ASTM D3753-19

(Specification)Standard Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Manholes and Wetwells

Standard Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Manholes and Wetwells

ABSTRACT

This specification covers glass fiber-reinforced polyester manholes and wetwells for use primarily in sanitary and storm sewer applications. Manhole and wetwell cylinders, manway reducers, and connectors shall be produced from glass fiber-reinforced polyester resin with construction determined by the particular process of manufacture and configuration. The stiffness, soundness, chemical resistance, compressive strength, flexural strength, modulus, and hardness shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers “fiberglass” (glass fiber-reinforced thermosetting-resin) manholes and wetwells fabricated with polyester, vinyl ester, or epoxy resin for use primarily in sanitary, storm, and industrial sewer applications.

1.2 The values given in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3753 −19

Standard Specification for

Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Manholes and Wetwells

This standard is issued under the fixed designation D3753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Electrical Insulating Materials

D790 Test Methods for Flexural Properties of Unreinforced

1.1 This specification covers “fiberglass” (glass fiber-

and Reinforced Plastics and Electrical Insulating Materi-

reinforced thermosetting-resin) manholes and wetwells fabri-

als

cated with polyester, vinyl ester, or epoxy resin for use

D883 Terminology Relating to Plastics

primarily in sanitary, storm, and industrial sewer applications.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

1.2 The values given in inch-pound units are to be regarded

tics

as the standard. The values in parentheses are provided for

D2412 Test Method for Determination of External Loading

information purposes only.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 The following precautionary caveat pertains only to the D2583 Test Method for Indentation Hardness of Rigid Plas-

test methods portion, Section 8, of this specification: This

tics by Means of a Barcol Impressor

standard does not purport to address all of the safety concerns, D2584 Test Method for Ignition Loss of Cured Reinforced

if any, associated with its use. It is the responsibility of the user

Resins

of this standard to establish appropriate safety, health, and D3892 Practice for Packaging/Packing of Plastics

environmental practices and determine the applicability of

3. Terminology

regulatory limitations prior to use.

3.1 General—Definitions are in accordance with Terminol-

NOTE 1—There is no known ISO equivalent to this standard.

ogy D883 and the abbreviations are in accordance with

1.4 This international standard was developed in accor-

Terminology D1600 unless otherwise indicated.

dance with internationally recognized principles on standard-

3.2 bench and invert, n—internalflowchannelwithasloped

ization established in the Decision on Principles for the

bench extending from the edge of the flow channel to the

Development of International Standards, Guides and Recom-

manhole wall designed to facilitate the flow of liquid through

mendations issued by the World Trade Organization Technical

the manhole between the pipe connectors.

Barriers to Trade (TBT) Committee.

3.3 bottom, n—aflat,domed,dished,orothershapedbottom

2. Referenced Documents

designedtomakethemanholeorwetwellwatertightatitsbase.

2

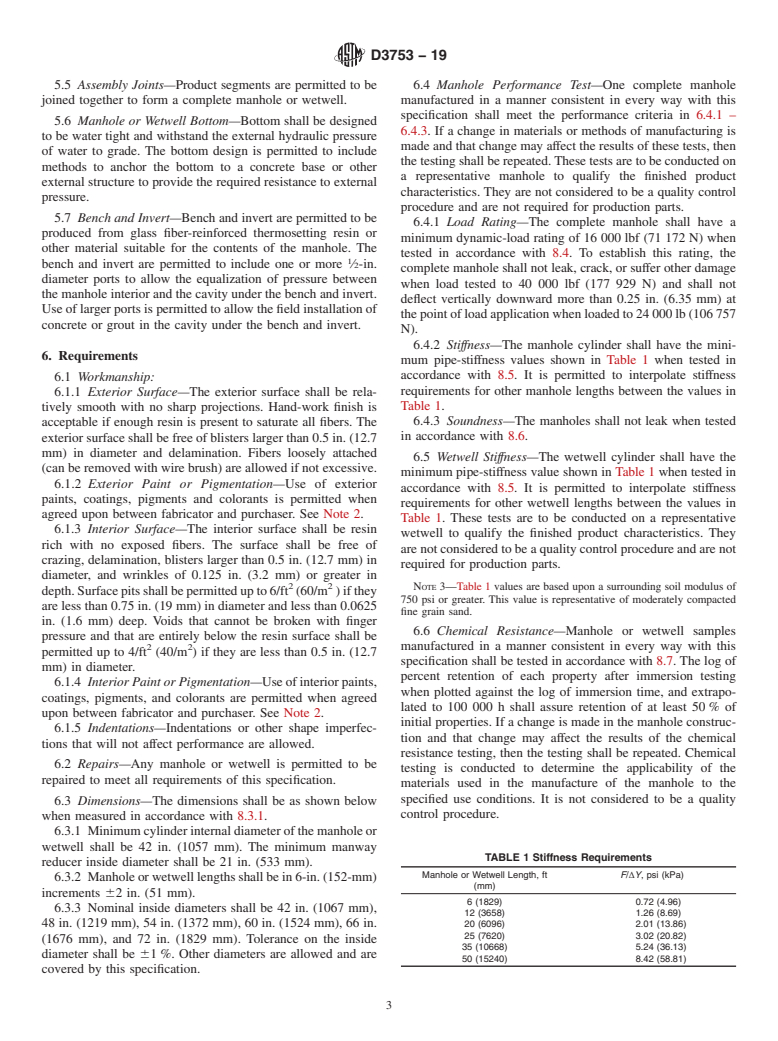

2.1 ASTM Standards: 3.4 expanded base manhole, n—a manhole with a larger

C581 Practice for Determining Chemical Resistance of

diameter base section and reduced diameter riser section. (See

Thermosetting Resins Used in Glass-Fiber-Reinforced

Fig. 1 for a typical manhole and an expanded base manhole.)

Structures Intended for Liquid Service

3.5 expanded base reducer, n—a portion of the manhole,

D695 Test Method for Compressive Properties of Rigid

between the manway reducer and bottom, that changes from

Plastics

one diameter to another in the cylindrical portion of the

D785 Test Method for Rockwell Hardness of Plastics and

structure.

3.6 manway reducer, n—the top portion of the manhole

through which entrance to the manhole is made and where the

1

This specification is under the jurisdiction of ASTM Committee D20 on

diameterincreasesfromtheentrancewaytothelargermanhole

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment. cylinder.

Current edition approved Sept. 1, 2019. Published September 2019. Originally

3.7 manhole, n—a constant diameter cylinder attached to a

ε1

approved in 1979. Last previous edition approved in 2012 as D3753 – 12 . DOI:

manway reducer designed to handle a manhole cover and ring.

10.1520/D3753-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.8 manhole cover and frame, n—those accessories used

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

withthemanholetoclosethemanwayentrance(includesgrade

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. adjustment rings).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3753−19

FIG. 1Typical Manhole and Expanded Base Manhole

3.9 manhole cylinder, n—the portion below the manway permittedtobeaddedasrequiredbythespe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3753 − 12 D3753 − 19 An American National Standard

Standard Specification for

Glass-Fiber-Reinforced Polyester Fiberglass (Glass-Fiber-

1

Reinforced Thermosetting-Resin) Manholes and Wetwells

This standard is issued under the fixed designation D3753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections added in April 2013.

1. Scope*

1.1 This specification covers glass “fiberglass” (glass fiber-reinforced polyesterthermosetting-resin) manholes and wetwells

fabricated with polyester, vinyl ester, or epoxy resin for use primarily in sanitary sanitary, storm, and stormindustrial sewer

applications.

1.2 The values given in inch-pound units are to be regarded as the standard. The values in parentheses are provided for

information purposes only.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C581 Practice for Determining Chemical Resistance of Thermosetting Resins Used in Glass-Fiber-Reinforced Structures

Intended for Liquid Service

D695 Test Method for Compressive Properties of Rigid Plastics

D785 Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2583 Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D3892 Practice for Packaging/Packing of Plastics

3. Terminology

3.1 General—Definitions are in accordance with Terminology D883 and the abbreviations are in accordance with Terminology

D1600 unless otherwise indicated.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved March 15, 2012Sept. 1, 2019. Published April 2012September 2019. Originally approved in 1979. Last previous edition approved in 20052012

ε1

as D3753 – 05D3753 – 12 . DOI: 10.1520/D3753-12E01.10.1520/D3753-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3753 − 19

3.2 bench and invert, n—internal flow channel with a sloped bench extending from the edge of the flow channel to the manhole

wall designed to facilitate the flow of liquid through the manhole between the pipe connectors.

3.3 bottom, n—a flat, domed, dished, or other shaped bottom designed to make the manhole or wetwell watertight at its base.

3.4 expanded base manhole, n—a manhole with the addition of eccentric or concentric reducers attached to cylinder sections

ofa larger diameter base section and reduced diameter riser section. (See Fig. 1 different diameter than the manhole to allow

changes in cylinder diameter.for a typical manhole and an expanded base manhole.)

3.5 ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.