ASTM D6545-00

(Test Method)Standard Test Method for Flammability of Textiles Used in Children's Sleepwear (Withdrawn 2009)

Standard Test Method for Flammability of Textiles Used in Children's Sleepwear (Withdrawn 2009)

SCOPE

1.1 This test method evaluates the relative flammability of textiles and garments intended for use in children's sleepwear. The procedures of this test method follow testing and laundering procedures used to evaluate the flammability of children's sleepwear contained in US Federal Regulations 16 CFR 1615 and 1616.

1.2 A textile used in children's sleepwear must be tested in its original state and after 50 laundering and drying cycles to assess the flame resistance of the textile relative to its use life.

1.3 The values stated in SI units are to be regarded as the standard; inch-pound units are provided for information only.

1.4 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, the test results may be used as elements of a fire-risk assessment, which takes into, account all of the factors, which are pertinent factors to the potential fire hazard of a particular end use.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determines the applicability of regulatory limitations prior to use. Specific precautionary information is found in 8.5 and 9.5.

WITHDRAWN RATIONALE

This test method evaluates the relative flammability of textiles and garments intended for use in children's sleepwear.

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was withdrawn in January 2009 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6545–00

Standard Test Method for

Flammability of Textiles Used in Children’s Sleepwear

This standard is issued under the fixed designation D 6545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Federal Standards and Regulations:

16 CFR Part 1610 Standard for the Flammability of Vinyl

1.1 This test method evaluates the relative flammability of

Plastic Film

textiles and garments intended for use in children’s sleepwear.

16 CFR Part 1611 Standard for the Flammability of Cloth-

The procedures of this test method follow testing and launder-

ing Textiles

ing procedures used to evaluate the flammability of children’s

16 CFR Part 1615 Standard for the Flammability of Chil-

sleepwear contained in US Federal Regulations 16 CFR 1615

dren’s Sleepwear: Sizes 0 through 6X

and 1616.

16 CFR Part 1616 Standard for the Flammability of Chil-

1.2 A textile used in children’s sleepwear must be tested in

dren’ Sleepwear: Sizes 7 through 14

its original state and after 50 laundering and drying cycles to

Department of Commerce Voluntary Product Standard, pre-

assess the flame resistance of the textile relative to its use life.

viously identified as Commercial Standard, CS 151-50

1.3 The values stated in SI units are to be regarded as the

“Body Measurements for the Sizing of Apparel for In-

standard; inch-pound units are provided for information only.

fants, Babies, Toddlers, and Children”

1.4 Thistestmethodshouldbeusedtomeasureanddescribe

the properties of materials, products, or assemblies in response

3. Terminology

to heat and flame under controlled laboratory conditions and

3.1 Definitions:

should not be used to describe or appraise the fire hazard or

3.1.1 char length, n—the distance from the original lower

fire risk of materials, products, or assemblies under actual fire

edgeofthespecimenexposedtotheflametotheendofthetear

conditions. However, the test results may be used as elements

or void in the charred, burned, or damaged area.

of a fire-risk assessment, which takes into, account all of the

3.1.2 children’s sleepwear, n—any product of wearing ap-

factors, which are pertinent factors to the potential fire hazard

parel such as nightgowns, pajamas, or similar or related items,

of a particular end use.

such as robes, intended to be worn primarily for sleeping or

1.5 This standard does not purport to address all of the

activities related to sleeping.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—While children’s sleepwear can in-

responsibility of the user of this standard to establish appro-

clude a range of configurations, these do not include diapers

priate safety and health practices and determines the applica-

and underwear, infant garments, and tight-fitting garments, as

bility of regulatory limitations prior to use. Specific precau-

defined by 16 CFR 1615 and 1616. The size range of these

tionary information is found in 8.5 and 9.5.

garments is limited to those defined in 16 CFR 1615 and 1616

2. Referenced Documents and the Department of Commerce/Commercial Standard

151-50 reference provides background information on how

2.1 ASTM Standards:

these size ranges were selected and how the body measure-

D 123 Terminology Relating to Textiles

ments were conducted.

2.2 AATCC Test Method

3.1.3 fabric piece (piece), n—a continuous, unseamed

Glossary of AATCC Standard Terminology

length of fabric, one or more of which make up a fabric

AATCC Test Method 124 - 1969 Appearance of Durable

production unit.

Press Fabrics After Repeated Home Laundering

3.1.4 fabric production unit (unit), n—any quantity of

finished fabric pieces which have a specific identify that

remains unchanged except for color or print pattern.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

3.1.4.1 Discussion—This fabric production unit, as speci-

and is the direct responsibility of Subcommittee D13.52 on Flammability.

fied in 16 CFR 1615, and 1616 can consist of quantities from

Current edition approved Nov. 10, 2000. Published November 2000.

This test method is not identical to 16 CFR Parts 1615 and 1616 and should not

be used in place of the CPSC standards.

3 5

Annual Book of ASTM Standards, Vol 07.01. Available from U.S. Government Printing Office, Superintendent of Docu-

Available from the American Association of Textile Chemists and Colorists, ments, Mail Stop SSOP, Washington, DC 20402-9328.

P.O. Box 12215, Research Triangle Park, NC 27709. Reference from the 1970 Available from the National Technical Information Service, 5285 Port Royal

edition of the manual. Street, Springfield, VA 22151, order CS 15150.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6545–00

5 000 linear yards for normal sampling or up to 10 000 linear 5.2 The procedure for flammability testing used in this test

yards for reduced sampling. Finished fabrics are those fabric method is technically equivalent to those used in 16 CFR 1615

pieceswhichhaveundergoneallprocessespriortobeingcutor

and 1616. The laundering requirements vary slightly because

slit into components to be manufactured into children’s sleep- the detergent that is cited in theAATCCTest Method 124-69 is

wear.

no longer commercially available. This test method does not

3.1.5 flame retardant, n—a chemical used to impart flame

include detailed specimen sampling plans, or the regulatory

resistance.

and record keeping requirements cited in the federal regula-

3.1.6 flame retardant treated, adj—having received a flame-

tions. Please consult 16 CFR 1615 and 1616 for information

retardant treatment.

for these operations.

3.1.6.1 Discussion—The term “flame retardant treated”

5.3 This test method is suitable for training technicians to

does not apply to textiles that are inherently flame resistant due

conductthefederaltestandcanserveasalaboratoryreference.

to the intrinsic properties of the material or the fiber-forming

5.4 In the future, if the U.S. Consumer Product Safety

polymer.

Commissionupdatesthefederalregulationstorevisethetextile

3.1.7 flammability, n—those characteristics of a material

refurbishing methods to those in current industry use, this test

that pertain to its relative ease of ignition and relative ability to

method will be revised to reflect those changes.

sustain combustion.

3.1.8 flammable textile, n—any combustible textile that

6. Apparatus and Materials

burns with a flame.

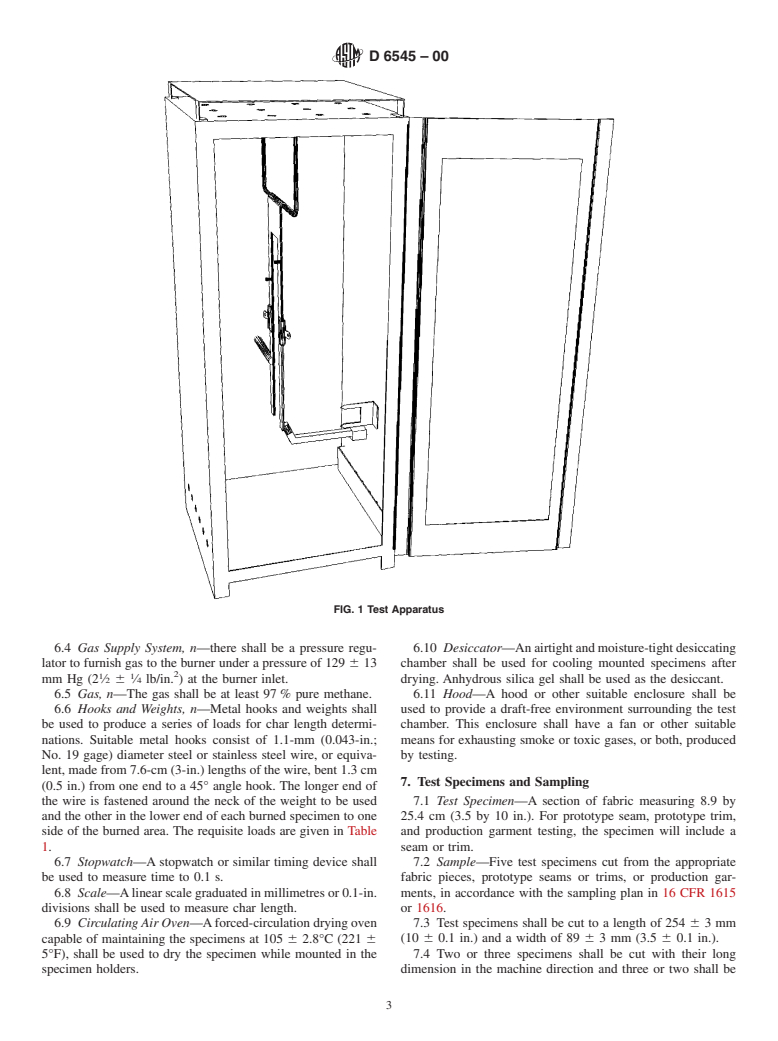

3.1.9 garment production unit (unit), n—any quantity of 6.1 TestChamber—Thetestchambershallbeconstructedof

finished garments which has a specific identity that remains

a steel or stainless steel cabinet with inside dimensions of 32.9

unchanged throughout the unit except for size, trim, findings, 6 0.15 cm (12.94 6 0.06 in.) wide, 32.9 6 0.15 cm (12.94 6

color, and print patterns.

0.06 in.) deep, and 76.2 6 0.15 cm (30 6 0.06 in.) high. The

3.1.9.1 Discussion—Asspecifiedin16CFR1615and1616,

cabinet shall have a frame, perpendicular to the front of the

a garment production unit is normally any quantity up to 500

cabinet, which permits the suspension of the specimen holder

dozen.

over the center of the base of the cabinet at such a height that

3.1.10 infant garment, n—a garment, which is, sized nine

the bottom of the specimen holder is 1.9 6 0.15 cm (0.75 6

months or smaller.

0.06 in.) above the highest point of the barrel of the gas burner.

3.1.10.1 Discussion—An infant garment may be either a

Thefrontofthecabinetshallbeaclose-fittingdoorwithaglass

one-piece garment (which does not exceed 64.8 cm [25.75 in.]

insert to permit observation of the entire test. The inside rear

in length) or a two-piece garment (no piece exceeding 40 cm

vertical surface of the cabinet may be painted flat black to

[15.75 in.] in length); and complies with all applicable require-

improve visibility of the burning specimen during the test. The

ments of the 16 CFR Part 1610 and 16 CFR part 1611; and

cabinet floor may be covered with a piece of noncombustible

bears a label stating the size of the garment expressed as age in

paper, fabric, or film whose length and width are approxi-

months.

mately 2.5 cm (1 in.) less than the cabinet floor dimensions.

3.1.11 item, n—a single article or unit.

The cabinet to be used in this test method is illustrated in Fig.

3.1.11.1 Discussion—In this test method, item refers to any

1 and detailed in Figs. 1-4.Asuitable flame height indicator is

article of children’s sleepwear or fabric or related material

shown in Fig. 5.

intended or promoted for use in children’s sleepwear.

6.2 Specimen Holder, n—The specimen holder is designed

3.2 For definitions of other terms used in this test method

to permit suspension of the specimen in a fixed vertical

refer to Terminology D 123 and to the Glossary of AATCC

position and to prevent curling of the specimen when the flame

Standard Terminology.

is applied. It shall consist of two U-shaped 0.19 cm (0.074 in.;

14-gage USS) thick steel or stainless steel plates, 42.2 6 0.15

4. Summary of Test Method

cm (16.62 6 0.06 in.) long, and 8.9 6 0.15 cm (3.5 6 0.06 in.)

4.1 This test method evaluates the extent of vertical flame wide, with aligning pins. The openings in the plates shall be

spread of a textile after a flame is applied to the bottom edge

35.6 cm (14 6 0.06 in.) long and 5.1 6 0.15 cm (2 6 0.06 in.)

of the specimen.The specimen is oriented vertically during the wide. The specimen shall be fixed between the plates, which

test and is exposed to a 38-mm (1.5-in.) flame for 3 s.

shall be held together with side clamps. The holder to be used

4.2 The extent of flame spread is determined by measuring in this test method is illustrated in Fig. 6.

the distance from the lower edge of the specimen to the point

6.3 Burner, n—Theburnershallbesubstantiallythesameas

at which the specimen ceases to tear when subjected to a

that illustrated in Figs. 7 and 8 . The burner shall have the

specified tearing load.

inside tube diameter of 1.1 cm (0.437 in.).The input line to the

burner shall be equipped with a needle valve to provide a

5. Significance and Use

variable orifice to adjust the height of the flame. The barrel of

5.1 This test method is suitable for evaluating flammability the burner shall be at an angle of 25° from the vertical. The

burner shall be equipped with an adjustable stop collar so that

characteristics and laundering durability of textiles used in the

manufacture of children’s sleepwear. It is not suitable for it may be quickly located correctly under the test specimen.

The burner shall be connected to the gas source by rubber or

evaluating the flammability characteristics of textiles for other

product applications or ignition scenarios. other flexible tubing.

D6545–00

FIG. 1 Test Apparatus

6.4 Gas Supply System, n—there shall be a pressure regu- 6.10 Desiccator—Anairtightandmoisture-tightdesiccating

lator to furnish gas to the burner under a pressure of 129 6 13 chamber shall be used for cooling mounted specimens after

1 1

mm Hg (2 ⁄2 6 ⁄4 lb/in. ) at the burner inlet. drying. Anhydrous silica gel shall be used as the desiccant.

6.5 Gas, n—The gas shall be at least 97 % pure methane. 6.11 Hood—A hood or other suitable enclosure shall be

6.6 Hooks and Weights, n—Metal hooks and weights shall used to provide a draft-free environment surrounding the test

be used to produce a series of loads for char length determi- chamber. This enclosure shall have a fan or other suitable

nations. Suitable metal hooks consist of 1.1-mm (0.043-in.; means for exhausting smoke or toxic gases, or both, produced

No. 19 gage) diameter steel or stainless steel wire, or equiva- by testing.

lent, made from 7.6-cm (3-in.) lengths of the wire, bent 1.3 cm

7. Test Specimens and Sampling

(0.5 in.) from one end to a 45° angle hook. The longer end of

the wire is fastened around the neck of the weight to be used 7.1 Test Specimen—A section of fabric measuring 8.9 by

and the other in the lower end of each burned specimen to one 25.4 cm (3.5 by 10 in.). For prototype seam, prototype trim,

side of the burned area. The requisite loads are given in Table and production garment testing, the specimen will include a

1. seam or trim.

6.7 Stopwatch—A stopwatch or similar timing device shall 7.2 Sample—Five test specimens cut from the appropriate

be used to measure time to 0.1 s. fabric pieces, prototype seams or trims, or production gar-

6.8 Scale—Alinear scale graduated in millimetres or 0.1-in. ments, in accordance with the sampling plan in 16 CFR 1615

divisions shall be used to measure char length. or 1616.

6.9 CirculatingAir Oven—Aforced-circulationdryingoven 7.3 Test specimens shall be cut to a length of 254 63mm

capable of maintaining the specimens at 105 6 2.8°C (221 6 (10 6 0.1 in.) and a width of 89 6 3 mm (3.5 6 0.1 in.).

5°F), shall be used to dry the specimen while mounted in the 7.4 Two or three specimens shall be cut with their long

specimen holders. dimension in the machine direction and three or two shall be

D6545–00

FIG. 2 Front View

cut with their long dimension in the cross-machine direction. unit has met the flammability requirements of the federal

Each group of five specimens then constitutes one sample. standard both as produced and after 50 launderings.

Individual determinations for each specimen, and the average 7.6 Sampling of fabrics and garments for compliance to the

of the sample set constitute the test result. federal regulation is not part of this test method. Refer to 16

7.5 Fabrics used in the manufacture of children’s sleepwear CFR 1615 and 1616 for instructions on compliance sampling.

shall be tested after the final stage of production and after the

8. Preconditioning and Conditioning

fabric has been laundered 50 times in accordance with the

procedure in Section 10. Fabrics that have not been treated to 8.1 Precondition all specimens at 20 6 2°C (68 6 4°F) for

be made flame-resistant, and where there will be multiple a minimum of 4 h before conditioning.

production runs of this fabric type, are not required to be tested 8.2 After preconditioning, mount each specimen in a speci-

after 50 launderings; provided that the first fabric production men holder using a sufficient number of clamps or tape to

D6545–00

FIG. 3 Top View

ensure that the specimen cannot move within the specimen 9.3 Ignite the specimen within 30 s of removing it from the

holder. Ensure th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.