ASTM D3906-03(2008)

(Test Method)Standard Test Method for Determination of Relative X-ray Diffraction Intensities of Faujasite-Type Zeolite-Containing Materials

Standard Test Method for Determination of Relative X-ray Diffraction Intensities of Faujasite-Type Zeolite-Containing Materials

SIGNIFICANCE AND USE

Zeolites Y and X, particularly for catalyst and adsorbent applications, are a major article of manufacture and commerce. Catalysts and adsorbents comprising these zeolites in various forms plus binder and other components have likewise become important. Y-based catalysts are used for fluid catalytic cracking (FCC) and hydrocracking of petroleum, while X-based adsorbents are used for desiccation, sulfur compound removal, and air separation.

This X-ray procedure is designed to monitor these Y and X zeolites and catalysts and adsorbents, providing a number more or less closely related to percent zeolite in the sample. This number has proven useful in technology, research, and specifications.

Drastic changes in intensity of individual peaks in the XRD patterns of Y and X can result from changes of distribution of electron density within the unit cell of the zeolite. The electron density distribution is dependent upon the extent of filling of pores in the zeolite with guest molecules, and on the nature of the guest molecules. In this XRD method, the guest molecule H2O completely fills the pores. Intensity changes may also result if some or all of the cations in Y and X are exchanged by other cations.

Because of the factors mentioned in 4.3 that could vary the intensities of the XRD peaks, this XRD method will provide the best determination of relative crystallinity when the reference and sample have a similar history of preparation and composition.

Corrections are possible that can make this XRD method accurate for measuring percent zeolite in many specific situations. These corrections are well known to those skilled in X-ray diffraction. It is not practical to specify those corrections here.

SCOPE

1.1 This test method covers the determination of relative X-ray diffraction intensities of zeolites having the faujasite crystal structure, including synthetic Y and X zeolites, their modifications such as the various cation exchange forms, and the dealuminized, decationated, and ultrastable forms of Y. These zeolites have cubic symmetry with a unit cell parameter usually within the limits of 24.2 and 25.0˚ Å (2.42 and 2.50 nm).

1.2 The samples include zeolite preparations in the various forms, and catalysts and adsorbents containing these zeolites.

1.3 The term “intensity of an X-ray powder diffraction (XRD) peak” is the “integral intensity,” either the area of counts under the peak or the product of the peak height and the peak width.

1.4 This test method provides a number that is the ratio of intensity of portions of the XRD pattern of the sample to intensity of the corresponding portion of the pattern of a reference zeolite, NaY. (Laboratories may use a modified Y or X, for example, REY as a secondary standard.) The intensity ratio, expressed as a percentage, is then labeled “% XRD intensity/NaY.”

1.5 Under certain conditions such a ratio is the percent zeolite in the sample. These conditions include:

1.5.1 The zeolite in the sample is the same as the reference zeolite.

1.5.2 The absorption for the X-rays used is the same for the zeolite and the nonzeolite portions of the sample.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3906 − 03(Reapproved 2008)

Standard Test Method for

Determination of Relative X-ray Diffraction Intensities of

Faujasite-Type Zeolite-Containing Materials

This standard is issued under the fixed designation D3906; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of relative 2.1 ASTM Standards:

X-ray diffraction intensities of zeolites having the faujasite E177 Practice for Use of the Terms Precision and Bias in

crystal structure, including synthetic Y and X zeolites, their ASTM Test Methods

modifications such as the various cation exchange forms, and E456 Terminology Relating to Quality and Statistics

the dealuminized, decationated, and ultrastable forms of Y. E691 Practice for Conducting an Interlaboratory Study to

These zeolites have cubic symmetry with a unit cell parameter Determine the Precision of a Test Method

usually within the limits of 24.2 and 25.0˚ Å (2.42 and 2.50

3. Summary of Test Method

nm).

3.1 The XRD patterns of the zeolite containing sample and

1.2 The samples include zeolite preparations in the various

the reference sample (NaY), are obtained under the same

forms, and catalysts and adsorbents containing these zeolites.

conditions. If the XRD pattern of the zeolite is sufficiently

1.3 The term “intensity of an X-ray powder diffraction

strong, a comparison of intensities of eight peaks is used to

(XRD) peak” is the “integral intensity,” either the area of

give % XRD intensity/NaY. For lower zeolite content intensi-

counts under the peak or the product of the peak height and the

ties of the (533) peak (23.5° with Cu Kα radiation) are

peak width.

compared to provide “% XRD intensity/NaY (533).”

1.4 This test method provides a number that is the ratio of

4. Significance and Use

intensity of portions of the XRD pattern of the sample to

intensity of the corresponding portion of the pattern of a

4.1 Zeolites Y and X, particularly for catalyst and adsorbent

reference zeolite, NaY. (Laboratories may use a modified Y or applications, are a major article of manufacture and commerce.

X, for example, REY as a secondary standard.) The intensity

Catalysts and adsorbents comprising these zeolites in various

ratio, expressed as a percentage, is then labeled “% XRD

forms plus binder and other components have likewise become

intensity/NaY.”

important. Y-based catalysts are used for fluid catalytic crack-

ing (FCC) and hydrocracking of petroleum, while X-based

1.5 Under certain conditions such a ratio is the percent

adsorbents are used for desiccation, sulfur compound removal,

zeolite in the sample. These conditions include:

and air separation.

1.5.1 The zeolite in the sample is the same as the reference

zeolite.

4.2 This X-ray procedure is designed to monitor these Y and

1.5.2 The absorption for the X-rays used is the same for the

X zeolites and catalysts and adsorbents, providing a number

zeolite and the nonzeolite portions of the sample.

more or less closely related to percent zeolite in the sample.

This number has proven useful in technology, research, and

1.6 This standard does not purport to address all of the

specifications.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.3 Drastic changes in intensity of individual peaks in the

priate safety and health practices and determine the applica-

XRD patterns of Y and X can result from changes of distribu-

bility of regulatory limitations prior to use.

tion of electron density within the unit cell of the zeolite. The

electron density distribution is dependent upon the extent of

filling of pores in the zeolite with guest molecules, and on the

nature of the guest molecules. In this XRD method, the guest

This test method is under the jurisdiction of ASTM Committee D32 on

Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2008. Published May 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1980. Last previous edition approved in 2003 as D3906–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3906-03R08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3906 − 03 (2008)

Angle (°2θ)

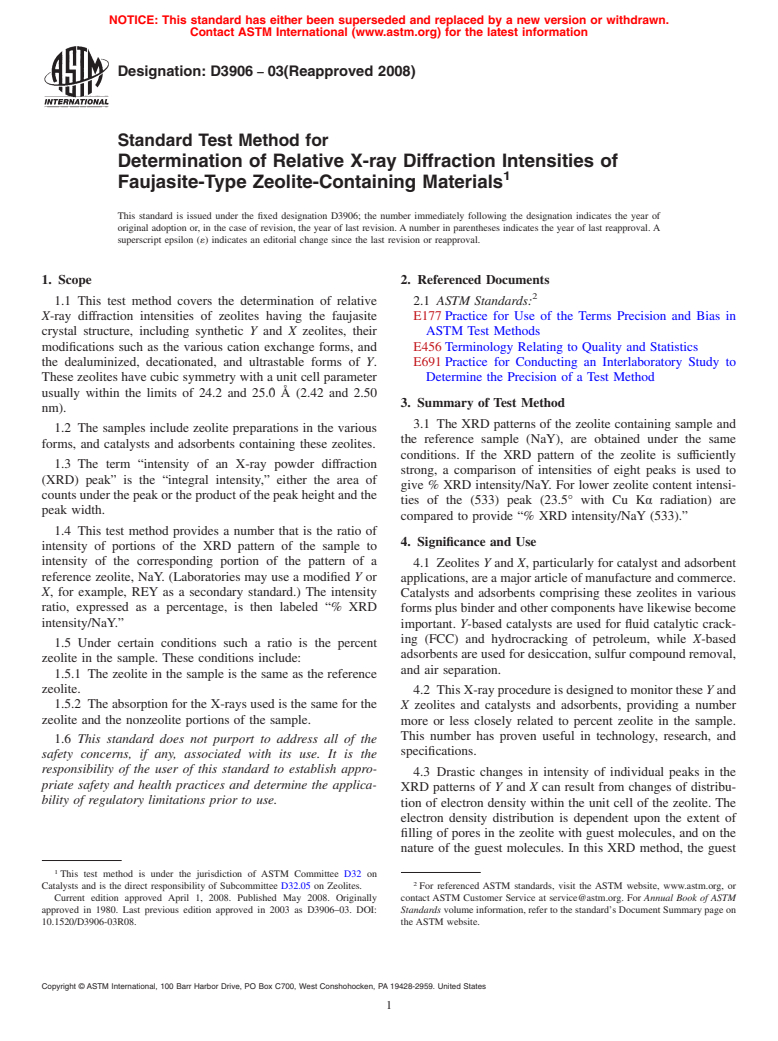

FIG. 1 X-Ray Diffraction Patterns of ASTM Zeolite Samples Upper—NaY; Lower—Cracking Catalyst Intensity

molecule H O completely fills the pores. Intensity changes 5.2 Drying Oven, set at 110°C.

may also result if some or all of the cations in Y and X are

5.3 Hydrator (Glass Laboratory Desiccator), maintained at

exchanged by other cations.

35 % relative humidity by a saturated solution of salt, such as

4.3.1 Because of the factors mentioned in 4.3 that could

CaCl ·6H O.

2 2

vary the intensities of the XRD peaks, this XRD method will

5.4 Planimeter or Appropriate Peak Profile Analysis or

providethebestdeterminationofrelativecrystallinitywhenthe

Digital Integration Software—If XRD is not equipped with

reference and sample have a similar history of preparation and

appropriate software data analysis capability.

composition.

6. Reagents and Materials

4.4 Corrections are possible that can make this XRD

methodaccurateformeasuringpercentzeoliteinmanyspecific

6.1 NaY Powder and RE Exchanged Y Powder, as reference

situations.These corrections are well known to those skilled in

standards.

X-ray diffraction. It is not practical to specify those corrections

7. Sampling

here.

7.1 Conduct sampling by splitting a large portion of the

5. Apparatus

sample and reference material homogeneously.

5.1 X-ray Diffractometer, equipped with a strip chart re-

corder or with computerized data acquisition and reduction

Available from National Institute of Standards and Technology (NIST), 100

capability, using copper K-alpha radiation. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

D3906 − 03 (2008)

Angle (°2θ)

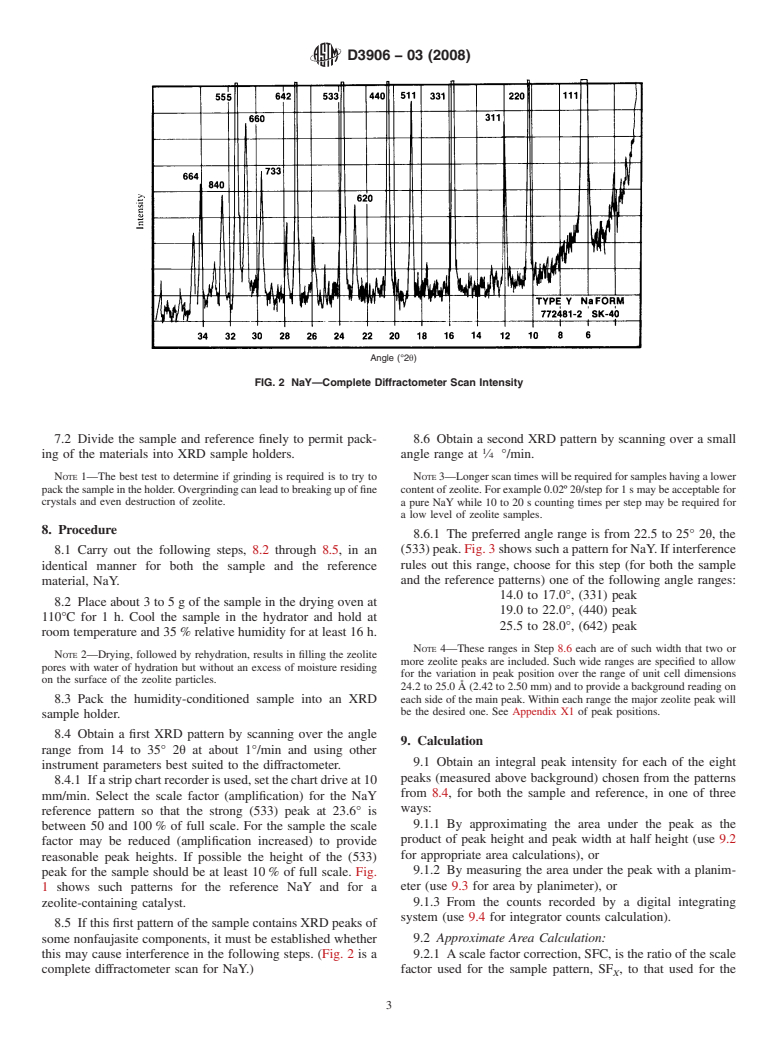

FIG. 2 NaY—Complete Diffractometer Scan Intensity

7.2 Divide the sample and reference finely to permit pack- 8.6 Obtain a second XRD pattern by scanning over a small

ing of the materials into XRD sample holders. angle range at ⁄4 °/min.

NOTE 1—The best test to determine if grinding is required is to try to NOTE3—Longerscantimeswillberequiredforsampleshavingalower

packthesampleintheholder.Overgrindingcanleadtobreakingupoffine

content of zeolite. For example 0.02º 2θ/step for 1 s may be acceptable for

crystals and even destruction of zeolite. a pure NaY while 10 to 20 s counting times per step may be required for

a low level of zeolite samples.

8. Procedure

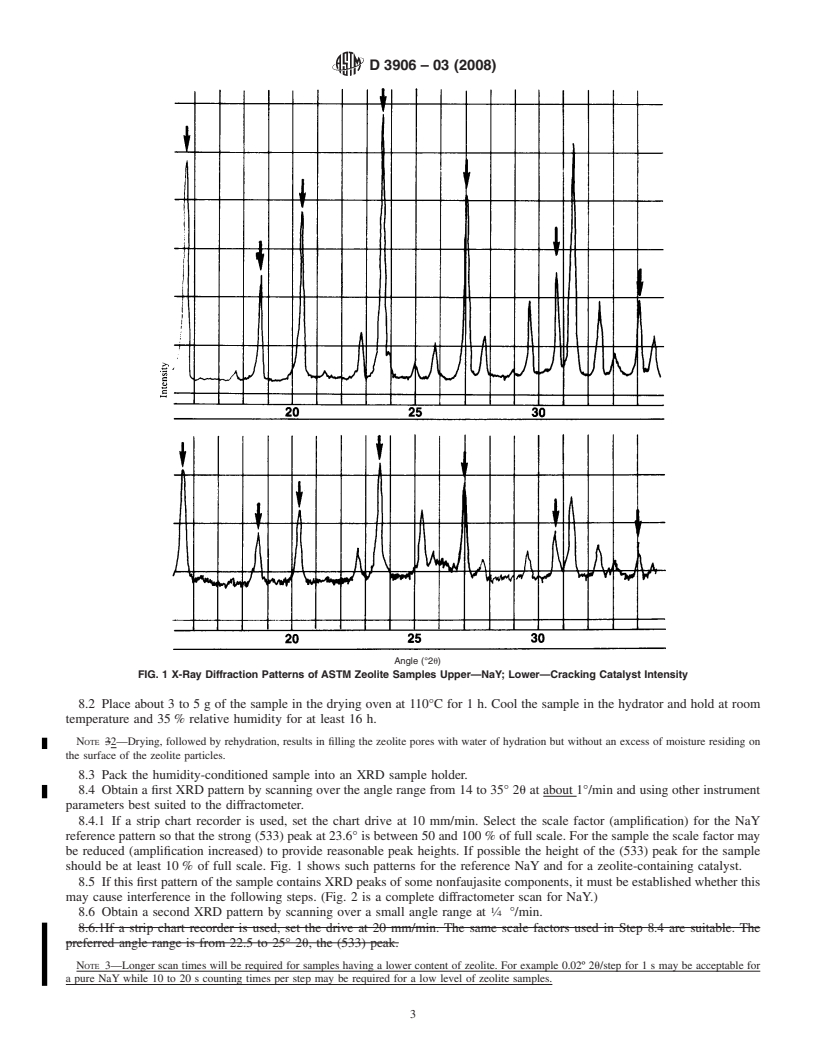

8.6.1 The preferred angle range is from 22.5 to 25° 2θ, the

(533) peak. Fig. 3 shows such a pattern for NaY. If interference

8.1 Carry out the following steps, 8.2 through 8.5,inan

rules out this range, choose for this step (for both the sample

identical manner for both the sample and the reference

and the reference patterns) one of the following angle ranges:

material, NaY.

14.0 to 17.0°, (331) peak

8.2 Place about 3 to5gofthe sample in the drying oven at

19.0 to 22.0°, (440) peak

110°C for 1 h. Cool the sample in the hydrator and hold at

25.5 to 28.0°, (642) peak

room temperature and 35 % relative humidity for at least 16 h.

NOTE 4—These ranges in Step 8.6 each are of such width that two or

NOTE 2—Drying, followed by rehydration, results in filling the zeolite

more zeolite peaks are included. Such wide ranges are specified to allow

pores with water of hydration but without an excess of moisture residing

for the variation in peak position over the range of unit cell dimensions

on the surface of the zeolite particles.

24.2 to 25.0 Å (2.42 to 2.50 mm) and to provide a background reading on

8.3 Pack the humidity-conditioned sample into an XRD each side of the main peak. Within each range the major zeolite peak will

be the desired one. See Appendix X1 of peak positions.

sample holder.

8.4 Obtain a first XRD pattern by scanning over the angle

9. Calculation

range from 14 to 35° 2θ at about 1°/min and using other

9.1 Obtain an integral peak intensity for each of the eight

instrument parameters best suited to the diffractometer.

peaks (measured above background) chosen from the patterns

8.4.1 Ifastripchartrecorderisused,setthechartdriveat10

from 8.4, for both the sample and reference, in one of three

mm/min. Select the scale factor (amplification) for the NaY

ways:

reference pattern so that the strong (533) peak at 23.6° is

9.1.1 By approximating the area under the peak as the

between 50 and 100 % of full scale. For the sample the scale

product of peak height and peak width at half height (use 9.2

factor may be reduced (amplification increased) to provide

for appropriate area calculations), or

reasonable peak heights. If possible the height of the (533)

9.1.2 By measuring the area under the peak with a planim-

peak for the sample should be at least 10 % of full scale. Fig.

eter (use 9.3 for area by planimeter), or

1 shows such patterns for the reference NaY and for a

9.1.3 From the counts recorded by a digital integrating

zeolite-containing catalyst.

system (use 9.4 for integrator counts calculation).

8.5 If this first pattern of the sample contains XRD peaks of

some nonfaujasite components, it must be established whether 9.2 Approximate Area Calculation:

this may cause interference in the following steps. (Fig. 2 is a 9.2.1 Ascale factor correction, SFC, is the ratio of the scale

complete diffractometer scan for NaY.) factor used for the sample pattern, SF , to that used for the

X

D3906 − 03 (2008)

Angle (°2θ)

FIG. 3 XRD ASTM NaY Intensity

reference pattern, SF .Thus, SFC = SF /SF . Scale factors are inpeakwidths,byuseofWFasdeterminedinStep9.2.2.Eight

R X R

usually expressed in terms of counts per second corresponding peaks are included in the summation in Table 1:

to full scale on the recorder. They ar

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3906–97 Designation:D3906–03 (Reapproved 2008)

Standard Test Method for

Determination of Relative X-ray Diffraction Intensities of

Faujasite-Type Zeolite-Containing Materials

This standard is issued under the fixed designation D 3906; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of relative X-ray diffraction intensities of zeolites having the faujasite crystal

structure, including synthetic Y and X zeolites, their modifications such as the various cation exchange forms, and the

dealuminized, decationated, and ultrastable forms of Y. These zeolites have cubic symmetry with a unit cell parameter usually

˚

within the limits of 24.2 and 25.0A25.0 Å (2.42 and 2.50 nm).

1.2 The samples include zeolite preparations in the various forms, and catalysts and adsorbents containing these zeolites.

1.3 The term “intensity of an X-ray powder diffraction (XRD) peak” is the “integral intensity,” either the area of counts under

the peak or the product of the peak height and the peak width.

1.4 This test method provides a number that is the ratio of intensity of portions of the XRD pattern of the sample to intensity

of the corresponding portion of the pattern of a reference zeolite, NaY. (Laboratories may use a modifiedY orX, for example, REY

as a secondary standard.) The intensity ratio, expressed as a percentage, is then labeled “% XRD intensity/NaY.”

1.5 Under certain conditions such a ratio is the percent zeolite in the sample. These conditions include:

1.5.1 The zeolite in the sample is the same as the reference zeolite.

1.5.2 The absorption for the X-rays used is the same for the zeolite and the nonzeolite portions of the sample.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This test method is under the jurisdiction of ASTM Committee D-32 on Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites.

Current edition approved March 10, 1997. Published October 1997. Originally published as D3906–80. Last previous edition D3906–91.

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites.

Current edition approved April 1, 2008. Published May 2008. Originally approved in 1980. Last previous edition approved in 2003 as D 3906–03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3906–03 (2008)

2. Referenced Documents

2.1 ASTM Standards:

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 456 Terminology Relating to Quality and Statistics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1The XRD patterns of the zeolite containing sample and the reference sample (NaY), are obtained under the same conditions.

Intensities of the (533) peak (23.5° with Cu Ka radiation) are compared to provide “% XRD intensity/NaY (533).” If the XRD

pattern of the zeolite is sufficiently strong, a comparison of the sums of intensities of eight peaks is used to give “% crystallinity.”

3.1 TheXRDpatternsofthezeolitecontainingsampleandthereferencesample(NaY),areobtainedunderthesameconditions.

If the XRD pattern of the zeolite is sufficiently strong, a comparison of intensities of eight peaks is used to give % XRD

intensity/NaY. For lower zeolite content intensities of the (533) peak (23.5° with Cu Ka radiation) are compared to provide “%

XRD intensity/NaY (533).”

4. Significance and Use

4.1 Zeolites Y and X, particularly for catalyst and adsorbent applications, are a major article of manufacture and commerce, use

of which has developed since the 1960s. commerce. Catalysts and adsorbents comprising these zeolites in various forms plus

binderandothercomponentshavelikewisebecomeimportantinthisperiod.important.Y-basedcatalystsareusedforfluidcatalytic

cracking(FCC)andhydrocrackingofpetroleum,whileX-basedadsorbentsareusedfordesiccation,sulfurcompoundremoval,and

air separation.

4.2 This X-ray procedure is designed to monitor these Y and X zeolites and catalysts and adsorbents, providing a number more

or less closely related to percent zeolite in the sample. This number has proven useful in technology, research, and specifications.

4.3 Drastic changes in intensity of individual peaks in the XRD patterns of Y and X can result from changes of distribution of

electron density within the unit cell of the zeolite. The electron density distribution is dependent upon the extent of filling of pores

in the zeolite with guest molecules, and on the nature of the guest molecules. In this XRD method, the guest molecule H O

completely fills the pores. Intensity changes may also result if some or all of the cations inY andX are exchanged by other cations.

4.3.1 Because of the factors mentioned in 4.3 that could vary the intensities of the XRD peaks, this XRD method will provide

the best determination of relative crystallinity when the reference and sample have a similar history of preparation and

composition.

4.4 Corrections are possible that can make this XRD method accurate for measuring percent zeolite in many specific situations.

These corrections are well known to those skilled in X-ray diffraction. It is not practical to specify those corrections here.

5. Apparatus

5.1 X-ray Diffractometer, equipped with a strip chart recorder or with computerized data acquisition and reduction capability,

using copper K-alpha radiation.

5.2 Drying Oven, set at 110°C.

5.3 Hydrator (Glass Laboratory Desiccator), maintained at 35 % relative humidity by a saturated solution of salt, such as

CaCl ·6H O.

2 2

5.4 Planimeter.

NOTE1—This planimeter may not be needed if the XRD instrument is equipped with a digital integrating circuit. Planimeter orAppropriate Peak Profile

Analysis or Digital Integration Software—If XRD is not equipped with appropriate software data analysis capability.

6. Reagents and Materials

6.1 NaY Powder and RE Exchanged Y Powder, as reference standards.

7. Sampling

7.1 Conduct sampling by splitting a large portion of the sample and reference material homogeneously.

7.2 Divide the sample and reference finely to permit packing of the materials into XRD sample holders.

NOTE2—The 1—The best test to determine if grinding is required is to try to pack the sample in the holder. Overgrinding can lead to breaking up of

fine crystals and even destruction of zeolite.

8. Procedure

8.1 Carry out the following steps, 8.2 through 8.5, in an identical manner for both the sample and the reference material, NaY.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from ASTM Committee D-32.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

D3906–03 (2008)

Angle (°2u)

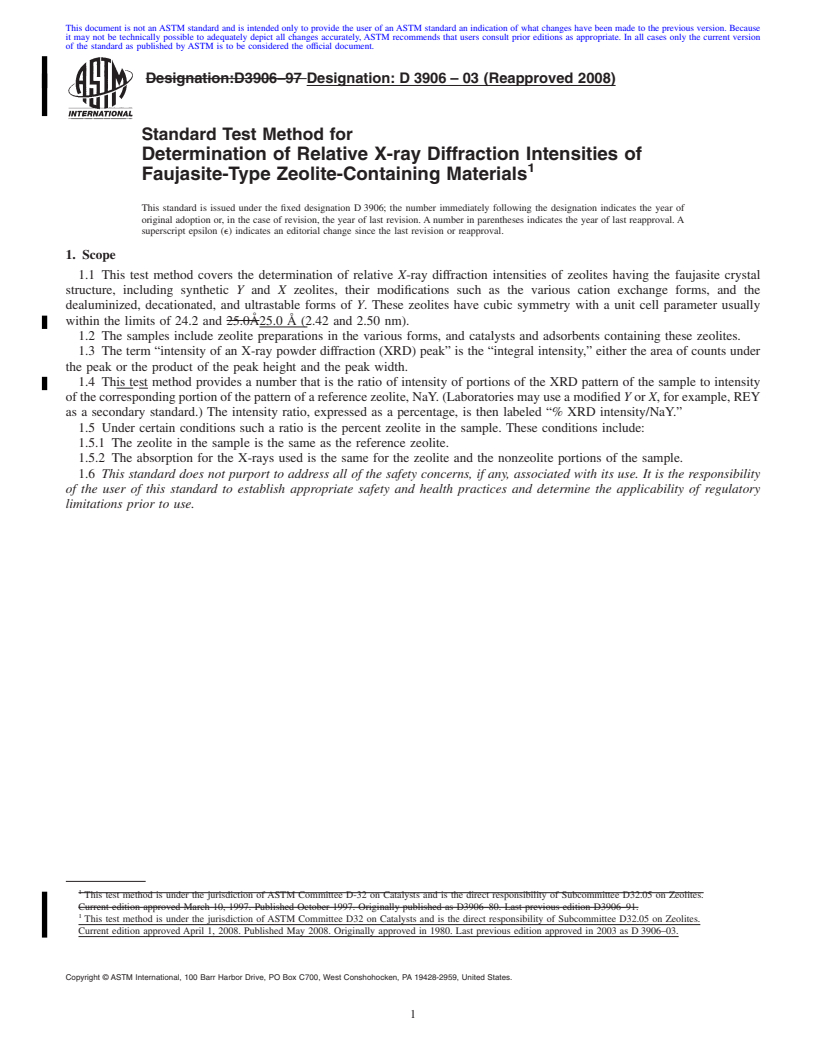

FIG. 1 X-Ray Diffraction Patterns of ASTM Zeolite Samples Upper—NaY; Lower—Cracking Catalyst Intensity

8.2 Place about 3 to5gofthe sample in the drying oven at 110°C for 1 h. Cool the sample in the hydrator and hold at room

temperature and 35 % relative humidity for at least 16 h.

NOTE 32—Drying, followed by rehydration, results in filling the zeolite pores with water of hydration but without an excess of moisture residing on

the surface of the zeolite particles.

8.3 Pack the humidity-conditioned sample into an XRD sample holder.

8.4 Obtain a first XRD pattern by scanning over the angle range from 14 to 35° 2u at about 1°/min and using other instrument

parameters best suited to the diffractometer.

8.4.1 If a strip chart recorder is used, set the chart drive at 10 mm/min. Select the scale factor (amplification) for the NaY

reference pattern so that the strong (533) peak at 23.6° is between 50 and 100 % of full scale. For the sample the scale factor may

be reduced (amplification increased) to provide reasonable peak heights. If possible the height of the (533) peak for the sample

should be at least 10 % of full scale. Fig. 1 shows such patterns for the reference NaY and for a zeolite-containing catalyst.

8.5 If this first pattern of the sample contains XRD peaks of some nonfaujasite components, it must be established whether this

may cause interference in the following steps. (Fig. 2 is a complete diffractometer scan for NaY.)

8.6 Obtain a second XRD pattern by scanning over a small angle range at ⁄4 °/min.

8.6.1If a strip chart recorder is used, set the drive at 20 mm/min. The same scale factors used in Step 8.4 are suitable. The

preferred angle range is from 22.5 to 25° 2u, the (533) peak.

NOTE 3—Longer scan times will be required for samples having a lower content of zeolite. For example 0.02º 2u/step for 1 s may be acceptable for

a pure NaY while 10 to 20 s counting times per step may be required for a low level of zeolite samples.

D3906–03 (2008)

Angle (°2u)

FIG. 2 NaY—Complete Diffractometer Scan Intensity

8.6.1 The preferred angle range is from 22.5 to 25° 2u, the (533) peak. Fig. 3 shows such a pattern for NaY. If interference rules

Angle (°2u)

FIG. 3 XRD ASTM NaY Intensity

D3906–03 (2008)

out this range, choose for this step (for both the sample and the reference patterns) one of the following angle ranges:

14.0 to 17.0°, (331) peak

19.0 to 22.0°, (440) peak

25.5 to 28.0°, (642) peak

NOTE 4—These ranges in Step 8.6 each are of such width that two or more zeolite peaks are included. Such wide ranges are specified to allow for the

variation in peak position over the range of unit cell dimensions 24.2 to 25.0 Å (2.42 to 2.50 mm) and to provide a background reading on each side

of the main peak. Within each range the major zeolite peak will be the desired one. See Appendix X1 of peak positions.

9. Calculation

9.1 Obtain an integral peak intensity for each of the eight peaks (measured above background) chosen from the patterns from

8.4, for both the sample and reference, in one of three ways:

9.1.1By approximating the area under the peak as the product of peak height and peak width at half height, or

9.1.2By measuring the area under the peak with a planimeter, or

9.1.3From the counts recorded by a digital integrating system.

9.1.1 By approximating the area under the peak as the product of peak height and peak width at half height (use 9.2 for

appropriate area calculations), or

9.1.2 By measuring the area under the peak with a planimeter (use 9.3 for area by planimeter), or

9.1.3 From the counts recorded by a digital integrating system (use 9.4 for integrator counts calculation).

9.2 Approximate Area Calculation :

9.2.1 Ascalefactorcorrection,SFC,istheratioofthescalefactorusedforthesamplepattern,SF ,tothatusedforthereference

X

pattern, SF . Thus, SFC = SF /SF . Scale factors are usually expressed in terms of counts per second corresponding to full scale

R X R

on the recorder. They are related inversely to amplification.

9.2.2 Measure the width of the (533) or alternative peaks obtained in Step 8.6. The width is measured at half the peak height,

that is, half way between the background and the peak maximum. Obtain the width factor,WF, which is the ratio of the peak width

of the sample, W , to that of the NaY reference material, W . Thus, WF = W /W W /W .

X R X R X R

NOTE 5—Peakbroadeningoccursforavarietyofreasons.Pertinentforzeolitearethefollowing:crystalsmaybeoflimitedsize,below0.2µm;crystals

maycontaindisorder;crystalsmayexistwitharangeofunitcelldimensions;anddiffractionmayoriginatefromvaryingdepthsbelowthesamplesurface,

limited by absorption, and related to density of packing of the sample.

9.2.3 The objective of the method, a value for “% XRD intensity/NaY,” is obtained in this step. This involves a comparison of

the sums of peak heights (measured above background) from the patterns obtained in Step 8.4. The ratio of these sums must be

corrected for difference in scale factor, by use of SFC as determined in Step 9.2.1, and for difference in peak widths, by use of

WF as determined in Step 9.2.2. Eight peaks are included in the summation in Table 1:

NOTE 6—The 2u value ranges tabulated in Table 1 are appropriate for zeolites with unit cell dimensions 24.2 to 25.0 Å.Å (2.42 to 2.50 nm).

NOTE 7—If nonzeolite components give XRD peaks interfering with certain of the tabulated peaks, these latter peaks should be omitted from the sums,

both for the sample and for the reference NaY.

9.2.4 The equation used is the following:

% XRD intensity/NaY 5 SFX 3 WF 3 ~S /S !3100 (1)

X R

!3 100

where:

S = sum of peak heights for the sample and

X

S = sum for the reference NaY.

R

This test method relies on two assumptions, that the peak intensities are properly expressed as the product of peak height and peak

half width, and that the ratio of half widths obtained from one peak, the (533) peak, is applicable to the other seven peaks used

inthesummation.Thefirstofthesetwoassumptionsisinvalidintherarecasewhenthepeaksaredoubletsresultingfrompresence

of two zeolites of distinctly different unit cell parameters. This preferred method is based on eight of the most intense diffraction

peaks, not because any single peak is more sensitive to details of crystal structure than is the sum of these eight peaks.

TABLE 1 Diffraction Angles 2u hkl Miller Indices

Peak 2u hkl

1 15.7 6 0.2 331

2 18.7 6 0.2 511, 333

3 20.4 6 0.3 440

4 23.7 6 0.4 533

5 27.1 6 0.5 642

6 30.8 6 0.5 822, 660

7 31.5 6 0.5 555, 751

8 34.2 6 0.6 664

D3906–03 (2008)

9.3 Area By Planimeter:

9.3.1 Obtain a value for “% XRD intensity/NaY” by comparing the sums of integrated peak intensities (measured above

background) by planimeter from the patterns obtained in 8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.