-Barrel

for detecting and minimizing core distortions, and methods for

Sampling of Soils

dissecting and preserving sediment cores.

D1587 Practice for Thin-Walled Tube Sampling for Geo-

1.2 In this guide, sampling procedures and equipment are

technical Purposes

divided into the following categories based on water depth:

D4220 Practices for Preserving and Transporting Soil

sampling in depths shallower than 0.5 m, sampling in depths

Samples

between0.5mand10m,andsamplingindepthsexceeding10

D4410 Terminology for Fluvial Sediment

m. Each category is divided into two sections: equipment for

collecting short cores and equipment for collecting long cores.

3. Terminology

1.3 Thisguideemphasizesgeneralprinciples.Onlyinafew

3.1 Definitions—For definitions of terms used in this guide,

instances are step-by-step instructions given. Because core

refer to Terminology D1129 and Terminology D4410.

sampling is a field-based operation, methods and equipment

3.2 Definitions of Terms Specific to This Standard:

must usually be modified to suit local conditions. This modi-

3.2.1 check valve—a device (see Fig. 1) mounted atop an

fication process requires two essential ingredients: operator

open-barrel core sampler.As the sampler moves down through

skill and judgment. Neither can be replaced by written rules.

water and sediment, the valve remains open to allow water to

1.4 Drawings of samplers are included to show sizes and

flow up through the barrel. When downward motion stops, the

proportions. These samplers are offered primarily as examples

valve closes. During retrieval, the valve remains closed and

(orgenericrepresentations)ofequipmentthatcanbepurchased

creates suction that holds the core inside the barrel.

commercially or built from plans in technical journals.

3.2.2 core—averticalcolumnofsedimentcutfromaparent

1.5 This guide is a brief summary of published scientific

deposit.

articles and engineering reports. These references are listed in

3.2.3 core catcher—a device (see Fig. 2) that grips and

this guide. These documents provide operational details that

supports the core while the sampler is being pulled from the

are not given in this guide but are nevertheless essential to the

sediment and hoisted to the water surface.

successful planning and completion of core sampling projects.

3.2.4 core conveyor—a device (see Fig. 3) for reducing

1.6 This standard does not purport to address all of the

friction between a core and the inside surface of a core barrel.

safety concerns, if any, associated with its use. It is the

3.2.5 core-barrel liner—a rigid, thin-wall tube mounted

responsibility of the user of this standard to establish appro-

inside the barrel of a core sampler. During the core-cutting

priate safety and health practices and determine the applica-

process, sediment moves up inside the liner.

bility of regulatory limitations prior to use. For specific

3.2.6 core sampler—an instrument for collecting cores.

warning statements, see 6.3 and 11.5.

3.2.7 extrude—Theactofpushingacorefromacorebarrel

2. Referenced Documents or a core-barrel liner.

3.2.8 open-barrel sampler—in simplest form, a straight

2.1 ASTM Standards:

tube open at both ends. More elaborate open-barrel samplers

D420 Guide to Site Characterization for Engineering, De-

have core catchers and check valves.

This guide is under the jurisdiction ofASTM Committee D19 on Water and is

the direct responsibility of Subcommittee D19.07 on Sediments, Geomorphology, Annual Book of ASTM Standards, Vol 04.08.

and Open-Channel Flow. Annual Book of ASTM Standards, Vol 11.01.

Current edition approved June 10, 2003. Published August 2003. Originally Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

approved in 1988. Last previous edition approved in 1999 as D4823–95(1999). this guide.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 4823 – 95 (2003)

NOTE—(a) Strips of metal foil slide up through the core barrel as the

cutting edge advances downward. (5) (b) The plastic sleeve unfolds from

pleats stored near the cutting edge. This sleeve surrounds the core as the

NOTE—Dark bands represent stiff sediments; light bands represent

barrel moves down. (4)

plastic sediments. As coring proceeds, sediment below the barrel moves

FIG. 3 Core Conveyors

laterallyawayfromthecuttingedgeandplasticsedimentsinsidethebarrel

are compressed. “A” is the core’s length and “B” is the barrel’s

penetration depth.

FIG. 1 Deformations Caused by Open-Barrel Core Samplers (1)

NOTE—During penetration the shear pins break but the flow-restricting

orifice holds the clevis and piston together. During retrieval, water in the

top chamber flows through the orifice and allows the piston and clevis to

separate. Cable tension pulls the clevis up against the stop but friction

NOTE—(a)Theleavesseparateduringpenetrationandthencloseduring

locks the piston and core barrel together.

retrieval. Strips of gauze can be woven around the leaves to provide

FIG. 4 Piston Immobilizer (9)

additional support. (3) (b) The lever trips down during retrieval to release

the spring and twist the fabric sleeve shut. (4) (c) The cupped plate drops

during retrieval to block the entrance and support the core. (4) (d) The

ofthecuttingbitand“B”isthedistancefromthesurfaceofthe

lever releases the spring-loaded blade which pivots downward to hold the

parent deposit to the bottom of the cutting bit.

core. (4)

3.2.12 repenetration—a mishap that occurs when a core

FIG. 2 Core Catchers

sampler collects two or more cores during one pass.

3.2.13 surface sampler—a device for collecting sediment

3.2.9 piston immobilizer—a special coupling (see Fig. 4) from the surface of a submerged deposit. Surface samplers are

that protects a core from disruptive forces that arise during sometimes referred to as grab samplers.

sampler pull-out. Piston immobilizers are also called split 3.2.14 trip release—amechanism(seeFig.5andFig.6(b))

pistons or break-away pistons. that releases a core sampler from its suspension cable and

3.2.10 piston sampler—a core sampler (see Fig. 5) with a allows the sampler to freely fall a predetermined distance

solid cylinder (piston) that seals against the inside walls of the before striking the bed.

core barrel. The piston remains fixed at the bed-surface 3.2.15 undisturbed sample—sediment particles that have

elevationwhilethecorebarrelcutsdownthroughthesediment. notbeenrearrangedrelativetooneanotherbytheprocessused

3.2.11 recovery ratio—the ratioA/B where “A” (see Fig. 1) to cut and isolate the particles from their parent deposit. All

is the distance from the top of the sediment core to the bottom core samples are disturbed to some degree because raising the

e1

D 4823 – 95 (2003)

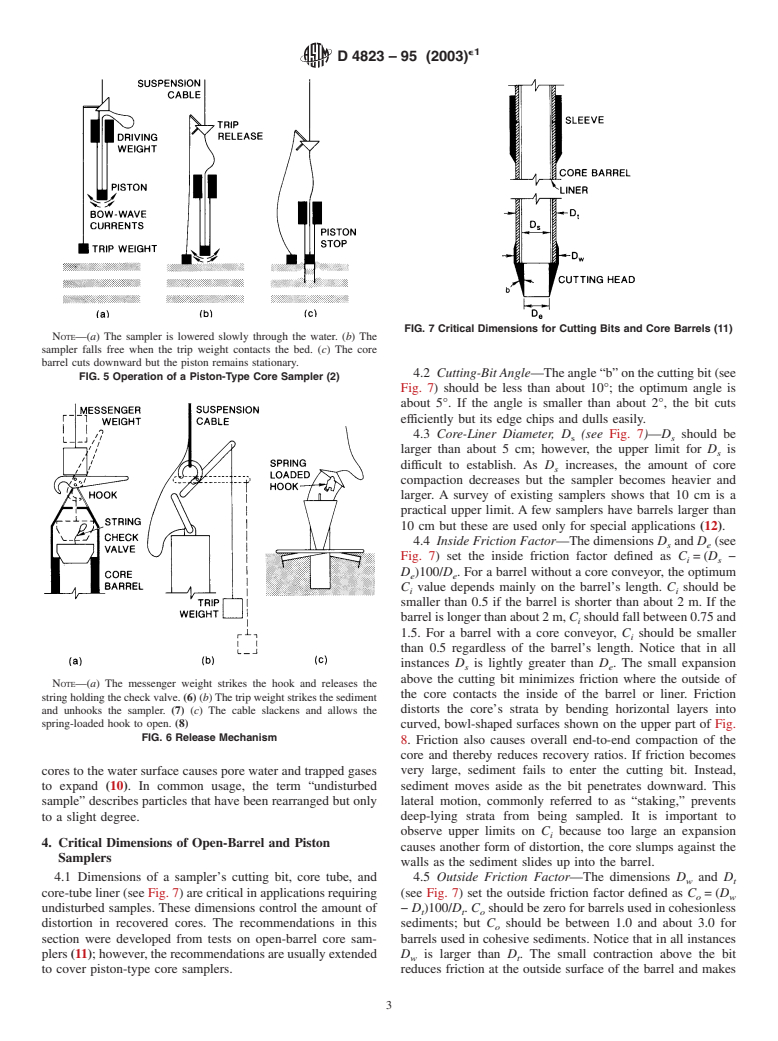

FIG. 7 Critical Dimensions for Cutting Bits and Core Barrels (11)

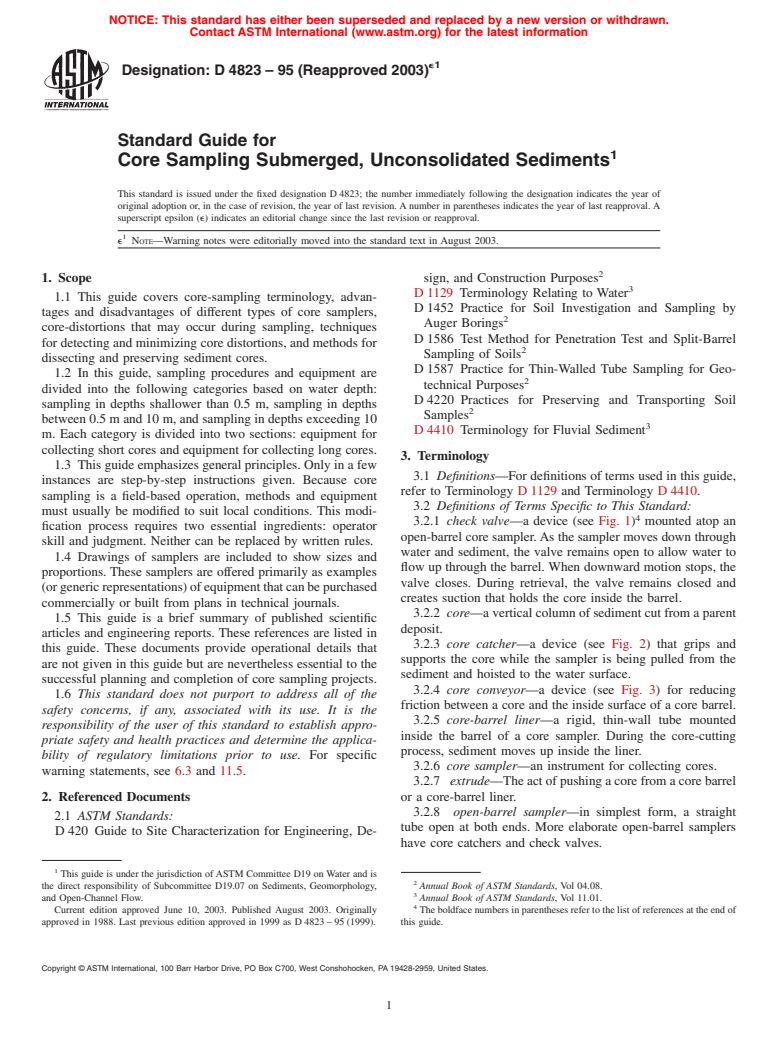

NOTE—(a) The sampler is lowered slowly through the water. (b) The

sampler falls free when the trip weight contacts the bed. (c) The core

barrel cuts downward but the piston remains stationary.

4.2 Cutting-BitAngle—Theangle“b”onthecuttingbit(see

FIG. 5 Operation of a Piston-Type Core Sampler (2)

Fig. 7) should be less than about 10°; the optimum angle is

about 5°. If the angle is smaller than about 2°, the bit cuts

efficiently but its edge chips and dulls easily.

4.3 Core-Liner Diameter, D (see Fig. 7)—D should be

s s

larger than about 5 cm; however, the upper limit for D is

s

difficult to establish. As D increases, the amount of core

s

compaction decreases but the sampler becomes heavier and

larger. A survey of existing samplers shows that 10 cm is a

practical upper limit. A few samplers have barrels larger than

10 cm but these are used only for special applications (12).

4.4 Inside Friction Factor—The dimensions D and D (see

s e

Fig. 7) set the inside friction factor defined as C =(D −

i s

D )100/D . For a barrel without a core conveyor, the optimum

e e

C value depends mainly on the barrel’s length. C should be

i i

smaller than 0.5 if the barrel is shorter than about 2 m. If the

barrelislongerthanabout2m, C shouldfallbetween0.75and

i

1.5. For a barrel with a core conveyor, C should be smaller

i

than 0.5 regardless of the barrel’s length. Notice that in all

instances D is lightly greater than D . The small expansion

s e

above the cutting bit minimizes friction where the outside of

NOTE—(a) The messenger weight strikes the hook and releases the

the core contacts the inside of the barrel or liner. Friction

stringholdingthecheckvalve. (6)(b)Thetripweightstrikesthesediment

distorts the core’s strata by bending horizontal layers into

and unhooks the sampler. (7) (c) The cable slackens and allows the

spring-loaded hook to open. (8) curved, bowl-shaped surfaces shown on the upper part of Fig.

FIG. 6 Release Mechanism

8. Friction also causes overall end-to-end compaction of the

core and thereby reduces recovery ratios. If friction becomes

cores to the water surface causes pore water and trapped gases very large, sediment fails to enter the cutting bit. Instead,

sediment moves aside as the bit penetrates downward. This

to expand (10). In common usage, the term “undisturbed

sample” describes particles that have been rearranged but only lateral motion, commonly referred to as “staking,” prevents

deep-lying strata from being sampled. It is important to

to a slight degree.

observe upper limits on C because too large an expansion

i

4. Critical Dimensions of Open-Barrel and Piston

causes another form of distortion, the core slumps against the

Samplers

walls as the sediment slides up into the barrel.

4.1 Dimensions of a sampler’s cutting bit, core tube, and 4.5 Outside Friction Factor—The dimensions D and D

w t

core-tubeliner(seeFig.7)arecriticalinapplicationsrequiring (see Fig. 7) set the outside friction factor defined as C =(D

o w

undisturbed samples. These dimensions control the amount of − D)100/D. C shouldbezeroforbarrelsusedincohesionless

t t o

distortion in recovered cores. The recommendations in this sediments; but C should be between 1.0 and about 3.0 for

o

section were developed from tests on open-barrel core sam- barrels used in cohesive sediments. Notice that in all instances

plers (11);however,therecommendationsareusuallyextended D is larger than D. The small contraction above the bit

w t

to cover piston-type core samplers. reduces friction at the outside surface of the barrel and makes

e1

D 4823 – 95 (2003)

decision frequently depends not only upon characteristics of

the two samplers but also upon other factors such as hoisting-

equipment capabilities, working platform stability, water

depth, operator experience, and the purpose for collecting the

cores.Thissectioncoversfactorstoconsiderbeforemakingthe

final choice.

5.2 Depth of Penetration—Most open-barrel samplers and

most piston samplers rely on momentum to drive their barrels

into sediment deposits. Momentum-driven samplers are re-

leased at a predetermined point so as to acquire momentum

while falling toward the bed. A momentum-driven piston

sampler generally penetrates deeper than a momentum-driven

open-barrel sampler provided the two samplers have equal

weights, equal barrel-diameters, and equal fall-distances (2).

5.3 Core Compaction—When compared under equal test

FIG. 8 Flow in and Strata-Bending Distortions Inside a Core

Barrel (13) conditions (see 5.2), a piston sampler causes less core com-

paction than an open-barrel sampler. However, the piston must

beheldmotionlessatthebed-surfaceelevationwhilethebarrel

it easier to push the core barrel into the bed. On a long barrel,

penetrates downward. If the piston is allowed to shift down

friction can be reduced by installing one or more sleeves (see

with the barrel, the core undergoes serious compaction.

Fig. 7). The sleeves not only plough a path for the barrel but

5.4 Flow-in Distortion—Flow-in distortion is caused by

they also serve as clamps to hold barrel sections together.

suction at the entrance of a sampler. Sediment is sucked into

4.6 Area Factor—The dimensions D and D set the area

w e

2 2

the barrel instead of being severed and encircles by the cutting

factor defined as C =(D ) 100/D . C should be less than

a w e a

edge. Flow-in rarely occurs with open-barrel samplers; how-

10 or possibly 15. Notice that C is proportional to the area of

a

ever, it can be a problem with piston samplers (14). Flow-in

sediment displaced by the bit divided by the area of the bit’s

usuallyoccursduringpull-outfollowingashallowpenetration.

entrance; therefore, C is an index of disturbance at the cutting

a

Conditionsleadingtoflow-inareshowninFig.5(c).Thebarrel

edge. A sampler with too large an area factor tends to

isattheendofitsdownwardtravelbutthepistonliesbelowthe

oversample during early stages of penetration when friction

piston stop. During pull-out, the upward force on the cable

along the inner wall of the barrel is low. Oversampling occurs

slides the piston up through the barrel before the cutting edge

because sediment laying below and outside the bit shift inward

clears the bed.As the piston slides, it pulls the core up through

as the bit cuts downward.

the barrel.As the core moves, sediment flows in to fill the void

4.7 Core-Barrel Length—Asampler’s core barrel should be

at the lower end of the barrel. Strata lines at the bottom of the

slightly longer than L, the longest core that can be collected

recovered core are distorted and resemble those in Fig. 8.A

without causing significant compaction. L and D (see Fig. 7)

s

pistonimmobilizerhelpspreventflow-indistortionbybreaking

setthecore-lengthfactordefinedas L = L/D . L shouldbeless

f s f

the connection between the cable and the piston during the

than 5.0 (or possibly 10) for a sampler used in cohesive

pull-out process.

sedi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.