ASTM D2583-06

(Test Method)Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

SCOPE

1.1 This test method covers the determination of indentation hardness of both reinforced and nonreinforced rigid plastics using a Barcol Impressor, Model No. 934-1 and Model No. 935.

1.2 The values stated in SI units are to be regarded as standard. The values given in brackets are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1

There is no known ISO equivalent to this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

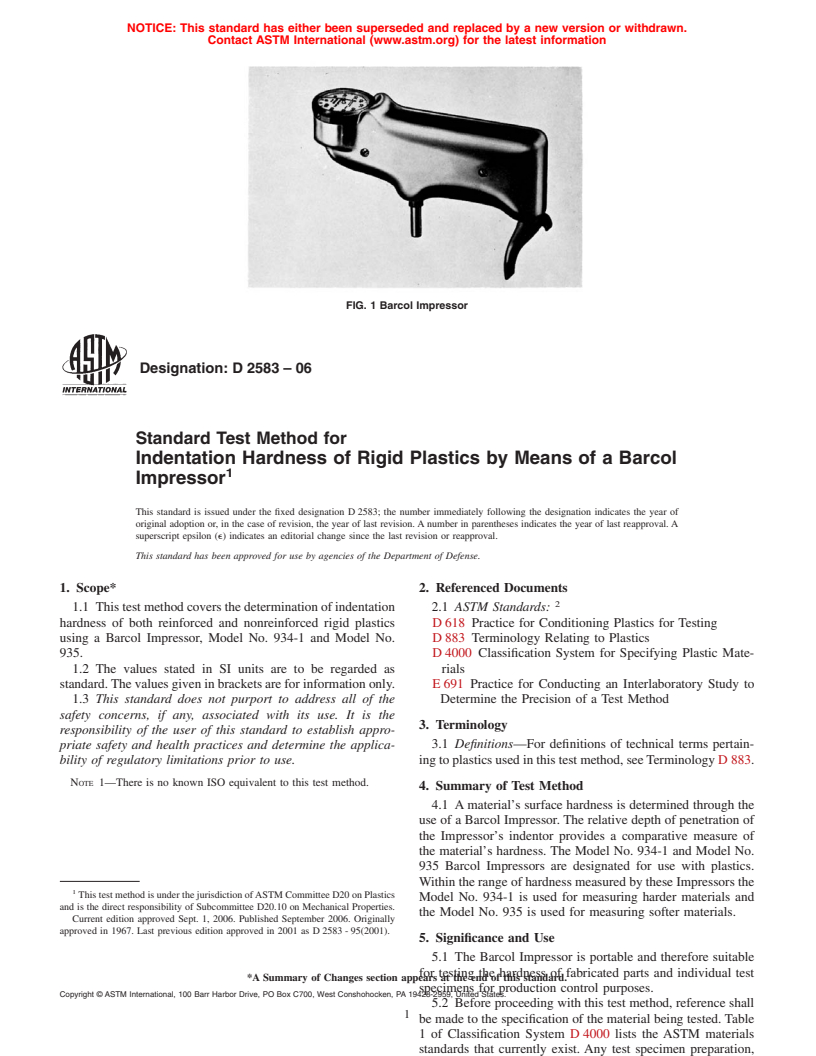

FIG. 1 Barcol Impressor

Designation:D2583–06

Standard Test Method for

Indentation Hardness of Rigid Plastics by Means of a Barcol

1

Impressor

This standard is issued under the fixed designation D 2583; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 Thistestmethodcoversthedeterminationofindentation 2.1 ASTM Standards:

hardness of both reinforced and nonreinforced rigid plastics D 618 Practice for Conditioning Plastics for Testing

using a Barcol Impressor, Model No. 934-1 and Model No. D 883 Terminology Relating to Plastics

935. D 4000 Classification System for Specifying Plastic Mate-

1.2 The values stated in SI units are to be regarded as rials

standard.Thevaluesgiveninbracketsareforinformationonly. E 691 Practice for Conducting an Interlaboratory Study to

1.3 This standard does not purport to address all of the Determine the Precision of a Test Method

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1 Definitions—For definitions of technical terms pertain-

ingtoplasticsusedinthistestmethod,seeTerminologyD 883.

bility of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this test method.

4. Summary of Test Method

4.1 Amaterial’s surface hardness is determined through the

use of a Barcol Impressor. The relative depth of penetration of

the Impressor’s indentor provides a comparative measure of

the material’s hardness. The Model No. 934-1 and Model No.

935 Barcol Impressors are designated for use with plastics.

Within the range of hardness measured by these Impressors the

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

Model No. 934-1 is used for measuring harder materials and

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

the Model No. 935 is used for measuring softer materials.

Current edition approved Sept. 1, 2006. Published September 2006. Originally

approved in 1967. Last previous edition approved in 2001 as D 2583 - 95(2001).

5. Significance and Use

5.1 The Barcol Impressor is portable and therefore suitable

for testing the hardness of fabricated parts and individual test

*A Summary of Changes section appears at the end of this standard.

specimens for production control purposes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

5.2 Before proceeding with this test method, reference shall

1

be made to the specification of the material being tested. Table

1 of Classification System D 4000 lists the ASTM materials

standards that currently exist. Any test specimen preparation,

---------------------- Page: 1 ----------------------

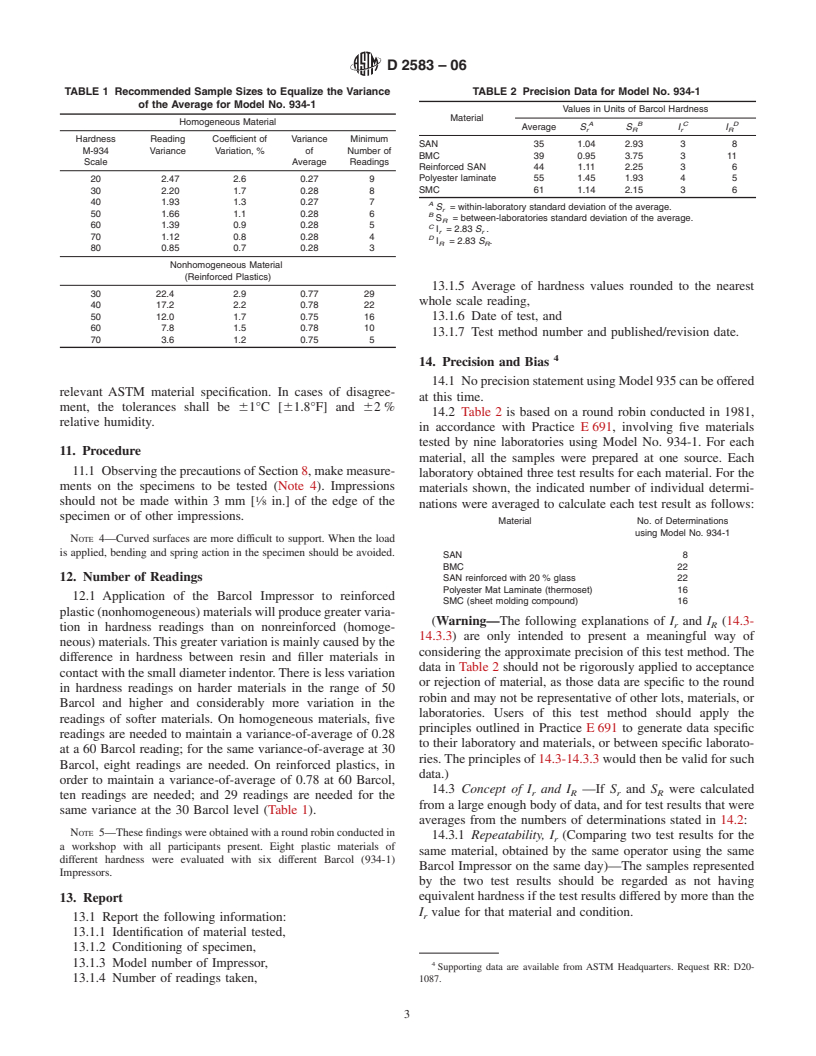

D2583–06

FIG. 2 Diagram of Barcol Impressor

6. Apparatus ( Fig. 1 and Fig. 2) thickness, so that the indentor is perpendicular to the surface

3 being tested. Grasp the instrument firmly between the legs and

6.1 Indentor —The indentor shall consist of a hardened

point sleeve. Apply a uniform downward force quickly, by

steel truncated cone having an angle of 26° with a flat tip of

hand, increasing the force on the case until the dial indication

0.157 mm [0.0062 in.] in diameter. It shall fit into a hollow

reaches a maximum (Note 3). Take care to avoid sliding or

spindle and be held down by a spring-loaded plunger. See Fig.

scraping while the indentor is in contact with the surface being

2.

tested. Record the maximum reading.

6.2 Indicating Device—The indicating dial shall have 100

divisions, each representing a depth of 0.0076-mm [0.0003-in.]

NOTE 2—It is recommended that measurements be made with the

penetration. The higher the reading is, the harder the material Model 934-1 Impressor when values above 90 are obtained with the

Model 935 Impressor and that measurements be made with the Model 935

is.

Impressor when values less than 20 are obtained with the Model No.

6.3 Calibration Standards—“Hard” and “soft” aluminum

934-1 Impressor. Values below 10 using the Model 935 Impressor are

alloy disks supplied by the manufacturer of the instrument.

inexact and should not be reported.

Other disks should not be used, even if they are of the same

NOTE 3—Drift in readings from the maximum occurs in some materials

alloy and temper as the manufacturer’s disks, as the hardness

and can be nonlinear with time.

of aluminum varies within any given alloy-temper param

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.