ASTM E1530-99

(Test Method)Standard Test Method for Evaluating the Resistance to Thermal Transmission of Thin Specimens of Materials by the Guarded Heat Flow Meter Technique

Standard Test Method for Evaluating the Resistance to Thermal Transmission of Thin Specimens of Materials by the Guarded Heat Flow Meter Technique

SCOPE

1.1 This test method covers a steady-state technique for the determination of the resistance to thermal transmission (thermal resistance) of thin specimens of materials and composites, especially in thicknesses of less than 12 mm. If the single or stacked thin specimens are homogeneous opaque solids and a representative thickness is used then thermal conductivity can be determined (see Notes 1 and 2). This test method is especially useful for materials in sheet and similar forms having a thermal resistance in the range from 20 to 400 X 10 -4 m2 K/W (an effective thermal conductivity in the approximate range 0.1 ∧ [lambda] ∧ 5 W/m[dot]K) over the approximate temperature range from 150 to 600 K. It can be used outside these ranges with reduced accuracy for thicker specimens and for thermal conductivities up to 10 W/m[dot]K. Note 1-A body is considered homogeneous when the above property is found by measurement to be independent of specimen dimensions. Note 2-This test method may also be used to evaluate the thermal conductance/resistance of materials in contact, such as gaskets, and thermal conductance of gasket materials under actual high-loading conditions of a particular application.

1.2 This test method is similar in concept to Test Method C518 but is modified to accommodate smaller test specimens having a higher thermal conductance. In addition, significant attention has been paid to ensure that the thermal resistance of contacting surfaces are minimized and reproducible such that instrumentation of calibration and test specimens with temperature sensors is unnecessary. There are cases, such as Practice F433, where the method is used with instrumentation of the reference specimen and utilization of an analog calculator. General information on improvements in this latter technique and on the modified calculation procedures are given in two appendices.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1530 – 99

Standard Test Method for

Evaluating the Resistance to Thermal Transmission of

Materials by the Guarded Heat Flow Meter Technique

This standard is issued under the fixed designation E 1530; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 220 Method for Calibration of Thermocouples by Com-

parison Techniques

1.1 This test method covers a steady-state technique for the

E 1142 Terminology Relating to Thermophysical Proper-

determination of the resistance to thermal transmission (ther-

ties

mal resistance) of materials in thicknesses of less than 25 mm.

E 1225 Test Method for Thermal Conductivity of Solids by

For homogeneous opaque solid specimens of a representative

Means of the Guarded-Comparative-Longitudinal Heat

thickness, thermal conductivity can be determined (see Note

Flow Technique

1). This test method is useful for materials having a thermal

−4 2

F 104 Classification System for Nonmetallic Gasket Mate-

resistance in the range from 10 to 400 3 10 m ·K/W thermal

rials

conductivity in the approximate range, 0.1< l < 30 W/(m·K)

F 433 Practice for Evaluating Thermal Conductivity of

over the approximate temperature range from 150 to 600 K. It

Gasket Materials

can be used ouside these ranges with reduced accuracy for

thicker specimens and for thermal conductivity values up to 60

3. Terminology

W/(m·K).

3.1 Definitions of Terms Specific to This Standard:

NOTE 1—A body is considered homogeneous when the preceding

3.1.1 heat flux transducer (HFT)—a device that produces an

property is found by measurement to be independent of specimen

electrical output that is a function of the heat flux, in a

dimensions.

predefined and reproducible manner.

1.2 This test method is similar in concept to Test Method

3.1.2 thermal conductance (C)—the time rate of heat flux

C 518, but is modified to accommodate smaller test specimens,

through a unit area of a body induced by unit temperature

having a higher thermal conductance. In addition, significant

difference between the body surfaces.

attention has been paid to ensure that the thermal resistance of

3.1.2.1 average temperature—the average temperature of a

contacting surfaces is minimized and reproducible.

surface is the area-weighted mean temperature of that surface.

1.3 The values stated in SI units are to be regarded as

3.1.3 thermal conductivity (l)—(of a solid material)—the

standard.

time rate of heat flow, under steady conditions, through unit

1.4 This standard does not purport to address all of the

area, per unit temperature gradient in the direction perpendicu-

safety concerns, if any, associated with its use. It is the

lar to the area:

responsibility of the user of this standard to establish appro-

3.1.3.1 apparent thermal conductivity—When other modes

priate safety and health practices and determine the applica-

of heat transfer through a material are present in addition to

bility of regulatory limitations prior to use.

conduction, the results of the measurements performed in

accordance with this test method will represent the apparent or

2. Related Documents

effective thermal conductivity for the material tested.

2.1 ASTM Standards:

3.1.4 thermal resistance (R)—the reciprocal of thermal

C 518 Test Method for Steady-State Heat Flux Measure-

conductance.

ments and Thermal Transmission Properties by Means of

3.2 Symbols:

the Heat Flow Meter Apparatus

3.2.1 l—thermal conductivity, W/(m·K) (Btu·in./h·ft ·°F).

2 2

C 1045 Practice for Calculating Thermal Transmission

3.2.2 C—thermal conductance, W/(M ·K) (Btu/(h·ft ·°F).

2 2

Properties Under Steady-State Test Conditions

3.2.3 R—thermal resistance, m ·K/W (h·ft ·°F/Btu).

3.2.4 Dx—specimen thickness, mm (in.).

2 2

3.2.5 A—specimen cross-sectional area, m (ft )

This test method is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.05 on Thermo-

physical Properties.

Current edition approved March 10, 1999. Published September 1999. Originally Annual Book of ASTM Standards, Vol 14.03.

published as E 1530 – 93. Last previous edition E 1530 – 93. Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 04.06. Annual Book of ASTM Standards, Vol 09.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1530–99

3.2.6 Q—heat flow, W (Btu/h). through the specimen, the HFT and the interfaces between the

3.2.7 f—heat flux transducer output, mV. specimen and the apparatus. The proportionality is obtained

3.2.8 N—heat flux transducer calibration constant, through prior calibration of the system with specimens of

2 2

W/(m )·mV (Btu/h·ft ·mV). known thermal resistance measured under the same conditions,

2 2

3.2.9 Nf—heat flux, W/m (Btu/h·ft ). such that contact resistance at the surface is made reproducible.

3.2.10 DT—temperature difference,° C °F.

5. Significance and Use

3.2.11 Tg—temperature of guard heater, °C °F.

5.1 This test method is designed to measure and compare

3.2.12 Tu—temperature of upper heater, °C (°F).

3.2.13 Tl—temperature of lower heater, °C (°F). thermal properties of materials under controlled conditions and

their ability to maintain required thermal conductance levels.

3.2.14 T —temperature of one surface of the specimen, °C

(°F).

6. Apparatus

3.2.15 T —temperature of the other surface of the speci-

men, °C (°F). 6.1 A schematic rendering of a typical apparatus is shown in

Fig. 1. The relative position of the HFT to sample is not

3.2.16 Tm—mean temperature of the specimen, °C (°F).

3.2.17 —unknown specimen. important (it may be on the hot or cold side) as the test method

s

3.2.18 —known calibration or reference specimen. is based on maintaining axial heat flow with minimal heat

r

3.2.19 —contacts. losses or gains radially. It is also up to the designer whether to

o

choose heat flow upward or downward or horizontally, al-

4. Summary of Test Method

though downward heat flow in a vertical stack is the most

4.1 A specimen and a heat flux transducer (HFT) are common one.

sandwiched between two flat plates controlled at different 6.2 Key Components of a Typical Device (The numbers 1 to

temperatures, to produce a heat flow through the test stack. A 22 in parentheses refer to Fig. 1):

reproducible load is applied to the test stack by pneumatic or 6.2.1 The compressive force for the stack is to be provided

hydraulic means, to ensure that there is a reproducible contact by either a regulated pneumatic or hydraulic cylinder (1) or a

resistance between the specimen and plate surfaces. A cylin- spring loaded mechanism. In either case, means must be

drical guard surrounds the test stack and is maintained at a provided to ensure that the loading can be varied and set to

uniform mean temperature of the two plates, in order to certain values reproducibility.

minimize lateral heat flow to and from the stack. At steady 6.2.2 The loading force must be transmitted to the stack

state, the difference in temperature between the surfaces through a gimball joint (2) that allows up to 5° swivel in the

contacting the specimen is measured with temperature sensors plane perpendicular to the axis of the stack.

embedded in the surfaces, together with the electrical output of 6.2.3 Suitable insulator plate (3) separates the gimball joint

the HFT. This output (voltage) is proportional to the heat flow from the top plate (4).

FIG. 1 Key Components of a Typical Device

E1530–99

6.2.4 The top plate (assumed to be the hot plate for the 6.3.2 Reproducible load of 0.28 MPa (40 psi) has been

purposes of this description) is equipped with a heater (5) and found to be satisfactory for solid samples. Minimum load shall

control thermocouple (6) adjacent to the heater, to maintain a not be below 0.07 MPa (10 psi).

certain desired temperature. (Other means of producing and 6.3.3 Temperature sensors are usually fine gage or small-

maintaining temperature may also be used as long as the diameter sheath thermocouples, however, ultraminiature resis-

requirements in 6.3 are met.) The construction of the top plate tance thermometers and linear thermistors may also be used.

is such as to ensure uniform heat distribution across its face 6.3.4 Operating range of a device using a mean temperature

contacting the sample (8). Attached to this face (or embedded guard shall be limited to from −100 to 300°C, when using

in close proximity to it) in a fashion that does not interfere with thermocoupules as temperature sensors, and from −180 to

the sample/plate interface, is a temperature sensor (7) (typi- 300°C with platinum resistance thermometers.

cally a thermocouple, thermistor) that defines the temperature

7. Sampling and Conditioning

of the interface on the plate side.

6.2.5 The sample (8) is in direct contact with the top plate

7.1 Cut representative test specimens from larger pieces of

on one side and an intermediate plate (9) on the other side.

the sample material or body.

6.2.6 The intermediate plate (9) is an optional item. Its

7.2 Condition the cut specimens in accordance with the

purpose is to provide a highly conductive environment to the

requirements of the appropriate material specifications if any.

second temperature sensor (10), to obtain an average tempera-

ture of the surface. If the temperature sensor (10) is embedded 8. Test Specimen

into the face of the HFT, or other means are provided to define

8.1 The specimen to be tested should be representative for

the temperature of the surface facing the sample, the use of the

the sample material. The recommended specimen configura-

intermediate plate is not mandatory.

tion is a 50.86 0.25-mm (2 6 0.010-in.) diameter disk, having

6.2.7 The heat flux transducer (HFT) is a device that will

smooth flat and parallel faces, 6 0.025 mm (6 0.001 in.), such

generate an electrical signal in proportion to the heat flux

that a uniform thickness within 0.025 mm (6 0.001 in.) is

across it. The level of output required (sensitivity) greatly

attained in the range from 0.5 to 25.4 (0.020 to 1.0 in.) For

depends on the rest of the instrumentation used to read it. The

testing specimens with thicknesses below 0.5 mm, a special

overall performance of the HFT and its readout instrumentation

technique, described in Annex A1, has to be used.

shall be such as to meet the requirements in Section 13.

6.2.8 The lower plate (12) is constructed similarly to the

9. Calibration

upper plate (4), except it is positioned as a mirror image.

9.1 Select the mean temperature and load conditions re-

6.2.9 An insulator plate (16) separates the lower plate (12)

quired. Adjust the upper heater temperature (T ) and lower

u

from the heat sink (17). In case of using circulating fluid in

heater temperature (T ) such that the temperature difference at

l

place of a heater/thermocouple arrangement in the upper or

the required mean temperature is no less than 30 to 35°C and

lower plates, or both, the heat sink may or may not be present.

the specimen DT is not less than 3°C). Adjust the guard heater

6.2.10 The entire stack is surrounded by a cylindrical guard

temperature (T ) such that it is at approximately the average of

g

(18) equipped with a heater (19) and a control thermocouple

T and T .

u l

(20) to maintain it at the mean temperature between the upper

9.2 Select at least two calibration specimens having thermal

and lower plates. A small, generally unfilled, gap separates the

resistance values that bracket the range expected for the test

guard from the stack. For instruments limited to operate in the

specimens at the temperature conditions required.

ambient region, no guard is required. A draft shield is recom-

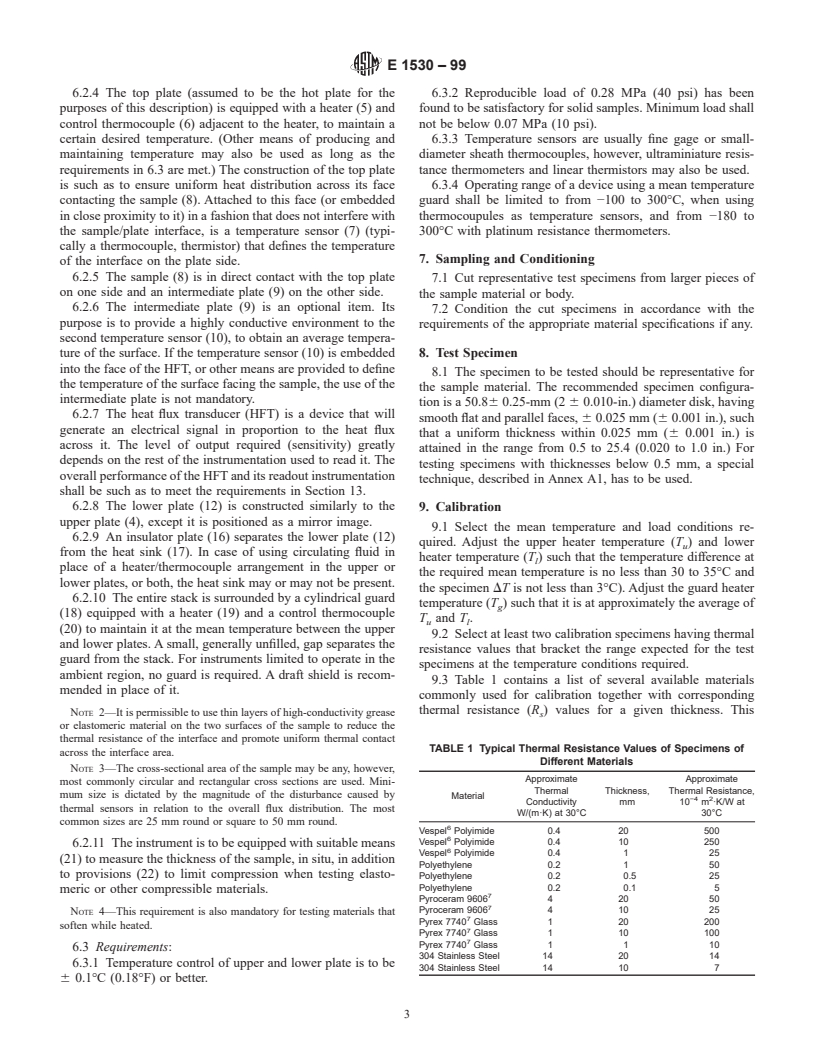

9.3 Table 1 contains a list of several available materials

mended in place of it.

commonly used for calibration together with corresponding

thermal resistance (R ) values for a given thickness. This

NOTE 2—It is permissible to use thin layers of high-conductivity grease

s

or elastomeric material on the two surfaces of the sample to reduce the

thermal resistance of the interface and promote uniform thermal contact

TABLE 1 Typical Thermal Resistance Values of Specimens of

across the interface area.

Different Materials

NOTE 3—The cross-sectional area of the sample may be any, however,

Approximate Approximate

most commonly circular and rectangular cross sections are used. Mini-

Thermal Thickness, Thermal Resistance,

mum size is dictated by the magnitude of the disturbance caused by

Material

−4 2

Conductivity mm 10 m ·K/W at

thermal sensors in relation to the overall flux distribution. The most

W/(m·K) at 30°C 30°C

common sizes are 25 mm round or square to 50 mm round.

Vespel Polyimide 0.4 20 500

Vespel Polyimide 0.4 10 250

6.2.11 The instrument is to be equipped with suitable means

Vespel Polyimide 0.4 1 25

(21) to measure the thickness of the sample, in situ, in addition

Polyethylene 0.2 1 50

to provisions (22) to limit compression when testing elasto-

Polyethylene 0.2 0.5 25

Polyethylene 0.2 0.1 5

meric or other compressible materials.

Pyroceram 9606 420 50

Pyroceram 9606 410 25

NOTE 4—This requirement is also mandatory for testing materials that

Pyrex 7740 Glass 1 20 200

soften while heated.

Pyrex 7740 Glass 1 10 100

Pyrex 7740 Glass 1 1 10

6.3 Requirements:

304 Stainless Steel 14 20 14

6.3.1 Temperature control of upper and lower plate is to be

304 Stainless Steel 14 10 7

6 0.1°C (0.18°F) or better.

E1530–99

information is provided to assist the user in selecting optimum 10.7.4 Repeat 10.3-10.5 using the test specimen. For com-

specimen thickness for testing a material and in deciding which pressible materials, it is mandatory to measure in situ the

calibration specimens to use. sample thickness under load, and to limit further compression

9.4 The range of thermal conductivity for which this test by suitable mechanical stop.

method is most suitable is such that the optimum thermal 10.8 Thermal Conductivity of Thin Specimens—For speci-

−4 −4 2

resistance range is from 10 3 10 to 400 3 10 m ·K/W. The mens less than approximately 0.5 mm (0.020 in.) in thickness

most commonly used calibration materials are the Pyrex 7740 (and less than 1 mm (0.040 in.) having l greater than 0.5

and Pyroceram 9606 , Vespel (polyimide) and stainless steel all W/(m·K)), a special stacking technique can be used. This is

having a well-established thermal conductivity as a function of described in de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.