ASTM D3753-05e1

(Specification)Standard Specification for Glass-Fiber-Reinforced Polyester Manholes and Wetwells

Standard Specification for Glass-Fiber-Reinforced Polyester Manholes and Wetwells

ABSTRACT

This specification covers glass fiber-reinforced polyester manholes and wetwells for use primarily in sanitary and storm sewer applications. Manhole and wetwell cylinders, manway reducers, and connectors shall be produced from glass fiber-reinforced polyester resin with construction determined by the particular process of manufacture and configuration. The stiffness, soundness, chemical resistance, compressive strength, flexural strength, modulus, and hardness shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers glass fiber-reinforced polyester manholes and wetwells for use primarily in sanitary and storm sewer applications.

1.2 The values given in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

´1

Designation: D3753 – 05

Standard Specification for

1

Glass-Fiber-Reinforced Polyester Manholes and Wetwells

This standard is issued under the fixed designation D3753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section 6.9 was editorially corrected in June 2007.

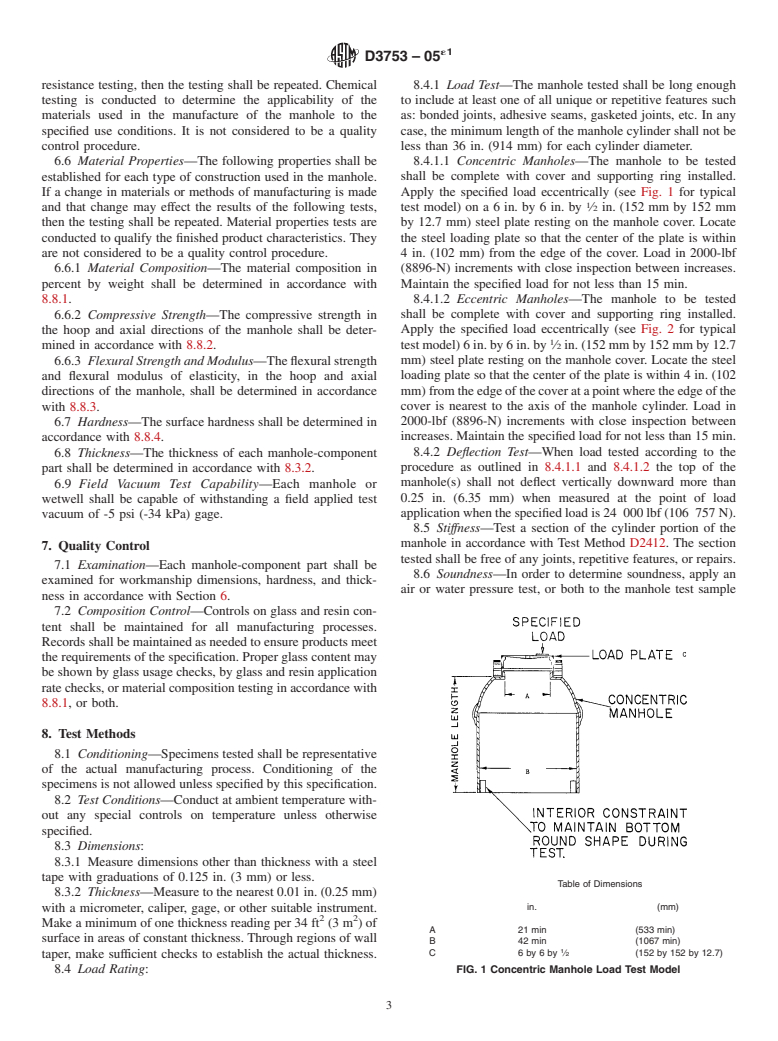

1. Scope* D2412 Test Method for Determination of External Loading

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.1 Thisspecificationcoversglassfiber-reinforcedpolyester

D2583 Test Method for Indentation Hardness of Rigid

manholes and wetwells for use primarily in sanitary and storm

Plastics by Means of a Barcol Impressor

sewer applications.

D2584 Test Method for Ignition Loss of Cured Reinforced

1.2 The values given in inch-pound units are to be regarded

Resins

as the standard. The values in parentheses are provided for

D3892 Practice for Packaging/Packing of Plastics

information purposes only.

1.3 The following precautionary caveat pertains only to the

3. Terminology

test methods portion, Section 8, of this specification: This

3.1 General—Definitions are in accordance with Terminol-

standard does not purport to address all of the safety concerns,

ogy D883 and the abbreviations are in accordance with

if any, associated with its use. It is the responsibility of the user

Terminology D1600 unless otherwise indicated.

of this standard to establish appropriate safety and health

3.2 manway reducer, n—the top portion of the manhole

practices and determine the applicability of regulatory limita-

through which entrance to the manhole is made and where the

tions prior to use.

diameterincreasesfromtheentrancewaytothelargermanhole

NOTE 1—There is no similar or equivalent ISO standard.

cylinder.

3.3 manhole, n—cylinder with the manway reducer de-

2. Referenced Documents

signed to handle a manhole cover and ring.

2

2.1 ASTM Standards:

3.4 manhole cover and ring, n—those accessories used with

C581 Practice for Determining Chemical Resistance of

the manhole to close the manway entrance (includes adjust-

Thermosetting Resins Used in Glass-Fiber-Reinforced

ment rings).

Structures Intended for Liquid Service

3.5 manhole/wetwell, n—the portion below the manway

D695 Test Method for Compressive Properties of Rigid

reducer that extends in a large diameter to the manhole base.

Plastics

May include eccentric or concentric reducers to allow changes

D785 Test Method for Rockwell Hardness of Plastics and

in cylinder diameter.

Electrical Insulating Materials

3.6 pipe connectors, n—connectors that provide access for

D790 Test Methods for Flexural Properties of Unreinforced

the sewer pipe into the manhole.

and Reinforced Plastics and Electrical Insulating Materials

3.7 resin rich, adj—describes that portion of the glass

3

fiber-reinforced polyester material where the resin-to-glass

D883 Terminology Relating to Plastics

ratio is significantly greater than in other portions of the

D1600 Terminology for Abbreviated Terms Relating to

manhole.

Plastics

3.8 wetwell, n—manholecylinderwithanopen,domed,flat,

or other top not designed to support a manhole cover and ring.

1

This specification is under the jurisdiction of ASTM Committee D20 on

4. Materials

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

4.1 Resin—The resins used shall be a commercial grade

Current edition approved July 1, 2005. Published July 2005. Originally approved

unsaturated polyester resin.

in 1979. Last previous edition approved in 1999 as D3753 – 99. DOI: 10.1520/

4.2 Reinforcing Materials—The reinforcing materials shall

D3753-05E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

be commercial grade of E-type glass fibers in the form of mat,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

continuous roving, chopped roving, or roving fabric, having a

Standards volume information, refer to the standard’s Document Summary page on

coupling agent that will provide a suitable bond between the

the ASTM website.

3

glass reinforcement and the resin.

Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

D3753 – 05

4.3 Surfacing Material—If reinforcing material is used on pressure and that are entirely below the resin surface shall be

2 2

the surface exposed to the contained substance, it shall be a permitted up to 4/ft (40/m ) if they are l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.