ASTM F903-10

(Test Method)Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Liquids

Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Liquids

SIGNIFICANCE AND USE

This test method is normally used to evaluate the barrier effectiveness against liquids of materials used for protective clothing and specimens from finished items of protective clothing.

Finished items of protective clothing include gloves, arm shields, aprons, suits, hoods, boots, and the like.

The phrase “specimens from finished items” encompasses seamed and other discontinuous regions as well as the usual continuous regions of protective clothing items.

A substitute challenge liquid (for example, water) is appropriate in some cases. However, it is possible that differences in chemical and molecular properties (for example, surface tension) lead to different results.

SCOPE

1.1 This test method is used to test specimens of protective clothing and candidate materials and constructions to be used in protective clothing. The resistance to visible penetration of the test liquid is determined with the liquid in continuous contact with the normally outside surface of the test specimen.

1.2 In some cases, significant amounts of hazardous materials will permeate specimens that pass the penetration tests. For more sensitive analysis use Test Method F739 to determine permeation.

1.3 This test method is not applicable to finger tips or crotch areas of gloves, which are possible failure points.

1.4 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards are given in Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F903 − 10

Standard Test Method for

Resistance of Materials Used in Protective Clothing to

1

Penetration by Liquids

ThisstandardisissuedunderthefixeddesignationF903;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Workers involved in the production, use, and transportation of liquid chemicals can be exposed to

numerous compounds capable of causing harm upon contact with the human body. The deleterious

effects of these chemicals can range from acute trauma such as skin irritation and burn to chronic

degenerative disease, such as cancer. Since engineering controls may not eliminate all possible

exposures, attention is often placed on reducing the potential for direct skin contact through the use

of protective clothing that resists permeation, penetration, and degradation.

This test method determines resistance to penetration only. Resistance to permeation and

degradation should be determined by other test methods.

1. Scope 2. Referenced Documents

2

1.1 This test method is used to test specimens of protective 2.1 ASTM Standards:

clothing and candidate materials and constructions to be used D1777 Test Method for Thickness of Textile Materials

in protective clothing. The resistance to visible penetration of E105 Practice for Probability Sampling of Materials

the test liquid is determined with the liquid in continuous F104 Classification System for Nonmetallic Gasket Materi-

contact with the normally outside surface of the test specimen. als

F739 Test Method for Permeation of Liquids and Gases

1.2 In some cases, significant amounts of hazardous mate-

throughProtectiveClothingMaterialsunderConditionsof

rials will permeate specimens that pass the penetration tests.

Continuous Contact

FormoresensitiveanalysisuseTestMethodF739todetermine

permeation.

3. Terminology

1.3 Thistestmethodisnotapplicabletofingertipsorcrotch

3.1 Definitions:

areas of gloves, which are possible failure points.

3.1.1 degradation, n—a deleterious change in one or more

1.4 The values as stated in inch-pound units are to be

properties of a material.

regarded as the standard. The values in parentheses are for

3.1.2 penetration, n—for chemical protective clothing, the

information only.

movement of substances through voids in aprotective clothing

1.5 This standard does not purport to address all of the material or item on a non-molecular level.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—Voids include gaps, pores, holes, and

responsibility of the user of this standard to establish appro-

imperfections in closures, seams, interfaces, and protective

priate safety and health practices and determine the applica-

clothing materials. Penetration does not require a change of

bility of regulatory limitations prior to use.Specifichazardsare

state; solid chemicals move through voids in the material as

given in Section 7.

solids, liquids as liquids, and gases as gases. Penetration is a

distinctly different mechanism from permeation.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal

Protective Clothing and Equipment and is the direct responsibility of Subcommittee

2

F23.30 on Chemicals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2010. Published February 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2004 as F903 - 03(2004). DOI: Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

10.1520/F0903-10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

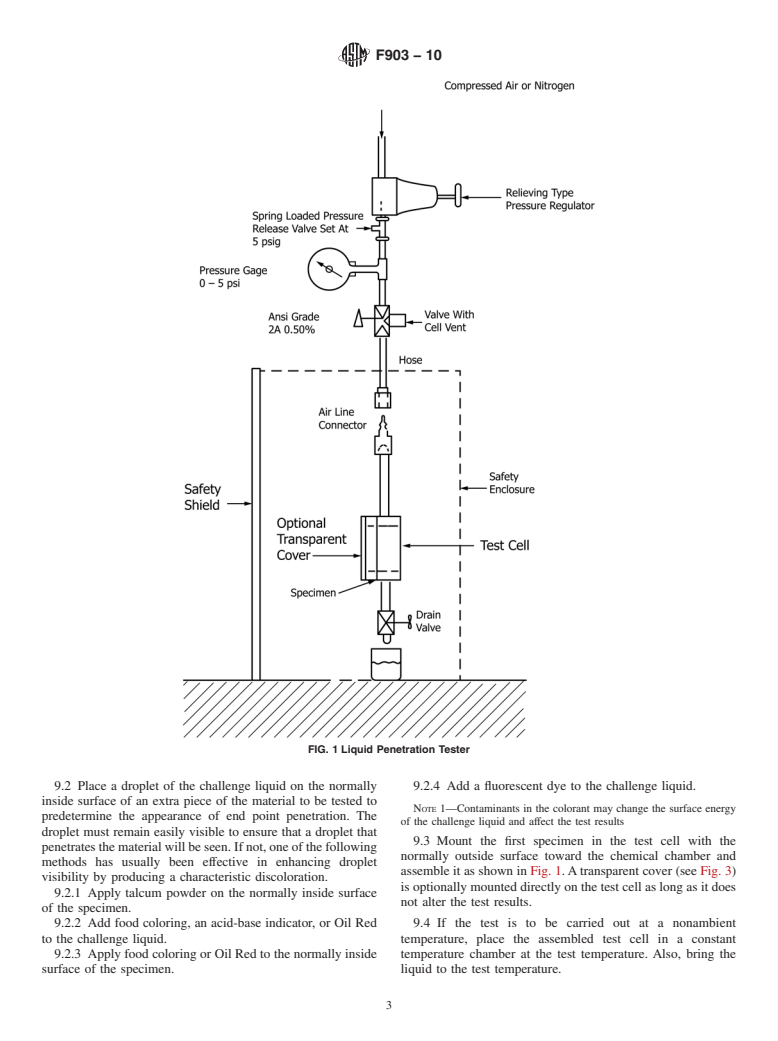

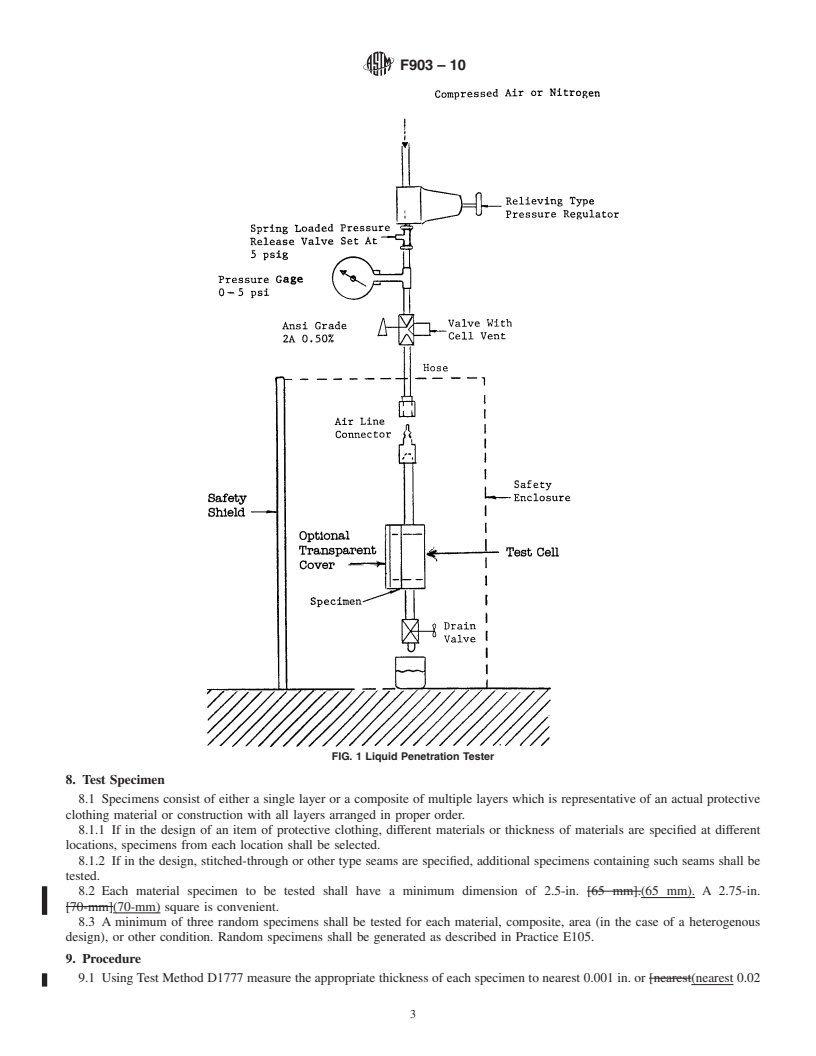

F903 − 10

3.1.3 permeation, n—for chemical protective clothing, the 6.2.3 Screen, retaining, optional (see Table 2), with at least

movement of chemicals as molecules through protective cloth- 50 % open area.The purpose of the screen is to limit distention

ing material items by the processes of (1) absorption of the of the test specimen to 0.2 in. (5 mm) or less. Examples of

chemical into the contact surface of the material, (2) diffusion retaining screens are 11 by 11 nylon screen, 14 by 14

3

of the absorbed molecules throughout the material, and (3) polypropylene screen, and 13 by 13 polyester screen.

desorption of the chemical from the opposite surface of the

material.

7. Hazards

3.1.3.1 Discussion—Permeation is a distinctly different

7.1 Beforecarryingoutthistestmethod,identifyandreview

mechanism from penetration.

safety precau

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F903–03 (Reapproved 2004) Designation:F903–10

Standard Test Method for

Resistance of Materials Used in Protective Clothing to

1

Penetration by Liquids

ThisstandardisissuedunderthefixeddesignationF903;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Workers involved in the production, use, and transportation of liquid chemicals can be exposed to

numerous compounds capable of causing harm upon contact with the human body. The deleterious

effects of these chemicals can range from acute trauma such as skin irritation and burn to chronic

degenerative disease, such as cancer. Since engineering controls may not eliminate all possible

exposures, attention is often placed on reducing the potential for direct skin contact through the use

of protective clothing that resists permeation, penetration, and degradation.

This test method determines resistance to penetration only. Resistance to permeation and

degradation should be determined by other test methods.

1. Scope

1.1 This test method is used to test specimens of protective clothing and candidate materials and constructions to be used in

protective clothing. The resistance to visible penetration of the test liquid is determined with the liquid in continuous contact with

the normally outside surface of the test specimen.

1.2 In some cases, significant amounts of hazardous materials will permeate specimens that pass the penetration tests. For more

sensitive analysis use Test Method F739 to determine permeation.

1.3 This test method is not applicable to finger tips or crotch areas of gloves, which are possible failure points.

1.4 The values as stated in inch-pound units are to be regarded as the standard. The values in bracketsparentheses are for

information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards are given in Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D1777 Test Method for Thickness of Textile Materials

E105 Practice for Probability Sampling Of Materials

F104 Classification System for Nonmetallic Gasket Materials

F739 Test Method for Permeation of Liquids and Gases through Protective Clothing Materials under Conditions of Continuous

Contact

3. Terminology

3.1 Definitions:

3.1.1 degradation, n—a deleterious change in one or more properties of a material.

3.1.2 penetration, n—the movement of matter through closures, porous materials, seams, and pinholes or other imperfections

in protective clothing on a nonmolecular level. —for chemical protective clothing, the movement of substances through voids in

1

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.30 on Chemical Resistance.

Current edition approved June 1, 2004. Published July 2004. Originally approved in 1984. Last previous edition approved in 2003 as F903-03. DOI: 10.1520/F0903-

03R04.on Chemicals.

Current edition approved Jan. 1, 2010. Published February 2010. Originally approved in 1984. Last previous edition approved in 2004 as F903 - 03(2004). DOI:

10.1520/F0903-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F903–10

aprotective clothing material or item on a non-molecular level.

3.1.2.1 Discussion—For this test method, the specific matter is a liquid chemical. —Voids include gaps, pores, holes, and

imperfections in closures, seams, interfaces, and protective clothing materials. Penetration does not require a change of state; solid

chemicals move through voids in the material as solids, liquids as liquids, and gases as gases. Penetration is a distinctly different

mechanism from permeation.

3.1.3 permeation, n—the process by which a chemical moves through a protective

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.