ASTM D2561-95

(Test Method)Standard Test Method for Environmental Stress-Crack Resistance of Blow-Molded Polyethylene Containers

Standard Test Method for Environmental Stress-Crack Resistance of Blow-Molded Polyethylene Containers

SCOPE

1.1 Under certain conditions of stress, and in the presence of environments such as soaps, wetting agents, oils, or detergents, blow-molded polyethylene containers may exhibit mechanical failure by cracking at stresses appreciably below those that would cause cracking in the absence of these environments.

1.2 This test method measures the environmental stress- crack resistance of containers, which is the summation of the influence of container design, resin, blow-molding conditions, post treatment, or other factors that can affect this property. Three procedures are provided as follows:

1.2.1 Procedure A, Stress-Crack Resistance of Containers to Commercial Liquids—This procedure is particularly useful for determining the effect of container design on stress-crack resistance or the stress-crack resistance of a proposed commercial package containing a proprietary liquid product.

1.2.2 Procedure B, Stress-Crack Resistance of a Specific Container to Polyoxyethylated Nonylphenol, a Stress-Cracking Agent—The conditions of test described in this procedure are designed for testing containers made from Type III polyethylene Specification D1248. Therefore, this procedure is recommended for containers made from Type III polyethylene only. This procedure is particularly useful for determining the effect of resin on the stress-crack resistance of the container.

1.2.3 Procedure C, Controlled Elevated Pressure Stress-Crack Resistance of a Specific Container to Polyoxyethylated Nonylphenol, a Stress-Cracking Agent—The internal pressure is controlled at a constant elevated level.

1.3 These procedures are not designed to test the propensity for environmental stress cracking in the neck of containers, such as when the neck is subjected to a controlled strain by inserting a plug.

1.4 The values stated in SI units are to be regarded as the standard.

Note 1—There is no similar or equivalent ISO standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8 and Notes 1 and 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2561 – 95

Standard Test Method for

Environmental Stress-Crack Resistance of Blow-Molded

Polyethylene Containers

This standard is issued under the fixed designation D 2561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 8 and Note 1 and Note

1.1 Under certain conditions of stress, and in the presence of

9.

environments such as soaps, wetting agents, oils, or detergents,

blow-molded polyethylene containers may exhibit mechanical

2. Referenced Documents

failure by cracking at stresses appreciably below those that

2.1 ASTM Standards:

would cause cracking in the absence of these environments.

D 374 Test Methods for Thickness of Solid Electrical Insu-

1.2 This test method measures the environmental stress-

lation

crack resistance of containers, which is the summation of the

D 618 Practice for Conditioning Plastics and Electrical

influence of container design, resin, blow-molding conditions,

Insulating Materials for Testing

post treatment, or other factors that can affect this property.

D 1248 Specification for Polyethylene Plastics Molding and

Three procedures are provided as follows:

Extrusion Materials

1.2.1 Procedure A, Stress-Crack Resistance of Containers to

E 145 Specification for Gravity-Convection and Forced-

Commercial Liquids—This procedure is particularly useful for

Ventilation Ovens

determining the effect of container design on stress-crack

resistance or the stress-crack resistance of a proposed commer-

3. Terminology

cial package containing a proprietary liquid product.

3.1 Definitions of Terms Specific to This Standard:

1.2.2 Procedure B, Stress-Crack Resistance of a Specific

3.2 failure—during this test method, the formation of any

Container to Polyoxyethylated Nonylphenol, a Stress-Cracking

imperfection, such as a crack, which results in a loss of

Agent—The conditions of test described in this procedure are

pressurizing gas or stress-cracking agent. A container has failed

designed for testing containers made from Type III polyethyl-

when:

ene Specification D 1248. Therefore, this procedure is recom-

3.2.1 It has lost pressure through any aperture other than

mended for containers made from Type III polyethylene only.

heat seal areas; or, in Procedure C, when there is a detectable

This procedure is particularly useful for determining the effect

flow of supply air into the bottle,

of resin on the stress-crack resistance of the container.

3.2.2 There is visible to an observer with normal eyesight

1.2.3 Procedure C, Controlled Elevated Pressure Stress-

any crack completely through the container wall, or

Crack Resistance of a Specific Container to Polyoxyethylated

3.2.3 There is evidence of the contained liquid on the

Nonylphenol, a Stress-Cracking Agent—The internal pressure

outside of the container through any aperture other than one at

is controlled at a constant elevated level.

the heat-seal area, or the contained liquid volume has been

1.3 These procedures are not designed to test the propensity

reduced.

for environmental stress cracking in the neck of containers,

such as when the neck is subjected to a controlled strain by

4. Summary of Test Method

inserting a plug.

4.1 Procedure A consists of exposing any filled, sealed,

1.4 The values stated in SI units are to be regarded as the

blow-molded container to the action of a potential stress-

standard.

cracking agent within the container, at an elevated temperature.

NOTE 1—There is no similar or equivalent ISO standard.

The time to failure is observed.

4.2 Procedure B consists of exposing a partly filled and

1.5 This standard does not purport to address all of the

sealed blow-molded standard container to the action of poly-

safety concerns, if any, associated with its use. It is the

oxyethylated nonylphenol, a stress-cracking agent, within the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

Annual Book of ASTM Standards, Vol 10.01.

1 3

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics Annual Book of ASTM Standards, Vol 08.01.

and is the direct responsibility of Subcommittee D20.20 on Plastic Products. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Nov. 10, 1995. Published January 1996. Originally Igepal CO-630 (Antarox CO-630) obtained from GAF Corp., Dyestuff and

published as D 2561 – 66 T. Last previous edition D 2561 – 91. Chemical Div., 140 W. 51 St., New York, NY 10020.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2561

FIG. 1 Apparatus for Procedure C

FIG. 2 Apparatus for Procedure C, Including Refinements in Failure Detection

container, as well as to the action of this agent as an external 6.1.1 Circulating-Air Oven, consistent with ovens pre-

environment, at an elevated temperature. The time to failure is scribed in Specification E 145, except for size, capable of

observed. maintaining a temperature of 60 6 1°C (140 6 1.8°F) and an

3 3

4.3 Procedure C consists of exposing a partly filled blow- airflow rate of 8.5 to 17 m /min (300 to 600 ft /min).

molded standard container to the action of polyoxyethylated

NOTE 2—Caution: A high-temperature safety switch is highly recom-

nonylphenol, a stress-cracking agent, within the container, as

mended on this oven. Some test liquids can cause extreme pressure

well as to a constant elevated pressure internally applied and at

buildup upon heating. Under these conditions bottles can rupture with

an elevated temperature. The time-to-failure can be determined

explosive force. This condition can cause injury to the operator as well as

damage to the ovens. The override cutoff switch should be set to turn off

in a tactual-visual manner, or instrumentally.

the oven heat if the test temperature is exceeded by as much as 10°C

5. Significance and Use

(18°F).

5.1 When properly used, these procedures may serve to

6.1.2 Balance, accurate to within 61.0 g (for weighing

isolate such factors as material, blow-molding conditions,

containers and contents) or a volumetric filling apparatus

post-treatment, etc., on the stress-crack resistance of the

accurate to 61 mL.

container.

6.2 For Procedures A and B Only:

5.2 Environmental stress cracking of blow-molded contain-

6.2.1 Heat-Seal Laminate for sealing the containers.

ers is governed by many factors. Since variance of any of these

6.2.2 Heat-Sealing Unit.

factors can change the environmental stress-crack resistance of

6.2.3 Torque Meter.

the container, the test results are representative only of a given

6.2.4 Glass Beakers, large enough to hold the contents of

test performed under defined conditions in the laboratory. The

one test container.

reproducibility of results between laboratories on containers

6.3 For Procedures A and C Only:

made on more than one machine from more than one mold has

6.3.1 Polyethylene Bags, approximately 0.038-mm (1.5-

not been established.

mil) thick, large enough to enclose completely a test container.

5.3 Results can be used for estimating the shelf life of

The bag should fit loosely around the container and be long

blow-molded containers in terms of their resistance to envi-

enough so that the bag opening can be closed above the

ronmental stress cracking provided this is done against a

container closure.

rigorous background of practical field experience and repro-

6.4 For Procedure C Only:

ducible test data.

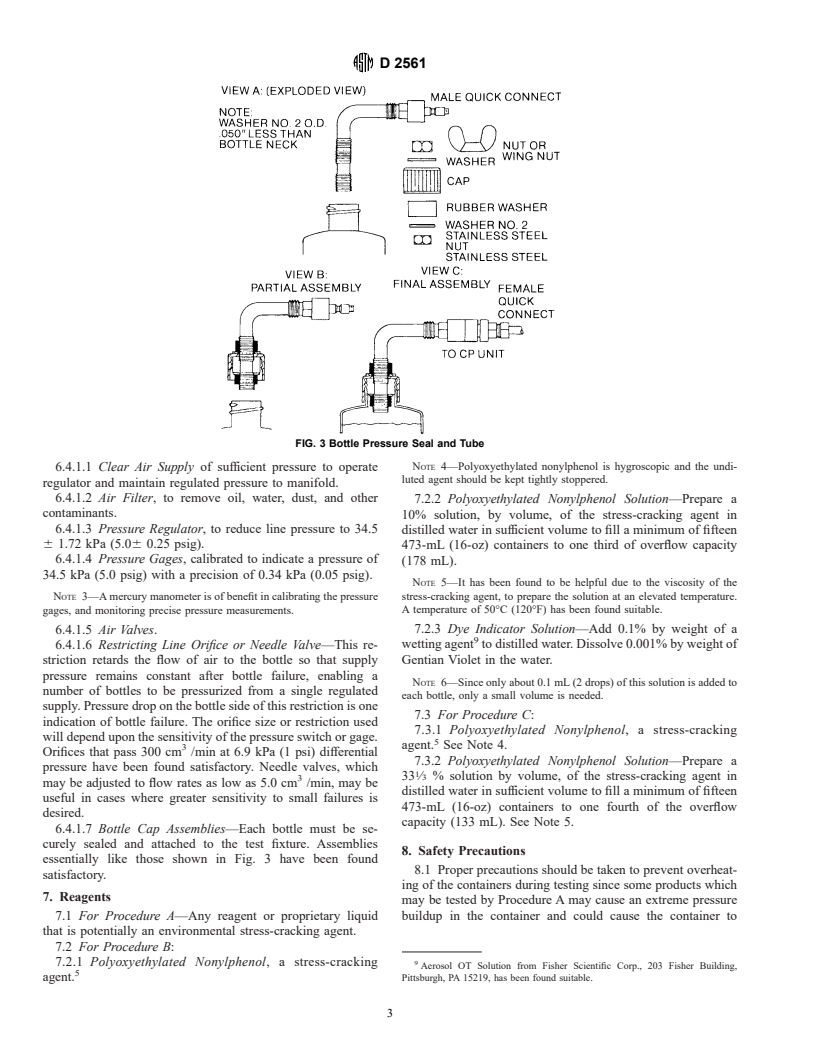

6.4.1 The essential parts of this apparatus are schematically

5.4 Before proceeding with this test method, reference

shown in Fig. 1. Additional refinements in fail detection can be

should be made to the specification of the material being tested.

added as shown in Fig. 2. The necessary equipment is as

Any test specimen preparation, conditioning, dimensions, or

follows:

testing parameters, or a combination thereof, covered in the

materials specification shall take precedence over those men-

A suitable polyethylene-foil laminate (aluminum seal) is available from Berlin

Packaging, 111 North Canal St., Suite 300, Chicago, IL 60606.

tioned in this test method. If there are no material specifica-

Selector Hand Sealing Iron (165 W) made by Selector of Shelton, CT, or Super

tions, then the default conditions apply.

Sealer made by Clamco Div., Cleveland Detroit Corp., 5400 Brookpark Rd.,

Cleveland, OH, is suitable.

6. Apparatus

Model 25 Owens-Illinois Spring Torque Tester, Owens-Illinois Glass Co.,

6.1 For Procedures A, B, and C: Toledo, OH, is suitable.

D 2561

FIG. 3 Bottle Pressure Seal and Tube

NOTE 4—Polyoxyethylated nonylphenol is hygroscopic and the undi-

6.4.1.1 Clear Air Supply of sufficient pressure to operate

luted agent should be kept tightly stoppered.

regulator and maintain regulated pressure to manifold.

6.4.1.2 Air Filter, to remove oil, water, dust, and other

7.2.2 Polyoxyethylated Nonylphenol Solution—Prepare a

contaminants.

10% solution, by volume, of the stress-cracking agent in

6.4.1.3 Pressure Regulator, to reduce line pressure to 34.5

distilled water in sufficient volume to fill a minimum of fifteen

6 1.72 kPa (5.06 0.25 psig).

473-mL (16-oz) containers to one third of overflow capacity

6.4.1.4 Pressure Gages, calibrated to indicate a pressure of

(178 mL).

34.5 kPa (5.0 psig) with a precision of 0.34 kPa (0.05 psig).

NOTE 5—It has been found to be helpful due to the viscosity of the

stress-cracking agent, to prepare the solution at an elevated temperature.

NOTE 3—A mercury manometer is of benefit in calibrating the pressure

A temperature of 50°C (120°F) has been found suitable.

gages, and monitoring precise pressure measurements.

7.2.3 Dye Indicator Solution—Add 0.1% by weight of a

6.4.1.5 Air Valves.

6.4.1.6 Restricting Line Orifice or Needle Valve—This re- wetting agent to distilled water. Dissolve 0.001% by weight of

Gentian Violet in the water.

striction retards the flow of air to the bottle so that supply

pressure remains constant after bottle failure, enabling a

NOTE 6—Since only about 0.1 mL (2 drops) of this solution is added to

number of bottles to be pressurized from a single regulated

each bottle, only a small volume is needed.

supply. Pressure drop on the bottle side of this restriction is one

7.3 For Procedure C:

indication of bottle failure. The orifice size or restriction used

7.3.1 Polyoxyethylated Nonylphenol, a stress-cracking

will depend upon the sensitivity of the pressure switch or gage.

3 agent. See Note 4.

Orifices that pass 300 cm /min at 6.9 kPa (1 psi) differential

7.3.2 Polyoxyethylated Nonylphenol Solution—Prepare a

pressure have been found satisfactory. Needle valves, which

3 33 ⁄3 % solution by volume, of the stress-cracking agent in

may be adjusted to flow rates as low as 5.0 cm /min, may be

distilled water in sufficient volume to fill a minimum of fifteen

useful in cases where greater sensitivity to small failures is

473-mL (16-oz) containers to one fourth of the overflow

desired.

capacity (133 mL). See Note 5.

6.4.1.7 Bottle Cap Assemblies—Each bottle must be se-

curely sealed and attached to the test fixture. Assemblies

8. Safety Precautions

essentially like those shown in Fig. 3 have been found

8.1 Proper precautions should be taken to prevent overheat-

satisfactory.

ing of the containers during testing since some products which

7. Reagents

may be tested by Procedure A may cause an extreme pressure

7.1 For Procedure A—Any reagent or proprietary liquid buildup in the container and could cause the container to

that is potentially an environmental stress-cracking agent.

7.2 For Procedure B:

7.2.1 Polyoxyethylated Nonylphenol, a stress-cracking

Aerosol OT Solution from Fisher Scientific Corp., 203 Fisher Building,

agent. Pittsburgh, PA 15219, has been found suitable.

D 2561

rupture explosively. Proper safety measures against over- Practice D 618 for those tests where conditioning is required.

heating are described in Note 2. In cases of disagreement, the tolerances shall be 61°C

8.2 Sometimes a container will fail by means of a small (61.8°F) and 62% relative humidity.

pinhole. Since the container is under pressure during the test, 10.2 Test Conditions—Conduct all tests at 60°C, unless

liquid may be forced out of the opening spraying the inside of instructed otherwise.

the oven and the operator, if an inspection is being made.

11. Procedure

Precautions to prevent this from happening are described in

11.1.4 and Note 10. 11.1 Procedure A:

8.3 Care should be taken in handling the stress-cracking 11.1.1 Obtain a minimum of 15 containers of the type and

agent since there is some possibility of its causing dermatitis. size chosen for test. Fill each to nominal capacity with the

8.4 Proper precautions should be taken in handling com- chosen test liquid, usually a proprietary liquid product or an

aqueous solution of polyoxyethylated nonylphenol.

pressed air equipment when following Procedure C.

NOTE 8—Partial filling, that is, one third of nominal capacity, has been

9. Test Specimen

found to increase the severity of the test with many test liquids. Thus, the

9.1 For Procedure A—A minimum of 15 blow-molded

partial fill may be used to accelerate the test. The use of an elevated

containers, representative of the lot to be tested, and fitted with controlled pressure as in Procedure C may also accelerate the test.

a screw closure affording a leakproof seal, shall be selected.

11.1.2 Heat-seal the containers with a suitable triple lami-

9.2 For Procedures B and C—A standard blow-molded

nate, polyethylene side to bottle. Apply a polyethylene or

container shall be used for this test. It is a 473-mL (16-oz)

suitably lined closure with sufficient torque to ensure a double

cylindrical bottle weighing approximately 20 g, as shown in

seal.

Fig. 4. A minimum of 15 containers shall be selected as in

NOTE 9—The pressure applied during sealing should be a minimum to

9.1.1. The minimum wall thickness of the container shall be

ensure no deformation of the container. The container should not be

not less than 0.305 mm (12 mil). The pinch-off area of the

handled in such a manner as to deform the walls during sealing. Any

container shall not extend into the chime radius.

deformation of the container during sealing may result in a volume change

which will affect the final test pressure. An application torque of 1.7 N·m

NOTE 7—Test Methods D 374, modifi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.