ASTM D3957-90(1996)e1

(Practice)Standard Practices for Establishing Stress Grades for Structural Members Used in Log Buildings

Standard Practices for Establishing Stress Grades for Structural Members Used in Log Buildings

SCOPE

1.1 These practices cover the visual stress-grading principles applicable to structural wood members of nonrectangu- lar shape, as typically used in log buildings. These practices are meant to supplement the ASTM standards listed below, which cover stress-grading of sawn lumber and round timbers. Pieces covered by these practices may also be used in building types other than log buildings.

1.2 The grading provisions used as illustrations herein are not intended to establish grades for purchase, but rather to show how stress-grading principles are applied to members used in log buildings. Detailed grading rules for commercial stress grades which serve as purchase specifications are established and published by agencies that formulate and maintain such rules and operate inspection facilities covering the various species.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 3957 – 90 (Reapproved 1996)

Standard Practices for

Establishing Stress Grades for Structural Members Used in

Log Buildings

This standard is issued under the fixed designation D 3957; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added in July 1996.

INTRODUCTION

These practices are based on the assumption that structural members in log buildings can be

stress-graded by methods that derive from accepted standards for conventional solid sawn lumber and

round timbers. It is assumed that the material to be graded bears enough similarity to either sawn

lumber or round timber, both in dimensional properties and in use, to warrant application of

stress-grading standards written for sawn-lumber or round-timber, or both. These practices, such as

Practice D 245 and Method D 2899, cannot be applied directly because the structural members used

in log buildings are generally neither perfectly rectangular nor perfectly round in section. These

practices use certain conventions regarding cross-sectional dimensions that make it possible to extend

established stress-grading methodologies to cover the members used in log buildings.

Where log member characteristics deviate from sawn lumber or round timber standards, there may

be uncertainty as to the exact effect of the deviation on strength properties. To compensate for this

uncertainty, some design stress values are herein derived with practices that are, by engineering

judgment, conservative. The philosophy guiding this approach is that while the absence of

experimental data may make a measure of conservatism unavoidable, the reliability of design stress

values must not be achieved through wood quality or size requirements that are an unnecessary burden

on the wood resource.

In general, the sawing, cutting, and shaving required to bring a piece to its final shape must be

completed before it can be visually graded using the principles in this standard. Small cuts may be

allowed after grading if it can be shown that either (1) the cuts do not affect the grade, or (2) the grade

takes the additional cuts into consideration.

Both sawn lumber standards and round timber standards are herein referenced, because these two

stress-grading methodologies can be assumed to apply to two different types of structural members

used in log buildings: wall-logs and round timber beams. Since wall-logs must be provided with a

means of joining together (for example, tongue-and-groove joints), they resemble sawn lumber and are

treated as such in the standard. Rafters, purlins, and beams, on the other hand, are sometimes left as

round logs, except for a small amount of sawing to provide a flat nailing surface. These practices thus

deal with stress-grading of wall-logs and round-timber beams separately.

1. Scope covered by these practices may also be used in building types

other than log buildings.

1.1 These practices cover the visual stress-grading prin-

1.2 The grading provisions used as illustrations herein are

ciples applicable to structural wood members of nonrectangu-

not intended to establish grades for purchase, but rather to

lar shape, as typically used in log buildings. These practices are

show how stress-grading principles are applied to members

meant to supplement the ASTM standards listed below, which

used in log buildings. Detailed grading rules for commercial

cover stress-grading of sawn lumber and round timbers. Pieces

stress grades which serve as purchase specifications are estab-

lished and published by agencies that formulate and maintain

These practices are under the jurisdiction of ASTM Committee D-7 on Wood

such rules and operate inspection facilities covering the various

and are the direct responsibility of Subcommittee D07.02 on Lumber and Engi-

species.

neered Wood Products.

1.3 This standard does not purport to address all of the

Current edition approved April 27, 1990. Published May 1990. Originally

published as D 3957 – 80. Last previous edition D 3957 – 80 (1984). safety concerns, if any, associated with its use. It is the

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3957

NF—Narrow Face

WF—Wide Face

FIG. 1 Typical Wall-Log Sections Showing Wide and Narrow Faces as Determined by Inscribed Rectangle

responsibility of the user of this standard to establish appro- 3.1.2 Wall-logs, as referred to in this standard, can also be

priate safety and health practices and determine the applica- used as beams, joists, etc., and do not have to be used as wall

bility of regulatory limitations prior to use. components.

3.1.3 Unless they qualify as round-timber beams under

2. Referenced Documents

Section 4 of this standard, wall-logs must be considered as

2.1 ASTM Standards: sawn lumber and therefore must respect the provisions of

D 9 Terminology Relating to Wood stress-grading described in Practice D 245. The manner in

D 25 Specification for Round Timber Piles which Practice D 245 is applied to wall-logs is described in

D 245 Practice for Establishing Structural Grades and Re- 3.2.

lated Allowable Properties for Visually Graded Lumber

3.2 Use of Rectangular Section Inscribed in Actual Sec-

D 2555 Test Methods for Establishing Clear Wood Strength

tions:

Values

3.2.1 A wall-log is to be graded as the largest piece of

D 2899 Method for Establishing Design Stresses for Round

rectangular lumber that can be embedded in the wall-log

Timber Piles

without protrusion from any wall-log surface except that each

D 3200 Specification and Methods for Establishing Recom-

corner may protrude up to ⁄2 in. in either or both directions

mended Design Stresses for Round Timber Construction

(Fig. 2). All provisions of Practice D 245 that would apply to

Poles

a piece with the same cross section as the inscribed rectangle

shall apply to the wall-log.

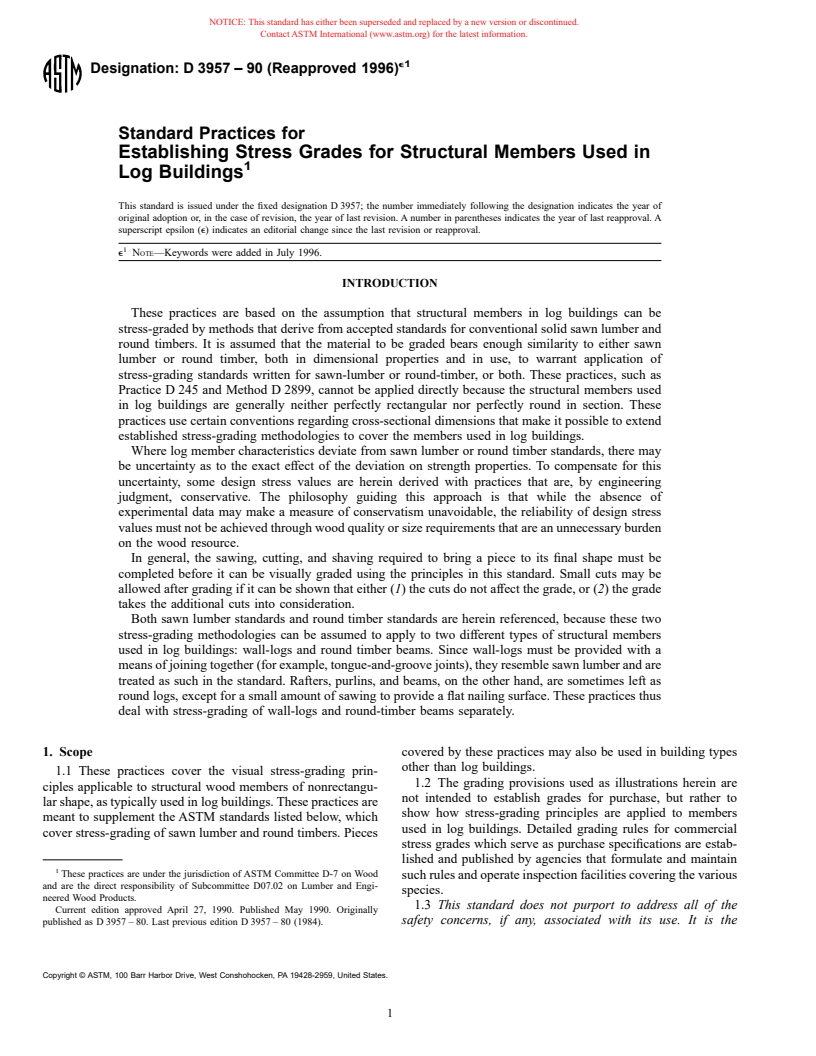

3. Stress-Grading of Wall-Logs

3.2.2 Maximum knot sizes shall be determined by the wide

3.1 General:

and narrow face dimensions of the inscribed rectangle, using

3.1.1 This section is intended to apply to wood members,

knot tables in Practice D 245. Boundaries between portions of

referred to as wall-logs, which are normally stacked horizon-

the wall-log surface considered “wide-face” and portions

tally or laid-up vertically to form a load-bearing, solid-wood

considered“ narrow-face” shall be found by extending the

wall, in any building. These structural members can vary

diagonals of the inscribed rectangle to the wall-log surface

greatly in dimension and section profile, and therefore previ-

(Fig. 3). Just as the wide and narrow faces of the inscribed

ously developed standards for solid sawn lumber are not

rectangle belong to a quadrant between diagonals, so shall the

readily applied to them (Fig. 1).

wide and narrow faces of the wall-log surface belong to the

same quadrants. In general, then, the surface boundaries

between wide and narrow faces may not coincide with actual

Annual Book of ASTM Standards, Vol 04.10. edges on the wall-log.

D 3957

(a) Wall-Log Without Saw Kerf: Maximum (b) Same Wall-Log, With Saw Kerf: Maxi- (c) Alternative Method: Maximum allow-

allowable narrow face knot, D, deter- mum allowable narrow face able narrow face knot, D*, determined

mined for A 3 B inscribed rectangle. knot 5D−d (top) and D (bottom). for A 3 B* inscribed rectangle.

FIG. 2 Determination of Inscribed Rectangle

this type, cuts into the inscribed rectangle may be treated as

follows.

3.2.4.1 If a face of an inscribed rectangle has a maximum

allowable knot size of D inches when the face is unpenetrated

by any cuts, then the maximum allowable knot size for knots

that do not encompass the sawcut is reduced to D − d inches

when the face is penetrated by a cut d inches wide. That is, a

1 1

saw cut ⁄2 in. wide could effectively increase a 2-in. knot to 2 ⁄2

in., as when the knot and the cut are tangent to each other.

Therefore, a cut ⁄2 in. wide will reduce the maximum allow-

able knot by ⁄2 in. (Fig. 3).

3.2.4.2 As an alternate to 3.2.4.1, reduce the maximum

allowable knot displacement D to D −2d where d is the

displacement of the sawcut(s) when the knot does not encom-

pass the sawcut. For example,a6by12in. with maximum

knot displacement of 50 %, and two grooves ⁄4 by 1 in. each

on one narrow face, a groove displacement of 2 %, the

allowable knot displacement for knots that do not encompass

the grooves would by reduced to 50 − 2(2) 5 46 %.

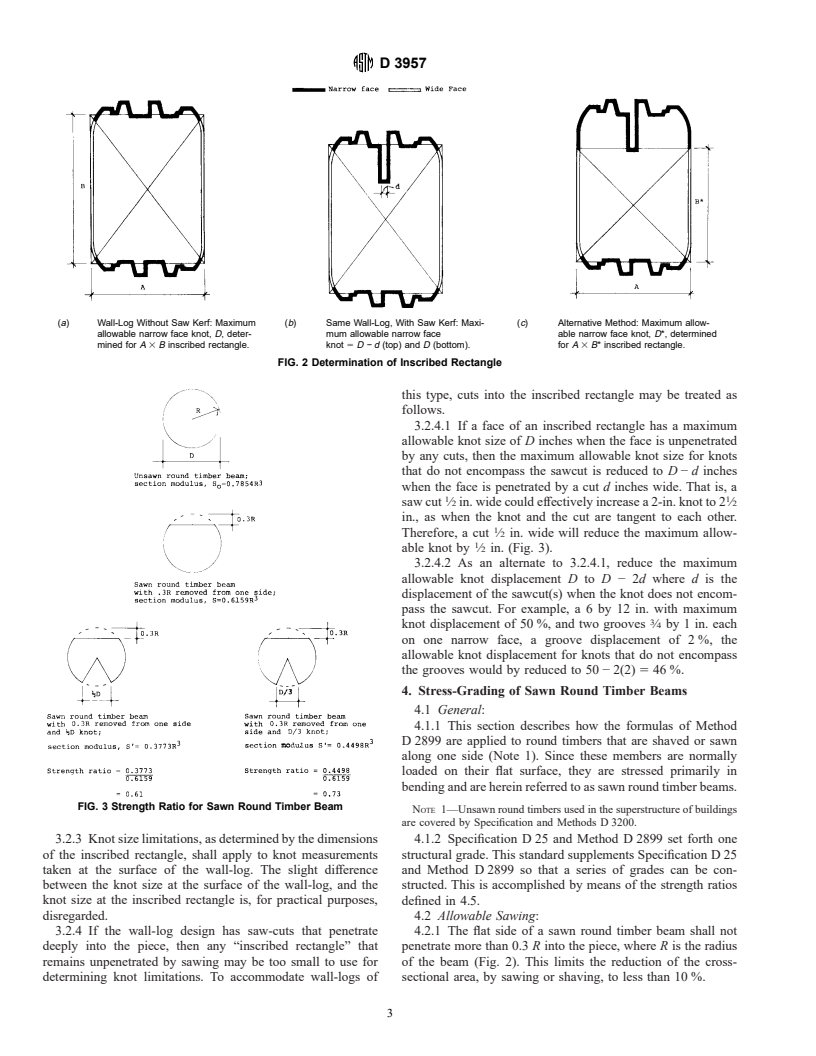

4. Stress-Grading of Sawn Round Timber Beams

4.1 General:

4.1.1 This section describes how the formulas of Method

D 2899 are applied to round timbers that are shaved or sawn

along one side (Note 1). Since these members are normally

loaded on their flat surface, they are stressed primarily in

bending and are herein referred to as sawn round timber beams.

FIG. 3 Strength Ratio for Sawn Round Timber Beam

NOTE 1—Unsawn round timbers used in the superstructure of buildings

are covered by Specification and Methods D 3200.

3.2.3 Knot size limitations, as determined by the dimensions 4.1.2 Specification D 25 and Method D 2899 set forth one

of the inscribed rectangle, shall apply to knot measurements structural grade. This standard supplements Specification D 25

taken at the surface of the wall-log. The slight difference and Method D 2899 so that a series of grades can be con-

between the knot size at the surface of the wall-log, and the structed. This is accomplished by means of the strength ratios

knot size at the inscribed rectangle is, for practical purposes, defined in 4.5.

disregarded. 4.2 Allowable Sawing:

3.2.4 If the wall-log design has saw-cuts that penetrate 4.2.1 The flat side of a sawn round timber beam shall not

deeply into the piece, then any “inscribed rectangle” that penetrate more than 0.3 R into the piece, where R is the radius

remains unpenetrated by sawing may be too small to use for of the beam (Fig. 2). This limits the reduction of the cross-

determining knot limitations. To accommodate wall-logs of sectional area, by sawing or shaving, to less than 10 %.

D 3957

4.2.2 A “form factor” equal to 1.18 is the factor by which

1in12 69

1in14 74

design-bending stresses of square-sawn pieces are multiplied in

1in15 76

order to derive design-bending stresses for beams with circular

NOTE 3—Round timbers that are sawn within the limitations stated in

cross-sections. Since sawn round timber beams do not have a

4.2 will have hybrid strength characteristics that are between those of

circular cross section, their form factor is set equal to 1.0 rather

sawn lumber and round timber. It can be assumed that the effect of a given

than 1.18. In order to apply the bending stress formula of

slope of grain on the bending strength of sawn round timber beams will

Method D 2899 to sawn round timber beams, the form factor

not be as great as its effect on the bending strength of sawn lumber. This

included in that formula must be set equal to 1.0.

assumption, which is based on engineering judgment, allows for the

4.3 Knot Measurement—Knots on the sawn face of a sawn application of the above strength ratios to sawn round timber beams.

round timber beam are measured by their smallest diameter.

4.5.2 In addition to factors for form and grade, the Method

Other knots are measured in accordance with Specification

D 2899 formula for design bending stress includes factors to

D 25.

account for load duration, tip weakness, and variability. These

4.4 Slope of Grain Measurement—Slope of grain in sawn

factors are also applied to sawn round timber beams.

round timber beams is measured by the angle between the

4.5.3 A formal factor of safety of 1.3 shall be included in the

direction of the fibers and the axis of the piece. As for lumber,

formula for design bending stresses used for sawn round timber

this angle is expressed as a slope.

beams.

4.5 Design Bending Stress Values:

4.6 Other Design Stresses:

4.5.1 Bending strength ratios are determined by slope of 4.6.1 Tension-Parallel-to-Grain—Design values for

grain or knot size, whichever is most restrictive. The substitu-

tension-parallel-to-grain in sawn round timber beams shall be

tion of alternative strength ratios into the design stress formula taken to be 55 % of design bending stresses, in accordance with

of Method D 2899 is not meant to result in higher allowable

the convention for lumber recommended by Practice D 245.

bending stresses than can be obtained when the bending 4.6.2 Compression-Parallel-to-Grain—For sawn round

strength ratio equals 0.76, that is, bending strength ratios

timber beams, the strength ratio for compression-parallel-to-

higher than 0.76 are not recommended for sawn round timber grain shall be taken to be equal to the bending strength ratio

beams.

described in 4.5.1. This strength ratio is to be used in the

Method D 2899 formula for compression-parallel-to-grain, as

NOTE 2—The formula in Method D 2899 for finding design bending

explained in Appendix X1.

stress values assumes that clear wood bending strength values should be

4.6.3 Shear—The Method D 2899 shear formula can be

reduced by a factor of 0.9 to account for “form and grade.” Since the form

factor for round timbers is 1.18, the strength ratio for grade restrictions in used for sawn round timber beams.

Specification D 25 is 0.76. To provide for other grade descriptions in sawn

4.6.4 Compression-Perpendicular-to-Grain—The Method

round timber beams, a strength ratio system similar to Practice D 245

D 2899 compression-perpendicular-to-grain formula can be

application to sawn lumber is proposed.

used for sawn round timber beams.

4.6.5 Modulus of Elasticity—Divide the average small clear

4.5.1.1 Knot Strength Ratios—Strength ratios for sawn

modulus of elasticity from Test Methods D 2555 by 0.94 to

round timber beams shall be determined assuming that knots

obtain the design value for modulus elasticity. Quality factors,

effectively reduce the cross-sectional area by a pie-shaped

for strength ratios less than 55 %, are applied to the modulus of

sector that radiates from the center of the beam to the

elasticity values of sawn round timber beams, in accordance

outermost boundaries of the knot (Fig. 3). It is further assumed

with Table 7 of Practice D 245.

that the sector of area lost to a knot lies opposite the sawn face,

4.7 Those limitations on decay, insect attack, straightness,

since this will most reduce the beam’s section modulus.

holes, scars, checks, shakes, and splits described in Specifica-

(a) Given (1) the section modulus, S, of a beam sawn to the

tion D 25 shall apply to all grades of sawn round timber beams.

limit of 4.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.