ASTM D4591-97

(Test Method)Standard Test Method for Determining Temperatures and Heats of Transitions of Fluoropolymers by Differential Scanning Calorimetry

Standard Test Method for Determining Temperatures and Heats of Transitions of Fluoropolymers by Differential Scanning Calorimetry

SCOPE

1.1 This test method defines conditions for the use of differential scanning calorimetry (DSC) with fluoropolymers. It covers the use of DSC analyses with the fluoropolymers, PTFE, PVDF, PCTFE, and PVF and their copolymers PFA, FEP, ECTFE, EFEP, VDF/HFP, VDF/TFE/HFP, VDF/CTFE. The test method is applicable to the analysis of powders as well as samples taken from semi-finished or finished products. The nature of fluoropolymers is such that special procedures are needed for running DSC analysis and interpreting the results.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI 10 are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1--There is currently no ISO standard that duplicates this test method. Pending ISO 12086-1 and ISO 12086-2 cover similar testing and reference this test method for testing conditions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4591 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining Temperatures and Heats of Transitions of

Fluoropolymers by Differential Scanning Calorimetry

This standard is issued under the fixed designation D 4591; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * (SI) (the Modernized Metric System)

E 473 Terminology Relating to Thermal Analysis

1.1 This test method defines conditions for the use of

E 793 Test Method for Heats of Fusion and Crystallization

differential scanning calorimetry (DSC) with fluoropolymers.

by Differential Scanning Calorimetry

It covers the use of DSC analyses with the fluoropolymers,

2.2 ISO Standards:

PTFE, PVDF, PCTFE, and PVF and their copolymers PFA,

ISO 12086-1 Plastics—Fluoropolymer Dispersion and

FEP, ECTFE, EFEP, VDF/HFP, VDF/TFE/HFP, VDF/CTFE.

Molding and Extrusion Materials—Part 1: Designation

The test method is applicable to the analysis of powders as well

and Specification

as samples taken from semi-finished or finished products. The

ISO 12086-2 Plastics—Fluoropolymer Dispersion and

nature of fluoropolymers is such that special procedures are

Molding and Extrusion Materials—Part 2: Preparation of

needed for running DSC analysis and interpreting the results.

Test Specimen and Determination of Properties

1.2 The values stated in SI units as detailed in Practice

E 380 are to be regarded as the standard and the practices of

3. Terminology

Practice E 380 incorporated herein.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 differential scanning calorimetry (DSC)—a technique

safety concerns, if any, associated with its use. It is the

in which the difference in energy inputs into a substance and a

responsibility of the user of this standard to establish appro-

reference material is measured as a function of temperature,

priate safety and health practices and determine the applica-

while the substance and reference material are subjected to a

bility of regulatory limitations prior to use.

controlled increase or decrease in temperature.

NOTE 1—There is currently no ISO standard that duplicates this test

3.1.2 Refer to Terminology E 473 for general terminology

method. Pending ISO 12086-1 and ISO 12086-2 cover similar testing and

used in this test method.

reference this test method for testing conditions.

3.2 Abbreviated Terms:

3.2.1 Abbreviations used in this test method are in accord-

2. Referenced Documents

ance with Terminology D 1600.

2.1 ASTM Standards:

3.2.2 PTFE—polytetrafluoroethylene.

D 1600 Terminology for Abbreviated Terms Relating to

2 3.2.3 PFA—perfluoro(alkoxy alkane) resin.

Plastics

3.2.4 FEP—perfluoro(ethylene-propene) copolymer.

D 3417 Test Method for Heats of Fusion and Crystallization

3 3.2.5 ETFE—ethylene-tetrafluoroethylene copolymer.

of Polymers by Thermal Analysis

3.2.6 PVDF—poly(vinylidene fluoride).

D 3418 Test Method for Transition Temperatures of Poly-

3.2.7 PCTFE—polymonochlorotrifluoroethylene.

mers by Thermal Analysis

3.2.8 ECTFE—ethylene-monochlorotrifluoroethylene co-

D 4894 Specification for Polytetrafluoroethylene (PTFE)

polymer.

Granular Molding and Ram Extrusion Materials

3.2.9 EFEP—ethylene-perfluoroethylene-propene copoly-

D 4895 Specification for Polytetrafluoroethylene (PTFE)

mer.

Resins Produced From Dispersion

3.2.10 VDF/HFP—vinylidene fluoride-hexafluoropropene

E 380 Practice for Use of the International System of Units

copolymer.

3.2.11 VDF/TFE—vinylidene fluoride-tetrafluoroethylene

copolymer.

3.2.12 VDF/TFE/HFP—vinylidene fluoride-

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi-

tetrafluoroethylene-hexafluoropropene copolymer.

als.

Current edition approved Sept. 10, 1997. Published March 1998. Originally

published as D 4591 – 87. Last previous edition D 4591 – 93a.

2 5

Annual Book of ASTM Standards, Vol. 08.01. Annual Book of ASTM Standards, Vol 14.02.

3 6

Annual Book of ASTM Standards, Vol 08.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.03. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

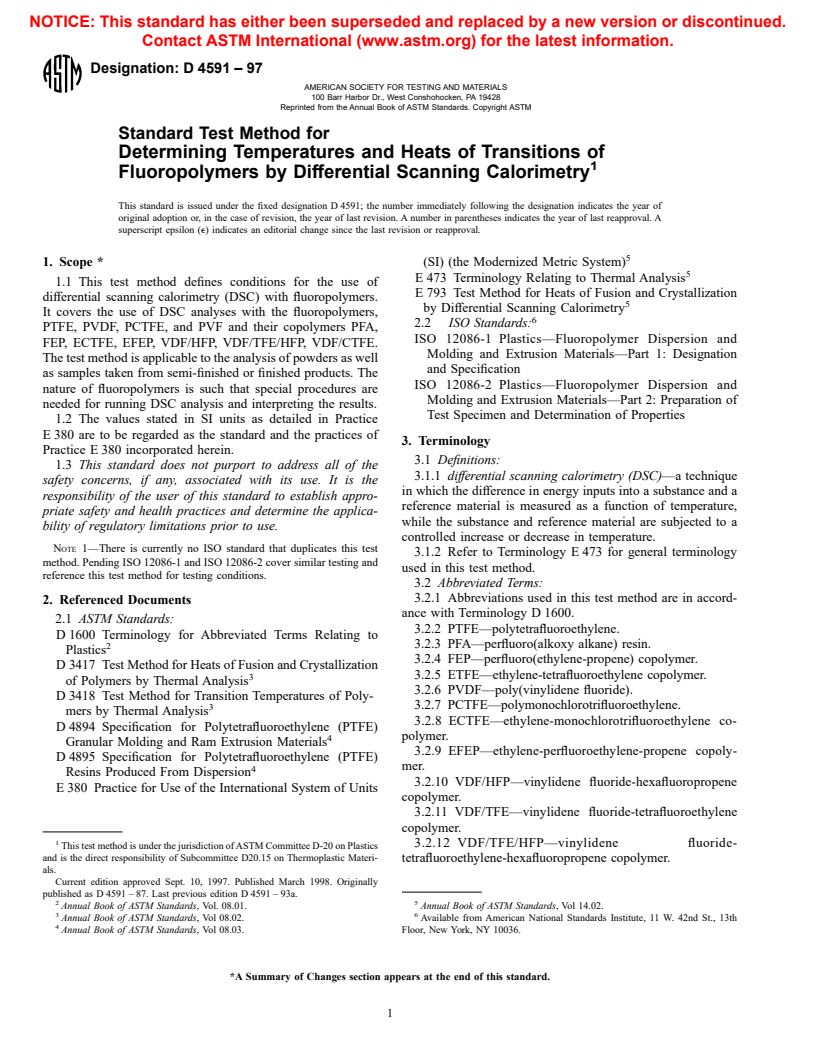

D 4591

NOTE 4—Noncomputerized area measurement shall be done with a

3.2.13 VDF/CTFE—vinylidene fluoride-

precision of 61 % or better.

chlorotrifluoroethylene copolymer.

3.2.14 PVF—poly(vinyl fluoride). 5.2 Specimen Holders and Covers, made from aluminum or

3.2.15 SSG—standard specific gravity. other materials of high thermal conductivity that do not react

with the specimen. It is preferable to use holders designed for

4. Significance and Use

the particular DSC instrument being used. For holders for

4.1 DSC analysis may be used with fluoropolymers to

which the cover has the shape of a small cup, the top should be

achieve at least four different objectives as follows:

inserted with the open side of the cup up.

4.1.1 To measure transition temperatures to aid in the

5.3 Nitrogen, or other inert gas supply for purging purposes.

identification of the various fluoropolymers, individually or in

5.4 Balance, with capacity greater than 15 mg, capable of

mixtures;

weighing to the nearest 0.01 mg.

4.1.2 To compare the relative levels of crystalline content of

6. Procedure

two or more specimens of a sample of a fluoropolymer relative

6.1 General Requirements—In general, the detailed meth-

to another sample by measuring the heat of fusion;

ods of Test Method D 3417 or Test Method D 3418 shall be

NOTE 2—Absolute values of crystalline content cannot be determined

used whenever possible. There are instances, however, when

until values for heats of fusion of the completely crystalline polymers are

following the procedures of Test Method D 3417 or Test

available.

Method D 3418 will not give the desired results, will not

4.1.3 To characterize PTFE (DSC thermal curves deter-

provide information needed for proper interpretation of the

mined on powders or products of PTFE that have never been

resultant thermal curve, or will require more time for the

melted convey appreciable information about details of mor-

analysis than need be spent for results having suitable preci-

phology and molecular structure);

sion. Examples of these instances include the following:

4.1.4 To supplement the test for standard specific gravity

6.1.1 The requirement that scans be started at room tem-

(SSG) described in Specifications D 4894 and D 4895 by using

perature, a provision usually not required with all fluoropoly-

the heat of crystallization of pure PTFE homopolymer, depend-

mers;

ing on the relative molecular weight of the specimen. The

6.1.2 The practice of running only a heating curve although

scope of Specification D 1457, however, includes PTFE resins

the cooling curve provides more information with many

modified with small amounts of comonomers, and many

fluoropolymers, and

commercial PTFE resins are modified in this manner. These

6.1.3 At times the thermal curve that results from the

modifications can have profound effects on crystallization

analysis provides information that cannot be interpreted in a

behavior. Published relationships between heat of crystalliza-

useful manner by the procedures of Test Method D 3417 or

tion and molecular weight refer to pure PTFE homopolymers

Test Method D 3418 but can be interpreted following the

and, therefore, cannot be applied to the modified resins.

procedures of Section 7.

6.2 Calibration—The procedures for calibration provided in

5. Apparatus

Test Method E 793 should be used. The comments in Test

5.1 Differential Scanning Calorimeter, capable of heating

Method D 3417 are helpful and should be reviewed. The

and cooling rates of at least 10.0 °C/min and of recording

calibration is carried out by using an appropriate amount of at

automatically the differential heat flow between a specimen

least two selected standards weighed to the nearest 0.01 mg.

and a reference material as a function of time, both to the

The standard materials should be selected so that their range

required sensitivity and precision. For comparison purposes,

includes the first-order transition temperature(s) of the fluo-

the same heating rate shall be used for all calibrations and test

ropolymer being tested. Appropriate materials are given in

runs. Thermal curves are recorded using a computerized data

Table 1 of Test Method E 793 and NIST Standard Reference

collection system or on a time-based recorder. The resulting

Materials. The instrument calibration can be validated using

curves are used for the measurement of peak areas either by

only one standard between calibrations.

computer integration or an alternative area measuring proce-

6.3 A standard specimen mass shall be in the range of 9 to

dure. The instrument should have a sensitiv

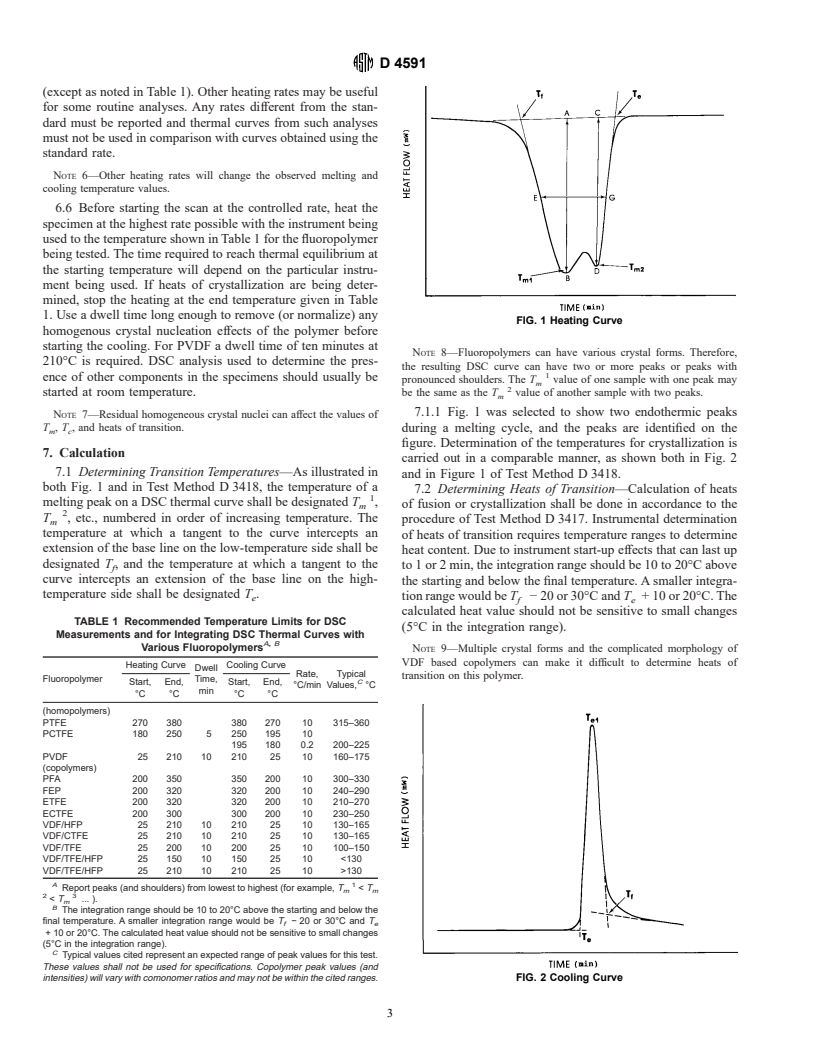

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.