ASTM A568/A568M-00b

(Specification)Standard Specification for Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements for

Standard Specification for Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements for

SCOPE

1.1 This specification covers the general requirements for steel sheet in coils and cut lengths. It applies to the following specifications that describe carbon steel and high-strength, low-alloy steel (HSLA) furnished as hot-rolled sheet and cold-rolled sheet: Specifications A 414/A 414M, A 424, A 606, A 659/A 659M, A 794, A 1008/A 1008M, and A 1011/A 1011M.

1.2 This specification is not applicable to hot-rolled heavy-thickness carbon sheet coils (ASTM Specification A 635/A 635M).

1.3 In case of any conflict in requirements, the requirements of the individual material specification shall prevail over those of this general specification.

1.4 For the purposes of determining conformance with this and the appropriate product specification referenced in , values shall be rounded to the nearest unit in the right hand place of figures used in expressing the limiting values in accordance with the rounding method of Practice E 29.

1.5 lists permissible variations in dimensions and mass (see Note 1) in SI [metric] units. The values listed are not exact conversions of the values listed in the inch-pound tables, but instead are rounded or rationalized values. Conformance to is mandatory when the "M" specification is used.

Note 1—The term weight is used when inch-pound units are the standard. However, under SI the preferred term is mass.

1.6 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.7 This specification and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: A 568/A 568M – 00b

Standard Specification for

Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-

Rolled and Cold-Rolled, General Requirements for

ThisstandardisissuedunderthefixeddesignationA568/A568M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope However, unless the order specifies the applicable “M” speci-

fication designation (SI units), the material shall be furnished

1.1 This specification covers the general requirements for

to inch-pound units.

steel sheet in coils and cut lengths. It applies to the following

specifications which describe carbon steel and high-strength,

2. Referenced Documents

low-alloy steel (HSLA) furnished as hot-rolled sheet and

2.1 ASTM Standards:

cold-rolled sheet: Specifications A 414/A 414MA 414/A

A366/A 366M Specification for Commercial Steel (CS)

414M, A 424A 424, A 606A 606, A 659/A 659MA 659/A

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

659M, A794A794, A1008/A1008MA1008/A 1008M, and

A370 TestMethodsandDefinitionsforMechanicalTesting

A1011/A1011MA1011/A 1011M.

of Steel Products

1.2 This specification is not applicable to hot-rolled heavy-

A414/A 414M Specification for Steel, Sheet, Carbon, for

thickness carbon sheet coils (ASTM Specification

Pressure Vessels

A635A635/A 635M/A635M).

A424 Specification for Steel, Sheet, for Porcelain Enamel-

1.3 Incaseofanyconflictinrequirements,therequirements

ing

of the individual material specification shall prevail over those

A569/A569M Specification for Steel, Carbon (0.15 Maxi-

of this general specification.

mum, Percent), Hot-Rolled Sheet and Strip Commercial

1.4 For the purposes of determining conformance with this

A570/A570M Specification for Structural Steel, Sheet and

and the appropriate product specification referenced in 1.1,

Strip, Carbon, Hot-Rolled

values shall be rounded to the nearest unit in the right hand

A 606 Specification for Steel, Sheet and Strip, High-

place of figures used in expressing the limiting values in

Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

accordance with the rounding method of Practice E29E29.

Improved Atmospheric Corrosion Resistance

1.5 AnnexA1listspermissiblevariationsindimensionsand

A 607 Specification for Steel, Sheet and Strip, High-

mass(seeNote1)inSI[metric]units.Thevalueslistedarenot

Strength, Low-Alloy, Columbium or Vanadium, or Both,

exact conversions of the values listed in the inch-pound tables,

Hot-Rolled and Cold-Rolled

butinsteadareroundedorrationalizedvalues.Conformanceto

A611 Specification for Structural Steel (SS), Sheet, Car-

Annex A1 is mandatory when the “M” specification is used.

bon, Cold-Rolled

NOTE 1—The term weight is used when inch-pound units are the

A620/A620M Specification for Drawing Steel (DS) Sheet,

standard. However, under SI the preferred term is mass.

Carbon, Cold-Rolled

1.6 The values stated in either inch-pound units or SI units

A622/A622M Specification for Drawing Steel (DS), Sheet

are to be regarded as standard. Within the text, the SI units are

and Strip, Carbon, Hot-Rolled

shown in brackets. The values stated in each system are not

A635/A 635M Specification for Steel, Sheet and Strip,

exact equivalents; therefore, each system must be used inde-

Heavy-Thickness Coils, Carbon, Hot-Rolled

pendentlyoftheother.Combiningvaluesfromthetwosystems

A659/A 659M Specification for Commercial Steel (CS),

may result in nonconformance with the specification.

Sheet and Strip, Carbon (0.16 Maximum to 0.25 Maxi-

1.7 This specification and the applicable material specifica-

mum Percent), Hot-Rolled

tions are expressed in both inch-pound units and SI units.

A 700 Practices for Packaging, Marking, and Loading

Methods for Steel Products for Domestic Shipment

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip. Discontinued; see 2000 Annual Book of ASTM Standards, Vol 01.03.

Current edition approved Sept. 10, 2000. Published November 2000. Originally Annual Book of ASTM Standards, Vol 01.03.

published as A568–66T. Last previous edition A568–00a. Annual Book of ASTM Standards, Vol 01.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

A 568/A 568M – 00b

A 715 Specification for Steel Sheet and Strip, High- 2.3 Federal Standards:

Strength, Low-Alloy, Hot-Rolled, and Steel Sheet, Cold- Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

Rolled, High-Strength, Low-Alloy, with Improved Form Fed.Std.No.183 ContinuousIdentificationMarkingofIron

ability and Steel Products

A 751 Test Methods, Practices, and Terminology for

3. Terminology

Chemical Analysis of Steel Products

3.1 Definitions of Terms Specific to This Standard:

A794 Specification for Commercial Steel (CS), Sheet,

3.1.1 Steel Types:

Carbon (0.16% Maximum to 0.25% Maximum), Cold-

3.1.2 carbon steel—the designation for steel when no mini-

Rolled

mumcontentisspecifiedorrequiredforaluminum,chromium,

A1008/A 1008M Specification for Steel, Sheet, Cold-

cobalt, columbium, molybdenum, nickel, titanium, tungsten,

Rolled, Carbon, Structural, High-Strength Low-Alloy and

vanadium,zirconium,oranyelementaddedtoobtainadesired

High-Strength Low-Alloy with Improved Formability

alloying effect; when the specified minimum for copper does

A1011/A 1011M Specification for Steel, Sheet and Strip,

notexceed0.40%;orwhenthemaximumcontentspecifiedfor

Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy

any of the following elements does not exceed the percentages

andHigh-StrengthLow-AlloywithImprovedFormability

noted: manganese 1.65, silicon 0.60, or copper 0.60.

E11 Specification for Wire-Cloth Sieves for Testing Pur-

3.1.2.1 Discussion—In all carbon steels small quantities of

poses

certain residual elements unavoidably retained from raw ma-

E29 Practice for Using Significant Digits in Test Data to

terialsaresometimesfoundwhicharenotspecifiedorrequired,

Determine Conformance with Specifications

such as copper, nickel, molybdenum, chromium, etc. These

E59 PracticeforSamplingSteelandIronforDetermination

elements are considered as incidental and are not normally

of Chemical Composition

determined or reported.

E290 TestMethodforSemi-GuidedBendTestforDuctility

3.1.3 high-strength, low-alloy steel—a specific group of

of Metallic Materials

steels in which higher strength, and in some cases additional

2.2 Military Standards:

resistance to atmospheric corrosion or improved formability,

MIL-STD-129 Marking for Shipment and Storage

are obtained by moderate amounts of one or more alloying

MIL-STD-163 Steel Mill Products Preparation for Ship-

elements.

ment and Storage

3.1.4 Product Types:

3.1.5 hot-rolled sheet—manufacturedbyhotrollingslabsin

Annual Book of ASTM Standards, Vol 14.02.

acontinuousmilltotherequiredthicknessandcanbesupplied

Discontinued; see 1996 Annual Book of ASTM Standards, Vol 03.05.

in coils or cut lengths as specified.

Annual Book of ASTM Standards, Vol 03.01.

(a) Hot-rolled carbon and high-strength low-alloy (HSLA)

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. steel sheet is classified by size as follows:

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

A 568/A 568M – 00b

and in thicknesses 0.019 in. [0.5 mm] through 0.82 in. [2.0 mm] carbon 0.25 %

Coils and Cut Lengths

maximum by cast analysis.

Width, in. Thickness, in.

B

When no special edge or finish (other than matte, commercial bright, or luster

12 to 48, incl 0.044 to 0.230, excl

finish) or single strand rolling of widths, or both under 24 in. [600 mm] is not

Over 48 0.044 to 0.180, excl

specified or required.

Coils and Cut Lengths

3.1.7 retests, n—an additional test, or tests, made from the

Width, mm Thickness, mm

Over 300 to 1200, incl 1.2 to 6.0, excl

original material when the original test did not meet the

Over 1200 1.2 to 4.5, excl

appropriate acceptance criteria required by a product specifi-

3.1.6 cold-rolled sheet—manufactured from hot-rolled des- cationandthefailurewasmechanicalinnaturesasdescribedin

caled coils by cold reducing to the desired thickness, generally Section 11.

followedbyannealingtorecrystallizethegrainstructure.Ifthe

3.1.8 resample, n—an additional test, or tests, made when

sheet is not annealed after cold reduction it is known as full the test on the original sample did not meet the appropriate

hard with a hardness of 84 HRB minimum and can be used for

acceptance criteria required by the product specification but

certain applications where ductility and flatness are not re- possible requiring that the material in question have an

quired.

appropriateamountdiscardedpriortosecuringthenewsample

(a)Cold-rolledcarbonsheetisclassifiedbysizeasfollows:

or samples.

Width, in. Thickness, in.

4. Materials and Manufacture

A

Through 12 Through 0.082

B

Over 12 through 23 15/16 Through 0.142 4.1 Unless otherwise specified, hot-rolled material shall be

Over 23 15/16 Through 0.142

furnished hot-rolled, not annealed, not pickled.

Width, mm Thickness, mm

4.2 Coil breaks, stretcher strains, and fluting can occur

A

To 300, incl Through 2.0

B

during the user’s processing of hot-rolled or hot-rolled pickled

Over 300 Through 4.0

A

sheet. When any of these features are detrimental to the

Cold-rolledsheetcoilsandcutlengths,slitfromwidercoilswithcutedge(only)

and in thicknesses through 0.082 in. [2.0 mm] carbon 0.25 % maximum by cast

application, the manufacturer shall be notified at time of

analysis.

ordering in order to properly process the sheet.

B

When no special edge or finish (other than matte, commercial bright, or luster

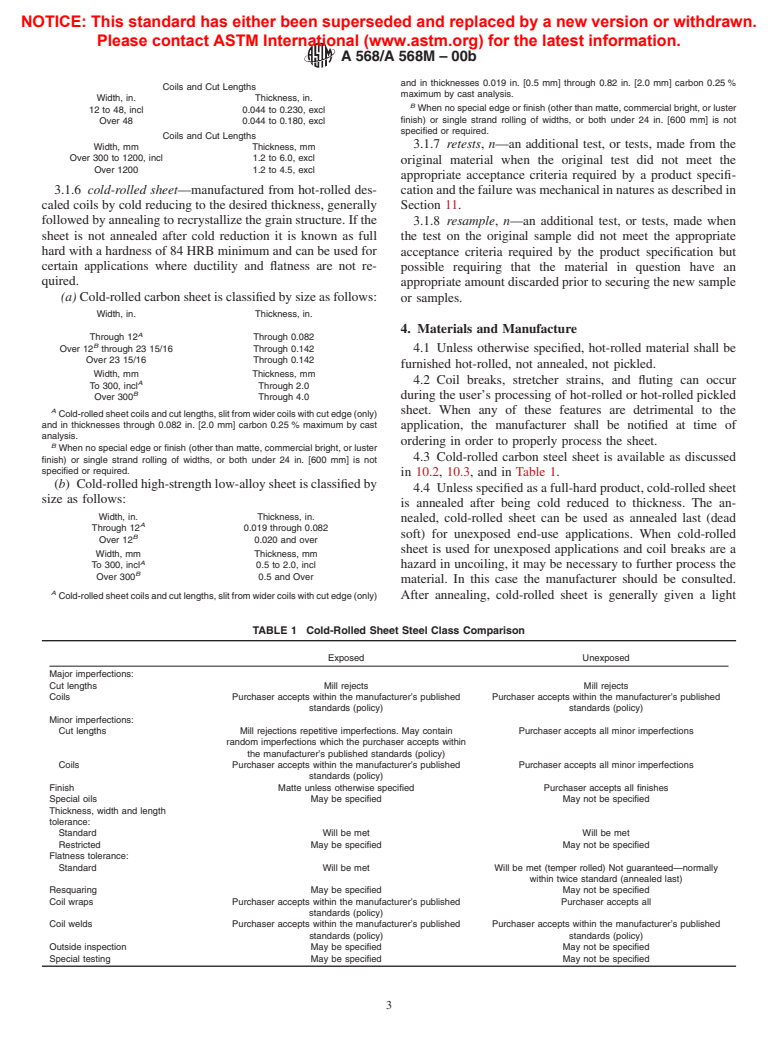

4.3 Cold-rolled carbon steel sheet is available as discussed

finish) or single strand rolling of widths, or both under 24 in. [600 mm] is not

specified or required.

in 10.2, 10.3, and in Table 1.

(b) Cold-rolledhigh-strengthlow-alloysheetisclassifiedby

4.4 Unlessspecifiedasafull-hardproduct,cold-rolledsheet

size as follows:

is annealed after being cold reduced to thickness. The an-

Width, in. Thickness, in.

nealed, cold-rolled sheet can be used as annealed last (dead

A

Through 12 0.019 through 0.082

soft) for unexposed end-use applications. When cold-rolled

B

Over 12 0.020 and over

sheet is used for unexposed applications and coil breaks are a

Width, mm Thickness, mm

A

To 300, incl 0.5 to 2.0, incl hazard in uncoiling, it may be necessary to further process the

B

Over 300 0.5 and Over

material. In this case the manufacturer should be consulted.

A

Cold-rolledsheetcoilsandcutlengths,slitfromwidercoilswithcutedge(only) After annealing, cold-rolled sheet is generally given a light

TABLE 1 Cold-Rolled Sheet Steel Class Comparison

Exposed Unexposed

Major imperfections:

Cut lengths Mill rejects Mill rejects

Coils Purchaser accepts within the manufacturer’s published Purchaser accepts within the manufacturer’s published

standards (policy) standards (policy)

Minor imperfections:

Cut lengths Mill rejections repetitive imperfections. May contain Purchaser accepts all minor imperfections

random imperfections which the purchaser accepts within

the manufacturer’s published standards (policy)

Coils Purchaser accepts within the manufacturer’s published Purchaser accepts all minor imperfections

standards (policy)

Finish Matte unless otherwise specified Purchaser accepts all finishes

Special oils May be specified May not be specified

Thickness, width and length

tolerance:

Standard Will be met Will be met

Restricted May be specified May not be specified

Flatness tolerance:

Standard Will be met Will be met (temper rolled) Not guaranteed—normally

within twice standard (annealed last)

Resquaring May be specified May not be specified

Coil wraps Purchaser accepts within the manufacturer’s published Purchaser accepts all

standards (policy)

Coil welds Purchaser accepts within the manufacturer’s published Purchaser accepts within the manufacturer’s published

standards (policy) standards (policy)

Outside inspection May be specified May not be specified

Special testing May be specified May not be specified

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

A 568/A 568M – 00b

TABLE 2 Tolerances for Product Analysis

skin pass to impart shape or may be given a heavier skin pass

or temper pass to prevent the phenomenon known as stretcher

Tolerance

straining or fluting, when formed. Temper passing also pro-

Limit, or Maximum of

Under Over

Element

vides a required surface texture.

Specified Element, %

Minimum Maximum

4.5 Temper Rolling:

Limit Limit

4.5.1 Unless otherwise specified, cold-rolled sheet for ex-

Carbon to 0.15 incl 0.02 0.03

over 0.15 to 0.40 incl 0.03 0.04

posed applications shall be temper rolled and is usually

over 0.40 to 0.80 incl 0.03 0.05

specified and furnished in the strain free condition as shipped.

over 0.80 0.03 0.06

SeeAppendixX1,EffectofAgingofCold-RolledCarbonSteel Manganese to 0.60 incl 0.03 0.03

over 0.60 to 1.15 incl 0.04 0.04

Sheet on Drawing and Forming.

over 1.15 to 1.65 incl 0.05 0.05

A

4.5.2 Cold-rolled sheet for unexposed applications may be

Phosphorus . . . 0.01

A

specified and furnished “annealed last” or “temper rolled.”“ Sulfur . . . 0.01

Silicon to 0.30 incl 0.02 0.03

Annealed last” is normally produced without temper rolling,

over 0.30 to 0.60 incl 0.05 0.05

A

but may be lightly temper rolled during oiling or rewinding.

Copper 0.02 . . .

A

Nickel to 1.00 incl . . . 0.03

Unexposed temper-rolled material may be specified strain-free

A

Chromium to 0.90 incl . . . 0.04

or nonfluting. Where specific hardness range or limit, or a

A

Molybdenum to 0.20 incl . . . 0.01

B B

specified surface texture is required, the application is consid-

Vanadium to 0.10 incl 0.01 0.01

B B

Columbium to 0.10 incl 0.01 0.01

ered as exposed.

(Niobium)

A B

Titanium to 0.15 incl 0.01 0.01

NOTE 2—Skin-passed sheet is subject to an aging phenomenon (see

C A

Aluminum to 0.10 incl 0.03 .

Appendix X1). Unless special kill

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.