ASTM E959-83(2010)

(Test Method)Standard Test Method for Characterizing the Performance of Refuse Size-Reduction Equipment

Standard Test Method for Characterizing the Performance of Refuse Size-Reduction Equipment

SIGNIFICANCE AND USE

Throughput, power and energy requirements, and product size are key parameters that describe the operation and performance of solid waste size-reduction equipment.

This test method can be used to determine if the size-reduction equipment is operating within specifications and meeting performance criteria.

Having determined the parameters given in 5.1, the equipment that has been subjected to the test may be compared to other equipment similarly tested in order to establish relative levels of performance among equipment.

The basic test period is a continuous two to four h duration. The use of several test periods may be warranted to assess adequately the performance of size reduction equipment.

SCOPE

1.1 This test method covers measuring the performance of solid waste size reduction equipment.

1.2 This test method can be used to measure the flow (that is, throughput) of solid waste through the size-reduction equipment, energy usage of the size-reduction device, and particle size of the shredded product.

1.3 This test method includes instructions for measuring energy usage, solid waste throughput, net processing time, and particle size distribution.

1.4 This test method applies only to size reduction equipment that produces a shredded product with a size corresponding to 90 % cumulative passing in the range of 0.5 to 15 cm (0.2–6 in.) on an air-dry weight basis. For material with nominal sizes outside of this range, the precision and bias statements for particle size designation (Section 15) may not apply.

1.5 This test method can be applied to size reduction equipment located anywhere within a processing line.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 Exception—The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 7 for specific hazard information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E959 − 83 (Reapproved 2010)

Standard Test Method for

Characterizing the Performance of Refuse Size-Reduction

1

Equipment

This standard is issued under the fixed designation E959; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers measuring the performance of 2.1 ASTM Standards:

solid waste size reduction equipment. E828 Test Method for Designating the Size of RDF-3 From

3

its Sieve Analysis (Withdrawn 2009)

1.2 This test method can be used to measure the flow (that

E929 Test Method for Measuring Electrical Energy Require-

is, throughput) of solid waste through the size-reduction

ments of Processing Equipment

equipment, energy usage of the size-reduction device, and

particle size of the shredded product.

3. Terminology Definitions:

1.3 This test method includes instructions for measuring

3.1 characteristic product size—the screen size correspond-

energy usage, solid waste throughput, net processing time, and

ing to 63.2 % cumulative passing by weight.

particle size distribution.

3.2 discrete throughput method—the method whereby av-

1.4 This test method applies only to size reduction equip-

erage throughput is calculated as the average of a number of

ment that produces a shredded product with a size correspond-

discrete throughput measurements conducted during a test

ing to 90 % cumulative passing in the range of 0.5 to 15 cm

period.

(0.2–6 in.) on an air-dry weight basis. For material with

3.3 idling time—time periods during which a size reduction

nominal sizes outside of this range, the precision and bias

device is freewheeling, that is, not processing refuse.

statements for particle size designation (Section 14) may not

3.4 net processing time—the time during which refuse is

apply.

processed through the size reduction device.

1.5 This test method can be applied to size reduction

3.5 nominal product size—the screen size corresponding to

equipment located anywhere within a processing line.

90 % cumulative passing by weight.

1.6 The values stated in SI units are to be regarded as

3.6 size reduction device or equipment—a device which size

standard. No other units of measurement are included in this

reduces (Synonyms: shredder, grinder, pulverizer, and mill).

standard.

1.6.1 Exception—The values given in parentheses are for

3.7 stationary belt method—a method of gross sample

information only.

collectioninwhichtheconveyorbeltisstoppedandthesample

1.7 This standard does not purport to address all of the of material is removed manually.

safety concerns, if any, associated with its use. It is the

3.8 time-averaged throughput method—the method

responsibility of the user of this standard to establish appro-

whereby the average throughput is calculated by dividing the

priate safety and health practices and determine the applica-

total mass size reduced by the net processing time.

bility of regulatory limitations prior to use. See Section 7 for

3.9 test interval—a test interval is equal to one-quarter of

specific hazard information.

the test period.

1 2

This test method is under the jurisdiction of ASTM Committee D34 on Waste For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Management and is the direct responsibility of Subcommittee D34.03 on Treatment, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Recovery and Reuse. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2010. Published January 2011. Originally the ASTM website.

3

approved in 1983. Last previous edition approved in 2005 as E959-83 (2005). DOI: The last approved version of this historical standard is referenced on

10.1520/E0959-83R10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E959 − 83 (2010)

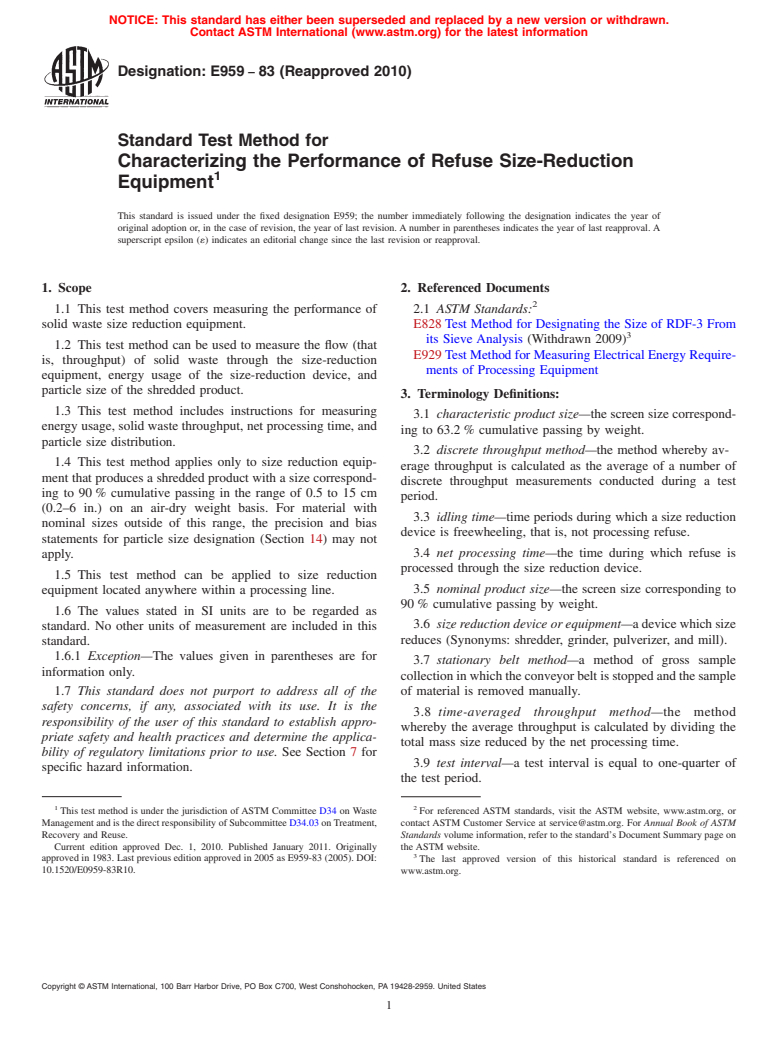

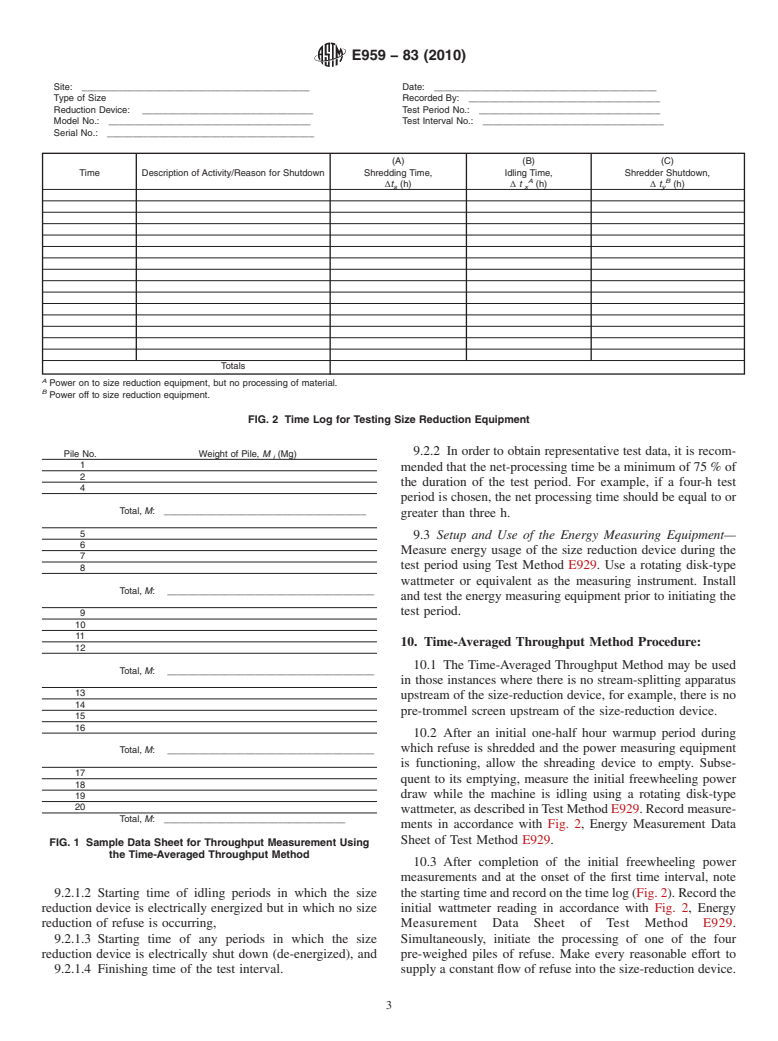

3.10 test period—the test period is two to four continuous h consistoflockoutoftheelectricalpowertotheconveyor,ready

of net-processing time. access to a safety “stop” cord located on the conveyor, or both.

7.2 This test method requires installation of electrical me-

4. Summary of Test Method

tering equipment. Consequently, the precautions described in

4.1 The duration of the test period is established and refuse

Test Method E929 should be observed.

is prepared for processing.

7.3 Gross samples should be collected sufficiently far from

4.2 An energy measuring system is installed.

the size reduction equipment such that test personnel ar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.