ASTM D1539-60(1998)

(Specification)Standard Specification for Dehydrated Castor Acids (Withdrawn 2007)

Standard Specification for Dehydrated Castor Acids (Withdrawn 2007)

SCOPE

1.1 This specification covers acids produced from dehydrated castor oil. Two types are covered as follows:

1.1.1 Type I -Distilled dehydrated castor acids.

1.1.2 Type II -Undistilled dehydrated castor acids.

WITHDRAWN RATIONALE

This specification covers acids produced from dehydrated castor oil. Two types are covered as follows: Type I-distilled dehydrated castor acids and Type II-undistilled dehydrated castor acids.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this specification was withdrawn in March 2007 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

Designation: D 1539 – 60 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Dehydrated Castor Acids

This standard is issued under the fixed designation D 1539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

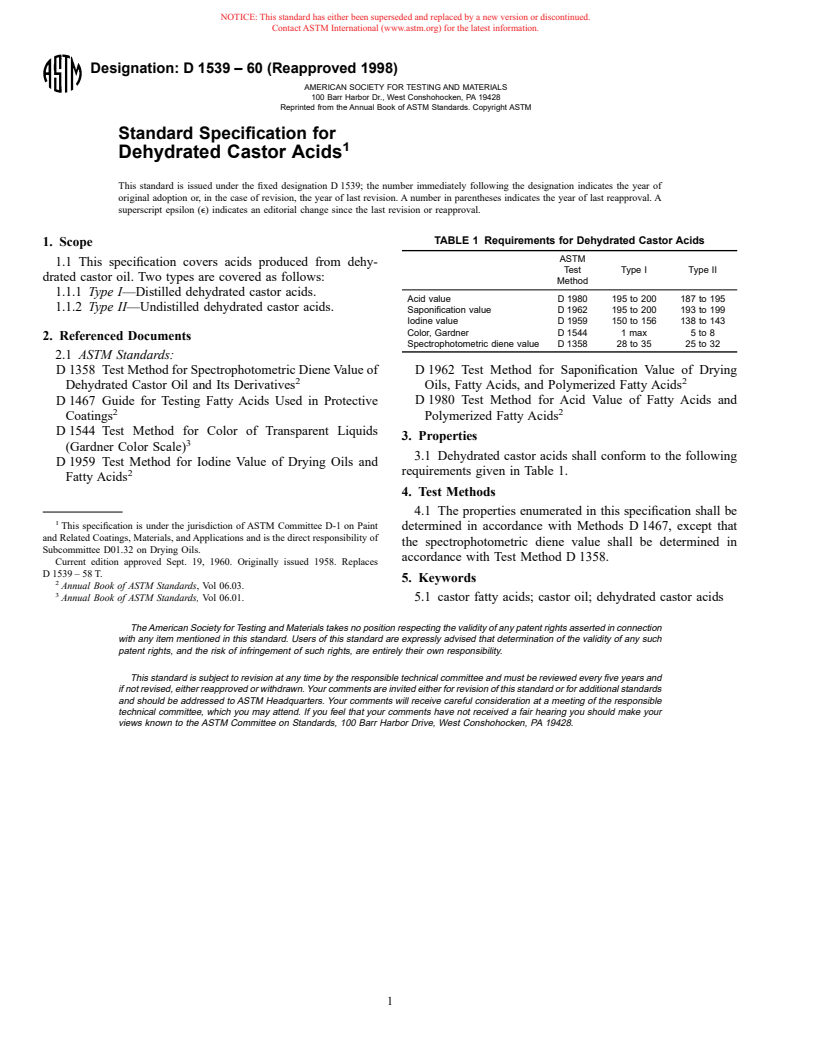

TABLE 1 Requirements for Dehydrated Castor Acids

1. Scope

ASTM

1.1 This specification covers acids produced from dehy-

Test Type I Type II

drated castor oil. Two types are covered as follows:

Method

1.1.1 Type I—Distilled dehydrated castor acids.

Acid value D 1980 195 to 200 187 to 195

1.1.2 Type II—Undistilled dehydrated castor acids.

Saponification value D 1962 195 to 200 193 to 199

Iodine value D 1959 150 to 156 138 to 143

Color, Gardner D 1544 1 max 5 to 8

2. Referenced Documents

Spectrophotometric diene value D 1358 28 to 35 25 to 32

2.1 ASTM Standards:

D 1358 Test Method for Spectrophotometric Diene Value of D 1962 Test Method for Saponification Value of Drying

2

2

Oils, Fatty Acids, and Polymerized Fatty Acids

Dehydrated Castor Oil and Its Derivatives

D 1467 Guide for Testing Fatty Acids Used in Protective D 1980 Test Method for Acid Value of Fatty Acids and

2

2

Polymerized Fatty Acids

Coatings

D 1544 Test Method for Color of Transparent Liquids

3. Properties

3

(Gardner Color Scale)

3.1 Dehydrated castor acids shall conform to the following

D 1959 Test Method for Iodine Value of Drying Oils and

requirements give

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 The satisfactory film integrity of emulsion coatings requires that as the aqueous phase evaporates the resinous portion of the vehicle coalesces into a continuous film. Low temperature impairs the fluidity of the resin particle and thereby their ability to coalesce. Vehicles that can withstand low temperatures are therefore required, and MFFT is an important quality feature of emulsion vehicles.

SCOPE

1.1 This test method covers the determination of the minimum temperature at which emulsion vehicles coalesce to form continuous films. The term “emulsion” in this test method includes latex vehicles.

1.2 This test method is limited to emulsions having minimum film formation temperatures below 90 °C.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Rosin and similar materials such as rosin derivatives often contain volatile material derived from the raw material used or formed as a result of the processing of the rosin. This volatile material can have a significant effect on the physical and chemical properties of the rosin and so a standard method for its determination is required.

SCOPE

1.1 This test method covers the determination of the volatile oil content of rosin or similar material. The oil may consist of naturally occurring terpene oil, such as heavy fractions of turpentine, resulting from incomplete distillation in the processing of the rosin, or of foreign nonterpene oil resulting from incomplete removal of mineral or coal-tar solvent used to extract the rosin from wood or still wastes. In certain cases the volatile oil could consist of decarboxylated rosin formed during the processing of the rosin.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 In general, with materials of these types, softening point does not take place at a definite temperature. As the temperature rises, these materials gradually change from brittle or exceedingly thick and slow-flowing materials to softer and less viscous liquids. For this reason, the determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results obtained are to be comparable.

SCOPE

1.1 This test method covers the determination of softening point of resins using a Mettler cup and ball apparatus, and may, under user-defined conditions, give results comparable to those obtained by Test Methods E28.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The testing procedures described in these test methods have been in use for many years and emphasize the physical properties of pine oil rather than its chemical composition. Test Methods D6387 describe a capillary gas chromatography method which is suitable for determining both the major and minor components found in pine oils.

SCOPE

1.1 These test methods cover procedures for sampling and testing pine oils, and are applicable to both natural pine oils derived from pine stumps either by the steam and solvent process or by destructive distillation, and also to synthetic pine oils obtained by the chemical hydration of terpene hydrocarbons.

1.2 The procedures given in these test methods appear in the following order:

Section

Sampling

4

Appearance

5

Color

6

Specific Gravity

7

Refractive Index

8

Composition

9

Moisture

10

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Saturated fatty acids solidify at a higher temperature than unsaturated fatty acids. This test method provides a means of measuring the solidification temperature of a sample containing both unsaturated and saturated fatty acids by cooling the specimen and measuring the temperature at which solidification occurs.

3.2 Samples containing higher levels of saturated acids will have a higher titer (solidification temperature) than those with lower levels of saturated acids.

3.3 Water present in the sample will raise the titer, so provisions are made in the test method to remove traces of moisture.

SCOPE

1.1 This test method covers the determination of the solidification (titer) point of fatty acids and is applicable to all fatty acids.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 In general, with materials of these types, softening does not take place at a definite temperature. As the temperature rises, these materials gradually change from brittle or exceedingly thick and slow-flowing materials to softer and less viscous liquids. For this reason, the determination of the softening point must be made by a fixed, arbitrary, and closely defined method if the results obtained are to be comparable.

3.2 In these test methods, the softening point is defined as the temperature at which a disk of the sample held within a horizontal ring is forced downward a distance of 25.4 mm (1 in.) under the weight of a steel ball as the sample is heated at 5 °C/min in a water, glycerin, silicone oil, ethylene glycol/water or glycerin/water bath.

3.3 The automatic method was chosen to be the reference method because a round robin demonstrated that it gave more precise results than the manual method.

SCOPE

1.1 These test methods are intended for determining the softening point of resins (including rosin and terpene resins) and similar materials by means of the ring-and-ball apparatus.

Note 1: For testing asphalts, tars, and pitches, see Test Method D36.

1.1.1 Test method using the automated ring and ball softening point apparatus is the reference method and the test method using the manual ring and ball method is an alternative method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Separation of the vehicle from the pigment in solvent-reducible paints is required in order to characterize paint vehicles by chemical, spectroscopic, or chromatographic techniques. Characterization of vehicles is important since they play a major role in the performance of coatings.

SCOPE

1.1 This practice covers the procedure for the separation of the vehicle from the pigment in solvent-reducible paint.

1.2 In the development of the practice the following materials were tested: white soya and white fish oil isophthalic alkyd semi-gloss enamels, white linseed oil paint, white soya and white linseed o-phthalic alkyd enamels. It is considered to be applicable to similar materials.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method provides a more precise way of measuring Gardner color than described in Test Method D1544. It is applicable to pine chemical products having colors from Gardner 1 to Gardner 18. The Gardner scale is not applicable to materials with colors lighter than 1 or darker than 18.

SCOPE

1.1 This test method covers the quantitative determination of the color of clear, yellow/brown, liquid materials using color measuring instruments. The results may be invalid if other materials are used. The test uses the Gardner color scale described in Test Method D1544. This test method applies to pine chemical products including tall oil, tall oil fatty acids, rosin, and related products.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The iodine value of a fatty acid product is a measure of the unsaturated fatty acid content of that product and consequently a measure of the ease of oxidation or drying capacity of that fatty acid product.

3.2 This test method measures the unsaturation as iodine value by addition of an iodine/chlorine reagent. The amount of reagent absorbed is determined by back titrating the excess reagent and comparing it to a blank determination.

3.3 In samples containing conjugated double bonds, the iodine value obtained is empirical since the reagent does not react stoichiometrically with conjugated unsaturation. Where no conjugation is present, the iodine value obtained is a measure of the total unsaturation. By using proper specimen weights, the empirical values obtained are useful for comparative purposes.

3.4 This test method was developed in order to replace the hazardous solvent, carbon tetrachloride, used in Test Method D1959 with the less hazardous and more available solvents, iso-octane and cyclohexane. As data on the satisfactory use of other solvents becomes available, this test method will be amended to include those solvents.

3.5 This test method should have applicability to fatty acids and oils other than tall oil fatty acid but that possibility has not been investigated.

SCOPE

1.1 This test method covers the Wijs procedure for determination of unsaturation (iodine value) of tall oil fatty acids.

1.2 Iodine value is a measure of the unsaturation of oils and fatty acids and is expressed in terms of the number of centigrams of iodine per gram of sample (weight percent of absorbed iodine).

1.3 When this test method is used to determine the iodine value of fatty acids having conjugated systems, the result is not a measure of total unsaturated, but rather is an empirical value that affords a comparison of unsaturation. Total unsaturation of conjugated systems may be measured in accordance with Test Method D1541.

1.4 The test method described here is not reliable for tall oil fatty acids containing an appreciable quantity of rosin.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 This test method is designed to broaden the scope of the previous edition of the test method by the inclusion of tall oil and tall oil derived from products as test materials. Test Methods D803 currently includes a method for the determination of unsaponifiable matter.

3.2 The amount of unsaponifiable matter in tall oil and other related products is important in characterizing such products as it indicates the level of nonacidic material, both free and combined, present in the test material. The unsaponifiable in naval stores products is primarily composed of higher molecular weight alcohols, sterols, and hydrocarbons.

SCOPE

1.1 This test method covers the determination of the percentage of material in pine chemicals products as defined in Terminology D804 including rosin, tall oil, and related products, other than insoluble dirt or similar visible foreign matter that does not yield a water-soluble soap when the sample is saponified with potassium hydroxide.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: It has been reported that this method may not be applicable to gum rosin, especially any gum rosin containing volatile terpenes. Volatile terpenes are by definition unsaponifiable matter, and can be lost under the drying conditions described in 8.4. The method is applicable to tall oil rosin and wood rosin as these rosins do not contain volatile terpenes.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.