ASTM A278M-93e1

(Specification)Standard Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 350°C (Withdrawn 2001)

Standard Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 350°C (Withdrawn 2001)

SCOPE

1.1 This specification covers gray iron for castings suitable for pressure-containing parts for use at temperatures up to 350°C.

1.2 Castings of all classes are suitable for use up to 230°C. For temperatures above 230°C and up to 350°C, only Class 275, 300, 325, 350, 380, and 415 castings are suitable.

1.3 This specification is the SI companion to Specification A278.

General Information

Standards Content (Sample)

e1

Designation: A 278M – 93

METRIC

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Gray Iron Castings for Pressure-Containing Parts for

1

Temperatures Up to 350°C

This standard is issued under the fixed designation A 278M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—The Tensile Requirements table was corrected editorially in July 1996.

1. Scope 5.1.4 Whether or not heat treatment is required for Class

275, 300, 325, 350, 380, and 415 castings to be used at

1.1 This specification covers gray iron for castings suitable

temperatures at 230°C or less (see 6.2),

for pressure-containing parts for use at temperatures up to

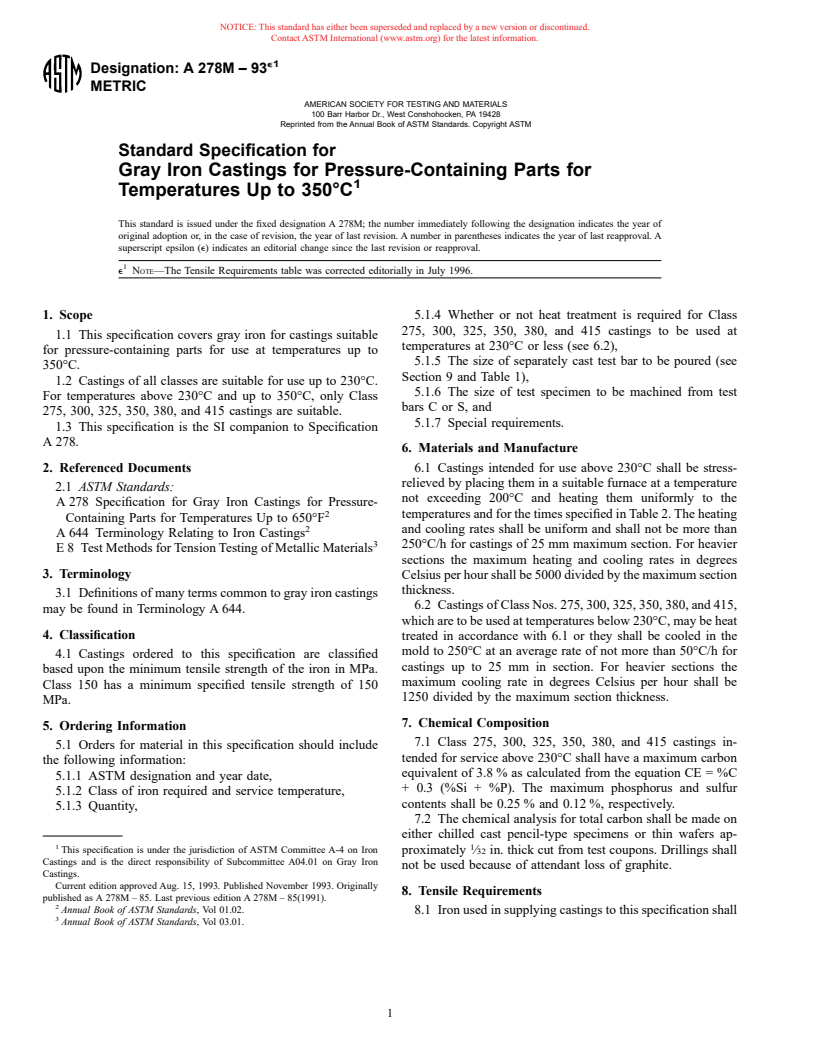

5.1.5 The size of separately cast test bar to be poured (see

350°C.

Section 9 and Table 1),

1.2 Castings of all classes are suitable for use up to 230°C.

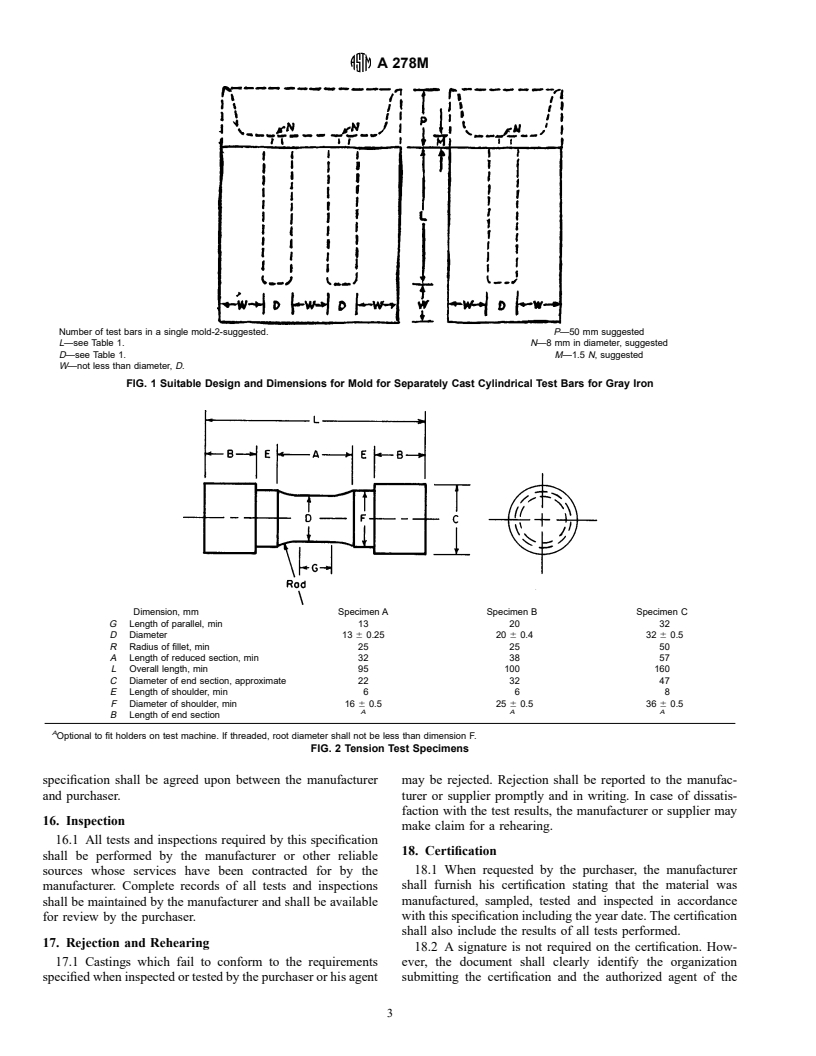

5.1.6 The size of test specimen to be machined from test

For temperatures above 230°C and up to 350°C, only Class

barsCorS,and

275, 300, 325, 350, 380, and 415 castings are suitable.

5.1.7 Special requirements.

1.3 This specification is the SI companion to Specification

A 278.

6. Materials and Manufacture

2. Referenced Documents 6.1 Castings intended for use above 230°C shall be stress-

relieved by placing them in a suitable furnace at a temperature

2.1 ASTM Standards:

not exceeding 200°C and heating them uniformly to the

A 278 Specification for Gray Iron Castings for Pressure-

2

temperatures and for the times specified in Table 2. The heating

Containing Parts for Temperatures Up to 650°F

2

and cooling rates shall be uniform and shall not be more than

A 644 Terminology Relating to Iron Castings

3

250°C/h for castings of 25 mm maximum section. For heavier

E 8 Test Methods for Tension Testing of Metallic Materials

sections the maximum heating and cooling rates in degrees

3. Terminology

Celsius per hour shall be 5000 divided by the maximum section

thickness.

3.1 Definitions of many terms common to gray iron castings

6.2 Castings of Class Nos. 275, 300, 325, 350, 380, and 415,

may be found in Terminology A 644.

which are to be used at temperatures below 230°C, may be heat

4. Classification

treated in accordance with 6.1 or they shall be cooled in the

mold to 250°C at an average rate of not more than 50°C/h for

4.1 Castings ordered to this specification are classified

castings up to 25 mm in section. For heavier sections the

based upon the minimum tensile strength of the iron in MPa.

maximum cooling rate in degrees Celsius per hour shall be

Class 150 has a minimum specified tensile strength of 150

1250 divided by the maximum section thickness.

MPa.

7. Chemical Composition

5. Ordering Information

7.1 Class 275, 300, 325, 350, 380, and 415 castings in-

5.1 Orders for material in this specification should include

tended for service above 230°C shall have a maximum carbon

the following information:

equivalent of 3.8 % as calculated from the equation CE = %C

5.1.1 ASTM designation and year date,

+ 0.3 (%Si + %P). The maximum phosphorus and sulfur

5.1.2 Class of iron required and service temperature,

contents shall be 0.25 % and 0.12 %, respectively.

5.1.3 Quantity,

7.2 The chemical analysis for total carbon shall be made on

either chilled cast pencil-type specimens or thin wafers ap-

1

1

This specification is under the jurisdiction of ASTM Committee A-4 on Iron

proximately ⁄32 in. thick cut from test coupons. Drillings shall

Castings and is the direct responsibility of Subcommittee A04.01 on Gray Iron

not be used because of attendant loss of graphite.

Castings.

Current edition approved Aug. 15, 1993. Published November 1993. Originally

8. Tensile Requirements

published as A 278M – 85. Last previous edition A 278M – 85(1991).

2

Annual Book of ASTM Standards, Vol 01.02.

8.1 Iron used in supplying castings to this specification shall

3

Annual Book of ASTM Standards, Vol 03.01.

1

---------------------- Page: 1 ----------------------

A 278M

TABLE 1 Diameters and Lengths of Cast Test Bars TABLE 4 Separately Cast Test Bars for Use When a Specific

Correlation Has Not Been Established Between the Test Bar and

As-Cast Diameter, mm Length, mm

the Casting

Nominal

Test Bar

Minimum Maximum Minimum Maximum

Thickness of the Wall of the Controlling Test Bar

(Mid-

(Bottom) (Top) (Specified) (Recommended)

Section of the Casting, mm

Length)

Under 6 S

A 23 22 25 125 150

6–12 A

B 33 32 36 150 230

13–25 B

C 54 53 58 175 255

A 26–50 C

S

Over 50 S

A

All dimensions of Test Bar S shall be as agreed upon by the manufacturer and

the purchaser.

11. Workmanship, Finish, and Appearance

TABLE 2 Stress Relieving Requirements

11.1 All castings shall be made in a workmanlike manner

A

Holding Time, h

Metal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.