ASTM F1508-96(2004)

(Specification)Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas and Liquid Services

Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas and Liquid Services

ABSTRACT

This specification covers spring-loaded, angle style, pressure relief valves for steam, gas, and liquid system applications. Pressure relief valves shall be of the following types and material grades: Type I, Grades A and B; Type II, Grades C and D; and Type III, Grades E and F. Hydrostatic shell test and set pressure, blowdown, and seat tightness test shall be performed to meet the specified requirements.

SCOPE

1.1 This specification covers spring-loaded, angle style, pressure relief valves for steam, gas, and liquid system applications (excluding boiler safety and hydraulic system relief valves).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F1508 – 96 (Reapproved 2004)

Standard Specification for

Angle Style, Pressure Relief Valves for Steam, Gas, and

1

Liquid Services

This standard is issued under the fixed designation F1508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A313/A313M Specification for Stainless Steel Spring Wire

A351/A351M Specification for Castings, Austenitic, for

1.1 This specification covers spring-loaded, angle style,

Pressure-Containing Parts

pressure relief valves for steam, gas, and liquid system

A479/A479M Specification for Stainless Steel Bars and

applications (excluding boiler safety and hydraulic system

Shapes for Use in Boilers and Other Pressure Vessels

relief valves).

A494/A494M Specification for Castings, Nickel and Nickel

2. Referenced Documents

Alloy

2

A689 Specification for Carbon and Alloy Steel Bars for

2.1 ASTM Standards:

Springs

A105/A105M Specification for Carbon Steel Forgings for

B21/B21M Specification for Naval Brass Rod, Bar, and

Piping Applications

Shapes

A125 Specification for Steel Springs, Helical, Heat-Treated

B61 Specification for Steam or Valve Bronze Castings

A182/A182M Specification for Forged or RolledAlloy and

B62 Specification for Composition Bronze or Ounce Metal

Stainless Steel Pipe Flanges, Forged Fittings, and Valves

Castings

and Parts for High-Temperature Service

B148 Specification for Aluminum-Bronze Sand Castings

A193/A193M Specification for Alloy-Steel and Stainless

B164 Specification for Nickel-Copper Alloy Rod, Bar, and

Steel Bolting Materials for High Temperature or High

Wire

Pressure Service and Other Special Purpose Applications

B637 Specification for Precipitation-Hardening Nickel Al-

A194/A194M Specification for Carbon and Alloy Steel

loy Bars, Forgings, and Forging Stock for High-

Nuts for Bolts for High Pressure or High Temperature

Temperature Service

Service, or Both

D5204 Classification System for Polyamide-Imide (PAI)

A216/A216M Specification for Steel Castings, Carbon,

Molding and Extrusion Materials

Suitable for Fusion Welding, for High-Temperature Ser-

F467 Specification for Nonferrous Nuts for General Use

vice

F468 Specification for Nonferrous Bolts, Hex Cap Screws,

A217/A217M Specification for Steel Castings, Martensitic

and Studs for General Use

Stainless and Alloy, for Pressure-Containing Parts, Suit-

3

2.2 ANSI Standards:

able for High-Temperature Service

ANSI B.1 Unified Screw Threads

A227/A227M Specification for Steel Wire, Cold-Drawn for

ANSI B16.5 Pipe Flanges and Flanged Fittings

Mechanical Springs

ANSI B16.34 Valves—Flanged, Threaded, and Welding

A229/A229M Specification for Steel Wire, Oil-Tempered

End

for Mechanical Springs

4

2.3 ASME Standard:

A231/A231M Specification for Chromium-VanadiumAlloy

Boiler and Pressure Vessel Code

Steel Spring Wire

5

2.4 API Standards:

A276 Specification for Stainless Steel Bars and Shapes

API Standard 526 Flanged Steel Safety-Relief Valves

API Standard RP 520, Part 1 Recommended Practice for

the Design and Installation of Pressure-Relieving Systems

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

in Refineries

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved May 1, 2004. Published May 2004. Originally

3

approved in 1996. Last previous edition approved in 1996 as F1508 – 96. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F1508-96R04. 4th Floor, New York, NY 10036.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Mechanical Engineers (ASME), ASME

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM International Headquarters, Three Park Ave., New York, NY 10016-5990.

5

Standards volume information, refer to the standard’s Document Summary page on Available from The American Petroleum Institute (API), 1220 L. St., NW,

the ASTM website. Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

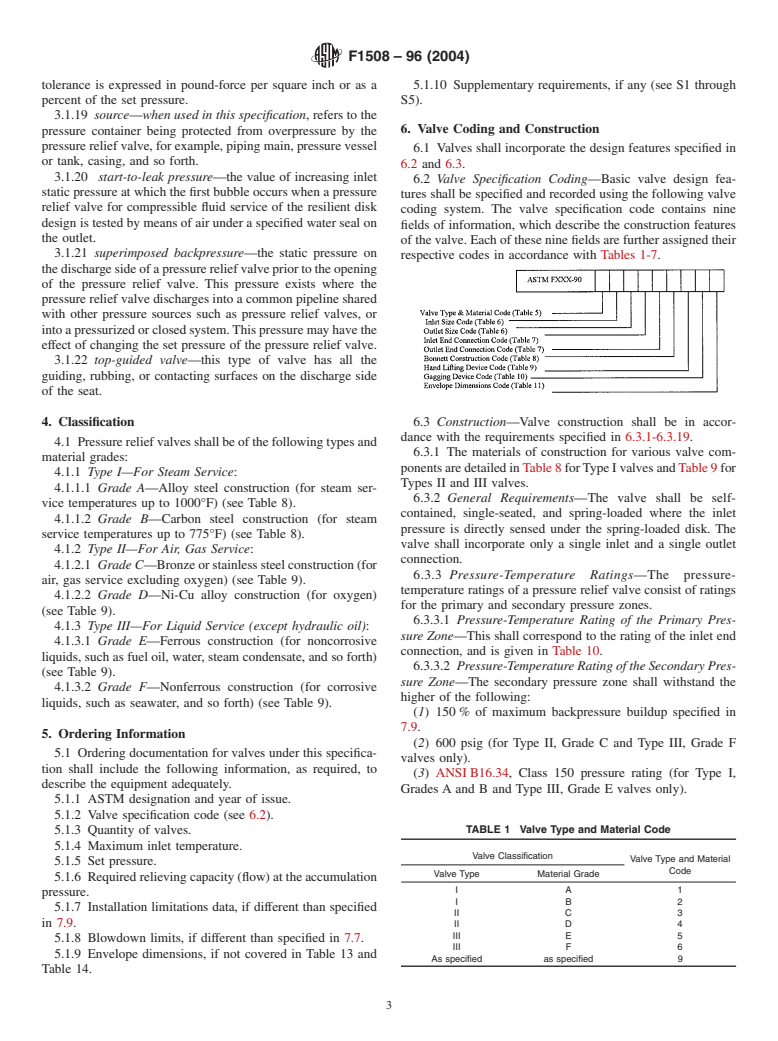

F1508 – 96 (2004)

6

2.5 Federal Specifications: 3.1.6 gagging device—a device, normally a screw (also

QQ-N-281 Nickel-Copper Alloy Bar, Rod, Plate, Sheet, called test gag), used to prevent the pressure relief valve from

Strip, Wire, Forgings, and Structural and Special Shaped opening during a hydrostatic pressure test of the equipment on

Sections which it is installed.

QQ-N-286 Nickel-Copper-Aluminum Alloy, Wrought

3.1.7 inlet pip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.