ASTM D2758-94(2009)

(Test Method)Standard Test Method for Engine Coolants by Engine Dynamometer (Withdrawn 2022)

Standard Test Method for Engine Coolants by Engine Dynamometer (Withdrawn 2022)

SIGNIFICANCE AND USE

This test method provides a laboratory technique capable of reproducing the complex environmental stresses a coolant encounters under actual engine operating conditions. The test method provides improved discrimination over glassware and simulated service tests and improved correlation with field service. Although the test method is particularly valuable for developing coolants for increased service requirements, it remains that field testing is necessary to evaluate coolant performance completely.

SCOPE

1.1 This test method covers a full-scale clean engine test designed to evaluate corrosion protection and inhibitor stability of engine coolants under simulated heavy-duty driving conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 6.

WITHDRAWN RATIONALE

This test method covers a full-scale clean engine test designed to evaluate corrosion protection and inhibitor stability of engine coolants under simulated heavy-duty driving conditions.

Formerly under the jurisdiction of Committee D15 on Engine Coolants and Related Fluids, this test method was withdrawn in April 2022 in accordance with Section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2758 − 94 (Reapproved 2009)

Standard Test Method for

1

Engine Coolants by Engine Dynamometer

This standard is issued under the fixed designation D2758; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope tion of (1) coolant samples, (2) metal corrosion specimens, and

(3) cooling system components.

1.1 This test method covers a full-scale clean engine test

designedtoevaluatecorrosionprotectionandinhibitorstability

4. Significance and Use

of engine coolants under simulated heavy-duty driving condi-

tions. 4.1 This test method provides a laboratory technique ca-

pable of reproducing the complex environmental stresses a

1.2 The values stated in SI units are to be regarded as the

coolant encounters under actual engine operating conditions.

standard. The values given in parentheses are for information

The test method provides improved discrimination over glass-

only.

ware and simulated service tests and improved correlation with

1.3 This standard does not purport to address all of the

field service. Although the test method is particularly valuable

safety concerns, if any, associated with its use. It is the

for developing coolants for increased service requirements, it

responsibility of the user of this standard to establish appro-

remains that field testing is necessary to evaluate coolant

priate safety and health practices and determine the applica-

performance completely.

bility of regulatory limitations prior to use. Specific hazards

statements are given in Section 6.

5. Apparatus

5.1 Test Engine— The test engine shall be a volume pro-

2. Referenced Documents

2 duction passenger car engine of cast iron or aluminum con-

2.1 ASTM Standards:

struction. Engine speed and brake horsepower should be

D1121 Test Method for Reserve Alkalinity of Engine Cool-

calculated and adjusted to be equivalent to a 96.5 km/h (60

ants and Antirusts

mph) level road load. Aluminum accessories, such as coolant

D1287 TestMethodforpHofEngineCoolantsandAntirusts

pump and timing chain cover, are optional.The engine shall be

D1384 Test Method for Corrosion Test for Engine Coolants

equipped with a matching radiator and pressure cap.Acoolant

in Glassware

overflow reservoir and closed-system pressure cap are

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

optional, except when specified by the manufacturer.Assemble

sion Test Specimens

the test components to provide a complete cooling system.The

3

2.2 Federal Standard:

relativepositioningoftheradiatorandengineshouldduplicate,

CFR Title 29 OSHA Regulations

as closely as practicable, the mounting in the automobile with

the fan omitted. All radiator hose lengths should be held to a

3. Summary of Test Method

minimum. The radiator shall be cooled by forced air.

3.1 This test method involves the operation of a standard

5.2 Instrumentation and Control (See Fig. 1)—Run the

passenger car engine on a dynamometer stand under constant

engine on a test stand coupled to an engine dynamometer with

speed, load, and coolant temperature conditions for a total of

appropriate accessories for control of the designated operating

700 h. The performance of the coolant is judged by examina-

conditions. Measure engine coolant temperature out of the

engine at a point immediately adjacent to the coolant outlet.

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Measure manifold vacuum, oil pressure, and exhaust pressure

Coolants and Related Fluids and is the direct responsibility of Subcommittee

at appropriate points and monitor them throughout the test in

D15.10 on Dynamometer and Road Tests.

order to ensure proper engine performance. Install a pressure

Current edition approved Nov. 1, 2009. Published December 2009. Originally

approved in 1968 as D2758 – 68 T. Last previous edition D2758 – 94 (2003). DOI:

gage in the outlet tank of a crossflow radiator or the top tank of

10.1520/D2758-94R09.

a downflow radiator to read the gage pressure.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

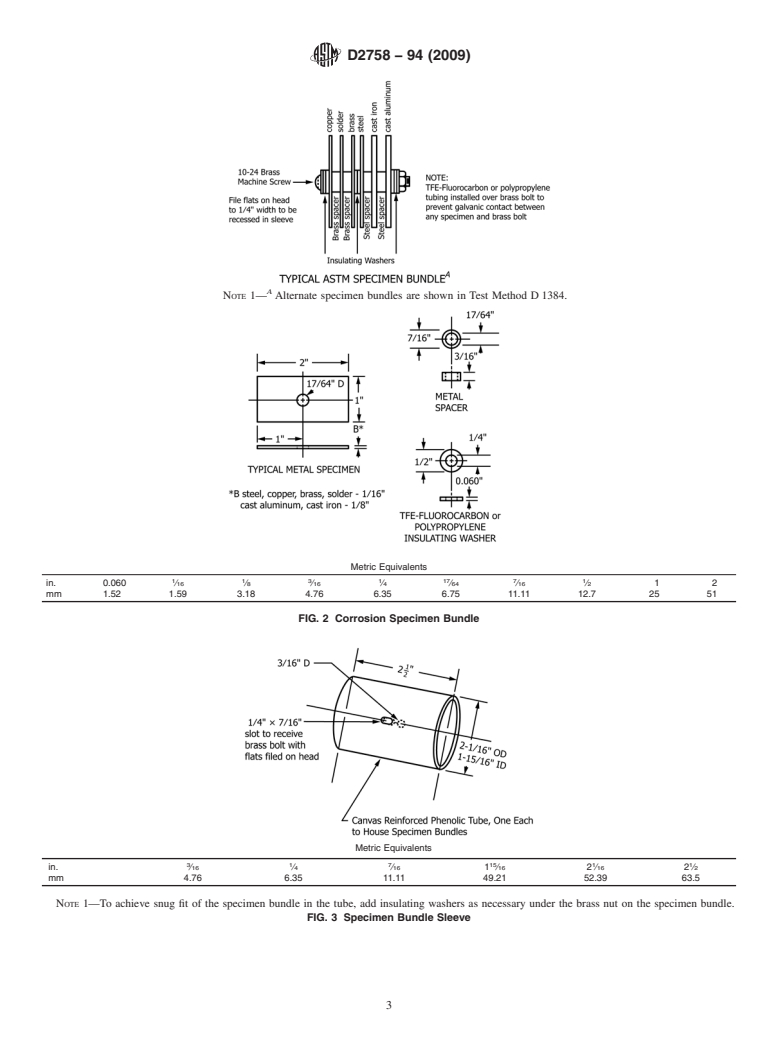

5.3 Corrosion Measurements:

Standards volume information, refer to the standard’s Document Summary page on

5.3.1 Evaluate corrosion protection using metal specimens.

the ASTM website.

3

The specimen arrangement shall be basically that used in Test

Available from the Occupational Safety and Health Administration, 200

Constitution Ave., N.W., Washington, DC 20008. Method D1384. The specimen bundle is shown in Fig. 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, Wes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.