ASTM B19-95

(Specification)Standard Specification for Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)

Standard Specification for Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)

SCOPE

1.1 This specification establishes the requirements for sheet, strip, plate, bar, and disks for the manufacture of ammunition of component parts thereof from alloy UNS C26000.

1.2 Values given in inch-pound units are the standard except for grain size which is stated in metric units. SI values given in parenthesis are for information only.

1.3 The following safety caveat pertains only to the test method described in Section 10 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 19 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)

This standard is issued under the fixed designation B 19; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-105 Sampling Procedures and Tables for Inspec-

tion by Attributes

1.1 This specification establishes the requirements for UNS

MIL-STD-129 Marking for Shipment and Storage

No. C26000 sheet, strip, plate, bar, and disks for the manu-

MIL-C-3993 Packaging of Copper and Copper-Base Alloy

facturer of ammunition of component parts thereof.

Mill Products

1.2 Values given in inch-pound units are the standard.

Values given in parenthesis are for information only.

3. Ordering Information

2. Referenced Documents 3.1 Contracts or purchase orders for product under this

specification should contain the following information:

2.1 ASTM Standards:

3.1.1 ASTM designation and year of issue (for example,

B 154 Test Method for Mercurous Nitrate Test for Copper

3 B19-XX),

and Copper Alloys

3.1.2 Product form: sheet, strip, plate, bar, or disks (blanks),

B 248 Specification for General Requirements for Copper

3 3.1.3 Temper (Section 6),

and Copper Alloy Plate, Sheet, Strip, and Rolled Bar

3.1.4 Dimension: thickness, width, length,

B 601 Practice for Temper Designations for Copper and

3 3.1.5 How furnished: flat lengths, coils, or blanks,

Copper Alloys—Wrought and Cast

3.1.6 Quantity: total weight each temper, form, and size, and

E 3 Methods of Preparation of Metallographic Specimens

4 3.1.7 When severe drawing or deep cupping is required.

E 8 Test Methods for Tension Testing of Metallic Materials

3.2 The following options are available and should be

E 112 Test Methods for Determining Average Grain Size

specified in the contrast or purchase order when required:

E 255 Practice for Sampling Copper and Copper Alloys for

3.2.1 Heat identification or traceability details,

Determination of Chemical Determination of Chemical

3.2.2 Caliber or diameter of Type IV cups or disks (Section

Composition

10),

E 478 Test Methods for Chemical Analysis of Copper

3.2.3 Mercurous Nitrate Test (Section 9),

Alloys

3.2.4 Product Marking (Section 18),

E 527 Practice for Numbering Metals and Alloys (UNS)

3.2.5 On site inspection (Section 12),

2.2 Federal Standards:

3.2.6 Certification (Section 3),

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3.2.7 Test Report (Mill) (Section 3), and

Fed. Std. No. 185 Identification Marking of Copper and

3.2.8 Product Marking (Section 18).

Copper-Base Alloy Mill Products

2.3 Military Standards:

4. Material and Manufacture

4.1 Material:

4.1.1 The material of manufacture shall be a cast bar of

copper alloy UNS C26000 of such purity, uniformity, and

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

soundness as to be suitable for processing into the products

Sheet and Strip.

prescribed herein.

Current edition approved Feb. 15, 1995. Published April 1995. Originally

e1 4.2 Manufacturing:

published as B 19 – 19 T. Last previous edition B 19 – 86 (1993) .

4.2.1 The product shall be manufactured by such hot work-

The UNS system for copper and copper alloys (see Practice E 527) is a simple

expansion of the former standard designation system accomplished by the addition

ing, cold working, and annealing processes as to produce a

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate

uniform wrought structure in the specified temper for the

composition variations of the base alloy.

finished product.

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 03.01. 4.2.2 The products shall be furnished with slit edges unless

Annual Book of ASTM Standards, Vol 03.05.

otherwise specified.

Annual Book of ASTM Standards, Vol 01.01.

4.3 In the event heat identification or traceability is required,

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

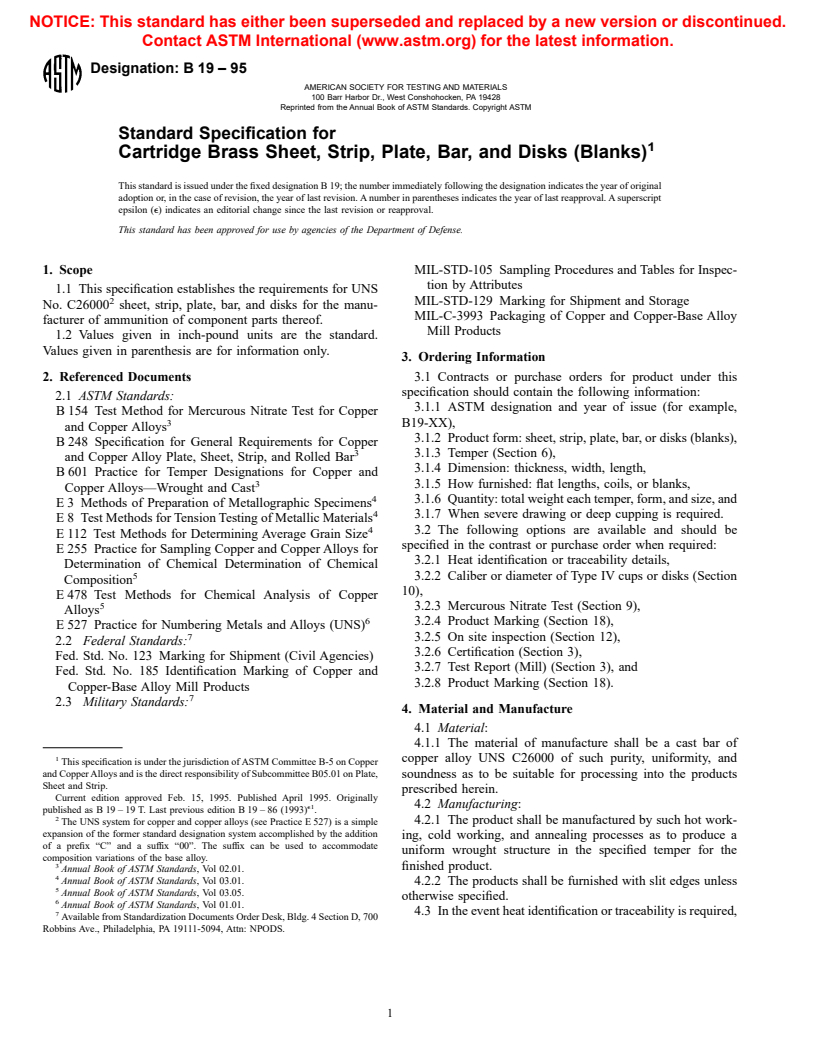

B19

TABLE 2 Tensile Strength Requirements for Rolled Tempers

the purchaser shall specify the details desired in the contract or

purchase order.

NOTE 1—Plate is generally available in only the soft O60, quarter-hard

H01, and half-hard H02 tempers. Required properties for other tempers

5. Chemical Composition

shall be agreed upon between the manufacturer or supplier and the

purchaser at time of placing the order or contract.

5.1 The product material shall conform to the requirements

A

Tensile Strength, ksi

prescribed in Table 1.

Temper Designation

B

(MPa)

5.1.1 These specification limits do not preclude the presence

Standard Former min max

of other elements. Limits for unnamed elements may be

H01 quarter hard 49 (340) 59 (405)

established and analysis required by agreement between manu-

H02 half hard 57 (395) 67 (460)

facturer and purchaser.

H03 three-quarter hard 64 (440) 74 (510)

5.2 Either copper or zinc may be taken as the difference

H04 hard 71 (490) 81 (560)

H06 extra hard 83 (570) 92 (635)

between the sum of all elements analyzed and 100 %. When all

H08 spring 91 (625) 100 (690)

elements in Table 1 are analyzed, their sum shall be 99.7 %

H10 extra spring 95 (655) 104 (720)

min.

A

ksi 1000 psi.

B

See Appendix X1.

6. Temper

6.1 Product tempers, as defined in Practice B 601, shall be

8.3.2 Material over 0.500 in. (12.70 mm) in thickness,

as follows:

except material for 20-mm disks, shall be furnished to a grain

6.1.1 Rolled Product: B 601, H01, H02, H03, H04, H06,

size of 0.070 to 0.150 mm inclusive.

H08, and H10.

8.3.3 Disks (blanks) of 20 mm and material for blanking

6.1.2 Annealed Product: OS015, OS025, OS035, OS050,

20-mm disks (blanks) shall be furnished to a grain size of 0.070

OS070, and OS100.

to 0.130 mm inclusive.

6.1.3 The purchaser should confer with the manufacturer or

8.4 Material ordered as-hot rolled shall be furnished to a

supplier for availability of product in a specific temper, form,

grain size as agreed upon between the manufacturer or supplier

and size.

and the producer.

8.5 Material to be used for the manufacture of primer cup

7. Mechanical Property Requirements

and primer anvils shall conform to the grain size requirements

7.1 Materials furnished under this specification shall con-

of Table 6.

form to the tension test requirements specified in this specifi-

cation.

9. Mercurous Nitrate Test

7.1.1 Rolled-to-temper material shall conform to the re-

9.1 When specified in the contract or purchase order, the

quirements specified in Table 2.

product shall meet the requirements of Test Method B 154.

7.1.2 Annealed material shall conform to the requirements

9.1.1 Mercury is a recognized health hazard. Proper equip-

specified in Table 3.

ment for the detection and removal of vapors is recommended.

7.1.3 Material furnished as-hot rolled shall conform to the

The use of suitable gloves while testing is advised.

requirements specified in Table 3.

10. Dimensions and Permissible Variations

8. Grain Size Requirements

10.1 The dimensions and tolerances covered by this speci-

8.1 Annealed sheet, strip, and bar furnished under this

fication, except as covered herein, shall be as specified in the

specification shall conform to the requirements specified in

current edition of Specification B 248, with particular reference

Table 4.

to Section 5 and the dimensional tables of that specification.

8.2 Except for material ordered by the U.S. Government,

10.2 The diameter of the disks measured at the large end

annealed material to be used for the manufacture of cartridge

shall not vary from that specified in the order by more than the

brass cups and disks shall conform to the requirements of Table

amounts shown in Table 7.

5.

10.3 Disks shall not vary in thickness by more than the

8.3 Annealed plate, bar, and disks ordered by the U.S.

amounts shown in Table 8, except that disks for 20-mm

Government shall meet the following requirements:

cartridge cases shall be not less than the thickness specified and

8.3.1 Material up to 0.500 in. (12.70 mm) in thickness

shall not exceed the specified thickness by more than 0.008 in.

inclusive, except material for 20 mm disks, shall be furnished

(0.20 mm) in the area 1 in. (25 mm) in diameter in the center

to a grain size of 0.055 to 0.120 mm inclusive.

of the disk.

10.4 Material to be used for the manufacture of primer cup

TABLE 1 Chemical Requirements

and primer anvil shall conform to the dimensional tolerances

requirements shown in Table 6.

NOTE 1—If the presence of bismuth is suspected during analysis,

10.5 Special dimensional tolerances shall be as agreed upon

further analysis shall be made, and if bismuth is found in excess of

0.006 %, the lot shall be rejected. between the manufacturer or supplier and the purchaser.

10.6 Straightness shall be determined by placing the piece

Composition, %

Copper Zinc

Lead, max Iron, max

on a level surface so that the arc or departure from straightness

68.5 to 71.5 0.07 0.05 remainder

is horizontal. The maximum depth of arc shall be measured to

B19

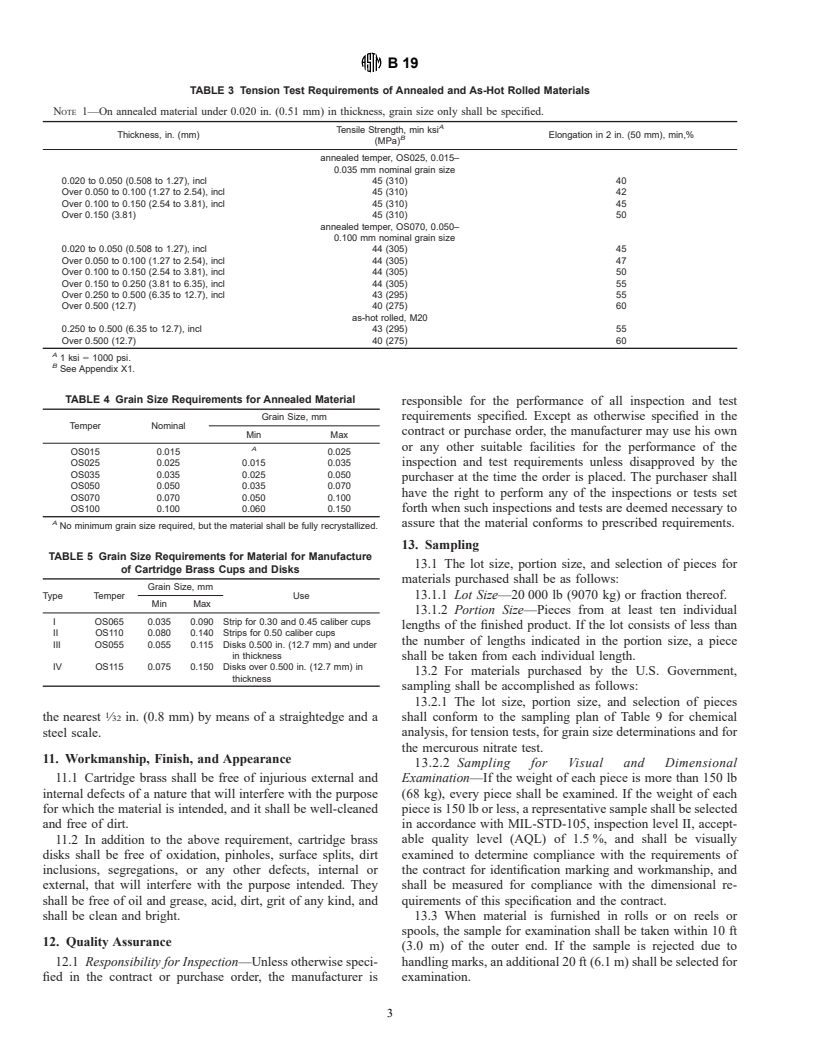

TABLE 3 Tension Test Requirements of Annealed and As-Hot Rolled Materials

NOTE 1—On annealed material under 0.020 in. (0.51 mm) in thickness, grain size only shall be specified.

A

Tensile Strength, min ksi

Thickness, in. (mm) Elongation in 2 in. (50 mm), min,%

B

(MPa)

annealed temper, OS025, 0.015–

0.035 mm nominal grain size

0.020 to 0.050 (0.508 to 1.27), incl 45 (310) 40

Over 0.050 to 0.100 (1.27 to 2.54), incl 45 (310) 42

Over 0.100 to 0.150 (2.54 to 3.81), incl 45 (310) 45

Over 0.150 (3.81) 45 (310) 50

annealed temper, OS070, 0.050–

0.100 mm nominal grain size

0.020 to 0.050 (0.508 to 1.27), incl 44 (305) 45

Over 0.050 to 0.100 (1.27 to 2.54), incl 44 (305) 47

Over 0.100 to 0.150 (2.54 to 3.81), incl 44 (305) 50

Over 0.150 to 0.250 (3.81 to 6.35), incl 44 (305) 55

Over 0.250 to 0.500 (6.35 to 12.7), incl 43 (295) 55

Over 0.500 (12.7) 40 (275) 60

as-hot rolled, M20

0.250 to 0.500 (6.35 to 12.7), incl 43 (295) 55

Over 0.500 (12.7) 40 (275) 60

A

1 ksi 5 1000 psi.

B

See Appendix X1.

TABLE 4 Grain Size Requirements for Annealed Material

responsible for the performance of all inspection and test

Grain Size, mm requirements specified. Except as otherwise specified in the

Temper Nominal

contract or purchase order, the manufacturer may use his own

Min Max

A or any other suitable facilities for the performance of the

OS015 0.015 0.025

OS025 0.025 0.015 0.035 inspection and test requirements unless disapproved by the

OS035 0.035 0.025 0.050

purchaser at the time the order is placed. The purchaser shall

OS050 0.050 0.035 0.070

have the right to perform any of the inspections or tests set

OS070 0.070 0.050 0.100

forth when such inspections and tests are deemed necessary to

OS100 0.100 0.060 0.150

A

assure that the material conforms to prescribed requirements.

No minimum grain size required, but the material shall be fully recrystallized.

13. Sampling

TABLE 5 Grain Size Requirements for Material for Manufacture

13.1 The lot size, portion size, and selection of pieces for

of Cartridge Brass Cups and Disks

materials purchased shall be as follows:

Grain Size, mm

Type Temper Use 13.1.1 Lot Size—20 000 lb (9070 kg) or fraction thereof.

Min Max

13.1.2 Portion Size—Pieces from at least ten individual

I OS065 0.035 0.090 Strip for 0.30 and 0.45 caliber cups

lengths of the finished product. If the lot consists of less than

II OS110 0.080 0.140 Strips for 0.50 caliber cups

the number of lengths indicated in the portion size, a piece

III OS055 0.055 0.115 Disks 0.500 in. (12.7 mm) and under

in thickness shall be taken from each individual length.

IV OS115 0.075 0.150 Disks over 0.500 in. (12.7 mm) in

13.2 For materials purchased by the U.S. Government,

thickness

sampling shall be accomplished as follows:

13.2.1 The lot size, portion size, and selection of pieces

shall conform to the sampling plan of Table 9 for chemical

the nearest ⁄32 in. (0.8 mm) by means of a straightedge and a

steel scale. analysis, for tension tests, for grain size determinations and for

the mercurous nitrate test.

11. Workmanship, Finish, and Appearance

13.2.2 Sampling for Visual and Dimensional

11.1 Cartridge brass shall be free of injurious external and Examination—If the weight of each piece is more than 150 lb

internal defects of a nature that will interfere with the purpose (68 kg), every piece shall be examined. If the weight of each

for which the material is intended, and it shall be well-cleaned piece is 150 lb or less, a representative sample shall be selected

and free of dirt. in accordance with MIL-STD-105, inspection level II, accept-

11.2 In addition to the above requirement, cartridge brass able quality level (AQL) of 1.5 %, and shall be visually

disks shall be free of oxidation, pinholes, surface splits, dirt examined to determine compliance with the requirements of

inclusions, segregations, or any other defects, internal or the contract for identification marking and workmanship, and

shall be measured for compliance with the dimensional re-

external, that will interfere with the purpose intended. They

shall be free of oil and grease, acid, dirt, grit of any kind, and quirements of this specification and the contract.

13.3 When material is furnished in rolls or on reels or

shall be clean and bright.

spools, the sample for examination shall be taken within 10 ft

12. Quality Assurance

(3.0 m) of the outer end. If the sample is rejected due to

12.1 Responsibility for Inspection—Unless otherwise speci- handling marks, an additional 20 ft (6.1 m) shall be selected for

fied in the contract or purchase order, the manufacturer is examination.

B19

TABLE 6 Dimensional Tolerances, Grain Size, and Temper of Brass for Primer Cup and Primer Anvils

Permissible Variation

Standard Temper Nominal Grain Size, mm or

Item Size case, caliber Thickness, in. (mm) in Thickness Plus and

Designations temper

Minus, in. (mm)

Cup 0.50 0.035 (0.899) 0.0008 (0.020) OS100 0.100 (OS100)

0.45 0.018 (0.458) or 0.001 (0.025) OS050 0.050 (OS050)

0.020 (0.508)

7.62 mm 0.027 (0.686) or 0.0008 (0.020) OS100 0.100 (OS100)

0.029 (0.737)

5.56 mm 0.027 (0.686) 0.0005 (0.0125) OS07

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.