ASTM D5679-16

(Practice)Standard Practice for Sampling Consolidated Solids in Drums or Similar Containers

Standard Practice for Sampling Consolidated Solids in Drums or Similar Containers

SIGNIFICANCE AND USE

5.1 This practice is intended for use in collecting samples of consolidated or compacted materials from drums or similar containers, but only in compliance with a suitable work plan prepared according to Practice D5283 and Guide D4687. If the plan so provides, samples may be collected from drums not intended to be opened and from drums that are unstable, ruptured or otherwise compromised. Special handling procedures (for example, remote drum opening, overpressurized drum opening, drum deheading, etc.) are described in Drum Handling Practices at Hazardous Waste Sites.

SCOPE

1.1 This practice covers typical equipment and methods for collecting samples of consolidated solids in drums or similar containers. These methods are adapted specifically for sampling drums having a volume of 110 U.S. gal (416 L) or less. These methods are applicable to hazardous material, product, or waste. Specific sample collection and handling requirements should be described in the site-specific work plan.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5679 − 16

Standard Practice for

Sampling Consolidated Solids in Drums or Similar

1

Containers

This standard is issued under the fixed designation D5679; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 NSC Document:

Accident Prevention Manual for Industrial Operations,

1.1 This practice covers typical equipment and methods for

3

1985

collecting samples of consolidated solids in drums or similar

4

2.3 Government Documents:

containers. These methods are adapted specifically for sam-

Drum Handling Practices at Hazardous Waste Sites,EPA/

pling drums having a volume of 110 U.S. gal (416 L) or less.

600/2-86/013, January 1986

These methods are applicable to hazardous material, product,

Occupational Safety and Health Guidance Manual for

or waste. Specific sample collection and handling requirements

Hazardous Waste Site Activities, National Institute for

should be described in the site-specific work plan.

Occupational Safety and Health (NIOSH), Occupational

1.2 The values stated in inch-pound units are to be regarded

Safety and Health Administration (OSHA), U.S. Coast

as the standard. The values given in parentheses are for

Guard (USCG), and U.S. Environmental Protection

information only.

Agency (EPA), October 1985

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the user of this standard to establish appro-

3.1.1 bonding—touching the sampling equipment to the

priate safety and health practices and determine the applica-

drum to form an electrically conductive path to minimize

bility of regulatory limitations prior to use.

potential electrical differences between the sampling equip-

ment and the drum, reducing the buildup of static electricity.

2. Referenced Documents

3

2 3.1.2 bung—usually a 2-in. (5.1-cm) or ⁄4-in. (1.3-cm)

2.1 ASTM Standards:

diameter threaded plug designed specifically to close a bung

C702 PracticeforReducingSamplesofAggregatetoTesting

hole.

Size

3.1.3 bung hole—an opening in a barrel or drum through

C783 Practice for Core Sampling of Graphite Electrodes

which it can be filled, emptied, or vented.

D4547 Guide for Sampling Waste and Soils for Volatile

Organic Compounds

3.1.4 consolidated—the characteristic of being cemented or

D4687 Guide for General Planning of Waste Sampling

compacted, or both, and not separated easily into smaller

D4700 Guide for Soil Sampling from the Vadose Zone

particles.

D5088 Practice for Decontamination of Field Equipment

3.1.5 deheading—removal of the lid of a closed-head drum;

Used at Waste Sites

usually accomplished with a drum deheader.

D5283 Practice for Generation of Environmental Data Re-

3.1.6 drum—implies any drum, barrel, or non-bulk con-

lated to Waste ManagementActivities: QualityAssurance

tainer of 5 to 110 U.S. gal (19 to 416 L) capacity.

and Quality Control Planning and Implementation

3.1.7 pail—a small container, usually with a capacity of 5

U.S. gal (19 L). Pails typically have bungs or spouts, or the

entire lid can be removed.

1

This practice is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.02 on

3.1.8 paperwork—all required site documentation, which

Sampling Techniques.

may include the manifests, waste profiles, material safety data

Current edition approved Sept. 1, 2016. Published September 2016. Originally

approved in 1995. Last previous edition approved in 2012 as D5679 – 95a (2012).

3

DOI: 10.1520/D5679-16. Available from National Safety Council (NSC), 1121 Spring Lake Dr., Itasca,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or IL 60143-3201, http://www.nsc.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

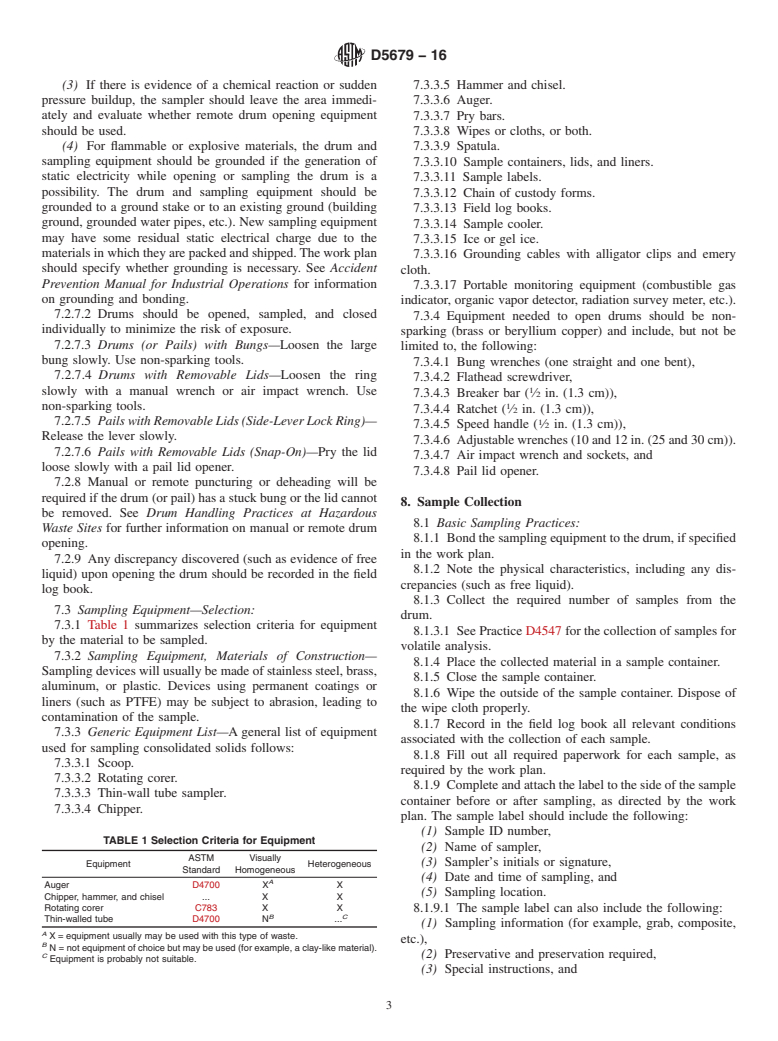

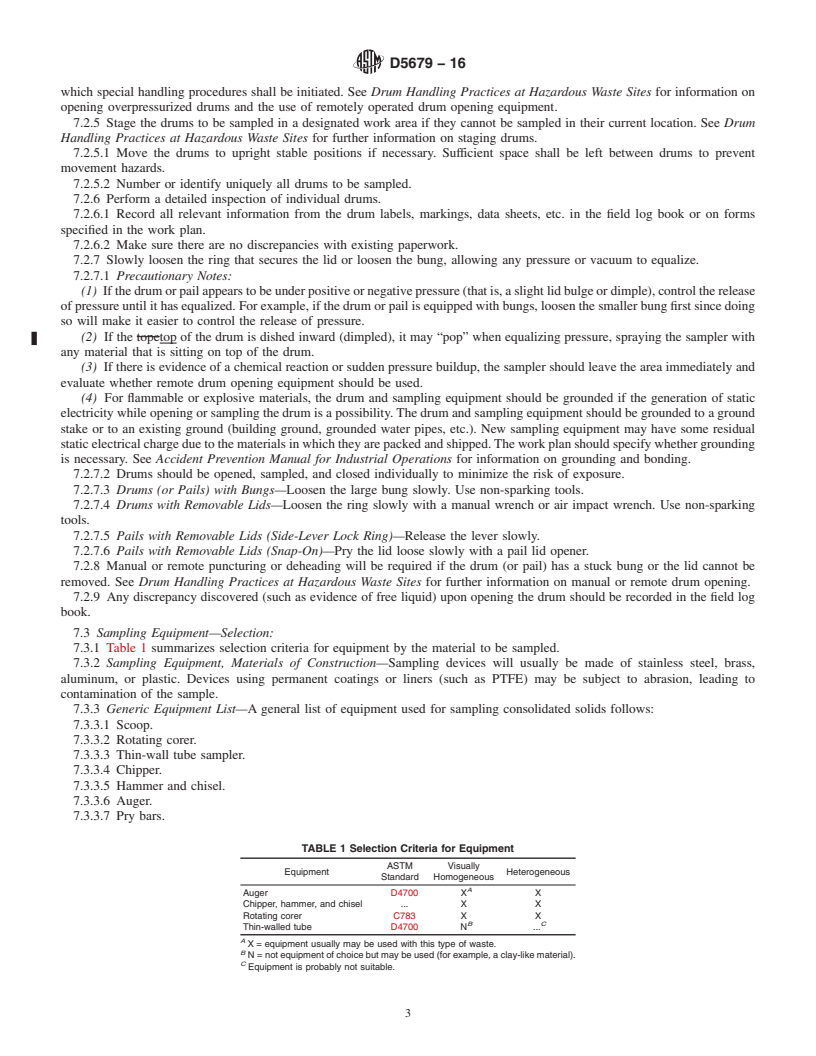

D5679 − 16

sheets (MSDS), site forms, sample labels, custody seals, and opportunitytobeincludedinasample.Sampleparticlesshould

chain of custody forms. be selected by techniques that will minimi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5679 − 95a (Reapproved 2012) D5679 − 16

Standard Practice for

Sampling Consolidated Solids in Drums or Similar

1

Containers

This standard is issued under the fixed designation D5679; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers typical equipment and methods for collecting samples of consolidated solids in drums or similar

containers. These methods are adapted specifically for sampling drums having a volume of 110 U.S. gal (416 L) or less. These

methods are applicable to hazardous material, product, or waste. Specific sample collection and handling requirements should be

described in the site-specific work plan.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C702 Practice for Reducing Samples of Aggregate to Testing Size

C783 Practice for Core Sampling of Graphite Electrodes

D4547 Guide for Sampling Waste and Soils for Volatile Organic Compounds

D4687 Guide for General Planning of Waste Sampling

D4700 Guide for Soil Sampling from the Vadose Zone

D5088 Practice for Decontamination of Field Equipment Used at Waste Sites

D5283 Practice for Generation of Environmental Data Related to Waste Management Activities: Quality Assurance and Quality

Control Planning and Implementation

2.2 NSC Document:

3

Accident Prevention Manual for Industrial Operations, 1985

4

2.3 Government Documents:

Drum Handling Practices at Hazardous Waste Sites, EPA/600/2-86/013, January 1986

Occupational Safety and Health Guidance Manual for Hazardous Waste Site Activities, National Institute for Occupational

Safety and Health (NIOSH), Occupational Safety and Health Administration (OSHA), U.S. Coast Guard (USCG), and U.S.

Environmental Protection Agency (EPA), October 1985

3. Terminology

3.1 Definitions:

3.1.1 bonding—touching the sampling equipment to the drum to form an electrically conductive path to minimize potential

electrical differences between the sampling equipment and the drum, reducing the buildup of static electricity.

3

3.1.2 bung—usually a 2-in. (5.1-cm) or ⁄4-in. (1.3-cm) diameter threaded plug designed specifically to close a bung hole.

1

This practice is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01.02 on Sampling

Techniques.

Current edition approved Nov. 1, 2012Sept. 1, 2016. Published November 2012September 2016. Originally approved in 1995. Last previous edition approved in 20062012

as D5679 – 95a (2006). (2012). DOI: 10.1520/D5679-95AR12.10.1520/D5679-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Safety Council (NSC), 1121 Spring Lake Dr., Itasca, IL 60143-3201, http://www.nsc.org.

4

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5679 − 16

3.1.3 bung hole—an opening in a barrel or drum through which it can be filled, emptied, or vented.

3.1.4 consolidated—the characteristic of being cemented or compacted, or both, and not separated easily into smaller particles.

3.1.5 deheading—removal of the lid of a closed-head drum; usually accomplished with a drum deheader.

3.1.6 drum—implies any drum, barrel, or non-bulk container of 5 to 110 U.S. gal (19 to 416 L) capacity.

3.1.7 pail—a small container, usually with a capacity of 5 U.S. gal (19 L). Pails typically have bungs or spouts, or the entire

lid can be removed.

3.1.8 paperwork—all required site documentation, which may include the manifests, was

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.