ASTM D3795-00a(2006)

(Test Method)Standard Test Method for Thermal Flow, Cure, and Behavior Properties of Pourable Thermosetting Materials by Torque Rheometer

Standard Test Method for Thermal Flow, Cure, and Behavior Properties of Pourable Thermosetting Materials by Torque Rheometer

SIGNIFICANCE AND USE

The continuous recording of torque and temperature while going through these various stages can be used to predict the behavior of the material during processing.

The torque rheometer test has two important functions. First, it is a means to predict flow/viscosity and cure characteristics of pourable thermosetting compounds. For example, the test provides useful data to predict the processibility of a material in a particular molding method. This information is also useful to optimize process conditions for a particular material such as the minimum pressure to fill a mold and the time to cure a part. A second capability of the test is to provide a graphic record of the batch-to-batch uniformity of the molding compound.

SCOPE

1.1 This test method covers the apparatus, and a specific test method, including the evaluation of results required for the determination of the thermal flow and cure behavior properties of pourable thermosetting materials.

1.2 This test method can be used:

1.2.1 As a control for the development and production of pourable thermosetting materials and to measure the different properties (for example, melting behavior, cure behavior, etc.) as well as the influence of various additives and fillers in any given formulations, and

1.2.2 Verify the uniformity of different production batches of the same formulation.

1.3 The values are stated in SI units.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in Section 7.Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3795 − 00a(Reapproved 2006)

Standard Test Method for

Thermal Flow, Cure, and Behavior Properties of Pourable

Thermosetting Materials by Torque Rheometer

This standard is issued under the fixed designation D3795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 Thistestmethodcoverstheapparatus,andaspecifictest 3.1 Definitions of Terms Specific to This Standard:

method, including the evaluation of results required for the

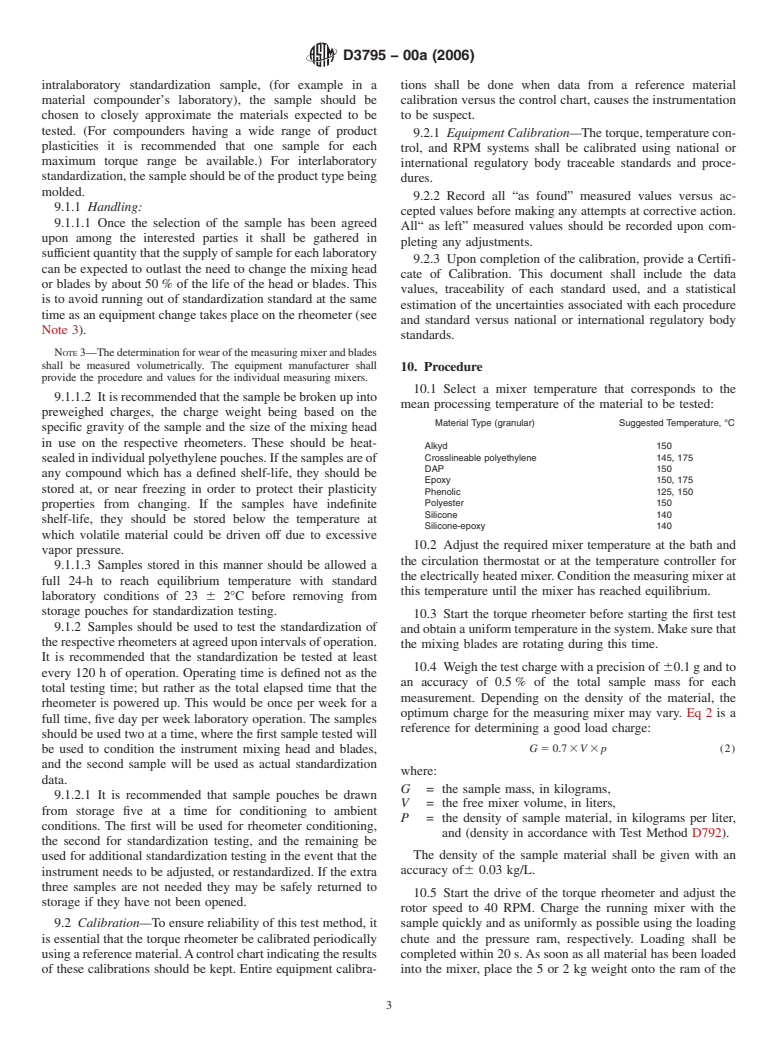

3.1.1 For the purpose of this test method, the following

determination of the thermal flow and cure behavior properties

definitions apply, (see Fig. 1):

of pourable thermosetting materials.

3.1.2 flow and cure behavior—the flow behavior is repre-

sented by the recorded torque curve from the loading peak

1.2 This test method can be used:

(Point t ), to the torque minimum (Point t ).The cure behavior

1 5

1.2.1 As a control for the development and production of

is represented by the recorded torque curve from the torque

pourable thermosetting materials and to measure the different

minimum(Point t )tothetorquemaximum(Point t ).Therate

5 4

properties (for example, melting behavior, cure behavior, etc.)

of curing is represented by the slope of the torque curve.

as well as the influence of various additives and fillers in any

given formulations, and

3.1.3 time—the residence time at torque t × X, where X is

1.2.2 Verify the uniformity of different production batches

a factor (preferably 1.3) is t (s). To determine t , draw a line

v v

of the same formulation.

att × Xparallelwiththetimeaxis.Theintersectionofthisline

with the left branch of the curve is t . The intersection of this

1.3 The values are stated in SI units.

line with the right branch of the curve is t :

1.4 This standard does not purport to address all of the

t 5 t 2 t unitsareseconds ~s! (1)

safety concerns, if any, associated with its use. It is the v 3 2

3.1.3.1 Discussion—Depending on the manufacturer of the

responsibility of the user of this standard to establish appro-

equipment, the software analysis program for the designated

priate safety and health practices and determine the applica-

values in this test method may differ (t , t , etc.).

bility of regulatory limitations prior to use. Specific precau- 1 2

3.1.3.2 Discussion—Upon agreement between interested

tions are given in Section 7.

parties, the value of X may be changed and be listed in any

NOTE 1—There is no similar or equivalent ISO standard.

report.

2. Referenced Documents

3.1.4 residencetimeordurationofplasticlife(t −t )—the

2 3

residence time is represented by a section of the recorded

2.1 ASTM Standards:

torque curve in which the molten material causes the lowest

D792Test Methods for Density and Specific Gravity (Rela-

torque, s.

tive Density) of Plastics by Displacement

D883Terminology Relating to Plastics

3.1.5 totalcuretime(t −t )—timefromwhenthematerial

4 0

D1898Practice for Sampling of Plastics (Withdrawn 1998)

is loaded into the mixer chamber up to complete cure, s.

E691Practice for Conducting an Interlaboratory Study to

3.1.6 torque:

Determine the Precision of a Test Method

3.1.6.1 initial torque (t )—the initial high torque peak once

material is loaded into the mixer chamber. Sometimes referred

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

to as the loading peak, Nm (Newton-meters).

and is the direct responsibility of Subcommittee D20.30 on Thermal Proper-

3.1.6.2 minimum torque (t )—the lowest point on the torque

ties.30.08).

curve representing maximum fluxing of material, Nm.

Current edition approved March 15, 2006. Published April 2006. Originally

approved in 1979. Last previous edition approved in 2000 as D3795–00a. DOI:

3.1.6.3 final torque or cure peak (t )—the final maximum

10.1520/D3795-00AR06.

torque value representing the final cure of material, Nm.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4. Summary of Test Method

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4.1 A sample of thermosetting material is charged into the

The last approved version of this historical standard is referenced on

www.astm.org. temperature controlled mixer/measuring head in which the

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D3795 − 00a (2006)

NOTE 2—Only the results obtained with identical measuring systems

can be compared with one another. In this context, the mixer type, type of

heating/cooling and loading weight used are of decisive importance.

6.1.4 Liquid heated mixers shall be equipped with a circu-

lation pump that has a capacity of at least 24 L/min at a back

pressure of approximately 500 mbars. The heat transfer me-

diumshallbestabilizedsiliconeoil,withamaximumviscosity

of 20 mm /s at 25°C. The oil temperature shall be monitored

by a device which has a resolution of 0.2°C or better.

6.1.5 Electricallyheatedmixerbowlsshallhaveaminimum

of one independent electric controller and a maximum of two

independent electric controllers that utilize modern control

techniquesandalgorithms.Thesecontrollersshallprovideboth

heatingandcoolingcycles.Thetemperaturecontrolensembles

that include the sensor, controller and actuators shall be

accurate to within 2.0°C throughout their working range.

Reported values shall have a precision of 0.2°C or better.

6.1.6 The torque recording ensemble shall be accurate to

NOTE 1—Top curve associated with temperature axis; bottom curve

0.25% of the reading.

associated with torque axis.

FIG. 1 Torque Rheometer Curve 6.1.7 For feeding flowable or granular sample materials a

loading device shall be used. For feeding other coarse materi-

als,apressureramactuatedmanuallyorpneumaticallyshallbe

used.Theloadingchutehastobemountedontothemixer,with

material is compacted, melted, cross-linked, hardened, and

a ram and eithera5or2kg weight or with an adjustable

crushed under constant shear.

pneumatic cylinder (see Note 2).

6.1.8 For recording of the stock temperature during the

5. Significance and Use

measuring process, the temperature measuring device is

5.1 The continuous recording of torque and temperature

mountedfrombelowintothebottomofthemeasuringmixerin

whilegoingthroughthesevariousstagescanbeusedtopredict

such a way that it penetrates 1.5 mm into the mixer bowl. The

the behavior of the material during processing.

stock temperature versus time, is recorded simultaneously

5.2 The torque rheometer test has two important functions.

together with the torque curve.

First, it is a means to predict flow/viscosity and cure charac-

6.1.9 SoftBrassSpatulaorStiffBrassBristleCleaningTool.

teristics of pourable thermosetting compounds. For example,

7. Hazards

the test provides useful data to predict the processibility of a

material in a particular molding method. This information is 7.1 Do not exceed the rated power of the instrument as

damage to the mixer or to the torque rheometer may result.

also useful to optimize process conditions for a particular

material such as the minimum pressure to fill a mold and the

7.2 Do not attempt to clean or insert objects into the mixer

time to cure a part.Asecond capability of the test is to provide

while it is running.

a graphic record of the batch-to-batch uniformity of the

7.3 Use adequate exhausts and safety devices necessary to

molding compound.

meet applicable safety codes.

7.4 Use insulated gloves to protect operator from hot mixer

6. Apparatus

surface.

6.1 Torque Rheometer, with a mixing bowl.

7.5 Refer to manufacturers’ operating instructions.

6.1.1 The torque rheometer shall be equipped with a drive

motorwithaload-independentspeedstabilityof 60.5%ofthe

8. Sampling

top rotor speed.

8.1 A batch of compound shall be considered as a unit of

6.1.2 The recording device selected shall be capable of

manufacture as prepared for shipment and may consist of a

recording the measurable variables of torque, stock tempera-

manufacturer’s blend of one or more production runs of

ture, and rotation per minute (RPM) as a function of time.The

material.

rheometer should also be equipped with a real time RPM

8.2 Suitable methods of sampling shall follow Practice

indicator.

D1898. A 400-g sample will be sufficient for tests required.

6.1.3 For the measurement, a surface hardened laboratory

internal mixer is used, specified by a bowl volume of 25, 30 or

8.3 Crushanycompoundinapreformstatetoaparticlesize

60 cm , that can be attached to the above mentioned torque

that would pass through the loading chute.

rheometer. Either a set of triangular or roller blades shall be

9. Sample Selection, Handling and Use for Rheometer

used counter-rotating with a speed ratio of 3:2 (left to right).

Standardization

(The mixer bowl may be heated with a circulated liquid

temperature controlled by a thermostat or electrically with at 9.1 Selection—The selection of the sample should be deter-

least two heating zones (see Note 2). mined by the use for which it is intended. If it is to be an

D3795 − 00a (2006)

intralaboratory standardization sample, (for example in a tions shall be done when data from a reference material

material compounder’s laboratory), the sample should be calibration versus the control chart, causes the instrumentation

chosen to closely approximate the materials expected to be to be suspect.

tested. (For compounders having a wide range of product

9.2.1 EquipmentCalibration—Thetorque,temperaturecon-

plasticities it is recommended that one sample for each

trol, and RPM systems shall be calibrated using national or

maximum torque range be available.) For interlaboratory

international regulatory body traceable standards and proce-

standardization,thesampleshouldbeoftheproducttypebeing

dures.

molded.

9.2.2 Record all “as found” measured values versus ac-

9.1.1 Handling:

cepted values before making any attempts at corrective action.

9.1.1.1 Once the selection of the sample has been agreed

All“ as left” measured values should be recorded upon com-

upon among the interested parties it shall be gathered in

pleting any adjustments.

sufficientquantitythatthesupplyofsampleforeachlaboratory

9.2.3 Upon completion of the calibration, provide a Certifi-

can be expected to outlast the need to change the mixing head

cate of Calibration. This document shall include the data

or blades by about 50% of the life of the head or blades. This

values, traceability of each standard used, and a statistical

is to avoid running out of standardization standard at the same

estimation of the uncertainties associated with each procedure

timeasanequipmentchangetakesplaceontherheometer(see

and standard versus national or international regulatory body

Note 3).

standards.

NOTE3—Thedeterminationforwearofthemeasuringmixerandblades

shall be measured volumetrically. The equipment manufacturer shall

10. Procedure

provide the procedure and values for the individual measuring mixers.

10.1 Select a mixer temperature that corresponds to the

9.1.1.2 Itisrecommendedthatthesamplebebrokenupinto

mean processing temperature of the material to be tested:

preweighed charges, the charge weight being based on the

Material Type (granular) Suggested Temperature, °C

specific gravity of the sample and the size of the mixing head

in use on the respective rheometers. These should be heat-

Alkyd 150

Crosslineable polyethylene 145, 175

sealedinindividualpolyethylenepouches.Ifthesamplesareof

DAP 150

any compound which has a defined shelf-life, they should be

Epoxy 150, 175

stored at, or near freezing in order to protect their plasticity

Phenolic 125, 150

Polyester 150

properties from changing. If the samples have indefinite

Silicone 140

shelf-life, they should be stored below the temperature at

Silicone-epoxy 140

which volatile material could be driven off due to excessive

10.2 Adjust the required mixer temperature at the bath and

vapor pressure.

the circulation thermostat or at the temperature controller for

9.1.1.3 Samples stored in this manner should be allowed a

theelectricallyheatedmixer.Conditionthemeasuringmixerat

full 24-h to reach equilibrium temperature with standard

this temperature until the mixer has reached equilibrium.

laboratory conditions of 23 6 2°C before removing from

storage pouches for standardization testing.

10.3 Start the torque rheometer before starting the first test

9.1.2 Samples should be used to test the standardization of

andobtainauniformtemperatureinthesystem.Makesurethat

therespectiverheometersatagreeduponintervalsofoperation.

the mixing blades are rotating during this time.

It is recommended that the standardization be tested at least

10.4 Weighthetestchargewithaprecisionof 60.1gandto

every 120 h of operation. Operating time is defined not as the

an accuracy of 0.5% of the total sample mass for each

total testing time; but rather as the total elapsed time that the

measurement. Depending on the density of the material, the

rheometer is powered up. This would be once per week for a

optimum charge for the measuring mixer may vary. Eq 2 is a

full time, five day per week laboratory operation. The samples

reference for determining a good load charge:

shouldbeusedtwoatatime,wherethefirstsampletestedwill

G 50.7 3V 3p (2)

be used to condition the instrument mixing head and blades,

and the second sample will be used as actual standardization

where:

data.

G = the sample mass, in kilograms,

9.1.2.1 It is recommended that sample pouches be drawn

V = the free mixer volume, in liters,

from storage five at a time for conditioning to ambient

P = the density of sample material, in kilograms per liter,

conditions. The first will be used for rheometer conditioning,

and (density in accordance with Test Method D792).

the second for standardization testing, and the remaining be

The density of the sample material shall be given with an

used for additional standardization testing in the event that the

accuracy of6 0.03 kg/L.

instrument needs to be adjusted, or restandardized. If the extra

three samples are not needed they may be safely returned to

10.5 Start the drive of the torque rheometer and adjust the

storage if they have not been opened.

rotor speed to 40 RPM. Charge the running mixer with the

9.2 Calibration—To ensure reliability of this test method, it sample quickly and as uniformly as possible using the loading

is essential t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.