ASTM D7737-11

(Test Method)Standard Test Method for Individual Geogrid Junction Strength

Standard Test Method for Individual Geogrid Junction Strength

SIGNIFICANCE AND USE

This index test method is to be used to determine the strength of an individual junction in a geogrid product. The test is performed in isolation, while in service the junction is typically confined. Thus the results from this test method are not anticipated to be related to design performance.

The value of junction strength can be used for manufacturing quality control, development of new products, or a general understanding of the in-isolation behavior of a particular geogrid’s junction (for example., in relation to handling during shipment and placement of the geogrid).

This test method is applicable to geogrid products with essentially orthogonal ribs, yarns or straps, that is, geogrids which are composed of ribs, yarns or straps that are entangled through weaving or knitting, welded, bonded or formed through drawing.

SCOPE

1.1 This test method is an index test which provides a procedure for determining the strength of an individual geogrid junction, also called a node. The test is configured such that a single rib is pulled from its junction with a cross-rib to obtain the maximum force, or strength of the junction. The procedure allows for the use of two different clamps with the appropriate clamp selected to minimize the influence of the clamping mechanism on the specific type of geogrid to be tested.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7737 − 11

StandardTest Method for

Individual Geogrid Junction Strength

This standard is issued under the fixed designation D7737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 geogrid, n—the force at failure.

3.2.4 integral, adj—a geosynthetic formed by a regular

1.1 This test method is an index test which provides a

network of integrally connected elements with apertures

procedure for determining the strength of an individual geogrid

greater than 6.35 mm (1⁄4 inch) to allow interlocking with

junction, also called a node. The test is configured such that a

surrounding soil, rock, earth, and other surrounding materials

single rib is pulled from its junction with a cross-rib to obtain

to primarily function as reinforcement. (D5262)

the maximum force, or strength of the junction. The procedure

allows for the use of two different clamps with the appropriate

3.2.5 index test, n—a test procedure which may contain

clamp selected to minimize the influence of the clamping

known bias, but which may be used to establish an order for a

mechanism on the specific type of geogrid to be tested.

set of specimens with respect to the property of interest.

1.2 The values stated in SI units are to be regarded as the

3.2.6 junction, n—the point where geogrid ribs are intercon-

standard.

nected to provide structure and dimensional stability.

1.3 This standard does not purport to address all of the

3.2.7 rib, n—for geogrids, the continuous elements of a

safety concerns, if any, associated with its use. It is the

geogrid which are interconnected to a node or junction.

responsibility of the user of this standard to establish appro-

3.2.8 rupture, n—for geogrids, the breaking or tearing apart

priate safety and health practices and determine the applica-

of ribs.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 This standard proposes a test method for performing

2.1 ASTM Standards: tension tests on geogrid junctions. The procedure provides two

clamping techniques for the junction to be tested including:

D4354 Practice for Sampling of Geosynthetics and Rolled

Erosion Control Products(RECPs) for Testing MethodAin which the clamps firmly grip the ribs transverse to

the test direction on each side of the junction; and, Method B

D4439 Terminology for Geosynthetics

D5262 Test Method for Evaluating the Unconfined Tension in which the ribs transverse to the test direction are constrained

in a slot, constraining rotation of the junction, while the rib in

Creep and Creep Rupture Behavior of Geosynthetics

the test direction passes through the slot without the junction

3. Terminology clamp applying confinement to the junction. The junction

clamping technique is selected for the specific type of geogrid

3.1 Definitions of other terms applying to this test method

in order to minimize rotation and corresponding peal of the

appear in Terminology D4439.

junction during the test. The rib in the test direction going

3.2 Definitions:

through the junction is then clamped at a distance from the

3.2.1 atmosphere for testing geosynthetics, n—air main-

junction and the system tensioned until junction (or rib) failure

tained at a relative humidity of 50 to 70 % and a temperature

occurs. This forces a tension or shear force to occur within the

of 21 6 2°C (70 6 4°F).

junction in the direction of the applied load. The junction has

3.2.2 breaking force, (F), n—the force at failure.

no normal pressure on it, i.e., it is horizontally unconfined.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D35 on 5.1 This index test method is to be used to determine the

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

strength of an individual junction in a geogrid product.The test

cal Properties.

is performed in isolation, while in service the junction is

Current edition approved Sept. 15, 2011. Published November 2011. DOI:

typically confined. Thus the results from this test method are

10.1520/D7731–11

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

not anticipated to be related to design performance.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The value of junction strength can be used for manu-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. facturing quality control, development of new products, or a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7737 − 11

general understanding of the in-isolation behavior of a particu- cell having an adequate load capacity to cover the full range of

lar geogrid’s junction (for example., in relation to handling products to be tested. The test recorder must be able to

during shipment and placement of the geogrid).

adequately record the complete force-elongation curve during

the test.

5.3 This test method is applicable to geogrid products with

essentially orthogonal ribs, yarns or straps, that is, geogrids

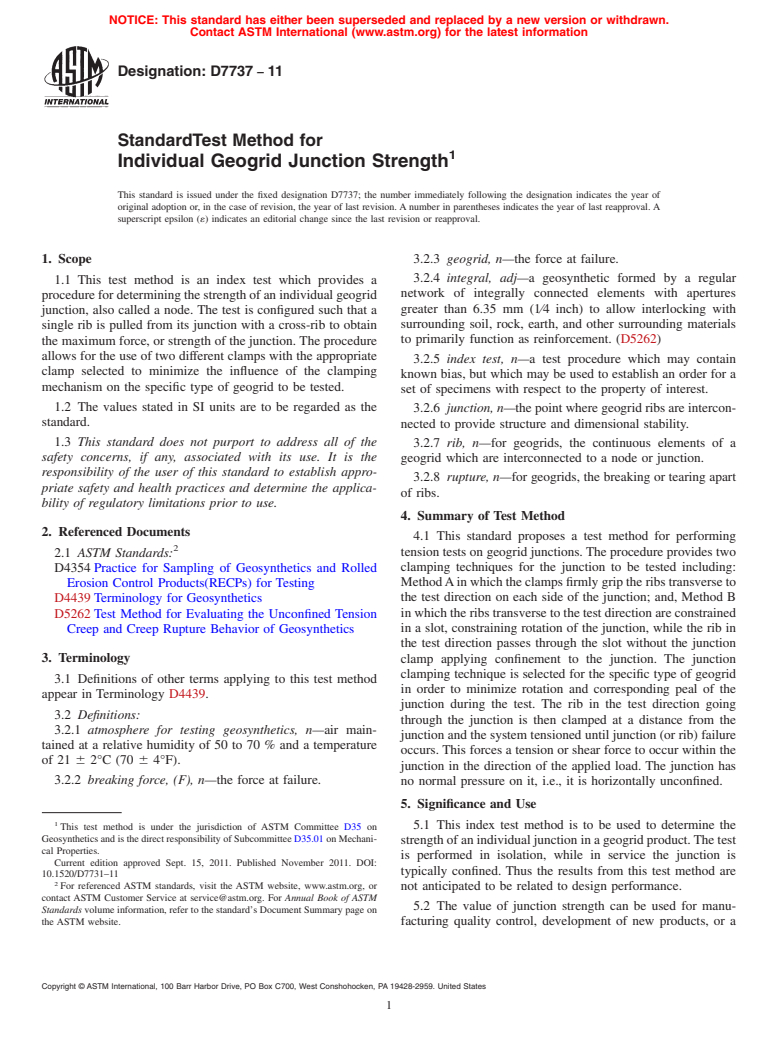

6.3 Method A: Junction Clamp (Rotation is Unconstrained)

which are composed of ribs, yarns or straps that are entangled

- The clamp assembly which holds the geogrid junction shall

through weaving or knitting, welded, bonded or formed

beofthesamedesignorequivalenttothatshowninFig.1.The

through drawing.

clamp must only confine the horizontal rib on each side of the

junction and not the junction itself. The ribs transverse to the

6. Apparatus

test direction should be placed horizontally level such that

6.1 The test apparatus for this method consists of three

torsion is not applied to the junction. The clamp cannot hinder

parts; the tensile testing machine, the junction clamp and the

or influence the junction. The two movable parts of the

rib clamp.

restraining clamp should be adjustable to allow the bearing

6.2 Tensile Testing Machine - The testing machine should surfaces to fit snugly without touching the junction of the

operate under a constant rate of extension. It should have the geogrid product being tested. The clamp assembly should

capabilitiesofmeasuringthetensileforce,typicallywithaload provide the appropriate clamping power to prevent slipping or

FIG. 1 Typical Junction Strength Test Specimen Test Setup [Rotation is not Constrained per Section 6.3]

D7737 − 11

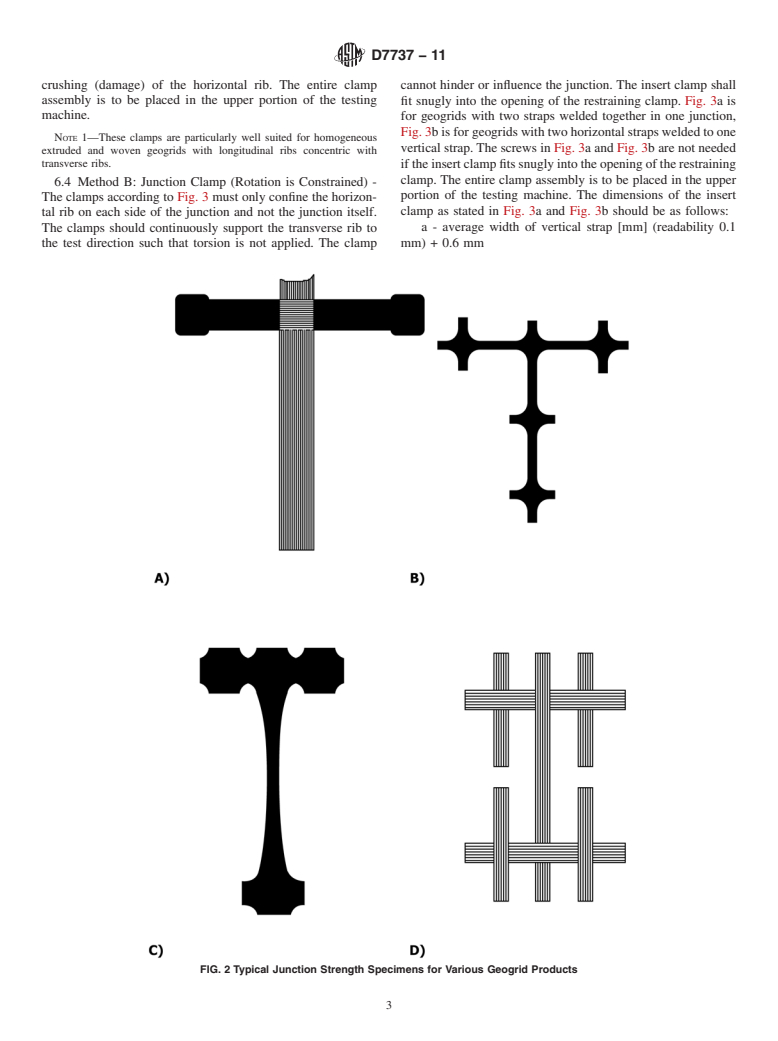

crushing (damage) of the horizontal rib. The entire clamp cannot hinder or influence the junction. The insert clamp shall

assembly is to be placed in the upper portion of the testing fit snugly into the opening of the restraining clamp. Fig. 3ais

machine.

for geogrids with two straps welded together in one junction,

Fig. 3b is for geogrids with two horizontal straps welded to one

NOTE 1—These clamps are particularly well suited for homogeneous

vertical strap. The screws in Fig. 3a and Fig. 3b are not needed

extruded and woven geogrids with longitudinal ribs concentric with

transverse ribs.

iftheinsertclampfitssnuglyintotheopeningoftherestraining

clamp. The entire clamp assembly is to be placed in the upper

6.4 Method B: Junction Clamp (Rotation is Constrained) -

portion of the testing machine. The dimensions of the insert

The clamps according to Fig. 3 must only confine the horizon-

clamp as stated in Fig. 3a and Fig. 3b should be as follows:

tal rib on each side of the junction and not the junction itself.

a - average width of vertical strap [mm] (readability 0.1

The clamps should continuously support the transverse rib to

the test direction such that torsion is not applied. The clamp mm) + 0.6 mm

FIG. 2 Typical Junction Strength Specimens for Various Geogrid Products

D7737 − 11

FIG. 3 Alternative Clamp for Constraining Rotation of the Geogrid Junction per Section 6.4

D7737 − 11

b-5-10mm

n = number of test specimens (rounded upward to a whole

c - average thickness of junction [mm] (readability 0.1

number),

mm) + 0.2 mm

v = reliable estimate of the coefficient of variation of indi-

d - average thickness of vertical strap [mm] (readability 0.1

vidual o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.