ASTM A689-97(2002)

(Specification)Standard Specification for Carbon and Alloy Steel Bars for Springs

Standard Specification for Carbon and Alloy Steel Bars for Springs

SCOPE

1.1 This specification covers hot-wrought steel bars to be used for the manufacture of general-purpose springs such as coil, torsion, and leaf.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 689 – 97 (Reapproved 2002)

Standard Specification for

Carbon and Alloy Steel Bars for Springs

This standard is issued under the fixed designation A 689; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 AISI grade number indicating the chemical composi-

tion (see 5.1), special chemistry required (see 5.2), or harden-

1.1 This specification covers hot-wrought steel bars to be

ability (see 5.3),

used for the manufacture of general-purpose springs such as

3.1.3 Quantity (number of bars or weight),

coil, torsion, and leaf.

3.1.4 Cross section description and dimensions or drawings

1.2 The values stated in inch-pound units are to be regarded

of section,

as the standard.

3.1.5 Bar lengths,

2. Referenced Documents 3.1.6 When purchaser’s processing requires cold shearing,

cold punching, and cold trimming, this should be noted.

2.1 ASTM Standards:

3.1.7 When special straightness or machine-cut lengths are

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

required, reference on the purchase order should be made to

Hot-Wrought and Cold-Finished, General Requirements

Tables A1.10 and A1.9 or Tables A2.10 and A2.9 for SI units

for

of Specification A 29/A 29M, and

A 255 Test Method for End-Quench Test for Hardenability

3.1.8 Weight limitations per shipping bundle.

of Steel

A 304 Specification for Carbon and Alloy Steel Bars, Sub-

4. Melting Practice

ject to End-Quench Hardenability Requirements

4.1 The steel shall be made by one or more of the following

A 322 Specification for Steel Bars,Alloy, Standard Grades

primary processes: open-hearth, basic-oxygen, or electric-

A 576 Specification for Steel Bars, Carbon, Hot-Wrought,

furnace. The primary melting may incorporate separate degas-

Special Quality

sing or refining and may be followed by secondary melting

E112 Test Methods for Determining the Average Grain

using electroslag remelting or vacuum arc remelting. Where

Size

secondary melting is employed, the heat shall be defined as all

3. Ordering Information

of the ingots remelted from a single primary heat.

3.1 Purchase orders for material to this specification shall

5. Chemical Composition or Hardenability Requirements

include the following information as required to describe the

5.1 Whenthesteelisspecifiedbychemicalcomposition,the

desired material adequately:

standard steel grades are the AISI series 1000, 4100, 5100,

3.1.1 ASTM designation A 689,

6100, 8600, and 9200, and those including Boron AISI series

10B00, 15B00, 50B00, and 51B00. The specific grades are

1 listed in Specifications A 322 and A 576.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5.2 Modifications may be made in the chemistry of the

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.15 on Bars.

standard AISI grades to suit the hardenability required for a

Current edition approved Sept. 10, 2002. Published October 1997. Originally

particular bar size, spring shape, or other special requirements.

e2

published as A 689 – 74. Last previous edition A 689 – 81a(1993) .

The steel supplier should be consulted on availability of any

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 03.01. special chemical compositions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 689 – 97 (2002)

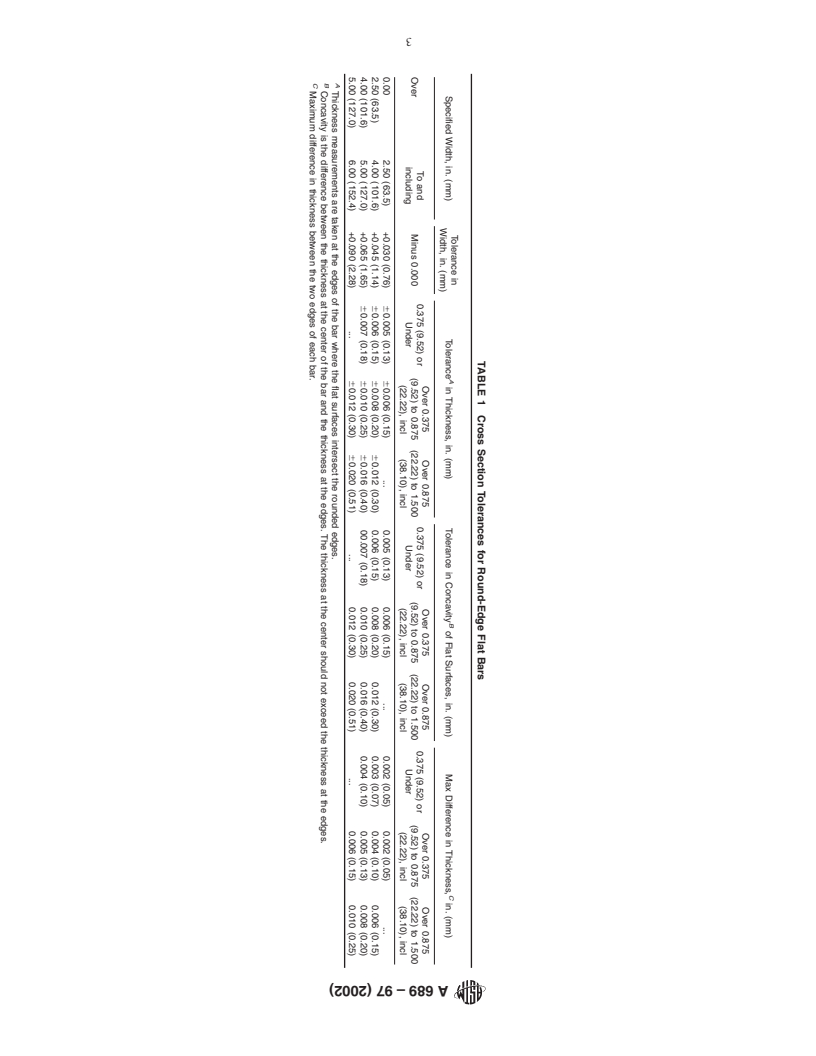

5.2.1 A chemical analysis of each heat of steel purchased 6.3 Flat (Rectangular and Including Square) Bars with

under 5.1 and 5.2 shall be made by the steel producer to Rounded Corners:

determine the percentage of the elements, which percentages 6.3.1 The rounded corner radii shall be in accordance with

shall conform to the requirements of the designatedAISI grade Table 2.

or special chemistry. The chemical analysis thus determined 6.3.2 For section tolerances see Table A1.3 or A2.3 for SI

shall be reported to the purchaser. units (for rectangular bars) and TableA1.1 orA2.1 for SI units

(for square bars) of Specification A 29/A 29M.

5.3 When the steel is specified by end-quench hardenability

6.4 Round Bars—For section tolerances see Table A1.1 or

requirements (alloy steels), the grade is identified by the suffix

A2.1 for SI units of Specification A 29/A 29M.

letter “H.” The standard alloy steel grades are the AISI series

6.5 Special Cross Section Shapes, such as Keystone—A

4100H,5100H,6100H,8600H,and9200Handthoseincluding

drawing of the cross section including the tolerances should

Boron AISI series 50B00H and 51B00H. The specific grades

accompanythepurchaseorder.Itisrecommendedthatthesteel

are listed in Specification A 304.

supplier be contacted concerning the availability of any special

5.3.1 Hardenability requirements (band limits) shall be

cross section.

shown on the purchase order as outlined in the applicable

6.6 Length and Straightness of Bars:

sections of Specification A 304.

6.6.1 For straightness and length tolerances, see Tables

5.3.2 The end-quench hardenability tests from each heat of

A1.10 and A1.8, or Tables A2.10 and A2.8 for SI units of

steel sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.