ASTM G77-05(2010)

(Test Method)Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test

Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test

SIGNIFICANCE AND USE

The significance of this test method in any overall measurement program directed toward a service application will depend on the relative match of test conditions to the conditions of the service application.

This test method seeks only to prescribe the general test procedure and method of calculating and reporting data. The choice of test operating parameters is left to the user. A fixed amount of sliding distance must be used because wear is usually non-linear with distance in this test.

SCOPE

1.1 This test method covers laboratory procedures for determining the resistance of materials to sliding wear. The test utilizes a block-on-ring friction and wear testing machine to rank pairs of materials according to their sliding wear characteristics under various conditions.

1.2 An important attribute of this test is that it is very flexible. Any material that can be fabricated into, or applied to, blocks and rings can be tested. Thus, the potential materials combinations are endless. However, the interlaboratory testing has been limited to metals. In addition, the test can be run with various lubricants, liquids, or gaseous atmospheres, as desired, to simulate service conditions. Rotational speed and load can also be varied to better correspond to service requirements.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. Wear test results are reported as the volume loss in cubic millimetres for both the block and ring. Materials of higher wear resistance will have lower volume loss.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G77 − 05 (Reapproved 2010)

Standard Test Method for

Ranking Resistance of Materials to Sliding Wear Using

1

Block-on-Ring Wear Test

ThisstandardisissuedunderthefixeddesignationG77;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers laboratory procedures for de-

E691Practice for Conducting an Interlaboratory Study to

termining the resistance of materials to sliding wear. The test

Determine the Precision of a Test Method

utilizes a block-on-ring friction and wear testing machine to

G40Terminology Relating to Wear and Erosion

rank pairs of materials according to their sliding wear charac-

teristics under various conditions.

3. Terminology

1.2 An important attribute of this test is that it is very

3.1 Definitions:

flexible.Anymaterialthatcanbefabricatedinto,orappliedto,

3.1.1 wear—damage to a solid surface, generally involving

blocks and rings can be tested. Thus, the potential materials

progressive loss of material, due to relative motion between

combinations are endless. However, the interlaboratory testing

that surface and a contacting substance or substances.

hasbeenlimitedtometals.Inaddition,thetestcanberunwith

3.1.2 Foradditionaldefinitionspertinenttothistestmethod,

various lubricants, liquids, or gaseous atmospheres, as desired,

see Terminology G40.

to simulate service conditions. Rotational speed and load can

also be varied to better correspond to service requirements.

4. Summary of Test Method

1.3 The values stated in SI units are to be regarded as the

4.1 Atest block is loaded against a test ring that rotates at a

standard. The values given in parentheses are for information

given speed for a given number of revolutions. Block scar

only.Wear test results are reported as the volume loss in cubic

volume is calculated from the block scar width, and ring scar

millimetres for both the block and ring. Materials of higher

volume is calculated from ring weight loss. The friction force

wear resistance will have lower volume loss.

required to keep the block in place is continuously measured

1.4 This standard does not purport to address all of the

during the test with a load cell. These data, combined with

safety concerns, if any, associated with its use. It is the

normal force data, are converted to coefficient of friction

responsibility of the user of this standard to establish appro-

values and reported.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 The significance of this test method in any overall

2. Referenced Documents

measurement program directed toward a service application

2

will depend on the relative match of test conditions to the

2.1 ASTM Standards:

conditions of the service application.

D2714Test Method for Calibration and Operation of the

Falex Block-on-Ring Friction and Wear Testing Machine

5.2 This test method seeks only to prescribe the general test

E122PracticeforCalculatingSampleSizetoEstimate,With

procedure and method of calculating and reporting data. The

Specified Precision, the Average for a Characteristic of a

choice of test operating parameters is left to the user. A fixed

Lot or Process

amount of sliding distance must be used because wear is

usually non-linear with distance in this test.

1

6. Apparatus and Materials

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of G02.40 on Non-Abrasive Wear.

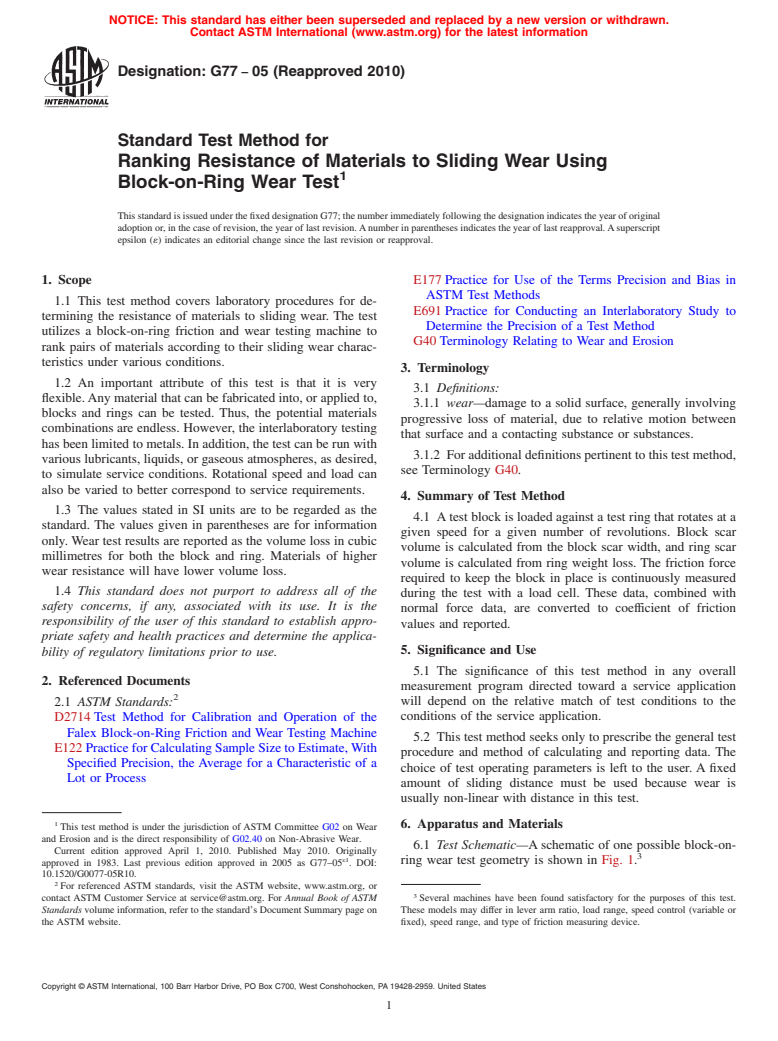

6.1 Test Schematic—Aschematic of one possible block-on-

Current edition approved April 1, 2010. Published May 2010. Originally

3

ε1

ring wear test geometry is shown in Fig. 1.

approved in 1983. Last previous edition approved in 2005 as G77–05 . DOI:

10.1520/G0077-05R10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Several machines have been found satisfactory for the purposes of this test.

Standards volume information, refer to the standard’s Document Summary page on These models may differ in lever arm ratio, load range, speed control (variable or

the ASTM website. fixed), speed range, and type of friction measuring device.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G77 − 05 (2010)

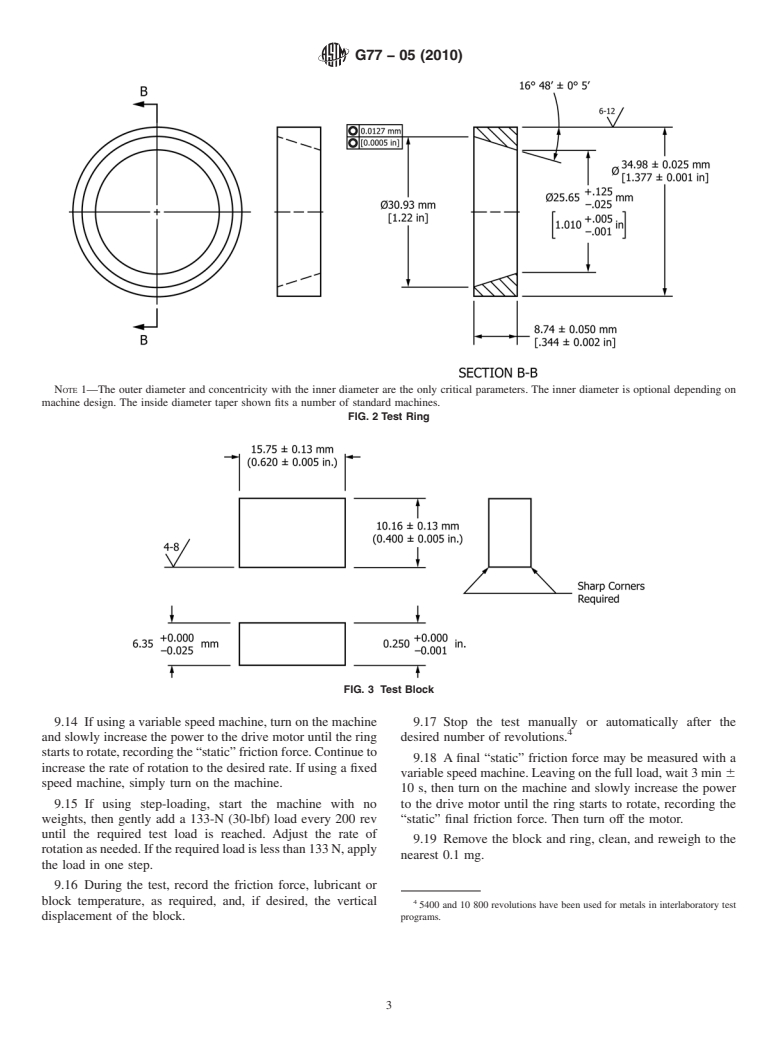

9. Procedure

9.1 Clean the block and ring using a procedure that will

remove any scale, oil film, or residue without damaging the

surfa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.