ASTM C198-91(1996)e1

(Test Method)Standard Test Method for Cold Bonding Strength of Refractory Mortar

Standard Test Method for Cold Bonding Strength of Refractory Mortar

SCOPE

1.1 This test method covers the determination of the bonding strength of air-setting refractory mortar by determining the flexural strength (modulus of rupture) at room temperature of oven-dried brick-mortar joints.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in SI units are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: C 198 – 91 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Cold Bonding Strength of Refractory Mortar

This standard is issued under the fixed designation C 198; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in September 1996.

1. Scope tions known or intended to be compatible for a particular use

should be tested.

1.1 This test method covers the determination of the bond-

3.3 Properties of the brick, including its strength, apparent

ing strength of air-setting refractory mortar by determining the

porosity, and pore size distribution, can affect the measurement

flexural strength (modulus of rupture) at room temperature of

of both the bonding strength of the brick-mortar composite and

oven-dried brick-mortar joints.

the intrinsic strength of the mortar. The average modulus of

1.2 The values stated in inch-pound units are to be regarded

rupture of the test brick, as determined by Test Method C 133,

as the standard. The values stated in SI units are for informa-

should exceed that expected for the mortar being tested. The

tion only.

testing of specific brands or lots of brick and mortar is

1.3 This standard does not purport to address all of the

preferred.

safety concerns, if any, associated with its use. It is the

3.4 Three modes of failure are available: the break may

responsibility of the user of this standard to establish appro-

occur within the brick itself, at the brick-mortar interface, or

priate safety and health practices and determine the applica-

within the mortar itself. The latter provides a practical mea-

bility of regulatory limitations prior to use.

surement of the strength of the mortar itself and is the

2. Referenced Documents

predominant mode of failure with the four-point flexure test

2.1 ASTM Standards:

described. The three-point flexure test measures the failure

C 78 Test Method for Flexural Strength of Concrete (Using strength of the brick-mortar composite. Failure within the brick

Simple Beam With Third-Point Loading)

itself suggests that either the particular brick contained a

C 133 Test Methods for Cold Crushing Strength and Modu- serious flaw, or that the mortar joint strength is of the same

lus of Rupture of Refractories

magnitude or greater than that of the refractory brick. The

C 651 Test Method for Flexural Strength of Manufactured mode of failure should always be reported in the final report.

Carbon and Graphite Articles Using Four-Point Loading at

3.5 A ruggedness test for this test method performed in

Room Temperature

1985 found the following variables to be rugged: specimen size

E 4 Practices for Force Verification of Testing Machines

(2.5 to 3.0 in.), mortared surface (cut versus uncut), joint

1 1

thickness ( ⁄16to ⁄8 in.), pulling of rods (fast versus slow), the

3. Significance and Use

loading rate (500 to 1000 lbf/min), the method of load

3.1 The data developed by this test method show the

application (3- versus 4-point), and the operator.

bonding strength and intrinsic strength of different qualities of

3.6 The cold bonding strengths of refractory mortars ob-

air-setting mortar. The procedures described in this test method

tained by this test method are suitable for use in research and

measure the bonding strength and intrinsic strength of air-

development, quality control, and for establishing and evalu-

setting mortars when used with specific brands or lots of

ating compliance with specifications between producers and

refractory brick.

consumers.

3.2 Note that it is possible to obtain results with these

methods for brick and mortar combinations which are incom-

4. Apparatus

patible for use at high operating temperatures. The user must

1 1

4.1 Brick—At least five 9 by 4 ⁄4 by 2 ⁄2-in. (230 by 114 by

determine this compatibility. Only brick and mortar combina-

65-mm) straight brick having plane surfaces and true rectan-

gular shape and an average modulus of rupture higher than that

expected from the mortar under test, when determined in

This test method is under the jurisdiction of ASTM Committee C-8 on

Refractories and is the direct responsibility of Subcommittee C08.09 on Monolithic

accordance with Test Methods C 133, compose a sample.

Refractories.

4.2 Spacing Rods—Two joint-thickness spacing rods made

Current edition approved Jan. 25, 1991. Published August 1991. Originally

published as C 198 – 45 T. Last previous edition C 198 – 83.

Annual Book of ASTM Standards, Vol 04.02.

3 5

Annual Book of ASTM Standards, Vol 15.01. Supporting data on ruggedness testing is available from ASTM. Request

Annual Book of ASTM Standards, Vol 03.01. RR:C-8-1008.

C 198

of ⁄16-in. (2-mm) diameter drill rod cut into 4-in. (102-mm) such as a 50 or 100-lb (23 or 45-kg) bag from which a 10-lb

lengths. (4.5 kg) sample may be obtained using acceptable sampling

4.3 Oven—A drying oven to accommodate at least five 9-in.

procedures. The 10-lb (4.5 kg) sample should be thoroughly

(230-mm) straight brick standing on end, and for use at 220 to mixed with water to a uniform, troweling consistency and

230°F (105 to 110°C).

stored in a covered container (resistant to possible corrosive

4.4 Testing Machine—A standard mechanical or hydraulic

action by the mortar) for at least 16 h prior to the test.

compression testing machine conforming to the requirements

NOTE 1—Reaction of phosphoric acid or aluminum phosphate with

of Practices E 4 and having a sensitivity of 20 lbf or less in the

metallics may cause the development of hydrogen gas in some mortars.

range from 0 to 4000 lbf (17.8 kN) may be used.

Therefore, the container should be covered only to minimize moisture

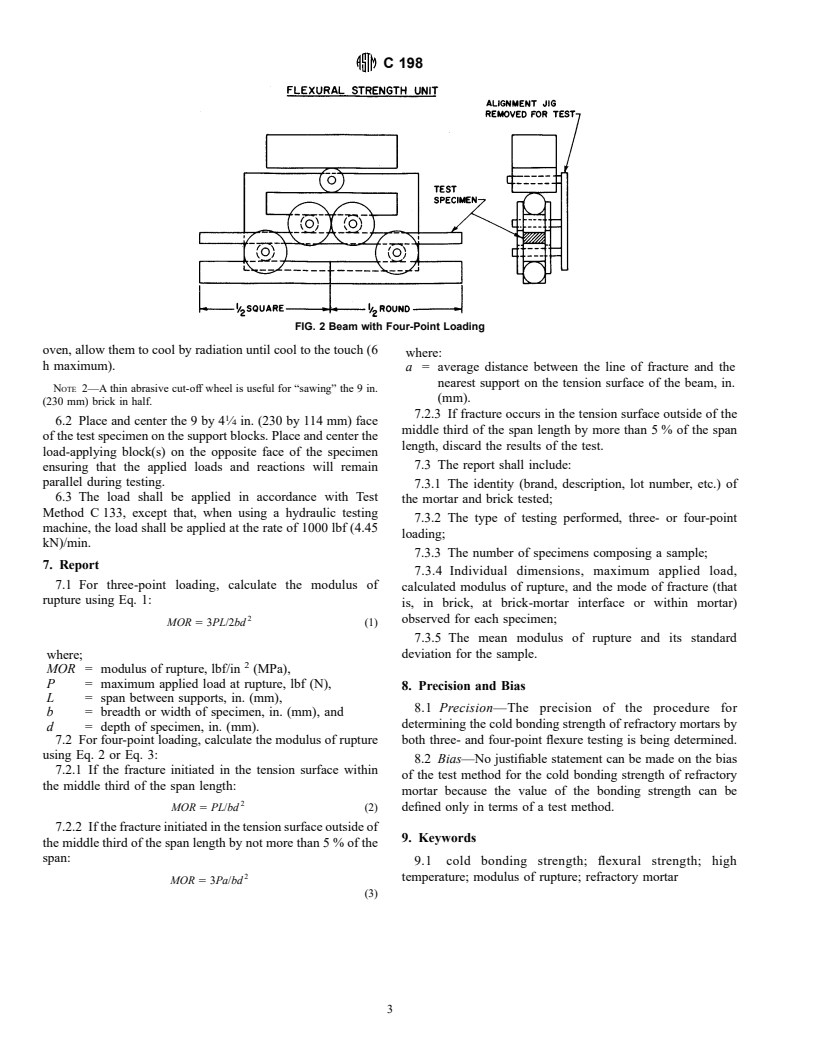

4.5 Loading Fixture—The fixtures shall provide load bear-

loss, not tightly sealed.

ing blocks which ensure that the forces are applied normal to

the beam without eccentricity. The directions of loads and

6. Procedure

reactions may be maintained parallel by judicious use of

6.1 Cut each of the bricks of the sample (see Note 2) into

linkages, roller bearings, and flexure plates. Eccentricity of

1 1

two equal parts on a plane parallel to the 2 ⁄2 by 4 ⁄4-in. (65 by

loading can be avoided by the use of spheri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.