ASTM A842-11A(2022)e1

(Specification)Standard Specification for Compacted Graphite Iron Castings

Standard Specification for Compacted Graphite Iron Castings

ABSTRACT

This specification deals with compacted graphite iron castings. These materials shall be examined metallographically for the acceptance graphite formation. The acceptable graphite formation in the microstructure of the test coupon or casting lug shall contain 80% minimum Type IV graphite. The iron shall conform to the requirements for tensile properties: tensile strength, yield strength, and elongation. Test bars and test coupons shall be cast in dried, baked, or chemically bonded molds consisting of an aggregate of silica sand with appropriate bonders and shall be subjected to the same thermal treatment as the castings they represent.

SCOPE

1.1 This specification covers castings made of compacted graphite iron, which is described as cast iron with the graphite in compacted (vermiform) shapes and essentially free of flake graphite in the bulk of the casting.

1.2 No precise quantitative relationship can be stated between the properties of iron in the various locations of the same casting and those of a test bar cast from the same iron (see Appendix X1).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

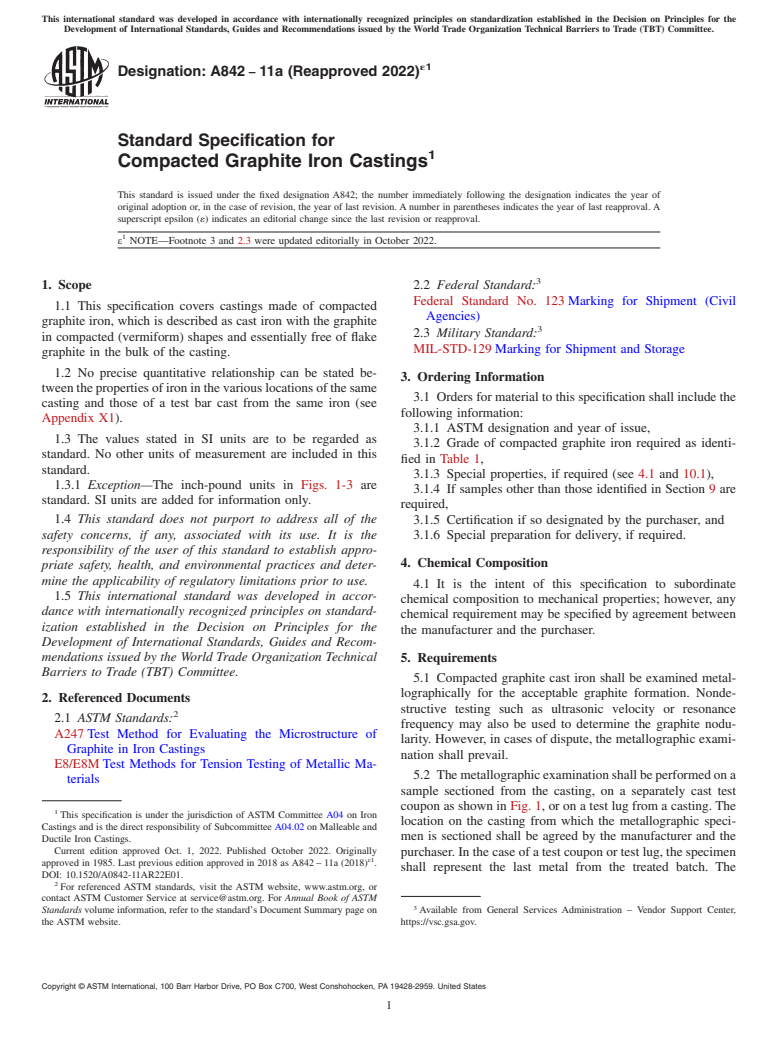

1.3.1 Exception—The inch-pound units in Figs. 1-3 are standard. SI units are added for information only.

Note 1: The length of the keel block shall be 6 in. (152 mm).

FIG. 3 Mold for Modified Keel Block

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:A842 −11a (Reapproved 2022)

Standard Specification for

Compacted Graphite Iron Castings

This standard is issued under the fixed designation A842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 3 and 2.3 were updated editorially in October 2022.

1. Scope 2.2 Federal Standard:

Federal Standard No. 123 Marking for Shipment (Civil

1.1 This specification covers castings made of compacted

Agencies)

graphite iron, which is described as cast iron with the graphite

2.3 Military Standard:

in compacted (vermiform) shapes and essentially free of flake

MIL-STD-129 Marking for Shipment and Storage

graphite in the bulk of the casting.

1.2 No precise quantitative relationship can be stated be-

3. Ordering Information

tweenthepropertiesofironinthevariouslocationsofthesame

3.1 Orders for material to this specification shall include the

casting and those of a test bar cast from the same iron (see

following information:

Appendix X1).

3.1.1 ASTM designation and year of issue,

1.3 The values stated in SI units are to be regarded as

3.1.2 Grade of compacted graphite iron required as identi-

standard. No other units of measurement are included in this

fied in Table 1,

standard.

3.1.3 Special properties, if required (see 4.1 and 10.1),

1.3.1 Exception—The inch-pound units in Figs. 1-3 are

3.1.4 If samples other than those identified in Section 9 are

standard. SI units are added for information only.

required,

1.4 This standard does not purport to address all of the 3.1.5 Certification if so designated by the purchaser, and

safety concerns, if any, associated with its use. It is the 3.1.6 Special preparation for delivery, if required.

responsibility of the user of this standard to establish appro-

4. Chemical Composition

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 It is the intent of this specification to subordinate

1.5 This international standard was developed in accor-

chemical composition to mechanical properties; however, any

dance with internationally recognized principles on standard-

chemical requirement may be specified by agreement between

ization established in the Decision on Principles for the

the manufacturer and the purchaser.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 5. Requirements

Barriers to Trade (TBT) Committee.

5.1 Compacted graphite cast iron shall be examined metal-

lographically for the acceptable graphite formation. Nonde-

2. Referenced Documents

structive testing such as ultrasonic velocity or resonance

2.1 ASTM Standards:

frequency may also be used to determine the graphite nodu-

A247 Test Method for Evaluating the Microstructure of

larity. However, in cases of dispute, the metallographic exami-

Graphite in Iron Castings

nation shall prevail.

E8/E8M Test Methods for Tension Testing of Metallic Ma-

5.2 Themetallographicexaminationshallbeperformedona

terials

sample sectioned from the casting, on a separately cast test

coupon as shown in Fig. 1, or on a test lug from a casting. The

This specification is under the jurisdiction of ASTM Committee A04 on Iron

location on the casting from which the metallographic speci-

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

men is sectioned shall be agreed by the manufacturer and the

Ductile Iron Castings.

Current edition approved Oct. 1, 2022. Published October 2022. Originally

purchaser. In the case of a test coupon or test lug, the specimen

ɛ1

approved in 1985. Last previous edition approved in 2018 as A842 – 11a (2018) .

shall represent the last metal from the treated batch. The

DOI: 10.1520/A0842-11AR22E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from General Services Administration – Vendor Support Center,

the ASTM website. https://vsc.gsa.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A842−11a (2022)

FIG. 1 Test Coupon for Microscopical Examination of Compacted Graphite Iron

from a casting, the location shall be agreed on by the purchaser

and the manufacturer and documented on the casting drawing.

It is the manufacturer’s required responsibility to maintain

adequate controls and documentation to assure the customer

that test specimen microstructures are representative of micro-

structure in the castings shipped.

5.4 The acceptable graphite formation in the microstructure

of the test coupon or casting lug shall contain 80 % minimum

Type IV graphite (see Plate 1, Graphite Form Types of Test

Method A247). The remainder of the graphite should be Type

I, II, or III, with no free flake graphite (Type VII) in the bulk

of the casting. The presence of up to 20 % of Types I, II, and

III graphite gives rise to the definition of a maximum of 20 %

nodularity in compacted graphite cast iron. The nodularity

percentage can be arrived at by using the manual particle

count, semiautomatic, or automatic image analysis methods.

Whichever method is used, the procedure should be agreed on

Metric Equivalents

in. mm in. mm

between the manufacturer and the purchaser.

1 1

⁄2 12.7 1 ⁄2 38.1

1 25.4 2 ⁄2 63.5

5.5 Unless otherwise specified, the matrix microstructure of

castingscoveredbythisspecificationshallbesubstantiallyfree

NOTE 1—The length of the keel block shall be 6 in. (152 mm).

of primary cementite.

FIG. 2 Keel Block 5.6 Flake graphite is not permitted except within the surface

rim zone of the casting. The amount of flake graphite at the

surface shall be agreed by the manufacturer and the purchaser.

casting lug dimension and location shall be agreed by manu-

NOTE 1—Flake graphite in the casting surface reduces fatigue life,

facturer and purchaser.

which should be taken into account during casting design. Machining

removes this flake graphite and shot blasting generally minimizes its

5.3 When castings are produced to this specification by

effect.

treating the iron in the mold for graphite form control, the

6. Tensile Requirements

manufacturer may use separately cast test coupons or cut test

specimens from castings to qualify conformance of the micro-

6.1 The iron as represented by the test specimens shall

structure requirements. When separately cast test coupons are

conform to the requirements for tensile properties, as identified

used, the test coupons shall have a chemical composition

in Table 1.

representative of that in the castings, produced from that iron

6.2 Tensile properties shall be determined using the test bar

poured, and having a cooling rate equivalent to that obtained

described in 7.1 or one of the test coupons described in 7.2,

through use of test molds as shown in Figs. 1-4.The size of the

except as provided in 10.4.

cast coupon representing the castings shall be the option of the

purchaser. In case no option is expressed, the manufacturer 6.3 The yield strength presented in Table 1 shall be deter-

shall make the choice. When test specimens are to be taken mined at 0.2 % offset by the offset method as described in Test

´1

A842−11a (2022)

FIG. 3 Mold for Modified Keel Block

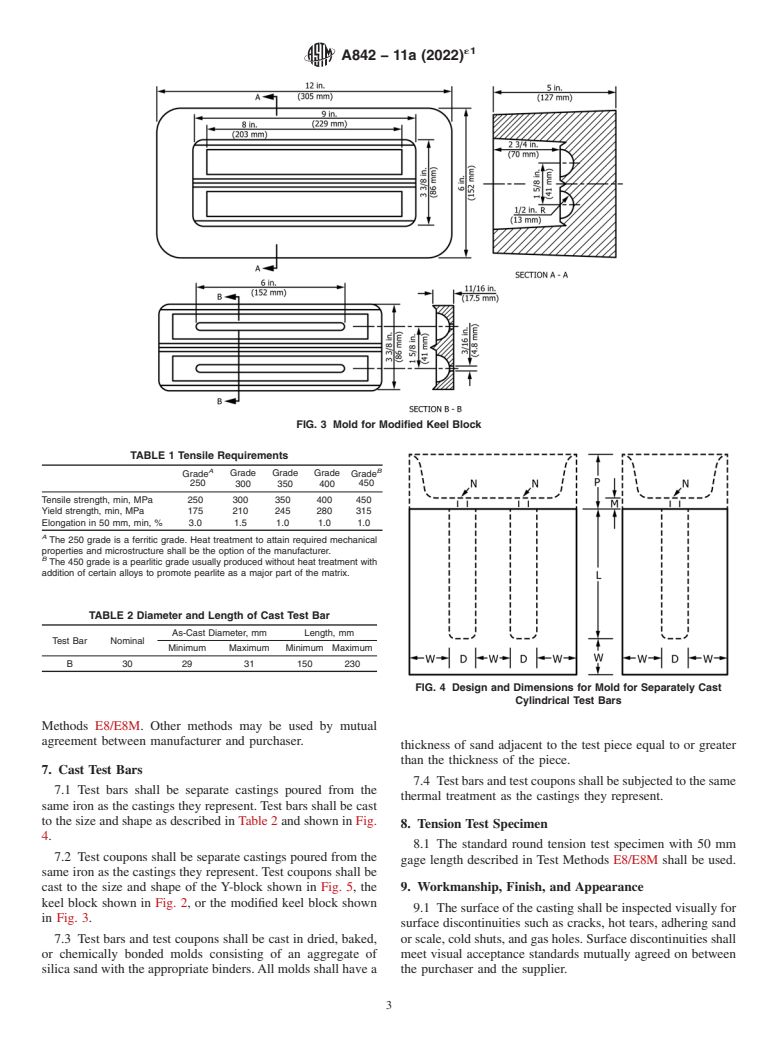

TABLE 1 Tensile Requirements

A B

Grade Grade Grade

Grade Grade

250 450

300 350 400

Tensile strength, min, MPa 250 300 350 400 450

Yield strength, min, MPa 175 210 245 280 315

Elongation in 50 mm, min, % 3.0 1.5 1.0 1.0 1.0

A

The 250 grade is a ferritic grade. Heat treatment to attain required mechanical

properties and microstructure shall be the option of the manufacturer.

B

The 450 grade is a pearlitic grade usually produced without heat treatment with

addition of certain alloys to promote pearlite as a major part of the matrix.

TABLE 2 Diameter and Length of Cast Test Bar

As-Cast Diameter, mm Length, mm

Test Bar Nominal

Minimum Maximum Minimum Maximum

B 30 29 31 150 230

FIG. 4 Design and Dimensions for Mold for Separately Cast

Cylindrical Test Bars

Methods E8/E8M. Other methods may be used by mutual

agreement between manufacturer and purchaser.

thickness of sand adjacent to the test piece equal to or greater

than the thickness of the piece.

7. Cast Test Bars

7.4 Testbarsandtestcouponsshallbesubjectedtothesame

7.1 Test bars shall be separate castings poured from the

thermal treatment as the castings they represent.

same iron as the casti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.