ASTM D7157-12(2018)

(Test Method)Standard Test Method for Determination of Intrinsic Stability of Asphaltene-Containing Residues, Heavy Fuel Oils, and Crude Oils (n-Heptane Phase Separation; Optical Detection)

Standard Test Method for Determination of Intrinsic Stability of Asphaltene-Containing Residues, Heavy Fuel Oils, and Crude Oils (<emph type="ital">n</emph >-Heptane Phase Separation; Optical Detection)

SIGNIFICANCE AND USE

5.1 This test method describes a sensitive method for estimating the intrinsic stability of an oil. The intrinsic stability is expressed as S-value. An oil with a low S-value is likely to undergo flocculation of asphaltenes when stressed (for example, extended heated storage) or blended with a range of other oils. Two oils each with a high S-value are likely to maintain asphaltenes in a peptized state and not lead to asphaltene flocculation when blended together.

5.2 This test method can be used by petroleum refiners to control and optimize the refinery processes and by blenders and marketers to assess the intrinsic stability of blended asphaltene-containing heavy fuel oils.

SCOPE

1.1 This test method covers a procedure for quantifying the intrinsic stability of the asphaltenes in an oil by an automatic instrument using an optical device.

1.2 This test method is applicable to residual products from thermal and hydrocracking processes, to products typical of Specifications D396 Grades No. 5L, 5H, and 6, and D2880 Grades No. 3-GT and 4-GT, and to crude oils, providing these products contain 0.5 % by mass or greater concentration of asphaltenes (see Test Method D6560).

1.3 This test method quantifies asphaltene stability in terms of state of peptization of the asphaltenes (S-value), intrinsic stability of the oily medium (So) and the solvency requirements of the peptized asphaltenes (Sa).

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7157 − 12 (Reapproved 2018)

Standard Test Method for

Determination of Intrinsic Stability of Asphaltene-Containing

Residues, Heavy Fuel Oils, and Crude Oils (n-Heptane

Phase Separation; Optical Detection)

This standard is issued under the fixed designation D7157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers a procedure for quantifying the

D396 Specification for Fuel Oils

intrinsic stability of the asphaltenes in an oil by an automatic

D2880 Specification for Gas Turbine Fuel Oils

instrument using an optical device.

D4057 Practice for Manual Sampling of Petroleum and

1.2 This test method is applicable to residual products from

Petroleum Products

thermal and hydrocracking processes, to products typical of

D4175 Terminology Relating to Petroleum Products, Liquid

Specifications D396 Grades No. 5L, 5H, and 6, and D2880

Fuels, and Lubricants

Grades No. 3-GT and 4-GT, and to crude oils, providing these

D4177 Practice for Automatic Sampling of Petroleum and

products contain 0.5 % by mass or greater concentration of

Petroleum Products

asphaltenes (see Test Method D6560).

D4870 Test Method for Determination of Total Sediment in

Residual Fuels

1.3 This test method quantifies asphaltene stability in terms

D6560 Test Method for Determination ofAsphaltenes (Hep-

of state of peptization of the asphaltenes (S-value), intrinsic

tane Insolubles) in Crude Petroleum and Petroleum Prod-

stabilityoftheoilymedium(So)andthesolvencyrequirements

ucts

of the peptized asphaltenes (Sa).

D6792 Practice for Quality Management Systems in Petro-

1.4 The values stated in SI units are to be regarded as

leum Products, Liquid Fuels, and Lubricants Testing

standard. No other units of measurement are included in this

Laboratories

standard.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 For definitions of some terms used in this test method,

responsibility of the user of this standard to establish appro-

refer to Terminology D4175.

priate safety, health, and environmental practices and deter-

3.1.2 asphaltenes, n—(rarely used in the singular), in petro-

mine the applicability of regulatory limitations prior to use.

leum technology, represent an oil fraction that is soluble in a

1.6 This international standard was developed in accor-

specified aromatic solvent but separates upon addition of an

dance with internationally recognized principles on standard-

excess of a specified paraffinic solvent.

ization established in the Decision on Principles for the

3.1.2.1 Discussion—In this test method, the aromatic sol-

Development of International Standards, Guides and Recom-

vent is toluene and the paraffinic solvent is n-heptane.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 3.1.3 compatibility, n—of crude oils or of heavy fuel oils,

the ability of two or more crude oils or fuel oils to blend

together within certain concentration ranges without evidence

of separation, such as the formation of multiple phases.

This test method is under the jurisdiction of Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.14 on Stability, Cleanliness and Compatibility of Liquid Fuels. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2018. Published June 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2012 as D7157 – 12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7157-12R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7157 − 12 (2018)

3.1.3.1 Discussion—Incompatible heavy fuel oils or crude aromaticsolventtothearomaticplusparaffinicsolventmixture

oils, when mixed or blended, result in the flocculation or having the same peptizing power as the oil.

precipitation of asphaltenes. Some oils may be compatible

3.2.5 solvent aromaticity, n—of a binary mixture of a

within certain concentration ranges in specific mixtures, but

paraffınic and an aromatic solvent, the solvency power of the

incompatible outside those ranges.

binary mixture.

3.2.5.1 Discussion—For the purpose of this test method,

3.1.4 flocculation, n—of asphaltenes from crude oils or

solvent aromaticity is defined as a ratio by volume of the

heavy fuel oils, the aggregation of colloidally dispersed as-

aromaticsolvent(toluene)totheparaffinicsolvent(n-heptane).

phaltenes into visible larger masses which may or may not

settle.

3.3 Symbols:

3.1.5 peptization, n—of asphaltenes in crude oils or heavy

FR = flocculation ratio

oils, the dispersion of asphaltenes to produce a colloidal

FR = maximum flocculation ratio

max

dispersion.

S = the intrinsic stability of an oil

Sa = the peptizability of an asphaltene

3.1.6 stability reserve, n—in petroleum technology, the

So = the peptizing power of an oil

property of an oil to maintain asphaltenes in a peptized state

X = paraffinic solvent consumption of undiluted oil, in

min

and prevent flocculation of asphaltenes.

mL/g of oil

3.1.6.1 Discussion—An oil with a low stability reserve is

likelytoundergoflocculationofasphalteneswhenstressed(for

4. Summary of Test Method

example, extended heated storage) or blended with a range of

4.1 Thistestmethodusesanintegratedautomatedanalytical

other oils.Two oils each with a high stability reserve are likely

measurement system with an optical probe for the detection of

to maintain asphaltenes in a peptized state and not lead to

asphaltene precipitation from a toluene solution of the sample.

flocculation when blended together.

4.2 Three test specimens are dissolved in three different

3.2 Definitions of Terms Specific to This Standard:

quantities of toluene. The three specimen/toluene solutions are

3.2.1 intrinsic stability (S-value), n— of refinery residual

automatically and simultaneously titrated with n-heptane to

streams, residual fuel oils and crude oils, an indication of the

cause precipitation of the asphaltenes. The optical probe

stability or available solvency power of an oil with respect to

monitors the formation of flocculated asphaltenes during the

precipitation of asphaltenes.

titration. Flocculated asphaltenes will alter the detected light

3.2.1.1 Discussion—Sincetheequationdefining S-valueis S

intensity. Start of flocculation is interpreted when the optical

=(1+ X ), where X is the minimum volume (in mL) of

probe detects a significant and sustained decrease in rate-of-

min min

paraffinic solvent, n-heptane, to be added to1gofoilto result

change of the light intensity.

in flocculation of asphaltenes, the smallest S-value is 1, which

4.3 A computer routine calculates stability parameters and

means the oil is unstable and can precipitate asphaltenes

subsequently the intrinsic stability of the oil from the added

without addition of any paraffinic solvent. A higher S-value

n-heptane at the inversion point, the mass of specimen, and the

indicates that an oil is more stable with respect to flocculation

volume of toluene, for the three specimen/toluene solutions.

of asphaltenes. S-value by this test method relates specifically

to toluene and n-heptane as the aromatic and paraffinic 5. Significance and Use

solvents, respectively.

5.1 This test method describes a sensitive method for

estimating the intrinsic stability of an oil.The intrinsic stability

3.2.2 inversion point, n—point in the n-heptane titration

is expressed as S-value. An oil with a low S-value is likely to

curve, where the onset of asphaltene flocculation leads to

undergo flocculation of asphaltenes when stressed (for

inversion of the light intensity.

example, extended heated storage) or blended with a range of

3.2.2.1 Discussion—At the first stage of the addition of

other oils. Two oils each with a high S-value are likely to

n-heptane to a dilution of specimen and toluene, light intensity

maintain asphaltenes in a peptized state and not lead to

increases through dilution. When asphaltenes start to

asphaltene flocculation when blended together.

flocculate, there will be a point where the increase in light

intensity through dilution matches the light intensity decrease

5.2 This test method can be used by petroleum refiners to

(inversion)asaresultofcoagulatedasphaltenesobstructingthe controlandoptimizetherefineryprocessesandbyblendersand

light beam.

marketerstoassesstheintrinsicstabilityofblendedasphaltene-

containing heavy fuel oils.

3.2.3 Sa, n—the S-value of an asphaltene, which is the

peptizability or ability of an asphaltene to remain in a colloidal

6. Interferences

dispersion.

6.1 High content of insoluble inorganic matter (sediment)

3.2.3.1 Discussion—Sa can also be described as one minus

has some interference in this test method. In this case, the

the ratio of So to S. Sa is linked to the length and number of

insoluble matter shall be removed by filtration according to

aromatic chains within the asphaltenes.

Test Method D4870.

3.2.4 So, n—the S-value of an oil.

6.2 Free water present in the oil can cause difficulties with

3.2.4.1 Discussion—So can also be described as the aro- the optical detector and should be removed by any suitable

matic equivalent of the oil expressed as the ratio of the means (for example, centrifugation) prior to testing.

D7157 − 12 (2018)

7. Apparatus 7.3 Dispenser, capable of delivering up to 10 mLof toluene

with an accuracy of 60.1 mL.

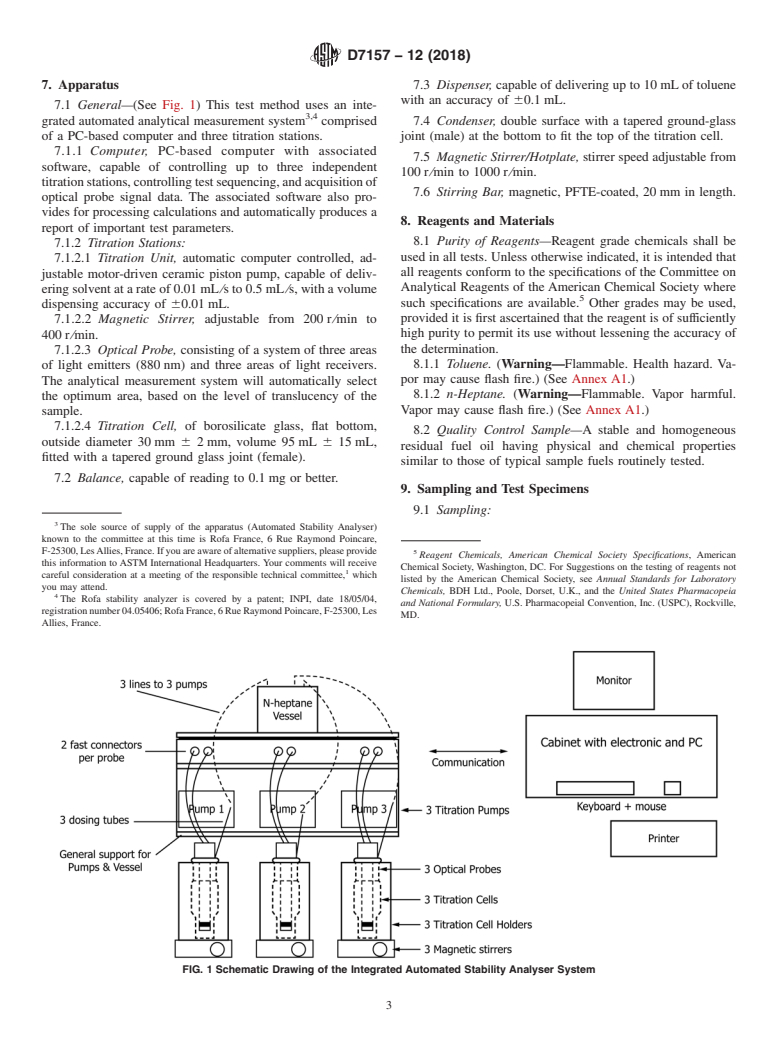

7.1 General—(See Fig. 1) This test method uses an inte-

3,4

grated automated analytical measurement system comprised 7.4 Condenser, double surface with a tapered ground-glass

of a PC-based computer and three titration stations. joint (male) at the bottom to fit the top of the titration cell.

7.1.1 Computer, PC-based computer with associated

7.5 Magnetic Stirrer/Hotplate, stirrer speed adjustable from

software, capable of controlling up to three independent

100 r⁄min to 1000 r⁄min.

titrationstations,controllingtestsequencing,andacquisitionof

7.6 Stirring Bar, magnetic, PFTE-coated, 20 mm in length.

optical probe signal data. The associated software also pro-

vides for processing calculations and automatically produces a

8. Reagents and Materials

report of important test parameters.

8.1 Purity of Reagents—Reagent grade chemicals shall be

7.1.2 Titration Stations:

used in all tests. Unless otherwise indicated, it is intended that

7.1.2.1 Titration Unit, automatic computer controlled, ad-

all reagents conform to the specifications of the Committee on

justable motor-driven ceramic piston pump, capable of deliv-

Analytical Reagents of the American Chemical Society where

ering solvent at a rate of 0.01 mL⁄s to 0.5 mL⁄s, with a volume

such specifications are available. Other grades may be used,

dispensing accuracy of 60.01 mL.

provided it is first ascertained that the reagent is of sufficiently

7.1.2.2 Magnetic Stirrer, adjustable from 200 r⁄min to

high purity to permit its use without lessening the accuracy of

400 r⁄min.

the determination.

7.1.2.3 Optical Probe, consisting of a system of three areas

8.1.1 Toluene. (Warning—Flammable. Health hazard. Va-

of light emitters (880 nm) and three areas of light receivers.

por may cause flash fire.) (See Annex A1.)

The analytical measurement system will automatically select

8.1.2 n-Heptane. (Warning—Flammable. Vapor harmful.

the optimum area, based on the level of translucency of the

Vapor may cause flash fire.) (See Annex A1.)

sample.

7.1.2.4 Titration Cell, of borosilicate glass, flat bottom,

8.2 Quality Control Sample—A stable and homogeneous

outside diameter 30 mm 6 2 mm, volume 95 mL 6 15 mL,

residual fuel oil having physical and chemical properties

fitted with a tapered ground glass joint (female).

similar to those of typical sample fuels routinely tested.

7.2 Balance, capable of reading to 0.1 mg or better.

9. Sampling and Test Specimens

9.1 Sampling:

The sole source of supply of the apparatus (Automated Stability Analyser)

known to the committee at this time is Rofa France, 6 Rue Raymond Poincare,

F-25300,LesAllies,France.Ifyouareawareofalternativesuppliers,pleaseprovide

Reagent Chemicals, American Chemical Society Specifications, American

this information to ASTM International Headquarters. Your comments will receive

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

careful consideration at a meeting of the responsible technical committee, which

listed by the American Chemical Society, see Annual Standards for Laboratory

you may attend.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

The Rofa stability analyzer is covered by a patent; INPI, date 18/05/04,

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

registrationnumber04.05406;RofaFrance,6RueRaymondPoincare,F-25300,Les

MD.

Allies, France.

FIG. 1 Schematic Drawing of the Integrated Automated Stability Analyser System

D7157 − 12 (2018)

9.1.1 Obtain representative samples in accordance with 10. Preparation of Apparatus

recognized sampling procedures such as Practices D4057 or

10.1 Prepare and set up the instrument for operation accord-

D4177.

ing to the manufacturer’s manual. (Refer to Fig. 1.)

9.1.2 Samples of very viscous materials may be warmed

10.2 Plug the optical probes into their connectors and place

until they are reasonably fluid before they are sampled.

them in their stand by position.

9.1.3 Store samples prior to taking test specimens at ambi-

ent temperatures.

10.3 Ensure that the reagent vessel contains sufficient

n-heptane to run the tests (minimum 200 mL).

9.2 Test Specimen Preparation:

9.2.1 Sample Temperature—If necessary, warm viscous

10.4 CleaningInstructions—Performthefollowingcleaning

samples until they can be mixed readily before opening the

procedure after the test procedure (see 12.1.8).

storage container. For fuels with a high wax content (high pour

10.4.1 Carefully remove the dosing tube and the optical

point) the temperature must be at least 15 °C above the pour

probe from the titration cell. Clean the optical probe with an

point.

appropriate solvent (toluene) (see 8.1.1).

9.2.2 Manually shake the sample thoroughly. If the sample

10.4.2 Remove the stirr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7157 − 12 D7157 − 12 (Reapproved 2018)

Standard Test Method for

Determination of Intrinsic Stability of Asphaltene-Containing

Residues, Heavy Fuel Oils, and Crude Oils (n-Heptane

Phase Separation; Optical Detection)

This standard is issued under the fixed designation D7157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This test method covers a procedure for quantifying the intrinsic stability of the asphaltenes in an oil by an automatic

instrument using an optical device.

1.2 This test method is applicable to residual products from thermal and hydrocracking processes, to products typical of

Specifications D396 Grades No. 5L, 5H, and 6, and D2880 Grades No. 3-GT and 4-GT, and to crude oils, providing these products

contain 0.5 mass% 0.5 % by mass or greater concentration of asphaltenes (see Test Method D6560).

1.3 This test method quantifies asphaltene stability in terms of state of peptization of the asphaltenes (S-value), intrinsic stability

of the oily medium (So) and the solvency requirements of the peptized asphaltenes (Sa).

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to useuse.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D396 Specification for Fuel Oils

D2880 Specification for Gas Turbine Fuel Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4870 Test Method for Determination of Total Sediment in Residual Fuels

D6560 Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products

D6792 Practice for Quality Management Systems in Petroleum Products, Liquid Fuels, and Lubricants Testing Laboratories

3. Terminology

3.1 Definitions:

3.1.1 For definitions of some terms used in this test method, refer to Terminology D4175.

3.1.2 asphaltenes, n—(rarely used in the singular), in petroleum technology, represent an oil fraction that is soluble in a specified

aromatic solvent but separates upon addition of an excess of a specified paraffinic solvent.

3.1.2.1 Discussion—

This test method is under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee D02.14

on Stability Stability, Cleanliness and CleanlinessCompatibility of Liquid Fuels.

Current edition approved Nov. 1, 2012June 1, 2018. Published February 2013June 2018. Originally approved in 2005. Last previous edition approved in 20092012 as

D7157D7157 – 12.–09. DOI: 10.1520/D7157-12.10.1520/D7157-12R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7157 − 12 (2018)

In this test method, the aromatic solvent is toluene and the paraffinic solvent is n-heptane.

3.1.3 compatibility, n—of crude oils or of heavy fuel oils, the ability of two or more crude oils or fuel oils to blend together

within certain concentration ranges without evidence of separation, such as the formation of multiple phases.

3.1.3.1 Discussion—

Incompatible heavy fuel oils or crude oils, when mixed or blended, result in the flocculation or precipitation of asphaltenes. Some

oils may be compatible within certain concentration ranges in specific mixtures, but incompatible outside those ranges.

3.1.4 flocculation, n—of asphaltenes from crude oils or heavy fuel oils, the aggregation of colloidally dispersed asphaltenes into

visible larger masses which may or may not settle.

3.1.5 peptization, n—of asphaltenes in crude oils or heavy oils, the dispersion of asphaltenes to produce a colloidal dispersion.

3.1.6 stability reserve, n—in petroleum technology, the property of an oil to maintain asphaltenes in a peptized state and prevent

flocculation of asphaltenes.

3.1.6.1 Discussion—

An oil with a low stability reserve is likely to undergo flocculation of asphaltenes when stressed (for example, extended heated

storage) or blended with a range of other oils. Two oils each with a high stability reserve are likely to maintain asphaltenes in a

peptized state and not lead to flocculation when blended together.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 intrinsic stability (S-value), n— of refinery residual streams, residual fuel oils and crude oils, an indication of the stability

or available solvency power of an oil with respect to precipitation of asphaltenes.

3.2.1.1 Discussion—

Since the equation defining S-value is S = (1 + X ), where X is the minimum volume (in mL) of paraffinic solvent, n-heptane,

min min

to be added to 1 g of oil to result in flocculation of asphaltenes, the smallest S-value is 1, which means the oil is unstable and can

precipitate asphaltenes without addition of any paraffinic solvent. A higher S-value indicates that an oil is more stable with respect

to flocculation of asphaltenes. S-value by this test method relates specifically to toluene and n-heptane as the aromatic and

paraffinic solvents, respectively.

3.2.2 inversion point, n—point in the n-heptane titration curve, where the onset of asphaltene flocculation leads to inversion of

the light intensity.

3.2.2.1 Discussion—

At the first stage of the addition of n-heptane to a dilution of specimen and toluene, light intensity increases through dilution. When

asphaltenes start to flocculate, there will be a point where the increase in light intensity through dilution matches the light intensity

decrease (inversion) as a result of coagulated asphaltenes obstructing the light beam.

3.2.3 Sa, n—the S-value of an asphaltene, which is the peptizability or ability of an asphaltene to remain in a colloidal

dispersion.

3.2.3.1 Discussion—

Sa can also be described as one minus the ratio of So to S.Sa is linked to the length and number of aromatic chains within the

asphaltenes.

3.2.4 So, n—the S-value of an oil.

3.2.4.1 Discussion—

So can also be described as the aromatic equivalent of the oil expressed as the ratio of the aromatic solvent to the aromatic plus

paraffinic solvent mixture having the same peptizing power as the oil.

3.2.5 solvent aromaticity, n—of a binary mixture of a paraffınic and an aromatic solvent, the solvency power of the binary

mixture.

D7157 − 12 (2018)

3.2.5.1 Discussion—

For the purpose of this test method, solvent aromaticity is defined as a ratio by volume of the aromatic solvent (toluene) to the

paraffinic solvent (n-heptane).

3.3 Symbols:

FR = flocculation ratio

FR = maximum flocculation ratio

max

S = the intrinsic stability of an oil

Sa = the peptizability of an asphaltene

So = the peptizing power of an oil

X = paraffinic solvent consumption of undiluted oil, in mL/g of oil

min

4. Summary of Test Method

4.1 This test method uses an integrated automated analytical measurement system with an optical probe for the detection of

asphaltene precipitation from a toluene solution of the sample.

4.2 Three test specimens are dissolved in three different quantities of toluene. The three specimen/toluene solutions are

automatically and simultaneously titrated with n-heptane to cause precipitation of the asphaltenes. The optical probe monitors the

formation of flocculated asphaltenes during the titration. Flocculated asphaltenes will alter the detected light intensity. Start of

flocculation is interpreted when the optical probe detects a significant and sustained decrease in rate-of-change of the light intensity.

4.3 A computer routine calculates stability parameters and subsequently the intrinsic stability of the oil from the added

n-heptane at the inversion point, the mass of specimen, and the volume of toluene, for the three specimen/toluene solutions.

5. Significance and Use

5.1 This test method describes a sensitive method for estimating the intrinsic stability of an oil. The intrinsic stability is

expressed as S-value. An oil with a low S-value is likely to undergo flocculation of asphaltenes when stressed (for example,

extended heated storage) or blended with a range of other oils. Two oils each with a high S-value are likely to maintain asphaltenes

in a peptized state and not lead to asphaltene flocculation when blended together.

5.2 This test method can be used by petroleum refiners to control and optimize the refinery processes and by blenders and

marketers to assess the intrinsic stability of blended asphaltene-containing heavy fuel oils.

6. Interferences

6.1 High content of insoluble inorganic matter (sediment) has some interference in this test method. In this case, the insoluble

matter shall be removed by filtration according to Test Method D4870.

6.2 Free water present in the oil can cause difficulties with the optical detector and should be removed by any suitable means

(for example, centrifugation) prior to testing.

7. Apparatus

3,4

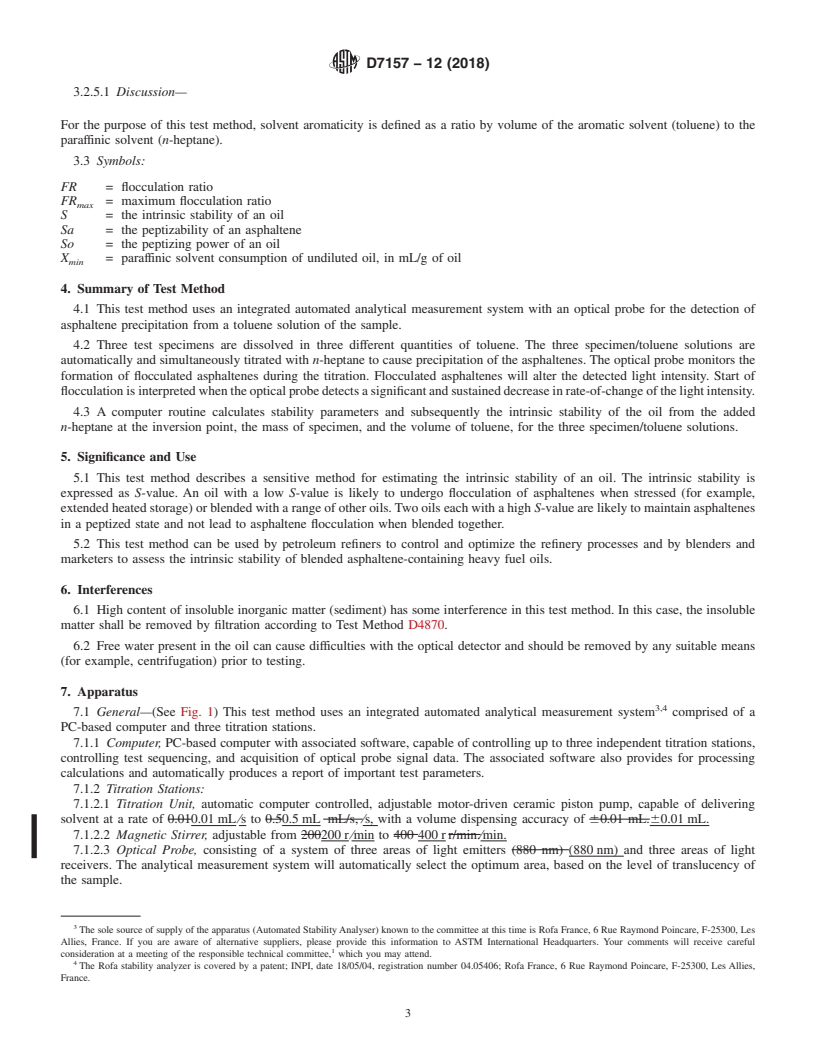

7.1 General—(See Fig. 1) This test method uses an integrated automated analytical measurement system comprised of a

PC-based computer and three titration stations.

7.1.1 Computer, PC-based computer with associated software, capable of controlling up to three independent titration stations,

controlling test sequencing, and acquisition of optical probe signal data. The associated software also provides for processing

calculations and automatically produces a report of important test parameters.

7.1.2 Titration Stations:

7.1.2.1 Titration Unit, automatic computer controlled, adjustable motor-driven ceramic piston pump, capable of delivering

solvent at a rate of 0.010.01 mL ⁄s to 0.50.5 mL mL/s, ⁄s, with a volume dispensing accuracy of 60.01 mL.60.01 mL.

7.1.2.2 Magnetic Stirrer, adjustable from 200200 r ⁄min to 400 400 r r/min.⁄min.

7.1.2.3 Optical Probe, consisting of a system of three areas of light emitters (880 nm) (880 nm) and three areas of light

receivers. The analytical measurement system will automatically select the optimum area, based on the level of translucency of

the sample.

The sole source of supply of the apparatus (Automated Stability Analyser) known to the committee at this time is Rofa France, 6 Rue Raymond Poincare, F-25300, Les

Allies, France. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

The Rofa stability analyzer is covered by a patent; INPI, date 18/05/04, registration number 04.05406; Rofa France, 6 Rue Raymond Poincare, F-25300, Les Allies,

France.

D7157 − 12 (2018)

FIG. 1 Schematic Drawing of the Integrated Automated Stability Analyser System

7.1.2.4 Titration Cell, of borosilicate glass, flat bottom, outside diameter 3030 mm 6 2 mm, 2 mm, volume 9595 mL 6 15 mL,

15 mL, fitted with a tapered ground glass joint (female).

7.2 Balance, capable of reading to 0.1 mg 0.1 mg or better.

7.3 Dispenser, capable of delivering up to 10 mL 10 mL of toluene with an accuracy of 60.1 mL. 60.1 mL.

7.4 Condenser, double surface with a tapered ground-glass joint (male) at the bottom to fit the top of the titration cell.

7.5 Magnetic Stirrer/Hotplate, stirrer speed adjustable from 100100 r ⁄min to 1000 1000 r r/min.⁄min.

7.6 Stirring Bar, magnetic, PFTE-coated, 20 mm 20 mm in length.

8. Reagents and Materials

8.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

8.1.1 Toluene. (Warning—WarningFlammable.—Flammable. Health hazard. Vapor may cause flash fire.) (See Annex A1.)

8.1.2 n-Heptane. (Warning—WarningFlammable.—Flammable. Vapor harmful. Vapor may cause flash fire.) (See Annex A1.)

8.2 Quality Control Sample—A stable and homogeneous residual fuel oil having physical and chemical properties similar to

those of typical sample fuels routinely tested.

9. Sampling and Test Specimens

9.1 Sampling:

9.1.1 Obtain representative samples in accordance with recognized sampling procedures such as Practices D4057 or D4177.

9.1.2 Samples of very viscous materials may be warmed until they are reasonably fluid before they are sampled.

9.1.3 Store samples prior to taking test specimens at ambient temperatures.

9.2 Test Specimen Preparation:

9.2.1 Sample Temperature—If necessary, warm viscous samples until they can be mixed readily before opening the storage

container. For fuels with a high wax content (high pour point) the temperature must be at least 15°C15 °C above the pour point.

9.2.2 Manually shake the sample thoroughly. If the sample contains high content of insoluble inorganic matter, filter the sample

through a 47-mm47 mm diameter glass fiber filter medium (such as Whatman Grade GF/A), using the Test Method D4870 filtration

apparatus. Specimen should be representative of the whole sample.

Reagent Chemicals, American Chemical Society Specifications, America

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.