ASTM D1050-05(2011)

(Specification)Standard Specification for Rubber Insulating Line Hose

Standard Specification for Rubber Insulating Line Hose

ABSTRACT

This specification covers acceptance testing of rubber insulating line hose for use as a portable protective device for protection of workers from accidental contact with live electrical conductors. Two types of line hose are provided and are designated as Type I, non-resistant to ozone, and Type II and Type III, resistant to ozone. Five classes of line hose, differing in electrical characteristics, are provided and are designated as Class 0, Class 1, Class 2, Class 3, and Class 4. Four styles of line hose, differing in design characteristics, are provided and are designated as Style A, Style B, Style C, and Style D. The line hose shall be constructed in four styles: straight style, connector-end style, extended-lip style, and connectorend extended-lip style. The line hose shall be formed with an interlocking lip of sufficient length to prevent the device from being dislodged accidentally from the conductor it covers. The interlocking lip shall be closely adjacent to the inside surface contour of the outer wall. The depth of adapter end of connector-end style line hose shall be not less than a certain value, and its inside diameter shall be such that it will snugly grip the end of the line hose of the same size which it joins. Each line hose shall conform to the physical requirements such as determined tensile strength, elongation, tension set, tear resistance and moisture absorption.

SCOPE

1.1 This specification covers acceptance testing of rubber insulating line hose for use as a portable protective device for protection of workers from accidental contact with live electrical conductors.

1.2 Two types of line hose are provided and are designated as Type I, non-resistant to ozone, and Type II and Type III, resistant to ozone.

1.3 Five classes of line hose, differing in electrical characteristics, are provided and are designated as Class 0, Class 1, Class 2, Class 3, and Class 4.

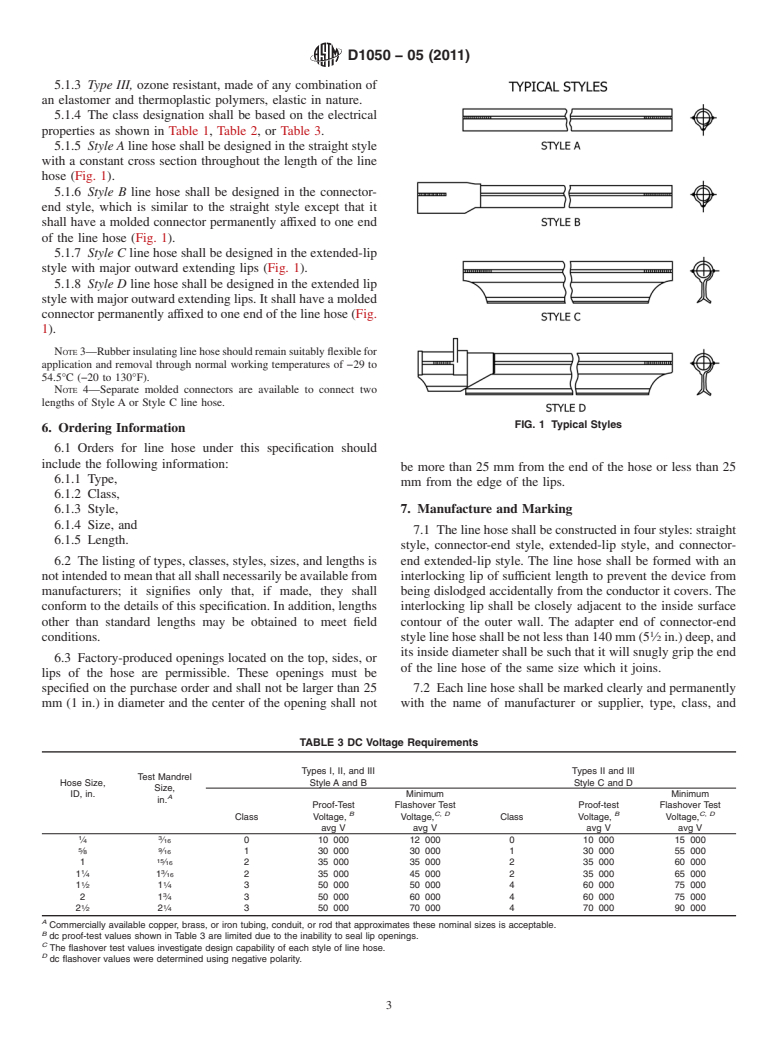

1.4 Four styles of line hose, differing in design characteristics, are provided and are designated as Style A, Style B, Style C, and Style D.

The following precautionary caveat pertains only to the test method portion, Sections 16, 17, 18, 19, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 18.1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1050 −05 (Reapproved 2011)

Standard Specification for

1

Rubber Insulating Line Hose

This standard is issued under the fixed designation D1050; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D573Test Method for Rubber—Deterioration in an Air

Oven

1.1 This specification covers acceptance testing of rubber

D624Test Method for Tear Strength of Conventional Vul-

insulating line hose for use as a portable protective device for

canized Rubber and Thermoplastic Elastomers

protection of workers from accidental contact with live elec-

D2865Practice for Calibration of Standards and Equipment

trical conductors.

for Electrical Insulating Materials Testing

1.2 Two types of line hose are provided and are designated

F819Terminology Relating to Electrical Protective Equip-

as Type I, non-resistant to ozone, and Type II and Type III,

ment for Workers

resistant to ozone.

3

2.2 Federal Specification:

1.3 Five classes of line hose, differing in electrical

PPP-B-636 Box, Shipping, Filterboard

characteristics, are provided and are designated as Class 0, 4

2.3 ANSI Standards:

Class 1, Class 2, Class 3, and Class 4.

C2National Electrical Safety Code, Section 44

1.4 Four styles of line hose, differing in design C39.5Safety Requirements for Electrical and Electronic

characteristics, are provided and are designated as Style A, Measuring and Controlling Instrumentation

Style B, Style C, and Style D. C84.1 Electric Power Systems and Equipment-Voltage

Ratings

1.5 The following precautionary caveat pertains only to the

test method portion, Sections 16, 17, 18, 19, of this specifica-

3. Terminology

tion:This standard does not purport to address all of the safety

concerns, if any, associated with its use. It is the responsibility 3.1 Definitions of Terms Specific to This Standard:

3.1.1 breakdown—the electrical discharge or arc occurring

of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory betweentheelectrodesandthroughtheequipmentbeingtested.

limitations prior to use.For specific precautionary statements,

3.1.2 flashover—the electrical discharge or arc occurring

see 18.1.1.

between electrodes and over or around, but not through, the

equipment being tested.

2. Referenced Documents

3.1.3 electrical testing facility—a location with qualified

2

2.1 ASTM Standards:

personnel,testingequipment,andproceduresfortheinspection

D297Test Methods for Rubber Products—ChemicalAnaly-

and electrical testing of electrical insulating protective equip-

sis

ment.

D412TestMethodsforVulcanizedRubberandThermoplas-

3.1.4 electrode clearance—the shortest path from the ener-

tic Elastomers—Tension

gized electrode to the ground electrode.

D570Test Method for Water Absorption of Plastics

3.1.5 insulated—separated from other conducting surfaces

by a dielectric substance (including air space) offering a high

resistance to the passage of current.

1

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

NOTE 1—When any object is said to be insulated, it is understood to be

Subcommittee F18.25 on Insulating Cover-Up Equipment. This standard replaces

insulated in a suitable manner for the conditions to which it is subjected.

ANSI Standard J6.1, which is no longer available

Otherwise, it is, within the purpose of this definition, uninsulated.

Current edition approved Sept. 1, 2011. Published September 2011. Originally

approved in 1949 as D1050–49T. Last previous edition approved in 2005 as

ε1

D1050–05 . DOI: 10.1520/D1050-05R11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Standardization Documents, Order Desk, Bldg. 4, Section D,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 700 Robbins Ave., Philadelphia, PA 19111-5094, ATTN: NPODS.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 West 42nd Street,

the ASTM website. 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1050−05 (2011)

Insulating covering of conductors is one means of making the conductor TABLE 1 Proof-Test/Use Voltage Relationship

insulated.

Nominal

Class of AC Proof- DC Proof-

Maximum

3.1.6 isolated—an object that is not rea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.