ASTM D5444-98

(Test Method)Standard Test Method for Mechanical Size Analysis of Extracted Aggregate

Standard Test Method for Mechanical Size Analysis of Extracted Aggregate

SCOPE

1.1 This test method covers a procedure for determination of the particle size distribution of fine and coarse aggregates extracted from bituminous mixtures using sieves with square openings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5444–98

Standard Test Method for

Mechanical Size Analysis of Extracted Aggregate

This standard is issued under the fixed designation D 5444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

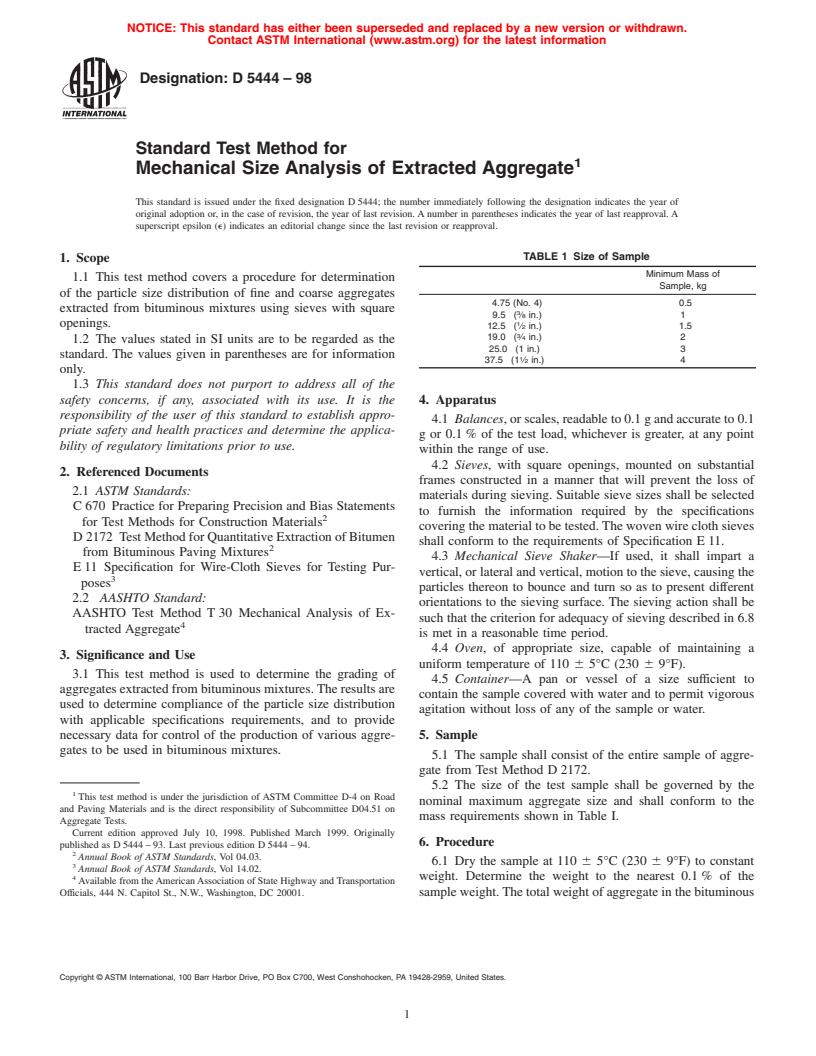

TABLE 1 Size of Sample

1. Scope

Minimum Mass of

1.1 This test method covers a procedure for determination

Sample, kg

of the particle size distribution of fine and coarse aggregates

4.75 (No. 4) 0.5

extracted from bituminous mixtures using sieves with square

9.5 ( ⁄8 in.) 1

openings.

12.5 ( ⁄2 in.) 1.5

19.0 ( ⁄4 in.) 2

1.2 The values stated in SI units are to be regarded as the

25.0 (1 in.) 3

standard. The values given in parentheses are for information

37.5 (1 ⁄2 in.) 4

only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4. Apparatus

responsibility of the user of this standard to establish appro-

4.1 Balances, or scales, readable to 0.1 g and accurate to 0.1

priate safety and health practices and determine the applica-

g or 0.1 % of the test load, whichever is greater, at any point

bility of regulatory limitations prior to use.

within the range of use.

4.2 Sieves, with square openings, mounted on substantial

2. Referenced Documents

frames constructed in a manner that will prevent the loss of

2.1 ASTM Standards:

materials during sieving. Suitable sieve sizes shall be selected

C 670 Practice for Preparing Precision and Bias Statements

to furnish the information required by the specifications

for Test Methods for Construction Materials

covering the material to be tested.The woven wire cloth sieves

D 2172 Test Method for Quantitative Extraction of Bitumen

shall conform to the requirements of Specification E 11.

from Bituminous Paving Mixtures

4.3 Mechanical Sieve Shaker—If used, it shall impart a

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

vertical, or lateral and vertical, motion to the sieve, causing the

poses

particles thereon to bounce and turn so as to present different

2.2 AASHTO Standard:

orientations to the sieving surface. The sieving action shall be

AASHTO Test Method T 30 Mechanical Analysis of Ex-

such that the criterion for adequacy of sieving described in 6.8

tracted Aggregate

is met in a reasonable time period.

4.4 Oven, of appropriate size, capable of maintaining a

3. Significance and Use

uniform temperature of 110 6 5°C (230 6 9°F).

3.1 This test method is used to determine the grading of

4.5 Container—A pan or vessel of a size sufficient to

aggregates extracted from bituminous mixtures.The results are

contain the sample covered with water and to permit vigorous

used to determine compliance of the particle size distribution

agitation without loss of any of the sample or water.

with applicable specifications requirements, and to provide

necessary data for control of the production of various aggre- 5. Sample

gates to be used in bituminous mixtures.

5.1 The sample shall consist of the entire sample of aggre-

gate from Test Method D 2172.

5.2 The size of the test sample shall be governed by the

This test method is under the jurisdiction of ASTM Committee D-4 on Road

nominal maximum aggregate size and shall conform to the

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

mass requirements shown in Table I.

Aggregate Tests.

Current edition approved July 10, 1998. Published March 1999. Originally

6. Procedure

published as D 5444 – 93. Last previous edition D 5444 – 94.

Annual Book of ASTM Standards, Vol 04.03.

6.1 Dry the sample at 110 6 5°C (230 6 9°F) to constant

Annual Book of ASTM Standards, Vol 14.02.

weight. Determine the weight to the nearest 0.1 % of the

Available from theAmericanAssociation of State Highway and Transportation

Officials, 444 N. Capitol St., N.W., Washington, DC 20001. sample weight.The total weight of aggregate in the bituminous

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5444–98

mixture being tested is the sum of the weights of the dried any sieve at the completion of the sieving operation shall not

2 2

aggregates and the mineral matter contained in the extracted exceed 6 kg/m (4 g/in. ) of sieving surface. For sieves with

bitumen. The latter is to be taken as the sum of the weight of openings 4.75 mm (No. 4) and larger, the weight in kg/m of

ash in the extract and the increase in weight of the filter sieving surface shall not exceed the product of 2.5 3 (sieve

element as determined in Test Method D 2172. opening in mm). In no case shall the weight be so great as to

cause permanent deformation of the sieve cloth.

6.2 After drying and weighing the test sample, place it in a

6.8 Continue sieving for a sufficient period and in such

container and cover it with water. Add a sufficient amount of

manner that, after completion, not more than 0.5 % by weight

wetting agent to ensure a thorough separation of the material

of the total sample passes any sieve during 1 min of continuous

finer than the 75-µm sieve from the coarser particles (see

hand sieving performed as follows: hold the individual sieve,

Note). The contents of the container shall be agitated vigor-

provided with a snug-fitting pan and cover, in a slightly

ously and the washwater poured immediately over a nest of

inclined position in one hand. Strike the side of the sieve

twosievesconsistingofa2.00or1.18-mmsievesuperimposed

sharply and with an upward motion against the inclined

on a 75-µm sieve. The use of a large spoon to stir and agitate

position in one hand. Strike the side of the sieve sharply and

the aggregate in the washwater has been found satisfactory.

with an upward motion against the heel of the other hand at a

NOTE 1—Wetting agents may include any dispersing agent such as a

rate of approximately 150 times per minute, turning the sieve

liquid detergent, or a soap, that will promote the separation of fine

approximately

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.