ASTM D6479-01

(Test Method)Standard Test Method for Determining the Edgecomb Resistance of Woven Fabrics Used in Inflatable Restraints

Standard Test Method for Determining the Edgecomb Resistance of Woven Fabrics Used in Inflatable Restraints

SCOPE

1.1 This test method covers the procedures for determining the resistance to edgecombing of a woven fabric used in inflatable restraints.

1.2 Procedures and apparatus other than those stated in this standard may be used by agreement of purchaser and supplier with the specific deviations from the standard practice acknowledged in the report.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 6479 – 01

Standard Test Method for

Determining the Edgecomb Resistance of Woven Fabrics

1

Used in Inflatable Restraints

This standard is issued under the fixed designation D 6479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tion of yarns from their normal orthagonal configuration in a

woven fabric due to seam stress or similar action near the edge

1.1 This test method covers the procedures for determining

of a cut part

the resistance to edgecombing of a woven fabric used in

3.1.2 inflatable restraint, n—a vehicular safety device de-

inflatable restraints.

signed to cushion an occupant or equipment during collision;

1.2 Procedures and apparatus other than those stated in this

airbag.

standard may be used by agreement of purchaser and supplier

3.1.3 seam slippage, n—in sewn fabrics, the displacement

with the specific deviations from the standard practice ac-

of the fabric yarn parallel and adjacent to the stitch line

knowledged in the report.

3.1.4 yarn slippage,, n—in sewn fabrics, the displacement

1.3 The values stated in either SI units or inch-pound units

of one or more yarns from the original position, causing

are to be regarded separately as standard. The values stated in

differences in alignment, spacing, or both.

each system are not exact equivalents; therefore, each system

3.2 For definitions of other textile terms used in this test

must be used independent of the other.

method, refer to Terminology D 123.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 One end of a test specimen is clamped within one jaw of

priate safety and health practices and determine the applica-

a CRE tensile testing machine and a special fixture pierces a

bility of regulatory limitations prior to use.

row of equally spaced needle holes through the opposite end of

2. Referenced Documents the specimen. In accordance with Test Method D 5035, a

tensile force is applied to the specimen until rupture occurs.

2.1 ASTM Standards:

The measurement of the force required to cause rupture is the

D 76 Specification for Tensile Testing Machines for Tex-

2

measurement of edgecomb resistance.

tiles

2

D 123 Terminology Relating to Textiles

5. Significance and Use

2

D 1776 Practice for Conditioning Textiles for Testing

5.1 A measurement of a fabric’s edgecomb resistance indi-

D 2904 Practice for Interlaboratory Testing of a Textile Test

2 cates the relative tendency of a fabric to pull apart under seam

Method that Produces Normally Distributed Data

stress or similar action. The related concepts of yarn slippage

D 2906 Practice for Statements on Precision and Bias for

2 and seam slippage are limited to sewn seams, whereas the

Textiles

measurement of edgecomb resistance is made at the edge of a

D 5035 Test Method for Breaking Force and Elongation of

3 cut part in the absence of a sewn seam. The absence of a sewn

Textile Fabrics (Raveled Strip)

seam in this test method eliminates the effect that a particular

D 5822 (Test Method for Determining Seam Strength in

3 stitch might have on the tendency of a yarn to slip near an edge

Inflatable Restraint Cushion)

of a cut part

E 691 Practice for Conducting an Interlaboratory Study to

2 5.2 This test method is useful for material design evalua-

Determine The Precision of a Test Method

tions in such applications as airbags in which seam stress is a

3. Terminology major concern.

5.3 This method may be used as a complement to Test

3.1 Definitions:

Method D 5822.

3.1.1 edgecombing, n—for inflatable restraints, the separa-

6. Apparatus

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles

6.1 Tensile Testing Machine—A constant-rate-of-extension

and are the direct responsibility of Subcommittee D13.20 on Inflatable Restraints.

(CRE) type, that is designed for the tensile forces anticipated,

Current edition approved April 10, 2001. Published June 2001. Originally

published as D 6479–99. Last previous edition D 6479 – 00. that is operated at a rate of 200 6 10 mm/min (86 0.5 in./min),

2

Annual Book of ASTM Standards, Vol 07.01.

that has a force range selected such that the anticipated break

3

Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 6479

occurs between 10 and 90 % of full scale load, and that has 7.4 From the laboratory sample, select five test specimens

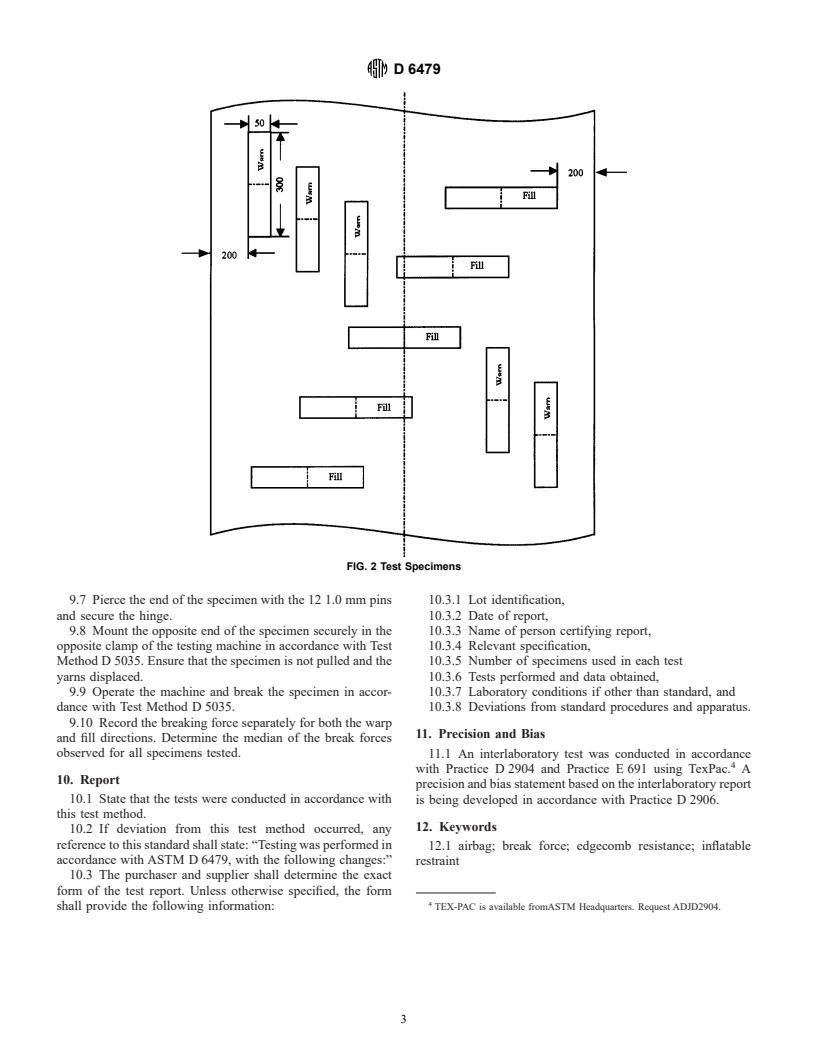

jaws and grip faces as agreed upon by purchaser and supplier. each from the warp and fill directions (Fig. 2).

6.2 Clamps, jaws with smooth, flat, parallel faces a mi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.