ASTM D7194-19

(Specification)Standard Specification for Aerospace Parts Machined from Polychlorotrifluoroethylene (PCTFE)

Standard Specification for Aerospace Parts Machined from Polychlorotrifluoroethylene (PCTFE)

ABSTRACT

This specification establishes the requirements for parts intended for aerospace use and machined from polychlorotrifluoroethylene (PCTFE) homopolymers. This specification, however, does not cover parts machined from PCTFE copolymer, PCTFE film or tape, or modified PCTFE. Material covered by this specification is on four types, differentiated based on intended uses and exposures: Types I (high service pressure) and II (low service pressure) for use in air and oxygen media, Type II for use in inert and reactive media, and Type IV for use in other media. The parts shall be manufactured from virgin, unplasticized, pure PCTFE homopolymer, and the use of recycled polymer or regrind shall be prohibited. The base material shall be free of defects and contaminants. The finished parts shall be white or gray in color with a natural translucent appearance, and shall be free of voids, scratches, fissures, inclusions, or entrapped air bubbles. Tests for specific gravity, melting point, tensile strength and elongation, deformation under load, zero strength time, mechanical impact (in ambient liquid oxygen and pressurized liquid and gaseous oxygen environments), and dimensional stability shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification is intended to be a means of calling out finished machined parts ready for aerospace use. Such parts may also find use in selected commercial applications where there are clear benefits derived from the use of parts with high molecular weight, good molecular weight retention during processing, dimensional stability, controlled crystallinity, and tightly controlled engineering tolerances.

1.2 This specification establishes requirements for parts machined from virgin, unplasticized, 100 % polychlorotrifluoroethylene (PCTFE) homopolymers.

1.3 This specification does not cover parts machined from PCTFE copolymers, PCTFE film or tape less than 0.25-mm (0.010-in.) thick, or modified PCTFE (containing pigments or plasticizers).

1.4 This specification does not allow parts containing recycled material.

1.5 The specification does not cover PCTFE parts intended for general use applications, in which control of dimensional stability, molecular weight, and crystallinity are not as important. For machined PCTFE parts intended for general use, use Specification D7211.

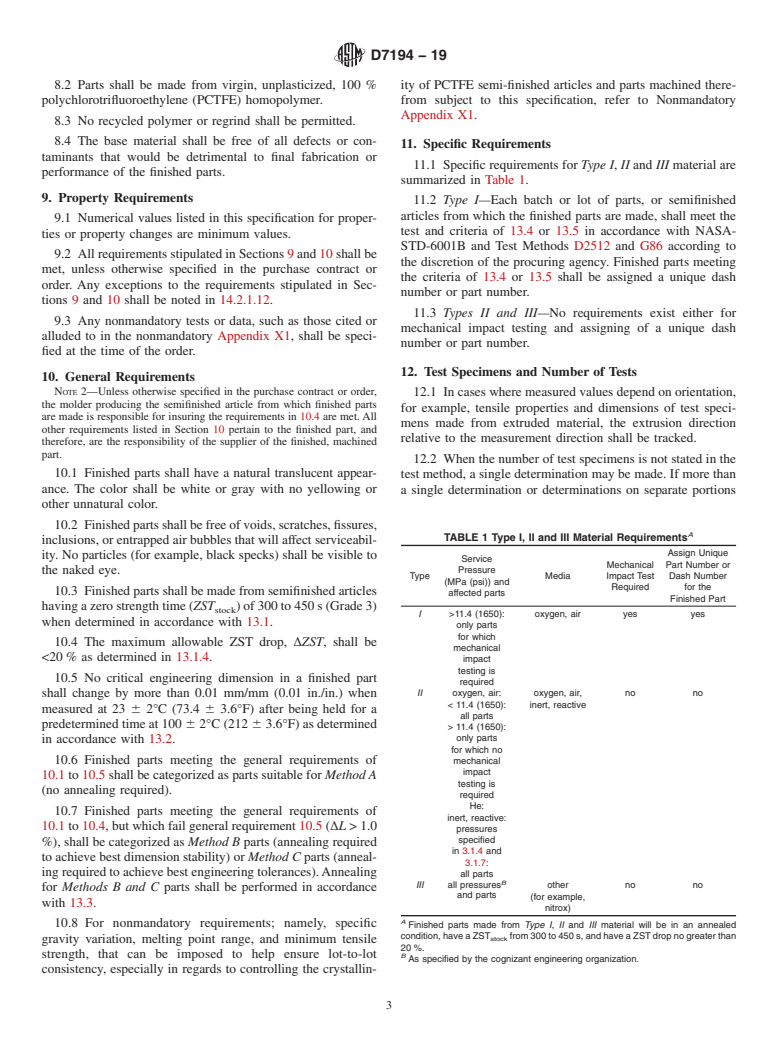

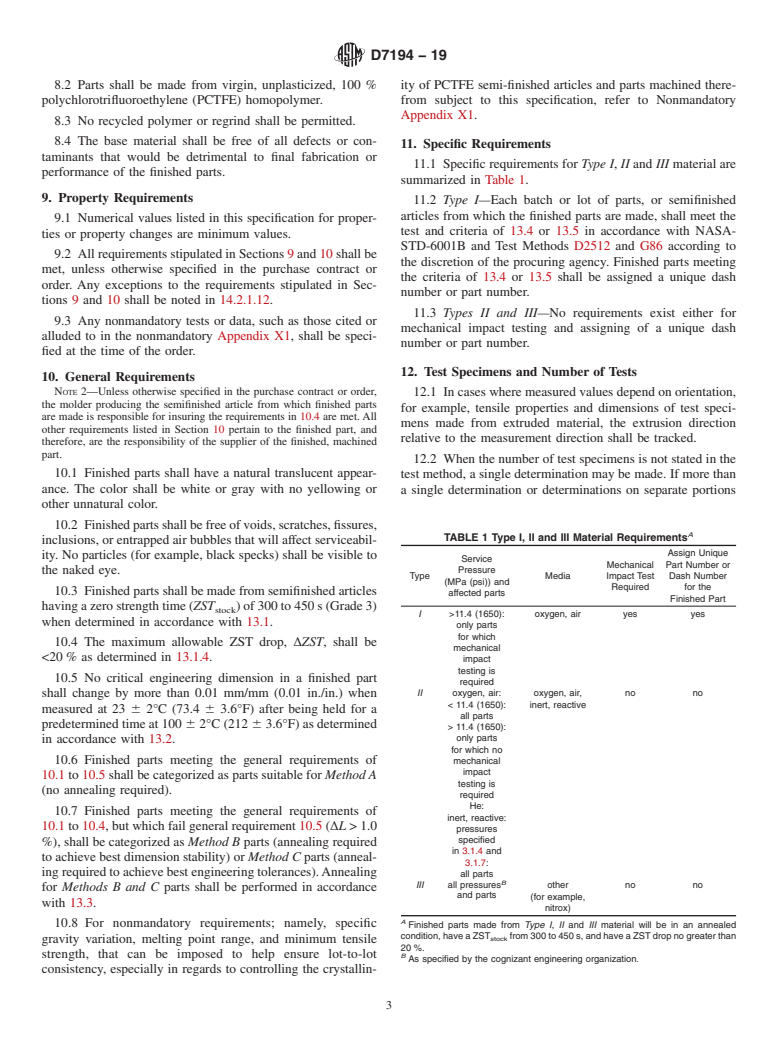

1.6 This specification classifies parts into three classes based upon intended uses and exposures: oxygen-containing media, reactive media, and inert media.

1.7 Application—PCTFE components covered by this specification are virgin, 100 % PCTFE resin, free of plasticizers and other additives. The components are combustion resistant in oxygen, dimensionally stable, and meet other specific physical characteristics appropriate for their end use. They are used in valves, regulators, and other devices in oxygen, air, helium, nitrogen, hydrogen, ammonia, and other aerospace media systems. The components typically are used as valve seats, o-rings, seals, and gaskets. They are removed and replaced during normal maintenance procedures. The components provide reliable sealing surfaces resulting in proper closure of valves and related devices and no leakage from the system into the environment. They will experience static mechanical loading, cyclic mechanical loading, temperatures ranging from cryogenic to 71°C (160°F), and pressures up to 68.9 MPa (10,000, psig) for oxygen and air media, and 103.4 MPa (15,000 psig) for inert media.

1.8 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.9 The following precautionary caveat pertains only to the test methods portion, Section 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental pra...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7194 −19

Standard Specification for

Aerospace Parts Machined from Polychlorotrifluoroethylene

1

(PCTFE)

This standard is issued under the fixed designation D7194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope during normal maintenance procedures. The components pro-

vide reliable sealing surfaces resulting in proper closure of

1.1 This specification is intended to be a means of calling

valves and related devices and no leakage from the system into

outfinishedmachinedpartsreadyforaerospaceuse.Suchparts

the environment. They will experience static mechanical

may also find use in selected commercial applications where

loading, cyclic mechanical loading, temperatures ranging from

there are clear benefits derived from the use of parts with high

cryogenic to 71°C (160°F), and pressures up to 68.9 MPa

molecular weight, good molecular weight retention during

(10,000, psig) for oxygen and air media, and 103.4 MPa

processing, dimensional stability, controlled crystallinity, and

(15,000 psig) for inert media.

tightly controlled engineering tolerances.

1.8 The values stated in SI units are to be regarded as

1.2 This specification establishes requirements for parts

standard. The values in parentheses are for information only.

machined from virgin, unplasticized, 100 % polychlorotrifluo-

1.9 The following precautionary caveat pertains only to the

roethylene (PCTFE) homopolymers.

test methods portion, Section 13, of this specification: This

1.3 This specification does not cover parts machined from

standard does not purport to address all of the safety concerns,

PCTFE copolymers, PCTFE film or tape less than 0.25-mm

if any, associated with its use. It is the responsibility of the user

(0.010-in.) thick, or modified PCTFE (containing pigments or

of this standard to establish appropriate safety, health, and

plasticizers).

environmental practices and determine the applicability of

1.4 This specification does not allow parts containing re-

regulatory limitations prior to use.

cycled material.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 The specification does not cover PCTFE parts intended

1.10 This international standard was developed in accor-

for general use applications, in which control of dimensional

dance with internationally recognized principles on standard-

stability, molecular weight, and crystallinity are not as impor-

ization established in the Decision on Principles for the

tant. For machined PCTFE parts intended for general use, use

Development of International Standards, Guides and Recom-

Specification D7211.

mendations issued by the World Trade Organization Technical

1.6 This specification classifies parts into three classes

Barriers to Trade (TBT) Committee.

based upon intended uses and exposures: oxygen-containing

2. Referenced Documents

media, reactive media, and inert media.

2

2.1 ASTM Standards:

1.7 Application—PCTFEcomponentscoveredbythisspeci-

D618 Practice for Conditioning Plastics for Testing

fication are virgin, 100 % PCTFE resin, free of plasticizers and

D638 Test Method for Tensile Properties of Plastics

other additives. The components are combustion resistant in

D792 Test Methods for Density and Specific Gravity (Rela-

oxygen, dimensionally stable, and meet other specific physical

tive Density) of Plastics by Displacement

characteristics appropriate for their end use. They are used in

D883 Terminology Relating to Plastics

valves, regulators, and other devices in oxygen, air, helium,

D1204 Test Method for Linear Dimensional Changes of

nitrogen, hydrogen, ammonia, and other aerospace media

Nonrigid Thermoplastic Sheeting or Film at Elevated

systems. The components typically are used as valve seats,

Temperature

o-rings, seals, and gaskets. They are removed and replaced

D1430 ClassificationSystemforPolychlorotrifluoroethylene

(PCTFE) Plastics

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2019. Published August 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2012 as D7194 - 12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7194-19. the ASTM website.

Copyright

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7194 − 12 D7194 − 19

Standard Specification for

Aerospace Parts Machined from Polychlorotrifluoroethylene

1

(PCTFE)

This standard is issued under the fixed designation D7194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification is intended to be a means of calling out finished machined parts ready for aerospace use. Such parts may

also find use in selected commercial applications where there are clear benefits derived from the use of parts with known or

controlled crystallinity, high molecular weight, good molecular weight retention during processing, dimensional stability in the

finished part, stability, controlled crystallinity, and tightly controlled engineering tolerances.

1.2 This specification establishes requirements for parts machined from virgin, unplasticized, 100 % polychlorotrifluoroethylene

(PCTFE) homopolymers.

1.3 This specification does not cover parts machined from PCTFE copolymers, PCTFE film or tape less than 0.25-mm

(0.010-in.) thick, or modified PCTFE (containing pigments or plasticizers).

1.4 This specification does not allow parts containing recycled material.

1.5 The specification does not cover PCTFE parts intended for general use applications, in which control of dimensional

stability, molecular weight, and crystallinity are not as important. For machined PCTFE parts intended for general use, use

Specification D7211.

1.6 This specification classifies parts into three classes based upon intended uses and exposures: oxygen-containing media,

reactive media, and inert media.

1.7 Application—PCTFE components covered by this specification are virgin, 100 % PCTFE resin, free of plasticizers and other

additives. The components are combustion resistant in oxygen, dimensionally stable, and meet other specific physical

characteristics appropriate for their end use. They are used in valves, regulators, and other devices in oxygen, air, helium, nitrogen,

hydrogen, ammonia, and other aerospace media systems. The components typically are used as valve seats, o-rings, seals, and

gaskets. They are removed and replaced during normal maintenance procedures. The components provide reliable sealing surfaces

resulting in proper closure of valves and related devices and no leakage from the system into the environment. They will experience

static mechanical loading, cyclic mechanical loading, temperatures ranging from cryogenic to 71 ºC (160 ºF), 71°C (160°F), and

pressures up to 68.9 MPa (10,000, psig) for oxygen and air media, and 103.4 MPa (15,000 psig) for inert media.

1.8 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.9 The following precautionary caveat pertains only to the test methods portion, Section 1213, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and to determine the applicability

of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

NOTE 1—There is no known ISO equivalent to this standard.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Oct. 1, 2012Aug. 1, 2019. Published November 2012August 2019. Originally approved in 2005. Last previous edition approved in 20052012

as D5111 - 05.D5111 - 12. DOI: 10.1520/D7194-12.10.1520/D7194-19.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7194 − 19

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Grav

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7194 − 19

Standard Specification for

Aerospace Parts Machined from Polychlorotrifluoroethylene

1

(PCTFE)

This standard is issued under the fixed designation D7194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope during normal maintenance procedures. The components pro-

vide reliable sealing surfaces resulting in proper closure of

1.1 This specification is intended to be a means of calling

valves and related devices and no leakage from the system into

out finished machined parts ready for aerospace use. Such parts

the environment. They will experience static mechanical

may also find use in selected commercial applications where

loading, cyclic mechanical loading, temperatures ranging from

there are clear benefits derived from the use of parts with high

cryogenic to 71°C (160°F), and pressures up to 68.9 MPa

molecular weight, good molecular weight retention during

(10,000, psig) for oxygen and air media, and 103.4 MPa

processing, dimensional stability, controlled crystallinity, and

(15,000 psig) for inert media.

tightly controlled engineering tolerances.

1.8 The values stated in SI units are to be regarded as

1.2 This specification establishes requirements for parts

standard. The values in parentheses are for information only.

machined from virgin, unplasticized, 100 % polychlorotrifluo-

1.9 The following precautionary caveat pertains only to the

roethylene (PCTFE) homopolymers.

test methods portion, Section 13, of this specification: This

1.3 This specification does not cover parts machined from

standard does not purport to address all of the safety concerns,

PCTFE copolymers, PCTFE film or tape less than 0.25-mm

if any, associated with its use. It is the responsibility of the user

(0.010-in.) thick, or modified PCTFE (containing pigments or

of this standard to establish appropriate safety, health, and

plasticizers).

environmental practices and determine the applicability of

1.4 This specification does not allow parts containing re-

regulatory limitations prior to use.

cycled material.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 The specification does not cover PCTFE parts intended

1.10 This international standard was developed in accor-

for general use applications, in which control of dimensional

dance with internationally recognized principles on standard-

stability, molecular weight, and crystallinity are not as impor-

ization established in the Decision on Principles for the

tant. For machined PCTFE parts intended for general use, use

Development of International Standards, Guides and Recom-

Specification D7211.

mendations issued by the World Trade Organization Technical

1.6 This specification classifies parts into three classes

Barriers to Trade (TBT) Committee.

based upon intended uses and exposures: oxygen-containing

2. Referenced Documents

media, reactive media, and inert media.

2

2.1 ASTM Standards:

1.7 Application—PCTFE components covered by this speci-

D618 Practice for Conditioning Plastics for Testing

fication are virgin, 100 % PCTFE resin, free of plasticizers and

D638 Test Method for Tensile Properties of Plastics

other additives. The components are combustion resistant in

D792 Test Methods for Density and Specific Gravity (Rela-

oxygen, dimensionally stable, and meet other specific physical

tive Density) of Plastics by Displacement

characteristics appropriate for their end use. They are used in

D883 Terminology Relating to Plastics

valves, regulators, and other devices in oxygen, air, helium,

D1204 Test Method for Linear Dimensional Changes of

nitrogen, hydrogen, ammonia, and other aerospace media

Nonrigid Thermoplastic Sheeting or Film at Elevated

systems. The components typically are used as valve seats,

Temperature

o-rings, seals, and gaskets. They are removed and replaced

D1430 Classification System for Polychlorotrifluoroethylene

(PCTFE) Plastics

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2019. Published August 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2012 as D7194 - 12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7194-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.