ASTM G120-15

(Practice)Standard Practice for Determination of Soluble Residual Contamination by Soxhlet Extraction

Standard Practice for Determination of Soluble Residual Contamination by Soxhlet Extraction

SIGNIFICANCE AND USE

5.1 It is expected that this practice will be suitable to identify and quantify contaminants found in systems, system materials, and components used in systems requiring a high level of cleanliness, such as components for oxygen service. Nonmetallic piece parts such as seals and valve seats can be tested as received. Warning—If parts being tested are to be subsequently installed in an oxygen-enriched system, residual extraction solvent remaining in the part due to inadequate drying may increase the susceptibility of the system to ignition. The extraction solvent shall be thoroughly removed from the parts prior to service.

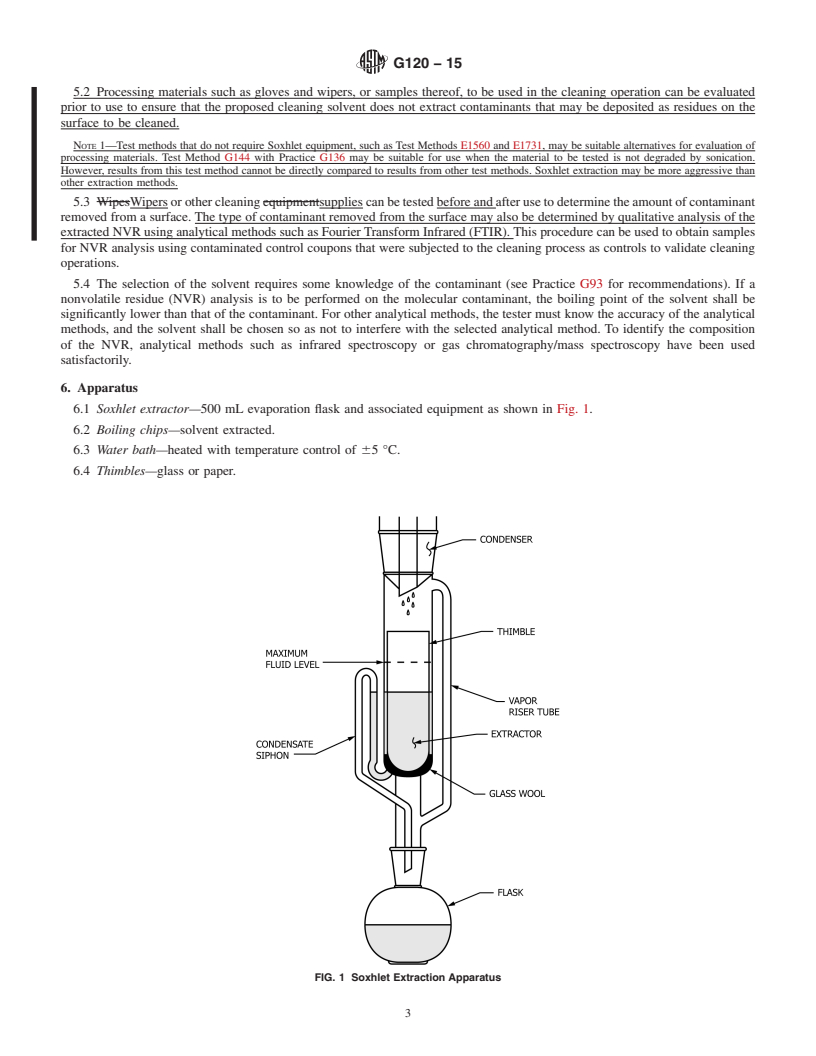

5.2 Processing materials such as gloves and wipers, or samples thereof, to be used in the cleaning operation can be evaluated prior to use to ensure that the proposed cleaning solvent does not extract contaminants that may be deposited as residues on the surface to be cleaned.

Note 1: Test methods that do not require Soxhlet equipment, such as Test Methods E1560 and E1731, may be suitable alternatives for evaluation of processing materials. Test Method G144 with Practice G136 may be suitable for use when the material to be tested is not degraded by sonication. However, results from this test method cannot be directly compared to results from other test methods. Soxhlet extraction may be more aggressive than other extraction methods.

5.3 Wipers or other cleaning supplies can be tested before and after use to determine the amount of contaminant removed from a surface. The type of contaminant removed from the surface may also be determined by qualitative analysis of the extracted NVR using analytical methods such as Fourier Transform Infrared (FTIR). This procedure can be used to obtain samples for NVR analysis using contaminated control coupons that were subjected to the cleaning process as controls to validate cleaning operations.

5.4 The selection of the solvent requires some knowledge of the contaminant (see Practice G93 for recommenda...

SCOPE

1.1 This practice describes a procedure for the determination of residual contamination in materials to be used within or in contact with hardware requiring a high level of cleanliness, such as components for oxygen service, by Soxhlet extraction.

1.2 This practice may be used for extracting nonvolatile and semivolatile residues from solids such as new and used gloves, new and used wipers, contaminated test specimens or control coupons, small piece parts (metallic or nonmetallic), etc. When used with proposed consumable cleaning materials (wipers, gloves, etc.), this practice may be used to determine the potential of the proposed solvent to extract contaminants (plasticizers, residual detergents, brighteners, etc.) from the cleaning material and deposit them on the surface being cleaned.

1.3 This practice is not suitable for the evaluation of particulate contamination.

1.4 The values stated in SI units are standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G120 − 15

Standard Practice for

Determination of Soluble Residual Contamination by

1

Soxhlet Extraction

This standard is issued under the fixed designation G120; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope volatile Residue From Cleanroom Wipers

E1731 Test Method for Gravimetric Determination of Non-

1.1 This practice describes a procedure for the determina-

volatile Residue from Cleanroom Gloves

tion of residual contamination in materials to be used within or

F331 Test Method for Nonvolatile Residue of Solvent Ex-

in contact with hardware requiring a high level of cleanliness,

tract from Aerospace Components (Using Flash Evapora-

such as components for oxygen service, by Soxhlet extraction.

tor)

1.2 This practice may be used for extracting nonvolatile and

G93 Practice for Cleaning Methods and Cleanliness Levels

semivolatile residues from solids such as new and used gloves,

for Material and Equipment Used in Oxygen-Enriched

new and used wipers, contaminated test specimens or control

Environments

coupons, small piece parts (metallic or nonmetallic), etc. When

G127 Guide for the Selection of Cleaning Agents for

used with proposed consumable cleaning materials (wipers,

Oxygen-Enriched Systems

gloves, etc.), this practice may be used to determine the

G136 Practice for Determination of Soluble Residual Con-

potential of the proposed solvent to extract contaminants

taminants in Materials by Ultrasonic Extraction

(plasticizers, residual detergents, brighteners, etc.) from the

G144 Test Method for Determination of Residual Contami-

cleaning material and deposit them on the surface being

nation of Materials and Components by Total Carbon

cleaned.

Analysis Using a High Temperature Combustion Analyzer

1.3 This practice is not suitable for the evaluation of

particulate contamination. 3. Terminology

1.4 The values stated in SI units are standard. 3.1 Definitions:

3.1.1 contaminant, n—unwanted molecular and particulate

1.5 This standard does not purport to address all of the

matter that could affect the performance of the components or

safety concerns, if any, associated with its use. It is the

materials upon which they reside.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.2 contamination, n—a process of contaminating.

bility of regulatory limitations prior to use.

3.1.3 control coupon (witness coupon), n—a coupon made

from the same material and prepared in exactly the same way

2. Referenced Documents

as the test coupons, and which is used to verify the validity of

2

2.1 ASTM Standards:

the method or part thereof.

D1193 Specification for Reagent Water

3.1.3.1 Discussion—In this test method, the control coupon

E1235 Test Method for Gravimetric Determination of Non-

will be contaminated in the same manner as the test coupons

volatile Residue (NVR) in Environmentally Controlled

and will be subjected to the identical extraction procedure.

Areas for Spacecraft

3.1.4 molecular contaminant, n—non-particulate contami-

E1560 Test Method for Gravimetric Determination of Non-

nation.

3.1.4.1 Discussion—A molecular contaminant may be in a

gaseous, liquid, or solid state and may be uniformly or

1

This practice is under the jurisdiction of ASTM Committee G04 on Compat-

non-uniformly distributed.

ibility and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the

direct responsibility of Subcommittee G04.02 on Recommended Practices.

3.1.4.2 Discussion—Molecular contaminants account for

Current edition approved Oct. 1, 2015. Published October 2015. Originally

most of the NVR.

approved in 1993. Last previous edition approved in 2008 as G120 – 01(2008).

DOI: 10.1520/G0120-15.

3.1.5 nonvolatile residue (NVR), n—residual molecular and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

particulate matter remaining following the filtration of a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

solvent containing contaminants and complete evaporation of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the solvent at a specified temperature.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G120 − 15

3.1.6 particle (particulate contaminant), n—a piece of mat- composition of the NVR, analytical methods such as infrared

ter in a solid state with observable length, width, and thickness. spectroscopy or

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G120 − 01 (Reapproved 2008) G120 − 15

Standard Practice for

Determination of Soluble Residual Contamination by

1

Soxhlet Extraction

This standard is issued under the fixed designation G120; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes a procedure for the determination of residual contamination in systems and components materials

to be used within or in contact with hardware requiring a high level of cleanliness, such as oxygen, components for oxygen service,

by Soxhlet extraction.

1.2 This practice may be used for extracting nonvolatile and semivolatile residues from solids such as new and used gloves, new

and used wipes,wipers, contaminated test specimens or control coupons, small pieces of hardware, component softgoods,piece

parts (metallic or nonmetallic), etc. When used with proposed consumable cleaning materials (wipes,(wipers, gloves, etc.), from

the cleaning materials this practice may be used to determine the potential of the proposed solvent to extract contaminants

(plasticizers, residual detergents, brighteners, etc.) from the cleaning material and deposit them on the surface being cleaned.

1.3 This practice is not suitable for the evaluation of particulate contamination.

1.4 The values stated in SI units are standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E1235 Test Method for Gravimetric Determination of Nonvolatile Residue (NVR) in Environmentally Controlled Areas for

Spacecraft

E1560 Test Method for Gravimetric Determination of Nonvolatile Residue From Cleanroom Wipers

E1731 Test Method for Gravimetric Determination of Nonvolatile Residue from Cleanroom Gloves

F331 Test Method for Nonvolatile Residue of Solvent Extract from Aerospace Components (Using Flash Evaporator)

G93 Practice for Cleaning Methods and Cleanliness Levels for Material and Equipment Used in Oxygen-Enriched Environments

G127 Guide for the Selection of Cleaning Agents for Oxygen-Enriched Systems

G136 Practice for Determination of Soluble Residual Contaminants in Materials by Ultrasonic Extraction

G144 Test Method for Determination of Residual Contamination of Materials and Components by Total Carbon Analysis Using

a High Temperature Combustion Analyzer

3. Terminology

3.1 Definitions:

3.1.1 contaminant, n—unwanted molecular and particulate matter that could affect the performance of the components or

materials upon which they reside.

3.1.2 contamination, n—a process of contaminating.

1

This practice is under the jurisdiction of ASTM Committee G04 on Compatibility and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

responsibility of Subcommittee G04.02 on Recommended Practices.

Current edition approved Sept. 1, 2008Oct. 1, 2015. Published October 20082015. Originally approved in 1993. Last previous edition approved in 20012008 as

G120 – 01.G120 – 01(2008). DOI: 10.1520/G0120-01R08.10.1520/G0120-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G120 − 15

3.1.3 control coupon (witness coupon), n—a coupon made from the same material and prepared in exactly the same way as the

test coupons, and which is used to verify the validity of the method or part thereof.

3.1.3.1 Discussion—

In this test method, the control coupon will be contaminated in the same manner as the test coupons and will be subjected to the

identical extraction procedure.

3.1.4 molecular contaminant, n—non-particulate contamination.

3.1.4.1 Discussion—

A molecular contaminant may be in a gaseous, liquid, or solid state and may be uniformly or non-uniformly distributed.

3.1.4.2 Discussion—

Molecular contaminants ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.