ASTM D1188-96(2002)

(Test Method)Standard Test Method for Bulk Specific Gravity and Density of Compacted Bituminous Mixtures Using Paraffin-Coated Specimens

Standard Test Method for Bulk Specific Gravity and Density of Compacted Bituminous Mixtures Using Paraffin-Coated Specimens

SCOPE

1.1 This test method covers the determination of bulk specific gravity of specimens of Parafilm-coated, compacted bituminous mixtures as defined in Terminology E 12.

1.2 This method should be used with samples that contain open or interconnecting voids or absorb more than 2% of water by volume, or both, as determined by Section 8.

1.3 The bulk specific gravity of the compacted bituminous mixtures may be used in calculating the unit weight of the mixture.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1188 – 96 (Reapproved 2002)

Standard Test Method for

Bulk Specific Gravity and Density of Compacted Bituminous

1

Mixtures Using Coated Samples

This standard is issued under the fixed designation D1188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Significance and Use

1.1 This test method covers the determination of bulk 3.1 This test method is useful in calculating percent air

specific gravity of specimens of Parafilm-coated, compacted voids as given in Test Method D3203. Since specific gravity

bituminous mixtures as defined in Terminology E12. has no units, it must be converted to density when this type of

1.2 This method should be used with samples that contain measurement is required. This conversion is made by multi-

open or interconnecting voids or absorb more than 2% of plyingthespecificgravityatagiventemperaturebythedensity

water by volume, or both, as determined by Section 8. of water at the same temperature.

1.3 The bulk specific gravity of the compacted bituminous

4. Apparatus

mixtures may be used in calculating the unit weight of the

mixture. 4.1 Balance, with ample capacity, and with sufficient sensi-

tivity to enable bulk specific gravities to the specimens to be

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the calculated to at least four significant figures, that is, to at least

three decimal places. It shall be equipped with a suitable

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- apparatus to permit weighing the specimen while it is sus-

pended in water. The balance shall conform to Specification

bility of regulatory limitations prior to use.

D4753 as a class GP2 balance.

2. Referenced Documents

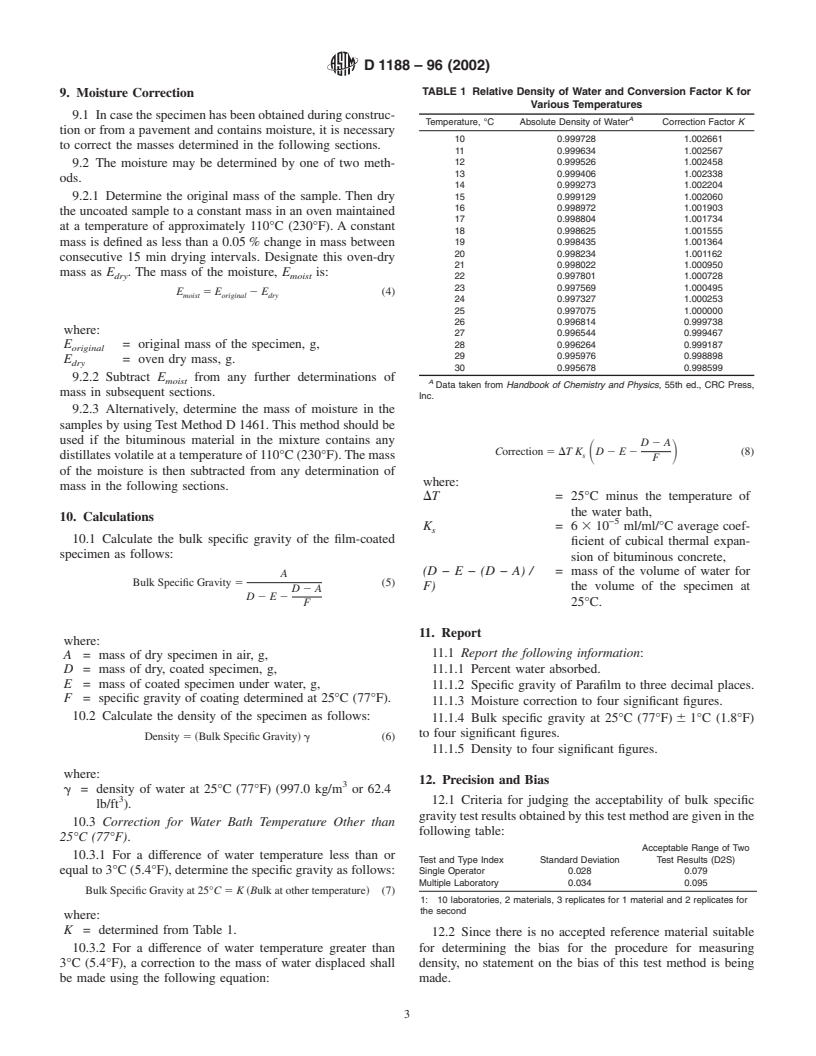

4.1.1 Since there are no more significant figures in the

2.1 ASTM Standards: quotient (bulk specific gravity) than appear in either the

2

D979 Practice for Sampling Bituminous Paving Mixtures dividend(themassofthespecimeninair)orinthedivisor(the

D1461 Test Method for Moisture or Volatile Distillates in volume of the specimen, obtained from the difference in mass

2

Bituminous Paving Mixtures ofthespecimeninairandinwater),thismeansthatthebalance

D2726 Test Method for Bulk Specific Gravity and Density must have a sensitivity capable of providing both mass and

2

of Non-Absorptive Compacted Bituminous Mixtures volume values to at least four figures. For example, a sensi-

D3203 Test Method for Percent Air Voids in Compacted tivity of 0.1 g would provide four significant figures for the

2

Dense and Open Bituminous Paving Mixtures determination of a mass in the range from 130.0 to 999.9 g

D4753 Specification for Evaluating, Selecting and Speci- when the specific gravity is 2.300.

fying Balances and Scales for Use in Testing Soil, Rock, 4.2 Water Bath, for immersing the specimen in water while

3

and Related Construction Materials suspended, equipped with either an overflow outlet for main-

E12 Terminology Relating to Density and Specific Gravity taining a constant water level or an electronic tare feature on

4

of Solids, Liquids, and Gases the scale.

5. Materials

5.1 Parafilm—Is an elastomeric film obtainable from most

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

scientific suppliers.

and Paving Materials and is the direct responsibility of Subcommittee D04.21 on

5.2 Polyurethane Foam—A foam mat of a minimum of

Specific Gravity and Density of Bituminous Mixtures.

Current edition approved Aug. 10, 1996. Published October 1996. Originally

50 350cm(20 320in.)shallbeusedfortheworkingsurface

published as D1188–51. Last previous edition D1188–89.

by about 12.5 mm (0.5 in.) thick.Additionally, a minimum of

2

Annual Book of ASTM Standards, Vol 04.03.

3

one foam pad with a size approximately equal to the top

Annual Book of ASTM Standards, Vol 04.08.

4

Annual Book of ASTM Standards, Vol 15.05. surface dimensions of the sample shall be on hand.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 1188 – 96 (2002)

5.3 Calibration Cylinder—An approximately 100-mm (4- stretched to an approximately 150 3150-mm (6 36-in.)

in.) diameter by 60-mm (2.5-in.) smooth-sided aluminum square. Take care not to create holes in the film.

cylinder. 8.2.4 Place the stretched film over one end of the specimen

and press the sides of the film around the sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.