ASTM A407-23

(Specification)Standard Specification for Steel Wire, Cold-Drawn, for Coiled-Type Springs

Standard Specification for Steel Wire, Cold-Drawn, for Coiled-Type Springs

SCOPE

1.1 This specification covers round, cold-drawn, steel spring wire having properties and quality intended for the manufacture of the following types of upholstery springs:

1.1.1 Type A—Coiled (Marshall pack),

1.1.2 Type B—Coiled and knotted,

1.1.3 Type C—Coiled and knotted (offset style),

1.1.4 Type D—Coiled and hooked (single and cross helicals),

1.1.5 Type E—Coiled and hooked (short tension—regular tensile strength),

1.1.6 Type F—Coiled and hooked (short tension—high tensile strength),

1.1.7 Type G—Regular lacing,

1.1.8 Type H—Automatic lacing,

1.1.9 Type I—Zig-zag (U-formed),

1.1.10 Type J—Square-formed, and

1.1.11 Type K—Sinuous for furniture spring units.

1.2 These types of upholstery springs are used in the manufacture of automotive seat springs, furniture springs, bed spring units, mattresses, furniture cushions, and automobile seats. This wire is not intended for the manufacture of mechanical springs.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A407 − 23

Standard Specification for

1

Steel Wire, Cold-Drawn, for Coiled-Type Springs

This standard is issued under the fixed designation A407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers round, cold-drawn, steel spring

wire having properties and quality intended for the manufac-

2. Referenced Documents

ture of the following types of upholstery springs:

2

2.1 ASTM Standards:

1.1.1 Type A—Coiled (Marshall pack),

A370 Test Methods and Definitions for Mechanical Testing

1.1.2 Type B—Coiled and knotted,

of Steel Products

1.1.3 Type C—Coiled and knotted (offset style),

A941 Terminology Relating to Steel, Stainless Steel, Related

1.1.4 Type D—Coiled and hooked (single and cross

Alloys, and Ferroalloys

helicals),

E29 Practice for Using Significant Digits in Test Data to

1.1.5 Type E—Coiled and hooked (short tension—regular

Determine Conformance with Specifications

tensile strength),

1.1.6 Type F—Coiled and hooked (short tension—high 2.2 AIAG Standard:

AIAG B-10 Trading Partner Labels Implementation Guide-

tensile strength),

3

lines

1.1.7 Type G—Regular lacing,

1.1.8 Type H—Automatic lacing,

3. Terminology

1.1.9 Type I—Zig-zag (U-formed),

1.1.10 Type J—Square-formed, and

3.1 Definitions—For definitions of terms used in this

1.1.11 Type K—Sinuous for furniture spring units.

specification, refer to Terminology A941.

1.2 These types of upholstery springs are used in the

4. Ordering Information

manufacture of automotive seat springs, furniture springs, bed

4.1 Orders for material under this specification shall include

spring units, mattresses, furniture cushions, and automobile

the following information for each ordered item:

seats. This wire is not intended for the manufacture of

mechanical springs. 4.1.1 Quantity (weight),

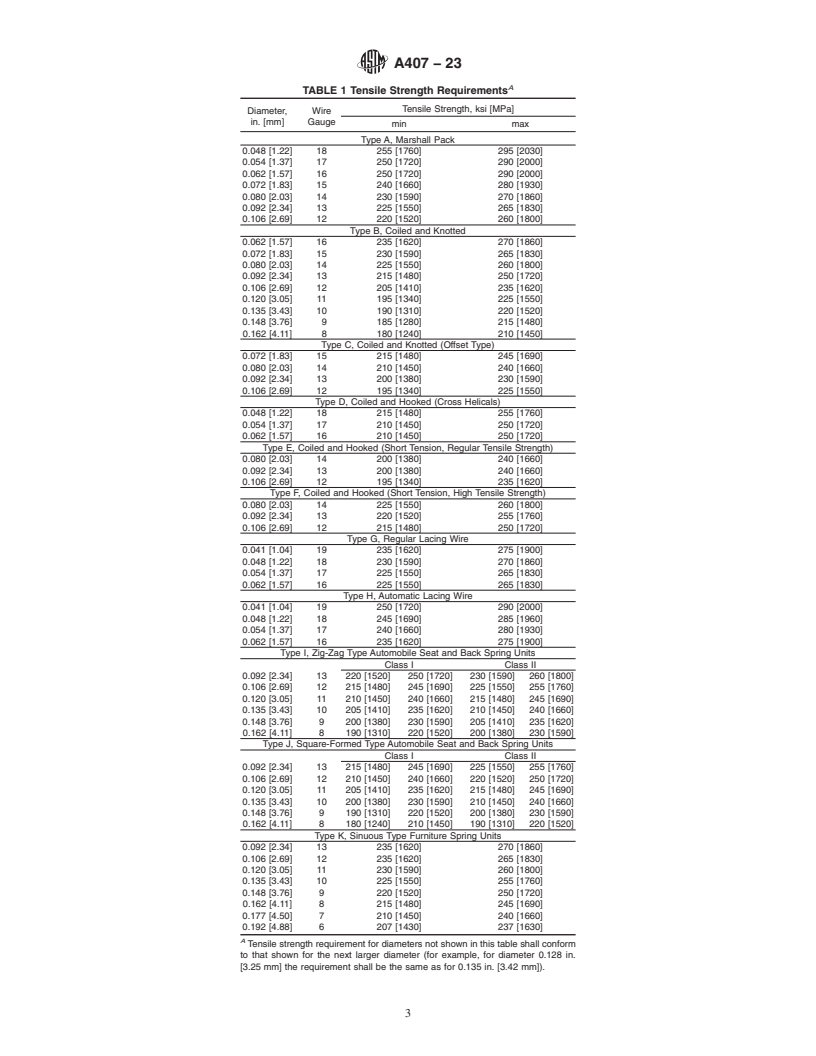

4.1.2 Name of material (name of specific type required)

1.3 The values stated in inch-pound units are to be regarded

(Section 1 and Table 1),

as standard. The values given in parentheses are mathematical

4.1.3 Diameter (Table 2),

conversions to SI units that are provided for information only

4.1.4 Packaging, marking, and loading (Section 14), and

and are not considered standard.

4.1.5 ASTM designation and date of issue.

1.4 This standard does not purport to address all of the

4.2 The purchaser shall have the option to specify additional

safety concerns, if any, associated with its use. It is the

requirements, including but not limited to:

responsibility of the user of this standard to establish appro-

4.2.1 Requirements for certifications, heat analysis, or test

priate safety, health, and environmental practices and deter-

reports, (see Sections 6 and 13),

mine the applicability of regulatory limitations prior to use.

4.2.2 Special packing, marking, and loading requirements

1.5 This international standard was developed in accor-

(see Section 14),

dance with internationally recognized principles on standard-

4.2.3 Other special requirements, if any.

ization established in the Decision on Principles for the

NOTE 1—A typical ordering description is as follows: 50 000 lb [15 000

Development of International Standards, Guides and Recom-

kg], cold-drawn upholstery spring wire Type B for coiling and knotting,

1 2

This specification is under the jurisdiction of ASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.03 on Steel Rod and Wire. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2023. Published April 2023. Originally the ASTM website.

3

approved in 1957. Last previous edition approved in 2018 as A407 – 18. DOI: Available from Automotive Industry Action Group (AIAG), 4400 Town Center,

10.1520/A0407-23. Southfield, MI 48075-1104, www.aiag.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A407 − 23

A A

TABLE 1 Tensile Strength Requirements TABLE 2 Permissible Variations in Wire Diameter

Diameter, in. [mm] Permissible Permissible Out-of-

T

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A407 − 18 A407 − 23

Standard Specification for

1

Steel Wire, Cold-Drawn, for Coiled-Type Springs

This standard is issued under the fixed designation A407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers round, cold-drawn, steel spring wire having properties and quality intended for the manufacture of

the following types of upholstery springs:

1.1.1 Type A—Coiled (Marshall pack),

1.1.2 Type B—Coiled and knotted,

1.1.3 Type C—Coiled and knotted (offset style),

1.1.4 Type D—Coiled and hooked (single and cross helicals),

1.1.5 Type E—Coiled and hooked (short tension—regular tensile strength),

1.1.6 Type F—Coiled and hooked (short tension—high tensile strength),

1.1.7 Type G—Regular lacing,

1.1.8 Type H—Automatic lacing,

1.1.9 Type I—Zig-zag (U-formed),

1.1.10 Type J—Square-formed, and

1.1.11 Type K—Sinuous for furniture spring units.

1.2 These types of upholstery springs are used in the manufacture of automotive seat springs, furniture springs, bed spring units,

mattresses, furniture cushions, and automobile seats. This wire is not intended for the manufacture of mechanical springs.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.03

on Steel Rod and Wire.

Current edition approved March 1, 2018April 1, 2023. Published April 2018April 2023. Originally approved in 1957. Last previous edition approved in 20132018 as

A407 – 07 (2013).A407 – 18. DOI: 10.1520/A0407-18.10.1520/A0407-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A407 − 23

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 AIAG Standard:

3

AIAG B-10 Trading Partner Labels Implementation Guidelines

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information for each ordered item:

4.1.1 Quantity (weight),

4.1.2 Name of material (name of specific type required) (Section 1 and Table 1),

4.1.3 Diameter (Table 2),

4.1.4 Packaging, marking, and loading (Section 14), and

4.1.5 ASTM designation and date of issue.

4.2 The purchaser shall have the option to specify additional requirements, including but not limited to:

4.2.1 Requirements for certifications, heat analysis, or test reports, (see Sections 6 and 13),

4.2.2 Special packing, marking, and loading requirements (see Section 14),

4.2.3 Other special requirements, if any.

NOTE 1—A typical ordering description is as follows: 50 000 lb [15 000 kg], cold-drawn upholstery spring wire Type B for coiling and knotting, size

0.080 in. [2.0 mm], 1500-lb [700 kg] coils on tubular carriers to ASTM A407–XX.

5. Materials and Manufacture

5.1 The steel shall be made by any commercially accepted steelmaking process.

5.2 The finished wire shall be free from injuri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.