ASTM F1385-07(2018)

(Practice)Standard Practice for Platforms in Cargo Tanks

Standard Practice for Platforms in Cargo Tanks

SIGNIFICANCE AND USE

3.1 This practice establishes the procedure for the construction and installation of platforms to be fabricated and installed by the shipyards within the cargo tanks.

SCOPE

1.1 This practice provides design, construction, and installation criteria for platforms in cargo tanks.

1.2 Where platforms are attached to ladders see Figs. 1-4.

FIG. 1 Cargo Platform—Bulkhead

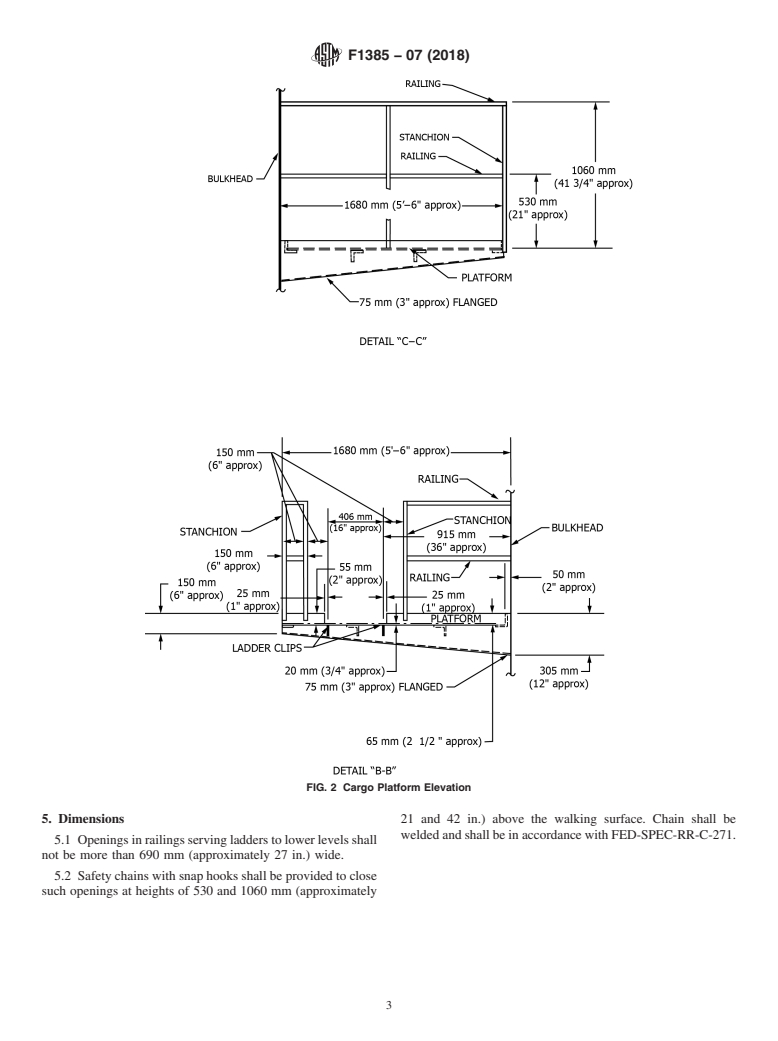

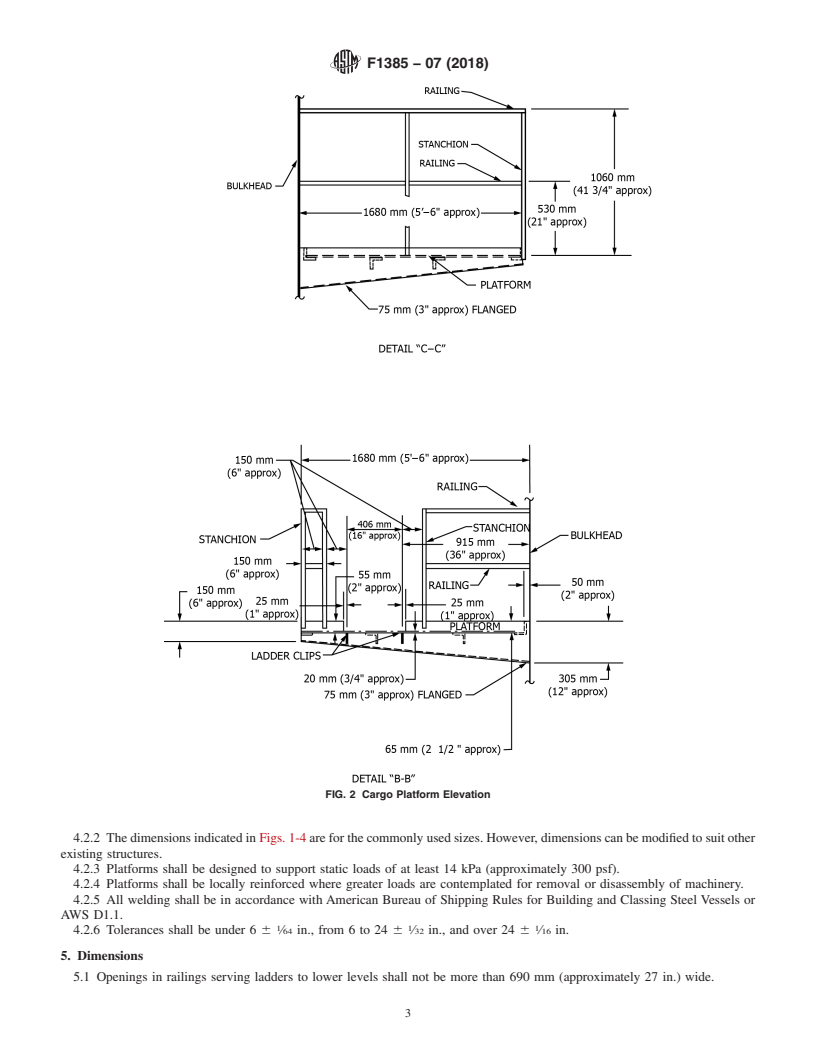

FIG. 2 Cargo Platform Elevation

FIG. 3 Cargo Platform—Girder

FIG. 4 Cargo Platforms Showing Typical Sections

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are included for information only and are not considered standard

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1385 − 07 (Reapproved 2018) An American National Standard

Standard Practice for

1

Platforms in Cargo Tanks

This standard is issued under the fixed designation F1385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

5

1. Scope 2.4 ABS Standard:

American Bureau of Shipping Rules for Building and

1.1 This practice provides design, construction, and instal-

Classing Steel Vessels

lation criteria for platforms in cargo tanks.

6

2.5 AWS Standard:

1.2 Where platforms are attached to ladders see Figs. 1-4.

AWS D1.1 Structural Welding Code—Steel

1.3 The values stated in SI units are to be regarded as

2.6 Other Standards:

standard. The values given in parentheses after SI units are

SAE-AMS-C-27725 Coatings, Corrosion Preventative,

included for information only and are not considered standard

Polyurethane, for Aircraft Integral Fuel Tanks for Use to

3

250 Degrees F (121 Degrees C)

1.4 This standard does not purport to address all of the

7

Steel Structures Painting Council Specification

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1 This practice establishes the procedure for the construc-

1.5 This international standard was developed in accor-

tion and installation of platforms to be fabricated and installed

dance with internationally recognized principles on standard- by the shipyards within the cargo tanks.

ization established in the Decision on Principles for the

4. Materials and Manufacture

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 Materials:

Barriers to Trade (TBT) Committee.

4.1.1 Gratings—Only MIL-G-18015 Type I and Type III

gratings are to be used.

2. Referenced Documents

4.1.2 Flanged Plate Supports—Fabricated from 10 by 380

2

3

2.1 ASTM Standards: mm (approximately ⁄8 by 15 in.) with a 75-mm (approximately

A36/A36M Specification for Carbon Structural Steel 3-in.) flange of carbon steel plate in accordance with Specifi-

3

cation A36/A36M.

2.2 Military Specification:

4.1.3 Angle Supports—75- by 75- by 10-mm (approxi-

MIL-G-18015 Grating, Metal, Other than Bar Type (Ship-

3

mately 3- by 3- by ⁄8-in.) structural angles of carbon steel in

board Use)

4 accordance with Specification A36/A36M.

2.3 Federal Standard:

4.1.4 Stanchions and railings—25 mm (approximately 1 in)

FED-SPEC-RR-C-271 Chain and Attachments, Welded and

diameter carbon steel in accordance with Specification A36/

Weldless

A36M.

4.1.5 Ladder Clips are to be made in accordance with

Specification A36/A36M.

4.2 Manufacture:

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

4.2.1 Platforms shall be constructed as shown in Figs. 1-4.

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery. 4.2.2 The dimensions indicated in Figs. 1-4 are for the

Current edition approved April 1, 2018. Published May 2018. Originally

commonly used sizes. However, dimensions can be modified to

approved in 1992. Last previous edition approved in 2012 as F1385 – 07 (2012).

suit other existing structures.

DOI: 10.1520/F1385-07R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5

Standards volume information, refer to the standard’s Document Summary page on Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

the ASTM website. Northchase Dr., Houston, TX 77060, http://www.eagle.org.

3 6

Available from Naval Sea Systems Command (NAVSEA), 1333 Isaac Hull Available from American Welding Society (AWS), 8669 NW 36 St., #130,

Ave., SE, Washington Navy Yard, DC 20376, http://www.navsea.navy.mil. Miami, FL 33166-6672, http://www.aws.org.

4 7

Available from DLA Document Services, Building 4/D, 700 Robbins Ave., Available from Society for Protective Coatings (SSPC), 800 Trumbull Dr.,

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil. Pittsburgh, PA 15205, http://www.sspc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1385 − 07 (2018)

FIG. 1 Cargo Platform—Bulkhead

4.2.3 Platforms shall be designed to support static loads of 4.2.5 All welding shall be in accordance with American

at least 14 kPa (approximately 300 psf). Bureau of Shipp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1385 − 07 (Reapproved 2012) F1385 − 07 (Reapproved 2018)An American National Standard

Standard Practice for

1

Platforms in Cargo Tanks

This standard is issued under the fixed designation F1385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides design, construction, and installation criteria for platforms in cargo tanks.

1.2 Where platforms are attached to ladders see Figs. 1-4.

1.3 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound units values given in parentheses

are for information only.after SI units are included for information only and are not considered standard

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

3

2.2 Military Specification:

MIL-G-18015 Grating, Metal, Other than Bar Type (Shipboard Use)

4

2.3 Federal Standard:

FED-SPEC-RR-C-271 Chain and Attachments, Welded and Weldless

5

2.4 ABS Standard:

American Bureau of Shipping Rules for Building and Classing Steel Vessels

6

2.5 AWS Standard:

AWS D1.1 Structural Welding Code—Steel

2.6 Other Standards:

SAE-AMS-C-27725 Coatings, Corrosion Preventative, Polyurethane, for Aircraft Integral Fuel Tanks for Use to 250 Degrees F

3

(121 Degrees C)

7

Steel Structures Painting Council Specification

3. Significance and Use

3.1 This practice establishes the procedure for the construction and installation of platforms to be fabricated and installed by

the shipyards within the cargo tanks.

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.03 on Outfitting

and Deck Machinery.

Current edition approved June 1, 2012April 1, 2018. Published October 2012May 2018. Originally approved in 1992. Last previous edition approved in 20072012 as F1385

– 07. – 07 (2012). DOI: 10.1520/F1385-07R12.10.1520/F1385-07R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Naval Sea Systems Command (NAVSEA), 1333 Isaac Hull Ave., SE, Washington Navy Yard, DC 20376, http://www.navsea.navy.mil.

4

Available from DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

5

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Northchase Dr., Houston, TX 77060, http://www.eagle.org.

6

Available from American Welding Society (AWS), 8669 NW 36 St., #130, Miami, FL 33166-6672, http://www.aws.org.

7

Available from Society for Protective Coatings (SSPC), 800 Trumbull Dr., Pittsburgh, PA 15205, http://www.sspc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1385 − 07 (2018)

FIG. 1 Cargo Platform—Bulkhead

4. Materials and Manufacture

4.1 Materials:

4.1.1 Gratings—Only MIL-G-18015 Type I and Type III gratings are to be used.

3

4.1.2 Flanged Plate Supports—Fabricated from 10 by 380 mm (approximately ⁄8 by 15 in.) with a 75-mm (approximately 3-in.)

flange of carbon steel plate in accordance with Specification A36/A36M.

3

4.1.3 Angle Supports—75- by 75- by 10-mm (approximately 3- by 3- by ⁄8-in.) structural angles of carbon steel in accordance

with Specification A36/A36M.

4.1.4 Stanchions and railings—25 mm (approximately 1 in) diameter carbon steel in accordance with Specification A36/A36M.

4.1.5 Ladder Clips are to be made in accordance with Specification A36/A36M.

4.2 Manufactu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.