ASTM F1882-06(2014)

(Specification)Standard Specification for Residential Basketball Systems

Standard Specification for Residential Basketball Systems

ABSTRACT

This specification covers the performance and safety requirements intended to reduce the potential hazards associated with the manufacture, assembly, maintenance, and use of complete residential basketball systems. This specification is not intended to address the following: equipment intended to be used in places of public assembly (schools, parks, public and private recreational facilities, and the likes); individual components, such as rim, backboard, pole, portable base system, net, or other components not sold as a complete residential basketball system as defined here; any residential basketball system that is mounted to any structure or surface (roof mounting, wall mounting, or any locally or self-manufactured components) other than that which is purchased as part of a complete residential basketball system; any basketball equipment that does not use a full size rim, 18-in. (45.72-cm) diameter, or is designed for operational heights of less then 6 ft 6 in. (1.98 m) from the playing surface to the bottom of the backboard; and accessories and add-ons.

SCOPE

1.1 This specification covers the manufacture, assembly, recommended maintenance and use of complete residential basketball systems.

1.2 This specification is intended to reduce the potential hazards associated with the installation and use of residential basketball systems.

1.3 This specification is not intended to apply to the following:

1.3.1 Equipment intended to be used in places of public assembly, such as, but not limited to, schools, parks, public and private recreational facilities.

1.3.2 Individual components, such as rim, backboard, pole, portable base system, net, or other component when that component is not sold as a complete residential basketball system as defined in this specification.

1.3.3 Any residential basketball system that is mounted to any structure or surface other than that which is purchased as part of a complete residential basketball system. Examples include, but are not limited to, roof mounting, wall mounting, or any locally or self-manufactured components.

1.3.4 Any basketball equipment that does not use a full size rim, 18-in. (45.72-cm) diameter, or is designed for operational heights of less then 6 ft 6 in. (1.98 m) from the playing surface to the bottom of the backboard.

1.3.5 Accessories and add-ons.

1.4 This specification shall apply only to products manufactured after six months from the date this specification is published.

1.5 This specification does not cover product performance or quality, except as related to safety.

1.6 The tests are intended to uncover hazards, rather than to demonstrate the reliability of the system. The fact that a mechanism or material of a system fails during testing only is relevant if the failure creates a potential hazard.

1.7 The rationale for provisions in this specification are given in Appendix X1 and Appendix X2.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1882 −06(Reapproved 2014) An American National Standard

Standard Specification for

Residential Basketball Systems

This standard is issued under the fixed designation F1882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The rationale for provisions in this specification are

given in Appendix X1 and Appendix X2.

1.1 This specification covers the manufacture, assembly,

recommended maintenance and use of complete residential 1.8 The values stated in inch-pound units are to be regarded

basketball systems. as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

1.2 This specification is intended to reduce the potential

and are not considered standard.

hazards associated with the installation and use of residential

basketball systems. 1.9 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 This specification is not intended to apply to the

responsibility of the user of this standard to establish appro-

following:

priate safety and health practices and determine the applica-

1.3.1 Equipment intended to be used in places of public

bility of regulatory limitations prior to use.

assembly,suchas,butnotlimitedto,schools,parks,publicand

private recreational facilities.

2. Referenced Documents

1.3.2 Individual components, such as rim, backboard, pole,

2.1 ASTM Standards:

portable base system, net, or other component when that

D2240 Test Method for Rubber Property—Durometer Hard-

component is not sold as a complete residential basketball

ness

system as defined in this specification.

C1048 Specification for Heat-Strengthened and Fully Tem-

1.3.3 Any residential basketball system that is mounted to

pered Flat Glass

any structure or surface other than that which is purchased as

F1148 Consumer Safety Performance Specification for

part of a complete residential basketball system. Examples

Home Playground Equipment

include, but are not limited to, roof mounting, wall mounting,

2.2 ANSI Standards:

or any locally or self-manufactured components.

ANSI Z535 Warning Labels

1.3.4 Any basketball equipment that does not use a full size

rim, 18-in. (45.72-cm) diameter, or is designed for operational ANSI Z97.1–2004 American National Standard for Safety

Glazing Materials Used in Buildings—Safety Perfor-

heights of less then 6 ft 6 in. (1.98 m) from the playing surface

to the bottom of the backboard. mance Specification and Methods of Test

1.3.5 Accessories and add-ons.

2.3 BSI Standard:

BSI 6206: 1981 Impact Performance Requirements for Flat

1.4 This specification shall apply only to products manufac-

Safety Glass and Safety Plastics for Use in Buildings

tured after six months from the date this specification is

2.4 Federal Standards:Available from the Consumer Prod-

published.

uct Safety Commission, Washington, DC 20207.

1.5 This specification does not cover product performance

16 CFR 1303 Ban of Lead-Containing Paint and Certain

or quality, except as related to safety.

Consumer Products Bearing Lead-Containing Paint

1.6 The tests are intended to uncover hazards, rather than to

16 CFR 1500.48 Technical Requirements for Determining a

demonstrate the reliability of the system. The fact that a

Sharp Point in Toys and Other Articles Intended for Use

mechanism or material of a system fails during testing only is

by Children Under 8-Years of Age

relevant if the failure creates a potential hazard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction ofASTM Committee F08 on Sports Standards volume information, refer to the standard’s Document Summary page on

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of the ASTM website.

F08.25 on Recreational Basketball Equipment. Available from National Electrical Manufacturers Association (NEMA), 1300

Current edition approved Nov. 1, 2014. Published December 2014. Originally N. 17th St., Suite 1847, Rosslyn, VA 22209.

approved in 1998. Last previous edition approved in 2006 as F1882 – 06. DOI: Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

10.1520/F1882-06R14. London W4 4AL, U.K.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1882−06 (2014)

16 CFR 1500.49 Technical Requirements for Determining a 3.1.17 supplemental restraint systems, n—additional meth-

Sharp Metal or Glass Edge in Toys and Other Articles ods of adding stability over and above recommended ballast to

Intended for Use by Children Under 8-Years of Age portable base systems, that is ground stakes and additional

weight.

3. Terminology

3.1.18 support system, n—structure provided to support rim

and backboard in playing position. Could include pole, por-

3.1 Definitions of Terms Specific to This Standard:

table base, or mounting brackets.

3.1.1 accessories and add-ons (items not covered in 3.1.3,

3.1.6, 3.1.10 and 3.1.16–3.1.17), n—including but not limited

4. General Requirements

to,suchthingsasballreturns,scoringandtrainingdevices,and

including items attached to the system not intended for use in 4.1 Acomplete residential basketball system, represented as

basketball. complying with this performance specification, shall meet all

applicable requirements specified herein.

3.1.2 adjusting mechanism, n—moveable components that

lock structural components in the desired position to facilitate

5. Performance Requirements

changes in rim height.

5.1 General—The standards listed in 5.3 – 5.6 apply only to

3.1.3 backboard, n—rigid, flat surface to provide rebound

the normal access area as described in 3.1.11 and Fig. 1.

surface for a basketball.

5.2 Paint Toxicity—All paints and finishes used on basket-

3.1.4 complete residential basketball system, n—any com-

ball equipment shall be in accordance with 16 CFR Part 1303.

bination of rim, net, backboard, portable or non-portable

5.3 Edges, Points, and Surfaces—Following assembly of

pole-type support system not specifically excluded in 1.3.1 –

the system, in accordance with the instructions to be provided

1.3.5 that is designed and marketed by the original manufac-

to the consumer, there shall be no exposed sharp edges, points,

turer to be used together, whether packaged together as a

or surfaces on any portion of the residential basketball equip-

system, or separately as individual components.

ment according to CPSC 16 CFR 1500.48 and 1500.49.

3.1.5 footing, n—the method for securing the placement of

5.4 Thereshallbenopinch,crush,orshearpointsasdefined

the system into the ground.

in 3.1.13.

3.1.6 full-size rim, n—moveable or fixed-type rim with an

5.5 Moving parts or height adjustment mechanisms outside

18-in. (45.72-cm) inside diameter.

the normal access area, which could pose a finger entrapment

3.1.7 ground base systems, n—systems that have a main

problem, shall be noted clearly in the warning label on the

support pole attached in ground by a footing.

system and the safety instructions for proper use to reduce the

3.1.8 hanging, v—when a player briefly suspends their full

risk of injury.

weight from any point on the rim.

5.6 Hardware—Hardware must comply with the section on

3.1.9 maximum offset, n—distancefromthefrontofthebase

Hardware, Nuts, and Bolts of Performance Specification

or pole, whichever extends furthest from the system, to the

F1148.

front face of the backboard.

5.6.1 An projections and protrusions must comply with

CPSC Handbook for Playground Safety Publication 325 and

3.1.10 net, n—a device that hangs below the rim that

Performance Specification F1148.

restricts the downward movement of the ball.

5.6.2 Lock washers, self-locking nuts, or other locking

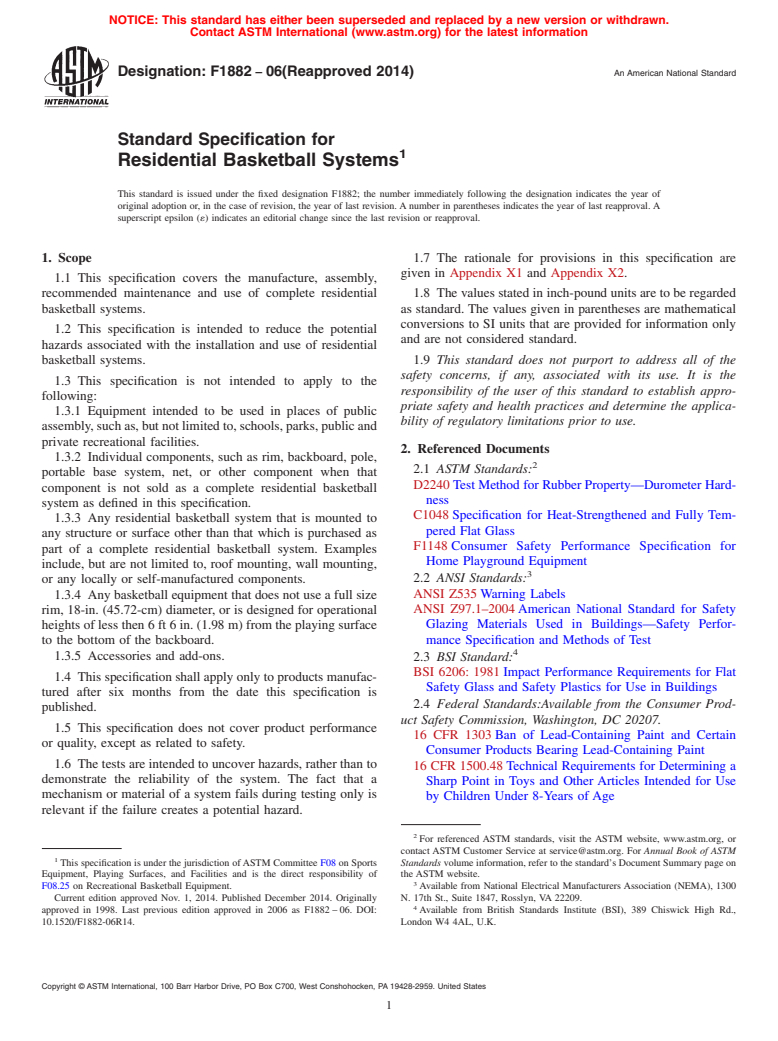

3.1.11 normal access area, n—as described in Fig. 1.

means shall be provided for all permanently attached bolts.

3.1.12 normal use, n—those safe-play modes that conform

5.7 Rims:

to the instructions that accompany the equipment. Misuse,

5.7.1 Rims—Each rim shall be attached to a support struc-

alteration, or modification are not considered normal use.

ture in such a way that ensures the rim and all structural

3.1.13 pinch, crush, shear points, n—any point that entraps

components stay attached should the backboard break.

at one or more positions a ⁄2-in. (13-mm) diameter neoprene

5.7.2 Backboards Made of Glass—All glass backboards

rod. Entrapment shall mean that force of more than 2 lb (0.90

shall be made of fully tempered glass. As specified in Speci-

kg)isrequiredtopullouttherod.Theneoprenerodsshallhave

fication C1048, “Fully tempered glass is approximately four

a hardness reading between 50 and 60 as determined by aType

times as strong as annealed glass of the same thickness and

A Durometer as given in Test Method D2240.

configuration. When broken, by impact, fully tempered glass

fractures into relatively small pieces meeting safety glazing

3.1.14 pole joint, n—mechanical method for connecting a

requirements thereby greatly reducing the likelihood of serious

multiple segment pole.

cutting or piercing injuries in comparison with ordinary an-

3.1.15 portable base systems, n—systems that have a ballast

nealed glass. Fully tempered glass is intended for used in

type support system that allows the system to be moved.

applications where its strength or safety characteristics may be

3.1.16 residential basketball equipment, n—equipment that required.” The very nature of basketball makes it obvious that

isintendedforthenormaluseandplayinresidentialbasketball the increased strength and safety characteristics of fully tem-

that includes the components given in 3.1.3, 3.1.6, 3.1.10 and pered glass should be required in any glass backboard appli-

3.1.17. cation.

F1882−06 (2014)

FIG. 1Normal Access Area

6. Stability/Structural Integrity there shall be no visible cracks, permanent deformation,

breakage, or deterioration of any component that may ad-

6.1 Portable Base System Testing (To Be Performed by the

versely affect the structural integrity or safety of the equip-

Manufacturer)—The test should be performed to determine the

ment.

ability of the portable base system to withstand anticipated

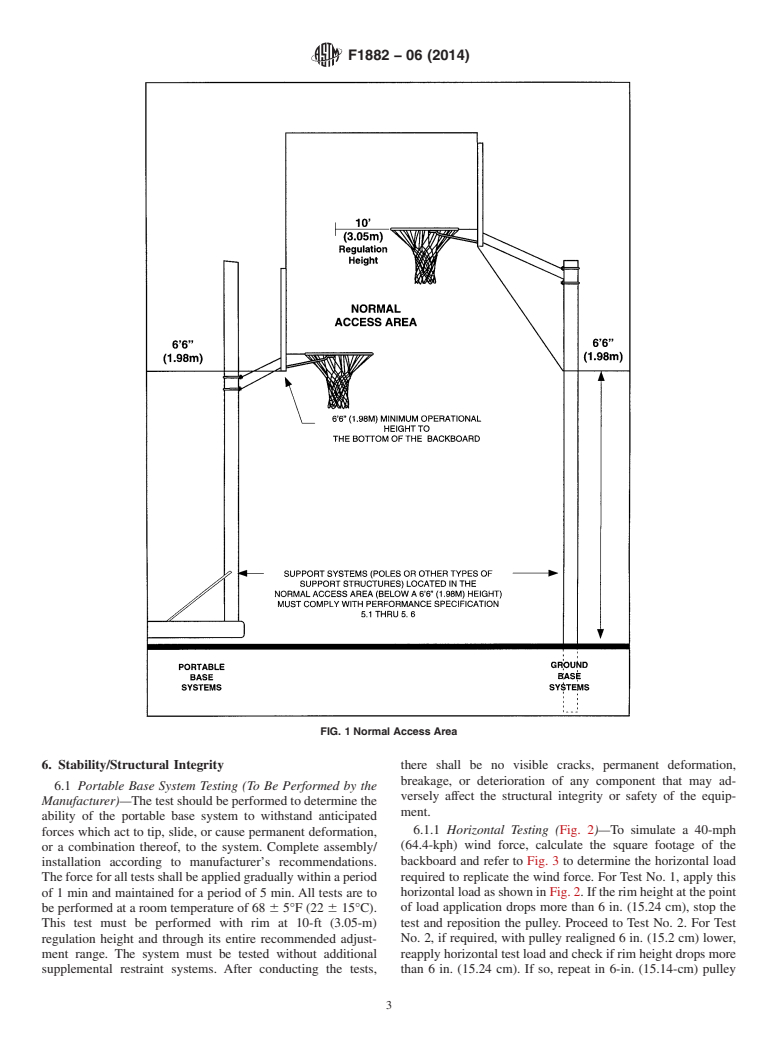

6.1.1 Horizontal Testing (Fig. 2)—To simulate a 40-mph

forces which act to tip, slide, or cause permanent deformation,

(64.4-kph) wind force, calculate the square footage of the

or a combination thereof, to the system. Complete assembly/

backboard and refer to Fig. 3 to determine the horizontal load

installation according to manufacturer’s recommendations.

Theforceforalltestsshallbeappliedgraduallywithinaperiod required to replicate the wind force. For Test No. 1, apply this

horizontalloadasshowninFig.2.Iftherimheightatthepoint

of 1 min and maintained for a period of 5 min. All tests are to

be performed at a room temperature of 68 6 5°F (22 6 15°C). of load application drops more than 6 in. (15.24 cm), stop the

test and reposition the pulley. Proceed to Test No. 2. For Test

This test must be performed with rim at 10-ft (3.05-m)

regulation height and through its entire recommended adjust- No. 2, if required, with pulley realigned 6 in. (15.2 cm) lower,

reapply horizontal test load and check if rim height drops more

ment range. The system must be tested without additional

supplemental restraint systems. After conducting the tests, than 6 in. (15.24 cm). If so, repeat in 6-in. (15.14-cm) pulley

F1882−06 (2014)

drops more than 6 in. (15.24 cm) stop test and reposition

pulley. Proceed to Test No. 2. For Test No. 2, if required, with

the pulley realigned 6 in. (15.24 cm) lower, reapply horizontal

test load and check if rim height drops more than 6 in. (15.24

cm). If so, repeat in 6 in. (15.24 cm) pulley height reduction

segments. The test must be performed in both a forward and

rearward directions.

6.2.2 Vertical Testing (Fig. 8)—Apply a 250-lb (113.4-kg)

load.

6.2.3 Glass backboards shall be tested in accordance with

BS 6206:1981 Appendix B Parts B.3 and B.4.

FIG. 2Portable Base Horizontal and Vertical Testing

6.2.3.1 App. B Part B.3—“Apparatus –The following appa-

ratus is required. B.3.1 Impactor, with a radius of curvature of

height reduction segments. The test must be performed in both the point of 0.20 mm = 0.05 mm. NOTE–Apointed hammer of

at least 75 g mass, or a spring loaded centre punch or similar

forward and rearward directions, and the system must not tip

over beyond the balance point, in accordance with Fig. 4. appliance can be used. B.3.2 Means of support, comprising a

flat base on which the test piece is laid without any mechanical

6.1.2 Horizontal Rim Weight (Fig. 5)—Determine the

constraint. In order to prevent scattering of fragments, the test

weight of the system (at the rim) while in a level horizontal

piece shall be simply held at the edges so that the fragments

position (80 lb (36.39 kg) max.

remain interlocked after breakage, without hindering extension

6.1.3 Vertical Minimum Load (Fig. 2)—This load is 101.25

lb (45.93 kg), and it must be applied vertically from the tip of of the test piece.”

the rim. With the required load, system must not tip over past

6.2.3.2 App. B Part B.4—“Procedure –Strike the test piece

its balance point in accordance with Fig. 4.

13 mm from its longest edge at the midpoint of that edge until

6.1.4 Balance Point of System Testing (Fig. 4)—Pull system

breakage occurs.”

forward to the point of balance where it will not fall forward or

6.2.3.3 Once breakage occurs, the results shall be inter-

backward. The maximum distance between the tip of rim and

preted in accordance with ANSI Z97.1, Section 5.1.4 (2): “A

the ground should be less than 5 ft 6 in. (1.68 m). When the

glazingmaterialshallbejudgedtopasstheimpacttest,ifwhen

system is released backwards above the natural balance point,

breakage occurs, the ten largest crack-free particles shall be

it must return system to the normal upright position.

selected within 5 min subsequent to the impact and shall weigh

2 2

6.1.5 Horizontal Side Testing (Fig. 6)—With a 25-lb (11.34-

no more than the equivalent weight of 10 in. (640 mm )ofthe

kg) load, the portable system must not tip over sideways to

originalspecimen.Forpurposesofimpacttestevaluationwhen

such a point where the rim/backboard touches the ground.

breakage occurs, the average thickness of a tempered glass

6.1.6 Portability Test on an Incline (

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1882 − 06 F1882 − 06 (Reapproved 2014) An American National Standard

Standard Specification for

Residential Basketball Systems

This standard is issued under the fixed designation F1882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the manufacture, assembly, recommended maintenance and use of complete residential basketball

systems.

1.2 This specification is intended to reduce the potential hazards associated with the installation and use of residential basketball

systems.

1.3 This specification is not intended to apply to the following:

1.3.1 Equipment intended to be used in places of public assembly, such as, but not limited to, schools, parks, public and private

recreational facilities.

1.3.2 Individual components, such as rim, backboard, pole, portable base system, net, or other component when that component

is not sold as a complete residential basketball system as defined in this specification.

1.3.3 Any residential basketball system that is mounted to any structure or surface other than that which is purchased as part

of a complete residential basketball system. Examples include, but are not limited to, roof mounting, wall mounting, or any locally

or self-manufactured components.

1.3.4 Any basketball equipment that does not use a full size rim, 18-in. (45.72-cm) diameter, or is designed for operational

heights of less then 6 ft 6 in. (1.98 m) from the playing surface to the bottom of the backboard.

1.3.5 Accessories and add-ons.

1.4 This specification shall apply only to products manufactured after six months from the date this specification is published.

1.5 This specification does not cover product performance or quality, except as related to safety.

1.6 The tests are intended to uncover hazards, rather than to demonstrate the reliability of the system. The fact that a mechanism

or material of a system fails during testing only is relevant if the failure creates a potential hazard.

1.7 The rationale for provisions in this specification are given in Appendix X1 and Appendix X2.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2240 Test Method for Rubber Property—Durometer Hardness

C1048 Specification for Heat-Strengthened and Fully Tempered Flat Glass

F1148 Consumer Safety Performance Specification for Home Playground Equipment

2.2 ANSI Standards:

ANSI Z535 Warning Labels

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment Equipment, Playing Surfaces, and Facilitiesand is the direct responsibility of

F08.25 on Recreational Basketball Equipment.

Current edition approved May 1, 2006Nov. 1, 2014. Published May 2006December 2014. Originally approved in 1998. Last previous edition approved in 20042006 as

F1882 – 04.F1882 – 06. DOI: 10.1520/F1882-06.10.1520/F1882-06R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from National Electrical Manufacturers Association (NEMA), 1300 N. 17th St., Suite 1847, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1882 − 06 (2014)

ANSI Z97.1–2004 American National Standard for Safety Glazing Materials Used in Buildings—Safety Performance

Specification and Methods of Test

2.3 BSI Standard:

BSI 6206: 1981 Impact Performance Requirements for Flat Safety Glass and Safety Plastics for Use in Buildings

2.4 Federal Standards:Available from the Consumer Product Safety Commission, Washington, DC 20207.

16 CFR 1303 Ban of Lead-Containing Paint and Certain Consumer Products Bearing Lead-Containing Paint

16 CFR 1500.48 Technical Requirements for Determining a Sharp Point in Toys and Other Articles Intended for Use by Children

Under 8-Years of Age

16 CFR 1500.49 Technical Requirements for Determining a Sharp Metal or Glass Edge in Toys and Other Articles Intended for

Use by Children Under 8-Years of Age

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 accessories and add-ons (items not covered in 3.1.3, 3.1.6, 3.1.10 and 3.1.16–3.1.17), n—including but not limited to, such

things as ball returns, scoring and training devices, and including items attached to the system not intended for use in basketball.

3.1.2 adjusting mechanism, n—moveable components that lock structural components in the desired position to facilitate

changes in rim height.

3.1.3 backboard, n—rigid, flat surface to provide rebound surface for a basketball.

3.1.4 complete residential basketball system, n—any combination of rim, net, backboard, portable or non-portable pole-type

support system not specifically excluded in 1.3.1 – 1.3.5 that is designed and marketed by the original manufacturer to be used

together, whether packaged together as a system, or separately as individual components.

3.1.5 footing, n—the method for securing the placement of the system into the ground.

3.1.6 full-size rim, n—moveable or fixed-type rim with an 18-in. (45.72-cm) inside diameter.

3.1.7 ground base systems, n—systems that have a main support pole attached in ground by a footing.

3.1.8 hanging, v—when a player briefly suspends their full weight from any point on the rim.

3.1.9 maximum offset, n—distance from the front of the base or pole, whichever extends furthest from the system, to the front

face of the backboard.

3.1.10 net, n—a device that hangs below the rim that restricts the downward movement of the ball.

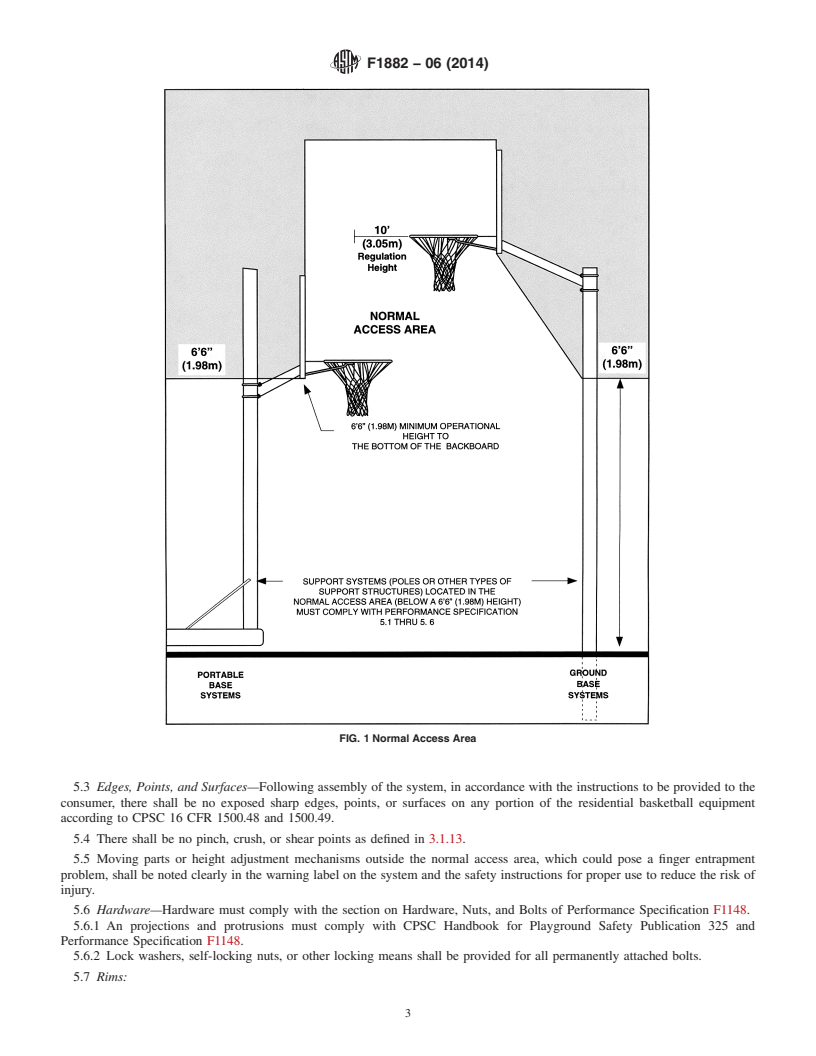

3.1.11 normal access area, n—as described in Fig. 1.

3.1.12 normal use, n—those safe-play modes that conform to the instructions that accompany the equipment. Misuse, alteration,

or modification are not considered normal use.

3.1.13 pinch, crush, shear points, n—any point that entraps at one or more positions a ⁄2-in. (13-mm) diameter neoprene rod.

Entrapment shall mean that force of more than 2 lb (0.90 kg) is required to pull out the rod. The neoprene rods shall have a hardness

reading between 50 and 60 as determined by a Type A Durometer as given in Test Method D2240.

3.1.14 pole joint, n—mechanical method for connecting a multiple segment pole.

3.1.15 portable base systems, n—systems that have a ballast type support system that allows the system to be moved.

3.1.16 residential basketball equipment, n—equipment that is intended for the normal use and play in residential basketball that

includes the components given in 3.1.3, 3.1.6, 3.1.10 and 3.1.17.

3.1.17 supplemental restraint systems, n—additional methods of adding stability over and above recommended ballast to

portable base systems, that is ground stakes and additional weight.

3.1.18 support system, n—structure provided to support rim and backboard in playing position. Could include pole, portable

base, or mounting brackets.

4. General Requirements

4.1 A complete residential basketball system, represented as complying with this performance specification, shall meet all

applicable requirements specified herein.

5. Performance Requirements

5.1 General—The standards listed in 5.3 – 5.6 apply only to the normal access area as described in 3.1.11 and Fig. 1.

5.2 Paint Toxicity—All paints and finishes used on basketball equipment shall be in accordance with 16 CFR Part 1303.

Available from British Standards Institute (BSI), 389 Chiswick High Rd., London W4 4AL, U.K.

F1882 − 06 (2014)

FIG. 1 Normal Access Area

5.3 Edges, Points, and Surfaces—Following assembly of the system, in accordance with the instructions to be provided to the

consumer, there shall be no exposed sharp edges, points, or surfaces on any portion of the residential basketball equipment

according to CPSC 16 CFR 1500.48 and 1500.49.

5.4 There shall be no pinch, crush, or shear points as defined in 3.1.13.

5.5 Moving parts or height adjustment mechanisms outside the normal access area, which could pose a finger entrapment

problem, shall be noted clearly in the warning label on the system and the safety instructions for proper use to reduce the risk of

injury.

5.6 Hardware—Hardware must comply with the section on Hardware, Nuts, and Bolts of Performance Specification F1148.

5.6.1 An projections and protrusions must comply with CPSC Handbook for Playground Safety Publication 325 and

Performance Specification F1148.

5.6.2 Lock washers, self-locking nuts, or other locking means shall be provided for all permanently attached bolts.

5.7 Rims:

F1882 − 06 (2014)

FIG. 2 Portable Base Horizontal and Vertical Testing

5.7.1 Rims—Each rim shall be attached to a support structure in such a way that ensures the rim and all structural components

stay attached should the backboard break.

5.7.2 Backboards Made of Glass—All glass backboards shall be made of fully tempered glass. As specified in Specification

C1048, “Fully tempered glass is approximately four times as strong as annealed glass of the same thickness and configuration.

When broken, by impact, fully tempered glass fractures into relatively small pieces meeting safety glazing requirements thereby

greatly reducing the likelihood of serious cutting or piercing injuries in comparison with ordinary annealed glass. Fully tempered

glass is intended for used in applications where its strength or safety characteristics may be required.” The very nature of basketball

makes it obvious that the increased strength and safety characteristics of fully tempered glass should be required in any glass

backboard application.

6. Stability/Structural Integrity

6.1 Portable Base System Testing (To Be Performed by the Manufacturer)—The test should be performed to determine the

ability of the portable base system to withstand anticipated forces which act to tip, slide, or cause permanent deformation, or a

combination thereof, to the system. Complete assembly/installation according to manufacturer’s recommendations. The force for

all tests shall be applied gradually within a period of 1 min and maintained for a period of 5 min. All tests are to be performed

at a room temperature of 68 6 5°F (22 6 15°C). This test must be performed with rim at 10-ft (3.05-m) regulation height and

through its entire recommended adjustment range. The system must be tested without additional supplemental restraint systems.

After conducting the tests, there shall be no visible cracks, permanent deformation, breakage, or deterioration of any component

that may adversely affect the structural integrity or safety of the equipment.

6.1.1 Horizontal Testing (Fig. 2)—To simulate a 40-mph (64.4-kph) wind force, calculate the square footage of the backboard

and refer to Fig. 3 to determine the horizontal load required to replicate the wind force. For Test No. 1, apply this horizontal load

as shown in Fig. 2. If the rim height at the point of load application drops more than 6 in. (15.24 cm), stop the test and reposition

the pulley. Proceed to Test No. 2. For Test No. 2, if required, with pulley realigned 6 in. (15.2 cm) lower, reapply horizontal test

load and check if rim height drops more than 6 in. (15.24 cm). If so, repeat in 6-in. (15.14-cm) pulley height reduction segments.

The test must be performed in both forward and rearward directions, and the system must not tip over beyond the balance point,

in accordance with Fig. 4.

6.1.2 Horizontal Rim Weight (Fig. 5)—Determine the weight of the system (at the rim) while in a level horizontal position (80

lb (36.39 kg) max.

6.1.3 Vertical Minimum Load (Fig. 2)—This load is 101.25 lb (45.93 kg), and it must be applied vertically from the tip of the

rim. With the required load, system must not tip over past its balance point in accordance with Fig. 4.

6.1.4 Balance Point of System Testing (Fig. 4)—Pull system forward to the point of balance where it will not fall forward or

backward. The maximum distance between the tip of rim and the ground should be less than 5 ft 6 in. (1.68 m). When the system

is released backwards above the natural balance point, it must return system to the normal upright position.

6.1.5 Horizontal Side Testing (Fig. 6)—With a 25-lb (11.34-kg) load, the portable system must not tip over sideways to such

a point where the rim/backboard touches the ground.

6.1.6 Portability Test on an Incline (Fig. 7)—When following manufacturer’s recommendations for moving the portable system,

the system must remain in its transport (movable) position when placed on a 5° slope in any direction.

6.1.7 When following the manufacturer’s recommendations for moving the portable system, the system must be capable of

being moved a distance of 50 ft (15.24 m).

6.2 Ground Base System Testing (to be performed by the manufacturer)—The test should be performed to determine the ability

of the ground base system to withstand anticipated forces which act to tip, slide, or cause permanent deformation, or a combination

thereof, to the system. Complete assembly/installation according to manufacturer’s recommendations. The force for all tests shall

be applied gradually within a period of 1 min and maintained for a period of 5 min. This test must be performed with rim at 10-ft

F1882 − 06 (2014)

NOTE 1—The backboard sizes listed are for comparison use only. Each manufacturer is responsible for calculating and documenting the size of then

backboard being tested.

FIG. 3 Wind Force on Backboard

FIG. 4 Portable Base Balance Point of System Testing

(3.05-m) regulation height and through its entire recommended adjustment range. After conducting the tests, there shall be no

visible cracks, permanent

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.