ASTM A878/A878M-19

(Specification)Standard Specification for Steel Wire, Modified Chromium Vanadium Valve Spring Quality

Standard Specification for Steel Wire, Modified Chromium Vanadium Valve Spring Quality

ABSTRACT

This specification covers the highest quality of round modified chromium vanadium alloy steel valve spring wires, uniform in quality and temper, intended for the manufacture of valve springs and other springs requiring high-fatigue properties when used at moderately elevated temperatures. This wire shall either be in the annealed and cold-drawn or oil-tempered condition. The steel shall be subjected to continuous casting and be free from detrimental pipe and undue segregation. Heat and product analysis shall conform to the chemical requirements for carbon, manganese, phosphorus, sulfur, silicon, chromium, and vanadium. Mechanical properties shall be determined by the following: annealing and cold-drawing, oil tempering, wrap testing, and special surface inspection. In the oil-tempered condition, steel shall conform to the tensile requirements for different wire diameters. Metallurgical characterization shall include surface condition, decarburization, and inclusion content. The wire or wire rod shall conform to the maximum inclusion content requirements for the surface and core zones.

SCOPE

1.1 This specification covers the highest quality of round and shaped modified chromium vanadium alloy steel valve spring wire, uniform in quality and temper, intended for the manufacture of valve springs and other springs requiring high-fatigue properties when used at moderately elevated temperatures. It is similar to the grade VD (referenced in EN 10270-2) intended for high fatigue levels. This wire shall be either in the annealed and cold-drawn or quenched and tempered condition as specified by purchaser.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independent of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A878/A878M −19

Standard Specification for

Steel Wire, Modified Chromium Vanadium Valve Spring

1

Quality

This standard is issued under the fixed designationA878/A878M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A751Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products

1.1 This specification covers the highest quality of round

E8/E8MTest Methods for Tension Testing of Metallic Ma-

and shaped modified chromium vanadium alloy steel valve

terials

spring wire, uniform in quality and temper, intended for the

E29Practice for Using Significant Digits in Test Data to

manufacture of valve springs and other springs requiring

Determine Conformance with Specifications

high-fatigue properties when used at moderately elevated

E45Test Methods for Determining the Inclusion Content of

temperatures. It is similar to the grade VD (referenced in EN

Steel

10270-2) intended for high fatigue levels. This wire shall be

3

either in the annealed and cold-drawn or quenched and 2.2 Federal Standard:

tempered condition as specified by purchaser. Fed. Std. No. 123Marking for Shipment (Civil Agencies)

4

1.2 The values stated in either SI units or inch-pound units 2.3 European Standard:

are to be regarded separately as standard. Within the text, the EN10270-2Steel Wire for Mechanical Springs Part 2: Oil-

inch-pound units are shown in brackets. The values stated in Hardened and Tempered Spring Steel Wire of Unalloyed

each system are not exact equivalents; therefore, each system and Alloyed Steels

shall be used independent of the other. Combining values from

the two systems may result in non-conformance with the

3. Terminology

standard.

3.1 Definitions of Terms Specific to This Standard:

1.3 This international standard was developed in accor-

3.1.1 billet, n—an as-cast or forged section, typically avail-

dance with internationally recognized principles on standard-

able for transport, inspection, and conditioning, that is used as

ization established in the Decision on Principles for the

raw material for wire rod manufacture.

Development of International Standards, Guides and Recom-

3.1.2 bloom, n—an as-cast or forged section used as raw

mendations issued by the World Trade Organization Technical

material for billet manufacture.

Barriers to Trade (TBT) Committee.

3.1.3 equivalent round diameter, n—diameter of a round

2. Referenced Documents

wire having equivalent cross sectional area to a given shaped

2

wire.

2.1 ASTM Standards:

A370Test Methods and Definitions for Mechanical Testing

3.1.4 round wire, n—wire having a circular cross section.

of Steel Products

3.1.5 shape factor, n—avalueusedtoobtaincrosssectional

A700Guide for Packaging, Marking, and Loading Methods

area for shaped wires when multiplied by measured width and

for Steel Products for Shipment

measured thickness.

A941TerminologyRelatingtoSteel,StainlessSteel,Related

3.1.6 shaped wire, n—wire having a non-circular cross

Alloys, and Ferroalloys

section.

3.2 Refer to Terminology A941 for additional definitions of

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

terms used in this standard.

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

Current edition approved Sept. 1, 2019. Published September 2019. Originally

approved in 1987. Last previous edition approved in 2017 as A878/A878M–17.

3

DOI: 10.1520/A0878_A0878M-19. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, https://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM quicksearch.dla.mil.

4

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization, CEN-CENELEC

the ASTM website. Management Centre, Avenue Marnix 17, B-1000 Brussels, Belgium.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

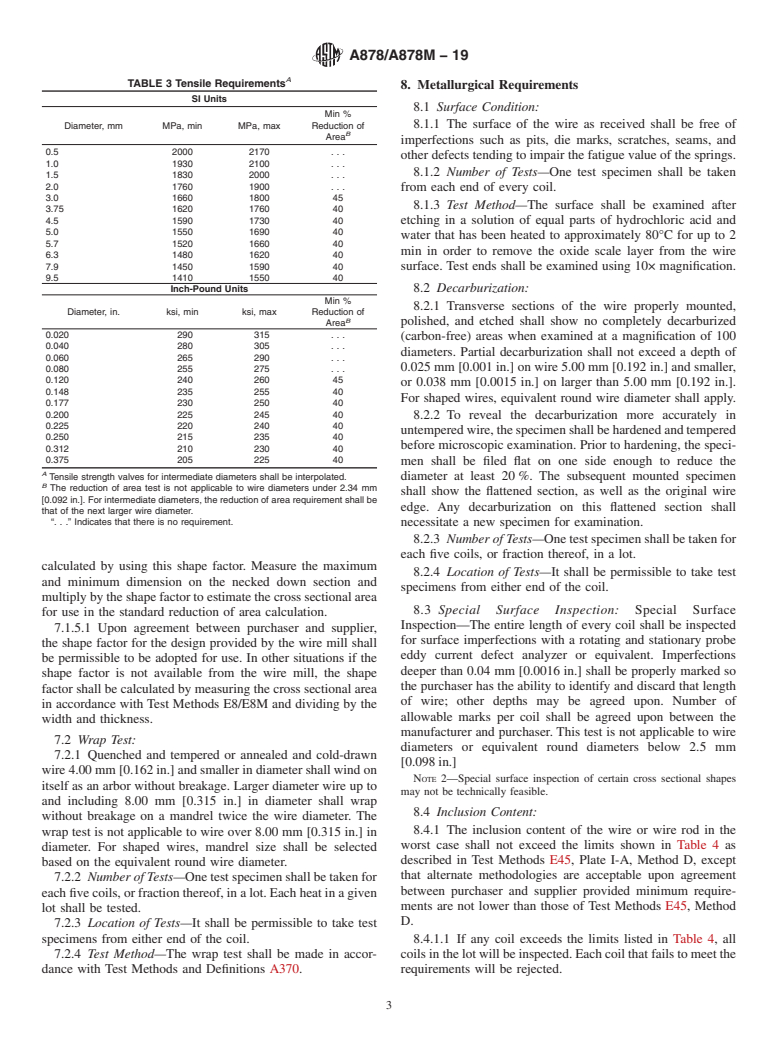

A878/A878M−19

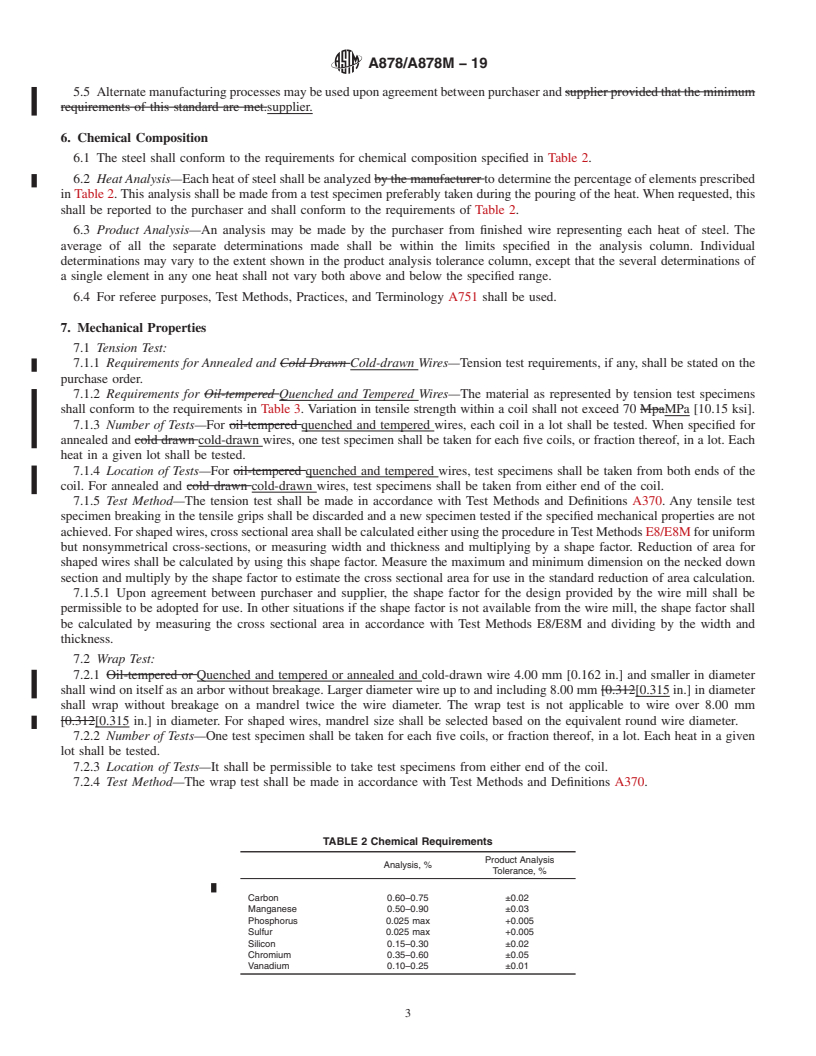

4. Ordering Information 6. Chemical Composition

4.1 Ordersformaterialunderthisspecificationshallinclude 6.1 Thesteelshallconformtotherequirementsforchemical

the following information for each ordered

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A878/A878M − 17 A878/A878M − 19

Standard Specification for

Steel Wire, Modified Chromium Vanadium Valve Spring

1

Quality

This standard is issued under the fixed designation A878/A878M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the highest quality of round and shaped modified chromium vanadium alloy steel valve spring

wire, uniform in quality and temper, intended for the manufacture of valve springs and other springs requiring high-fatigue

properties when used at moderately elevated temperatures. It is similar to the grade VD (referenced in EN 10270-2) intended for

high fatigue levels. This wire shall be either in the annealed and cold-drawn or oil-tempered quenched and tempered condition as

specified by purchaser.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the

inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall

be used independent of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E45 Test Methods for Determining the Inclusion Content of Steel

3

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3

2.3 Military Standard:

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage

4

2.3 European Standard:

EN10270-2 Steel Wire for Mechanical Springs Part 2: Oil-Hardened and Tempered Spring Steel Wire of Unalloyed and Alloyed

Steels

3. Terminology

3.1 Definitions:

3.1.1 For definition of terms used in this specification, refer to Terminology A941.

3.1 Definitions of Terms Specific to This Standard:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee A01.03

on Steel Rod and Wire.

Current edition approved Sept. 1, 2017Sept. 1, 2019. Published September 2017September 2019. Originally approved in 1987. Last previous edition approved in 20112017

as A878/A878M – 05 (2011).A878/A878M – 17. DOI: 10.1520/A0878_A0878M-17. 10.1520/A0878_A0878M-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-509819111-5094, https://

quicksearch.dla.mil.

4

Available from European Committee for Standardization, CEN-CENELEC Management Centre, Avenue Marnix 17, B-1000 Brussels, Belgium.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A878/A878M − 19

3.1.1 billet, n—an as-cast or forged section, typically available for transport, inspection, and conditioning, that is used as raw

material for wire rod manufacture.

3.1.2 bloom, n—an as-cast or forged section used as raw material for billet manufacture.

3.1.3 equivalent round diameter, n—diameter of a round wire having equivalent cross sectional area to a given shaped wire.

3.1.4 round wire, n—wire having a circular cross section.

3.1.5 shape factor, n— a value used to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.