ASTM D2061-07(2021)

(Test Method)Standard Test Methods for Strength Tests for Zippers

Standard Test Methods for Strength Tests for Zippers

SIGNIFICANCE AND USE

4.1 The usefulness of a zipper in service can be evaluated by these tests. No one test determines the suitability of a zipper for a specific end use. Since the tests are inter-related more than one may be needed for a complete evaluation.

4.2 These methods are considered satisfactory for acceptance testing of commercial shipments because the methods have been used extensively in the trade for this purpose, and because estimates of current between-laboratory precision are acceptable in most cases.

4.2.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, the test samples should be used that are as homogeneous as possible, that are drawn from the material from which the disparate test results were obtained, and that are randomly assigned in equal numbers to each laboratory for testing. Other materials with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

4.3 The method(s) in the standard along with those in Test Methods D2051, D2052, D2053, D2054, D2057, D2058, D2059/D2059M, D2060, and D2062 are a collection of proven test methods. They can be used as aids in the evaluation of zippers without the need for a thorough knowledge of zippers. The enumerated test methods do not provide for the evaluation of all zipper properties. Besides those properties measured by means of the enumerated test methods there are other properties that may be important for the satisfactory performance of a zipper. Test methods for measuring those properties have not been ...

SCOPE

1.1 These test methods cover the determination of the strengths for zipper and zipper parts. All methods are not suitable for use with all kinds of zipper. The restrictions, if any, are indicated in the scope for each individual test method. The test methods appear as follows:

Sections

Holding Strengths of Separable Units

25 – 32

Holding Strength of Slider Lock

92 – 100

Holding Strength of Stops

17 – 24

Resistance to Angular Pull-Off of Slider Pull

82 – 91

Resistance to Cushioned Compression of Sliders

33 – 42

Resistance to Pull-Off of Slider Pull

72 – 81

Resistance to Twist of Pull and Slider

52 – 61

Slider Deflection and Recovery

43 – 51

Strength of Chains and Elements

9 – 16

Torsional Resistance of Slider Pull for Removal of Components

62 – 71

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2061 − 07 (Reapproved 2021)

Standard Test Methods for

Strength Tests for Zippers

This standard is issued under the fixed designation D2061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D76/D76M Specification for Tensile Testing Machines for

Textiles

1.1 These test methods cover the determination of the

D123 Terminology Relating to Textiles

strengths for zipper and zipper parts. All methods are not

D1776/D1776M Practice for Conditioning and Testing Tex-

suitable for use with all kinds of zipper.The restrictions, if any,

tiles

are indicated in the scope for each individual test method. The

D2050 Terminology Relating to Subassemblies Used in the

test methods appear as follows:

Manufacture of Textiles

Sections

D2051 Test Method for Durability of Finish of Zippers to

Holding Strengths of Separable Units 25–32 Laundering

Holding Strength of Slider Lock 92 – 100

D2052 Test Method for Colorfastness of Zippers to Dry-

Holding Strength of Stops 17–24

cleaning

Resistance to Angular Pull-Off of Slider Pull 82–91

Resistance to Cushioned Compression of Sliders 33–42 D2053 Test Method for Colorfastness of Zippers to Light

Resistance to Pull-Off of Slider Pull 72–81

D2054 Test Method for Colorfastness of Zipper Tapes to

Resistance to Twist of Pull and Slider 52–61

Crocking

Slider Deflection and Recovery 43–51

Strength of Chains and Elements 9–16

D2057 Test Method for Colorfastness of Zippers to Laun-

Torsional Resistance of Slider Pull for Removal of 62–71

dering

Components

D2058 Test Method for Durability of Finish of Zippers to

1.2 The values stated in SI units are to be regarded as

Drycleaning

standard. The values given in parentheses after SI units are

D2059/D2059M Test Method for Resistance of Zippers to

provided for information only and are not considered standard.

Salt Spray (Fog)

1.3 This standard does not purport to address all of the

D2060 Test Methods for Measuring Zipper Dimensions

safety concerns, if any, associated with its use. It is the

D2062 Test Methods for Operability of Zippers

responsibility of the user of this standard to establish appro-

2.2 U. S. Government Standard:

priate safety, health, and environmental practices and deter-

MIL-105D Sampling Procedures and Tables for Inspection

mine the applicability of regulatory limitations prior to use.

by Attributes

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3. Terminology

ization established in the Decision on Principles for the

3.1 Definitions:

Development of International Standards, Guides and Recom-

3.1.1 For definitions of zipper terms used in this standard,

mendations issued by the World Trade Organization Technical

refer to Terminology D2050. For definitions of other textile

Barriers to Trade (TBT) Committee.

terminology used in this standard, refer to Terminology D123.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 Theusefulnessofazipperinservicecanbeevaluatedby

thesetests.Noonetestdeterminesthesuitabilityofazipperfor

a specific end use. Since the tests are inter-related more than

These test methods are under the jurisdiction of ASTM Committee D13 on

one may be needed for a complete evaluation.

Textiles are the direct responsibility of Subcommittee D13.54 on Subassemblies and

were developed in cooperation with the American Fastener and Closure Assn. 4.2 These methods are considered satisfactory for accep-

Current edition approved July 1, 2021. Published August 2021. Originally

tance testing of commercial shipments because the methods

approved in 1961. Last previous edition approved in 2013 as D2061 – 07 (2013).

have been used extensively in the trade for this purpose, and

DOI: 10.1520/D2061-07R21.

For referenced ASTM standards, visit the ASTM web site, www.astm.org, or

contact ASTM Customer Service at service@astm.org. ForAnnual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM web site. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2061 − 07 (2021)

because estimates of current between-laboratory precision are 6.1.1 Reliable Estimate of v—When there is a reliable

acceptable in most cases. estimate of v based upon extensive past records for similar

4.2.1 If there are differences of practical significance be- materials tested in the users laboratory as directed in the

tween reported test results for two laboratories (or more), method, calculate n using Eq 1.

comparative test should be performed to determine if there is a

2 2 2 2

n 5 t 3v /A 5 0.0270 v (1)

statistical bias between them, using competent statistical assis-

where:

tance. As a minimum, the test samples should be used that are

n = number of specimens (rounded upward to a whole

as homogeneous as possible, that are drawn from the material

from which the disparate test results were obtained, and that number),

v = reliable estimate of the coefficient of variation of

are randomly assigned in equal numbers to each laboratory for

individual observations in the users laboratory

testing. Other materials with established test values may be

under conditions of single-operation precision,

used for this purpose.The test results from the two laboratories

t = 1.645, the value of Student’s t for infinite degrees

should be compared using a statistical test for unpaired data, at

of freedom, two-sided limits and a 90 % probabil-

a probability level chosen prior to the testing series. If a bias is

ity level (t = 2.706),

found, either its cause must be found and corrected, or future

A = 10.0 % of the average, the value of the allowable

test results must be adjusted in consideration of the known

variation, and

bias.

2 2

0.0270 = a value calculated from t /A

4.3 The method(s) in the standard along with those in Test

6.1.2 No Reliable Estimate of v—When there is no reliable

Methods D2051, D2052, D2053, D2054, D2057, D2058,

estimate of v for the users laboratory, Eq 1 should not be used

D2059/D2059M, D2060, and D2062 are a collection of proven

directly. Instead, specify the number of specimens shown in

test methods. They can be used as aids in the evaluation of

Table 1. This number of specimens is calculated using values

zippers without the need for a thorough knowledge of zippers.

of v which are somewhat larger values of v than are usually

The enumerated test methods do not provide for the evaluation

found in practice. When a reliable estimate of v for the users

of all zipper properties. Besides those properties measured by

laboratory becomes available, Eq 1 will usually specify fewer

means of the enumerated test methods there are other proper-

than the number of specimens shown in Table 1.

ties that may be important for the satisfactory performance of

a zipper. Test methods for measuring those properties have not

6.2 Attributes—For methods for which the test result merely

been published either because no practical methods have yet

states whether there is conformance to the criteria for success

been developed or because a valid evaluation of the informa-

specified in the procedure, take the number of specimens

tion resulting from existing unpublished methods requires an

directed in MIL Standard 105D for the level of inspection

intimate and thorough knowledge of zippers.

agreed upon by the purchaser and the seller. The methods to

which these instructions apply are as follows:

5. Sampling

Sections

5.1 LotSample—Asalotsampleforacceptancetesting,take

Resistance to Cushioned Compression of Sliders 30–38

at random the number of individual containers from each

Resistance to Pull-Off of Slider Pull 56–74

shipping carton as directed in an applicable material specifi- Resistance to Angular Pull-Off of Slider Pull 75–83

Holding Strength of Slider Lock 84–91

cation or other agreement between the purchaser and the

supplier. Consider individual containers from each shipping

7. Test Specimen

carton to be the primary sampling units.

7.1 The test specimen may consist of a completely as-

NOTE 1—An adequate specification or other agreement between the

sembledzipper,lengthofchain,oracomponent,asspecifiedin

purchaserandsupplierrequirestakingintoaccountthevariabilitybetween

the individual method. Unless otherwise specified the zipper

shipping cartons and between zippers in a container to provide a sampling

shall not be attached to an application when testing.

plan with a meaningful producer’s risk, consumer’s risk, acceptable

quality level, and limiting quality level.

8. Conditioning

5.2 Laboratory Sample and Test Specimens—As a labora-

tory sample for acceptance testing, take the number of zippers

8.1 Bring the specimens to moisture equilibrium for testing

specified in Section 6 at random from each container in the lot in the standard atmosphere for testing textiles as directed in

sample. Consider the zippers as both the laboratory sample and Practice D1776/D1776M unless otherwise specified (see 38.1,

the test specimens. 48.1, 57.1, and 87.1). Preconditioning is not required for

zippers other than those made of nylon.

6. Number of Specimens

STRENGTHS OF CHAINS AND ELEMENTS

6.1 Variables—Take a number of zippers per individual

container from each shipping carton such that the user may

9. Scope

expect at the 90 % probability level that the test result for an

9.1 These test methods cover the determination of the

individual container is no more than 10 % of the average,

strengths of zipper chains and elements in tensile tests.

above or below the true average for the individual container.

Determine the number of zippers per individual container as 9.2 The element pull-off and element slippage tests apply to

follows: separate element zippers only.

D2061 − 07 (2021)

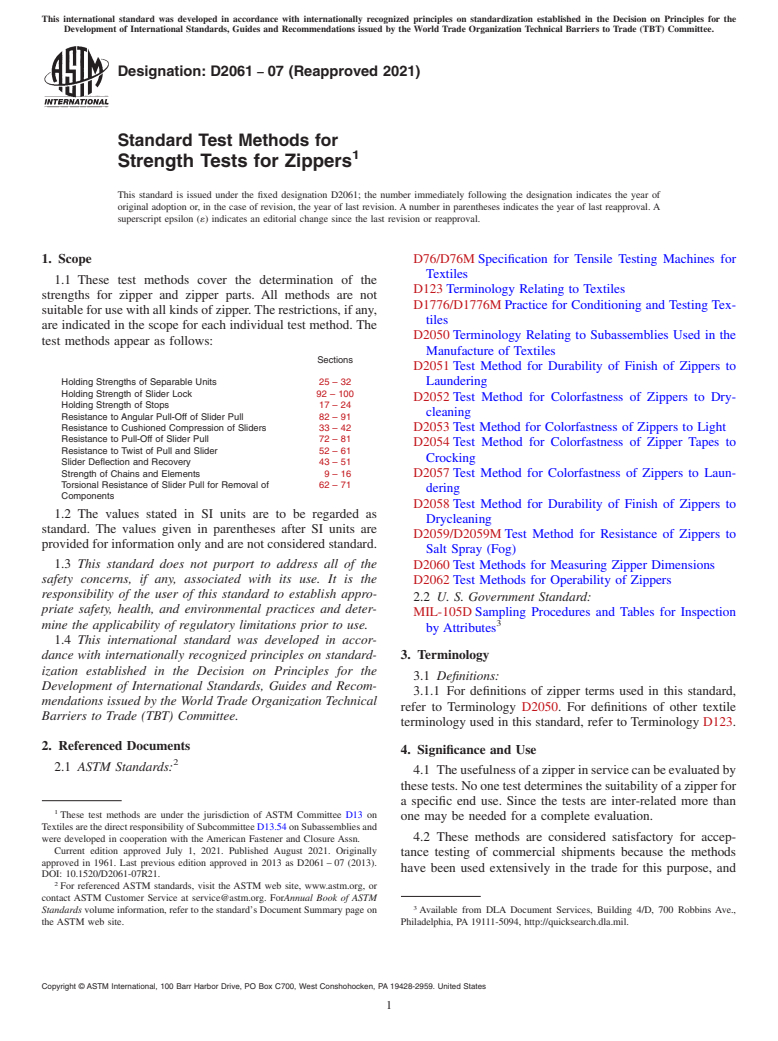

TABLE 1 Specimens Required Under Conditions of Known and Unknown Variability in User’s Laboratory Units as Indicated

No Reliable Estimate of v

Allowable Variation Equation for n, Using a Reliable

Property

Number of

A

Two-Sided Estimate of v

Basis

Specimens

Strength of chains and elements:

Chain crosswise strength 10.0 n = 0.027 × v 2 v = 8.45

Element pull-off 10.0 n = 0.027 × v 5 v = 12.56

Element slippage, lengthwise 10.0 n = 0.027 × v 7 v = 14.97

Holding strength of stops:

Top stop, holding 10.0 n = 0.027 × v 17 v = 24.77

Bottom stop holding, slider 10.0 n = 0.027 × v 22 v = 28.41

Bottom stop holding, crosswise 10.0 n = 0.027 × v 8 v = 16.16

Bottom stop holding, stringer separation 10.0 n = 0.027 × v 7 v = 15.60

Bridge top stop, stringer separation 10.0 n = 0.027 × v 31 v = 33.75

Holding strength of separable units:

Separable pin 10.0 n = 0.027 × v 7 v = 15.46

Fixed retainer 10.0 n = 0.027 × v 8 v = 16.34

Separating unit—crosswise 10.0 n = 0.027 × v 4 v = 10.70

Slider deflection and recovery:

2 B

mouth 10.0 n = 0.027 × v v = 93.11

2 B

pull 10.0 n = 0.027 × v v = 48.20

2 B

Resistance to twist of pull and slider: 10.0 n = 0.027 × v v = 51.4

A

The values of v in Table 1 are somewhat larger than will be usually found in practice (see 6.1.2).

B

No standard number of specimens is given for these tests since they are quite variable and are not recommended for acceptance testing except where the laboratories

of the purchaser and the seller have established their precision and bias, if any.

10. Summary of Test Method cannot be used interchangeably. In case of controversy, the

CRE method shall prevail.

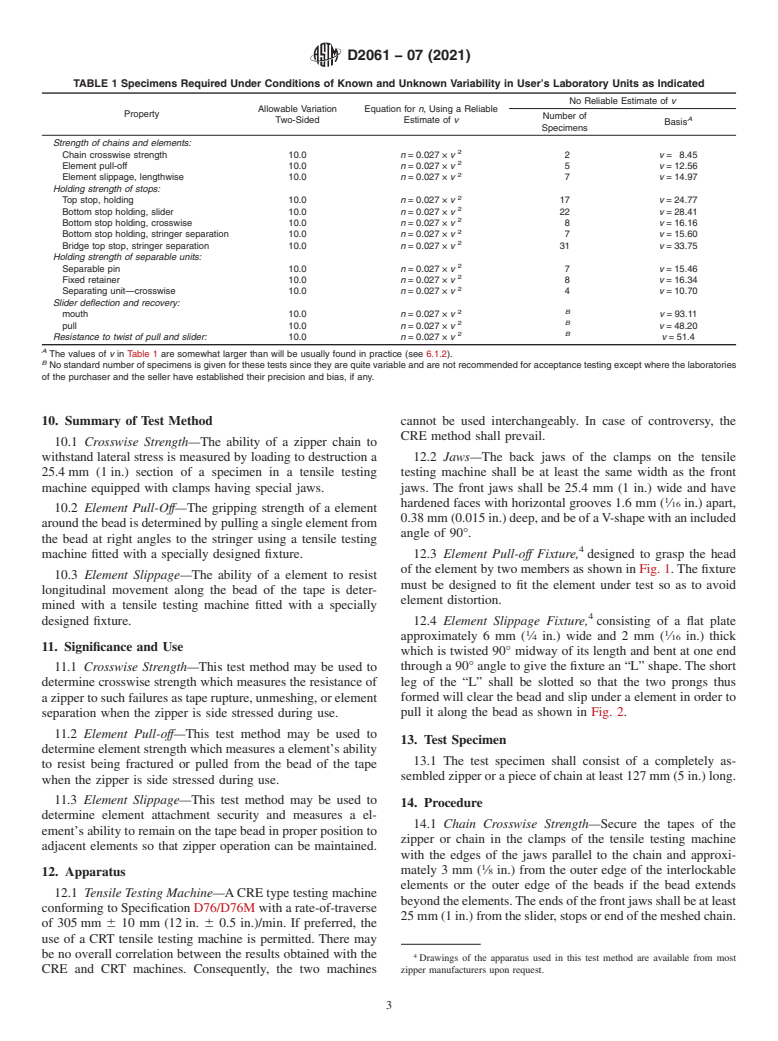

10.1 Crosswise Strength—The ability of a zipper chain to

withstand lateral stress is measured by loading to destruction a 12.2 Jaws—The back jaws of the clamps on the tensile

25.4 mm (1 in.) section of a specimen in a tensile testing testing machine shall be at least the same width as the front

machine equipped with clamps having special jaws. jaws. The front jaws shall be 25.4 mm (1 in.) wide and have

hardened faces with horizontal grooves 1.6 mm ( ⁄16 in.) apart,

10.2 Element Pull-Off—The gripping strength of a element

0.38mm(0.015in.)deep,andbeofaV-shapewithanincluded

around the bead is determined by pulling a single element from

angle of 90°.

the bead at right angles to the stringer using a tensile testing

machine fitted with a specially designed fixture. 12.3 Element Pull-off Fixture, designed to grasp the head

of the element by two members as shown in Fig. 1. The fixture

10.3 Element Slippage—The ability of a element to resist

must be designed to fit the element under test so as to avoid

longitudinal movement along the bead of the tape is deter-

element distortion.

mined with a tensile testing machine fitted with a specially

designed fixture. 12.4 Element Slippage Fixture, consisting of a flat plate

1 1

approximately 6 mm ( ⁄4 in.) wide and 2 mm ( ⁄16 in.) thick

11. Significance and Use

which is twisted 90° midway of its length and bent at one end

11.1 Crosswise Strength—This test method may be used to through a 90° angle to give the fixture an “L” shape. The short

leg of the “L” shall be slotted so that the two prongs thus

determine crosswise strength which measures the resistance of

a zipper to such failures as tape rupture, unmeshing, or element formed will clear the bead and slip under a element in order to

pull it along the bead as shown in Fig. 2.

separation when the zipper is side stressed during use.

11.2 Element Pull-off—This test method may be used to

13. Test Specimen

determine element strength which measures a element’s ability

13.1 The test specimen shall consist of a completely as-

to resist being fractured or pulled from the bead of the tape

sembled zipper or a piece of chain at least 127 mm (5 in.) long.

when the zipper is side stressed during use.

11.3 Element Slippage—This test method may be used to

14. Procedure

determine element attachment security and measures a el-

14.1 Chain Crosswise Strength—Secure the tapes of the

ement’s ability to remain on the tape bead in proper position to

zipper or chain in the clamps of the tensile testing machine

adjacent elements so that zipper operation can be maintained.

with the edges of the jaws parallel to the chain and approxi-

mately 3 mm ( ⁄8 in.) from the outer edge of the interlockable

12. Apparatus

elements or the outer edge of the beads if the bead extends

12.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.