ASTM A859/A859M-04(2019)e1

(Specification)Standard Specification for Age-Hardening Alloy Steel Forgings for Pressure Vessel Components

Standard Specification for Age-Hardening Alloy Steel Forgings for Pressure Vessel Components

ABSTRACT

This specification covers the standard requirements for low-carbon age-hardened nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components. Materials shall be manufactured to a killed fine austenitic grain size, by vacuum degas melting process. Heat treatment shall be conducted, according to class, by: normalizing and precipitation hardening (Grade A, Class 1); liquid quenching and precipitation hardening (Grade A, Class 2); or double liquid-quenching, tempering, double austenitizing, and precipitation hardening (Grade B). Heat and product analyses shall be used to evaluate the conformance of forgings to required chemical compositions. Tensile, notch toughness, and Charpy impact requirements shall be examined, for which one of four sampling methods may be employed. One tension test and one impact test (for three samples) shall be made for each forging. Dimensions and finishes of the forgings shall conform to that specified by the purchaser. Repair welding shall also be performed only if permitted by the purchaser.

SCOPE

1.1 This specification covers requirements for low-carbon age-hardening nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components.

1.2 Forgings under this specification are available as Grades A or B. Grade A may be ordered in one or two classes as follows:

1.2.1 Grade A Class 1—Normalized-and-precipitation-heat-treated, providing a minimum yield strength of 55 ksi [380 MPa] and a minimum tensile strength of 65 ksi [450 MPa].

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat-treated, providing a minimum yield strength of 65 ksi [450 MPa] and a minimum tensile strength of 75 ksi [515 MPa].

1.2.3 Grade A was the original steel composition in this specification.

1.3 Although the material is readily weldable, welding procedures are of fundamental importance and must be such as not to affect adversely the properties of the material, especially in the heat-affected zone. It is presupposed that welding procedures will be suitable for the material being welded.

1.4 Supplementary requirements, including those applicable in Specification A788/A788M, are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other and values from the two systems shall not be combined.

1.6 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: A859/A859M −04 (Reapproved 2019)

Standard Specification for

Age-Hardening Alloy Steel Forgings for Pressure Vessel

Components

This standard is issued under the fixed designationA859/A859M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—MPa value was added in 1.2.2 editorially in April 2019.

1. Scope 1.6 This specification is expressed in both inch-pound and

SI units. However, unless the order specifies the applicable

1.1 This specification covers requirements for low-carbon

“M” specification designation [SI units], the material shall be

age-hardening nickel-copper-chromium-molybdenum-

furnished to inch-pound units.

columbium alloy steel forgings for pressure vessel compo-

1.7 This international standard was developed in accor-

nents.

dance with internationally recognized principles on standard-

1.2 ForgingsunderthisspecificationareavailableasGrades

ization established in the Decision on Principles for the

A or B. Grade A may be ordered in one or two classes as

Development of International Standards, Guides and Recom-

follows:

mendations issued by the World Trade Organization Technical

1.2.1 GradeAClass 1—Normalized-and-precipitation-heat-

Barriers to Trade (TBT) Committee.

treated, providing a minimum yield strength of 55 ksi

[380 MPa] and a minimum tensile strength of 65 ksi

2. Referenced Documents

[450MPa].

2.1 ASTM Standards:

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat-

A275/A275MPracticeforMagneticParticleExaminationof

treated, providing a minimum yield strength of 65 ksi

Steel Forgings

[450 MPa] and a minimum tensile strength of 75 ksi

A370Test Methods and Definitions for Mechanical Testing

[515MPa].

of Steel Products

1.2.3 Grade A was the original steel composition in this

A388/A388MPractice for Ultrasonic Examination of Steel

specification.

Forgings

1.3 Although the material is readily weldable, welding

A788/A788MSpecification for Steel Forgings, General Re-

proceduresareoffundamentalimportanceandmustbesuchas

quirements

nottoaffectadverselythepropertiesofthematerial,especially

E208Test Method for Conducting Drop-Weight Test to

in the heat-affected zone. It is presupposed that welding

Determine Nil-Ductility Transition Temperature of Fer-

procedures will be suitable for the material being welded.

ritic Steels

1.4 Supplementaryrequirements,includingthoseapplicable E604Test Method for Dynamic Tear Testing of Metallic

in Specification A788/A788M, are provided for use when

Materials

additional testing or inspection is desired. These shall apply

2.2 ASME Standard:

only when specified individually by the purchaser in the order.

ASMEBoiler and Pressure Vessel Code—Section IX

1.5 The values stated in either SI units or inch-pound units

3. Ordering Information and General Requirements

are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to 3.1 In addition to the ordering information required by

ensure conformance with the standard, each system shall be Specification A788/A788M, the purchaser shall include with

used independently of the other and values from the two the inquiry and order a detailed drawing, sketch, or written

systems shall not be combined.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction ofASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.06 on Steel Forgings and Billets. the ASTM website.

Current edition approved March 1, 2019. Published April 2019. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 1986. Last previous edition approved in 2014 as A859/A859M–04 International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

(2014). DOI:10.1520/A0859_A0859M–04R19E01. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A859/A859M − 04 (2019)

description of the forging and the method of selecting test 5. Chemical Composition

location (see 6.3). When appropriate, the areas of significant

5.1 Heat Analysis—The heat analysis obtained from sam-

loading in the forging shall be designated.

pling in accordance with Specification A788/A788M shall

3.2 Material supplied to this specification shall conform to comply with Table 1.

the requirements of Specification A788/A788M, which out-

5.2 Product Analysis—The purchaser may use the product

lines additional ordering information, manufacturing

analysis provision of Specification A788/A788M to obtain a

requirements, testing and retesting methods and procedures,

product analysis from a forging representing each heat or

marking, certification, product analysis variations, and addi-

multiple heat.

tional supplementary requirements.

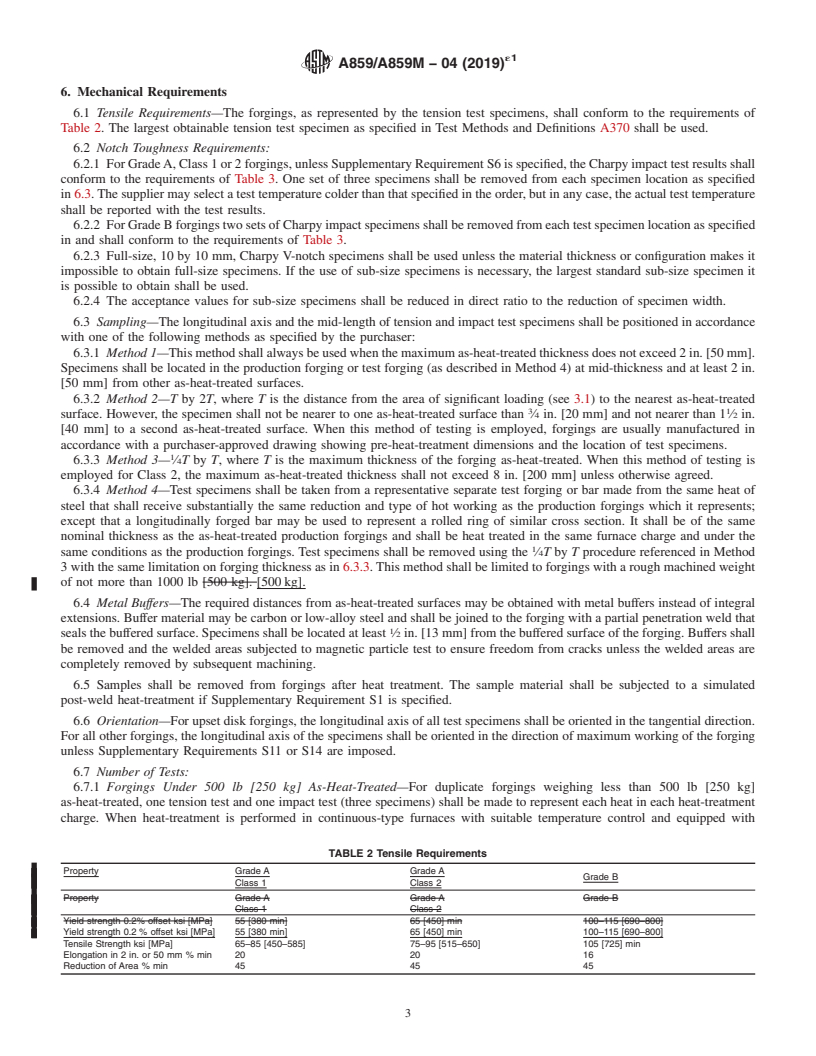

6. Mechanical Requirements

3.3 If the requirements of this specification are in conflict

with the requirements of Specification A788/A788M, the

6.1 Tensile Requirements—The forgings, as represented by

requirements of this specification shall prevail.

the tension test specimens, shall conform to the requirements

of Table 2. The largest obtainable tension test specimen as

4. Manufacture

specified in Test Methods and Definitions A370 shall be used.

4.1 Melting Practice—The steel shall be made to a killed,

6.2 Notch Toughness Requirements:

fine austenitic grain size, practice.

6.2.1 For Grade A, Class 1 or 2 forgings, unless Supple-

4.1.1 Vacuum degassing in accordance with Specification

mentary Requirement S6 is specified, the Charpy impact test

A788/A788M is highly recommended.

resultsshallconformtotherequirementsofTable3.Onesetof

threespecimensshallberemovedfromeachspecimenlocation

4.2 Heat Treatment:

as specified in 6.3. The supplier may select a test temperature

4.2.1 Normalizing may, at the manufacturer’s option, pre-

colder than that specified in the order, but in any case, the

cede the prescribed heat treatment cycle.

actual test temperature shall be reported with the test results.

4.2.2 Grade A Class 1 forgings shall be normalized at a

6.2.2 For Grade B forgings two sets of Charpy impact

temperatureintherangefrom1600to1725°F[870to940°C]

specimens shall be removed from each test specimen location

and then precipitation hardened in the range from 1000 to

as specified in and shall conform to the requirements of Table

1225°F [540 to 665°C] for a time to be determined by the

3.

material manufacturer.

6.2.3 Full-size, 10 by 10 mm, Charpy V-notch specimens

4.2.3 Grade A Class 2 forgings shall be liquid quenched

shall be used unless the material thickness or configuration

from a temperature in the range from 1600 to 1725°F [870 to

makes it impossible to obtain full-size specimens. If the use of

940°C]andthenprecipitationhardenedintherangefrom1000

sub-size specimens is necessary, the largest standard sub-size

to 1225°F [540 to 665°C] for a time to be determined by the

specimen it is possible to obtain shall be used.

material manufacturer.

6.2.4 The acceptance values for sub-size specimens shall be

4.2.4 Grade B forgings shall be double quenched and

reduced in direct ratio to the reduction of specimen width.

tempered (liquid quenched twice) by austenitizing twice at a

temperature in the range of 1600 to 1725°F [870 to 940°C], 6.3 Sampling—The longitudinal axis and the mid-length of

andthenprecipitationhardenedatatemperatureintherangeof tension and impact test specimens shall be positioned in

1000to1300°F[540to700°C]foratimetobedeterminedby accordance with one of the following methods as specified by

the manufacturer. the purchaser:

TABLE 1 Chemical Requirements

Composition, %

Element Grade A Grade B

Carbon 0.07 max 0.02–0.04

Manganese 0.40–0.70 0.75–1.05

Phosphorus, max 0.025 0.015

Sulfur, max 0.025 0.002

Silicon, max 0.40 0.40

Chromium 0.60–0.90 0.45–0.75

Nickel 0.70–1.00 3.35–3.85

Molybdenum 0.15–0.25 0.55–0.65

Copper 1.00–1.30 1.15–1.75

Columbium 0.02 min 0.02–0.06

Vanadium max . 0.008

Aluminum max . 0.03

Titanium max . 0.003

Tin max . 0.03

Arsenic max . 0.025

Antimony max . 0.025

Nitrogen . report

´1

A859/A859M − 04 (2019)

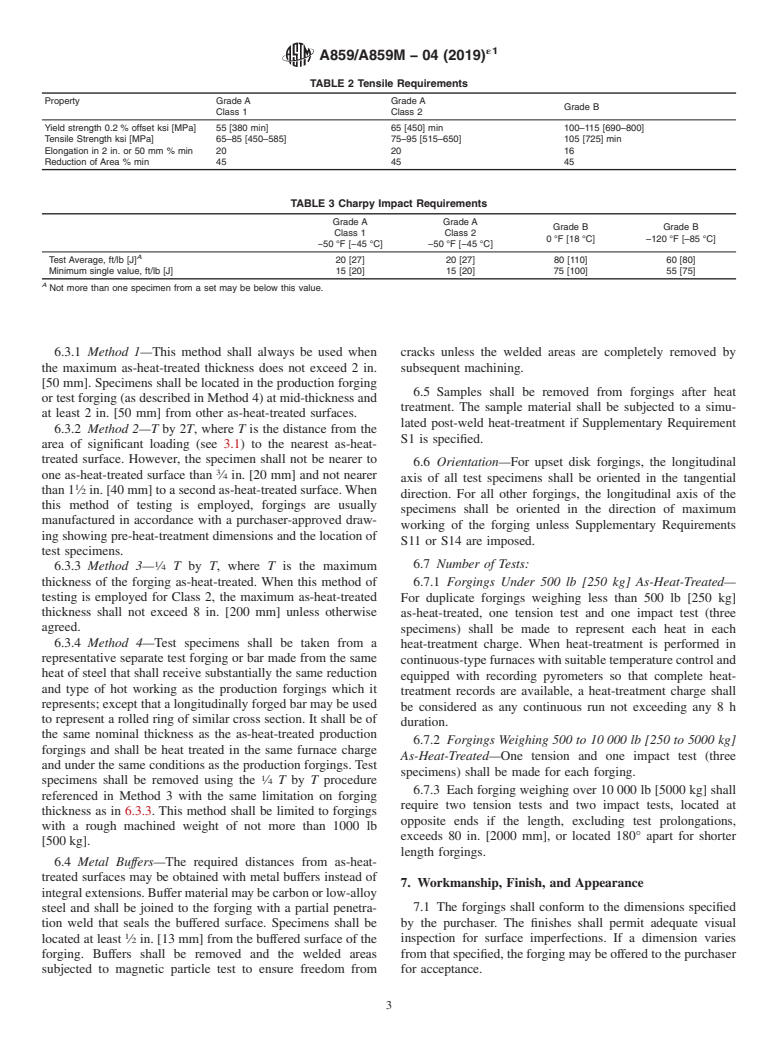

TABLE 2 Tensile Requirements

Property Grade A Grade A

Grade B

Class 1 Class 2

Yield strength 0.2 % offset ksi [MPa] 55 [380 min] 65 [450] min 100–115 [690–800]

Tensile Strength ksi [MPa] 65–85 [450–585] 75–95 [515–650] 105 [725] min

Elongation in 2 in. or 50 mm % min 20 20 16

Reduction of Area % min 45 45 45

TABLE 3 Charpy Impact Requirements

Grade A Grade A

Grade B Grade B

Class 1 Class 2

0 °F [18 °C] –120 °F [–85 °C]

−50 °F [−45 °C] −50 °F [−45 °C]

A

Test Average, ft/lb [J] 20 [27] 20 [27] 80 [110] 60 [80]

Minimum single value, ft/lb [J] 15 [20] 15 [20] 75 [100] 55 [75]

A

Not more than one specimen from a set may be below this value.

6.3.1 Method 1—This method shall always be used when cracks unless the welded areas are completely removed by

the maximum as-heat-treated thickness does not exceed 2 in. subsequent machining.

[50 mm]. Specimens shall be located in the production forging

6.5 Samples shall be removed from forgings after heat

ortestforging(asdescribedinMethod4)atmid-thicknessand

treatment. The sample material shall be subjected to a simu-

at least 2 in. [50 mm] from other as-heat-treated surfaces.

lated post-weld heat-treatment if Supplementary Requirement

6.3.2 Method 2—T by 2T, where T is the distance from the

S1 is specified.

area of significant loading (see 3.1) to the nearest as-heat-

treated surface. However, the specimen shall not be nearer to

6.6 Orientation—For upset disk forgings, the longitudinal

one as-heat-treated surface than ⁄4 in. [20 mm] and not nearer

axis of all test specimens shall be oriented in the tangential

than1 ⁄2in.[40mm]toasecondas-heat-treatedsurface.When

direction. For all other forgings, the long

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A859/A859M − 04 (Reapproved 2019)

Standard Specification for

Age-Hardening Alloy Steel Forgings for Pressure Vessel

Components

This standard is issued under the fixed designation A859/A859M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—MPa value was added in 1.2.2 editorially in April 2019.

1. Scope 1.6 This specification is expressed in both inch-pound and

SI units. However, unless the order specifies the applicable

1.1 This specification covers requirements for low-carbon

“M” specification designation [SI units], the material shall be

age-hardening nickel-copper-chromium-molybdenum-

furnished to inch-pound units.

columbium alloy steel forgings for pressure vessel compo-

1.7 This international standard was developed in accor-

nents.

dance with internationally recognized principles on standard-

1.2 Forgings under this specification are available as Grades

ization established in the Decision on Principles for the

A or B. Grade A may be ordered in one or two classes as

Development of International Standards, Guides and Recom-

follows:

mendations issued by the World Trade Organization Technical

1.2.1 Grade A Class 1—Normalized-and-precipitation-heat-

Barriers to Trade (TBT) Committee.

treated, providing a minimum yield strength of 55 ksi

[380 MPa] and a minimum tensile strength of 65 ksi

2. Referenced Documents

[450 MPa].

2.1 ASTM Standards:

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat-

A275/A275M Practice for Magnetic Particle Examination of

treated, providing a minimum yield strength of 65 ksi

Steel Forgings

[450 MPa] and a minimum tensile strength of 75 ksi

A370 Test Methods and Definitions for Mechanical Testing

[515 MPa].

of Steel Products

1.2.3 Grade A was the original steel composition in this

A388/A388M Practice for Ultrasonic Examination of Steel

specification.

Forgings

1.3 Although the material is readily weldable, welding

A788/A788M Specification for Steel Forgings, General Re-

procedures are of fundamental importance and must be such as

quirements

not to affect adversely the properties of the material, especially

E208 Test Method for Conducting Drop-Weight Test to

in the heat-affected zone. It is presupposed that welding

Determine Nil-Ductility Transition Temperature of Fer-

procedures will be suitable for the material being welded.

ritic Steels

1.4 Supplementary requirements, including those applicable

E604 Test Method for Dynamic Tear Testing of Metallic

in Specification A788/A788M, are provided for use when Materials

additional testing or inspection is desired. These shall apply

2.2 ASME Standard:

only when specified individually by the purchaser in the order.

ASME Boiler and Pressure Vessel Code—Section IX

1.5 The values stated in either SI units or inch-pound units

3. Ordering Information and General Requirements

are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to 3.1 In addition to the ordering information required by

ensure conformance with the standard, each system shall be Specification A788/A788M, the purchaser shall include with

used independently of the other and values from the two the inquiry and order a detailed drawing, sketch, or written

systems shall not be combined.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.06 on Steel Forgings and Billets. the ASTM website.

Current edition approved March 1, 2019. Published April 2019. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 1986. Last previous edition approved in 2014 as A859/A859M–04 International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

(2014). DOI:10.1520/A0859_A0859M–04R19E01. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A859/A859M − 04 (2019)

description of the forging and the method of selecting test 5. Chemical Composition

location (see 6.3). When appropriate, the areas of significant

5.1 Heat Analysis—The heat analysis obtained from sam-

loading in the forging shall be designated.

pling in accordance with Specification A788/A788M shall

comply with Table 1.

3.2 Material supplied to this specification shall conform to

the requirements of Specification A788/A788M, which out-

5.2 Product Analysis—The purchaser may use the product

lines additional ordering information, manufacturing

analysis provision of Specification A788/A788M to obtain a

requirements, testing and retesting methods and procedures,

product analysis from a forging representing each heat or

marking, certification, product analysis variations, and addi-

multiple heat.

tional supplementary requirements.

3.3 If the requirements of this specification are in conflict 6. Mechanical Requirements

with the requirements of Specification A788/A788M, the

6.1 Tensile Requirements—The forgings, as represented by

requirements of this specification shall prevail.

the tension test specimens, shall conform to the requirements

of Table 2. The largest obtainable tension test specimen as

4. Manufacture

specified in Test Methods and Definitions A370 shall be used.

4.1 Melting Practice—The steel shall be made to a killed,

6.2 Notch Toughness Requirements:

fine austenitic grain size, practice.

6.2.1 For Grade A, Class 1 or 2 forgings, unless Supple-

4.1.1 Vacuum degassing in accordance with Specification

mentary Requirement S6 is specified, the Charpy impact test

A788/A788M is highly recommended.

results shall conform to the requirements of Table 3. One set of

three specimens shall be removed from each specimen location

4.2 Heat Treatment:

as specified in 6.3. The supplier may select a test temperature

4.2.1 Normalizing may, at the manufacturer’s option, pre-

colder than that specified in the order, but in any case, the

cede the prescribed heat treatment cycle.

actual test temperature shall be reported with the test results.

4.2.2 Grade A Class 1 forgings shall be normalized at a

6.2.2 For Grade B forgings two sets of Charpy impact

temperature in the range from 1600 to 1725 °F [870 to 940 °C]

specimens shall be removed from each test specimen location

and then precipitation hardened in the range from 1000 to

as specified in and shall conform to the requirements of Table

1225 °F [540 to 665 °C] for a time to be determined by the

3.

material manufacturer.

6.2.3 Full-size, 10 by 10 mm, Charpy V-notch specimens

4.2.3 Grade A Class 2 forgings shall be liquid quenched

shall be used unless the material thickness or configuration

from a temperature in the range from 1600 to 1725 °F [870 to

makes it impossible to obtain full-size specimens. If the use of

940 °C] and then precipitation hardened in the range from 1000

sub-size specimens is necessary, the largest standard sub-size

to 1225 °F [540 to 665 °C] for a time to be determined by the

specimen it is possible to obtain shall be used.

material manufacturer.

6.2.4 The acceptance values for sub-size specimens shall be

4.2.4 Grade B forgings shall be double quenched and

reduced in direct ratio to the reduction of specimen width.

tempered (liquid quenched twice) by austenitizing twice at a

temperature in the range of 1600 to 1725 °F [870 to 940 °C], 6.3 Sampling—The longitudinal axis and the mid-length of

and then precipitation hardened at a temperature in the range of tension and impact test specimens shall be positioned in

1000 to 1300 °F [540 to 700 °C] for a time to be determined by accordance with one of the following methods as specified by

the manufacturer. the purchaser:

TABLE 1 Chemical Requirements

Composition, %

Element Grade A Grade B

Carbon 0.07 max 0.02–0.04

Manganese 0.40–0.70 0.75–1.05

Phosphorus, max 0.025 0.015

Sulfur, max 0.025 0.002

Silicon, max 0.40 0.40

Chromium 0.60–0.90 0.45–0.75

Nickel 0.70–1.00 3.35–3.85

Molybdenum 0.15–0.25 0.55–0.65

Copper 1.00–1.30 1.15–1.75

Columbium 0.02 min 0.02–0.06

Vanadium max . 0.008

Aluminum max . 0.03

Titanium max . 0.003

Tin max . 0.03

Arsenic max . 0.025

Antimony max . 0.025

Nitrogen . report

´1

A859/A859M − 04 (2019)

TABLE 2 Tensile Requirements

Property Grade A Grade A

Grade B

Class 1 Class 2

Yield strength 0.2 % offset ksi [MPa] 55 [380 min] 65 [450] min 100–115 [690–800]

Tensile Strength ksi [MPa] 65–85 [450–585] 75–95 [515–650] 105 [725] min

Elongation in 2 in. or 50 mm % min 20 20 16

Reduction of Area % min 45 45 45

TABLE 3 Charpy Impact Requirements

Grade A Grade A

Grade B Grade B

Class 1 Class 2

0 °F [18 °C] –120 °F [–85 °C]

−50 °F [−45 °C] −50 °F [−45 °C]

A

Test Average, ft/lb [J] 20 [27] 20 [27] 80 [110] 60 [80]

Minimum single value, ft/lb [J] 15 [20] 15 [20] 75 [100] 55 [75]

A

Not more than one specimen from a set may be below this value.

6.3.1 Method 1—This method shall always be used when cracks unless the welded areas are completely removed by

the maximum as-heat-treated thickness does not exceed 2 in. subsequent machining.

[50 mm]. Specimens shall be located in the production forging

6.5 Samples shall be removed from forgings after heat

or test forging (as described in Method 4) at mid-thickness and

treatment. The sample material shall be subjected to a simu-

at least 2 in. [50 mm] from other as-heat-treated surfaces.

lated post-weld heat-treatment if Supplementary Requirement

6.3.2 Method 2—T by 2T, where T is the distance from the

S1 is specified.

area of significant loading (see 3.1) to the nearest as-heat-

treated surface. However, the specimen shall not be nearer to

6.6 Orientation—For upset disk forgings, the longitudinal

one as-heat-treated surface than ⁄4 in. [20 mm] and not nearer

axis of all test specimens shall be oriented in the tangential

than 1 ⁄2 in. [40 mm] to a second as-heat-treated surface. When

direction. For all other forgings, the longitudinal axis of the

this method of testing is employed, forgings are usual

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A859/A859M − 04 (Reapproved 2014) A859/A859M − 04 (Reapproved 2019)

Standard Specification for

Age-Hardening Alloy Steel Forgings for Pressure Vessel

Components

This standard is issued under the fixed designation A859/A859M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—MPa value was added in 1.2.2 editorially in April 2019.

1. Scope

1.1 This specification covers requirements for low-carbon age-hardening nickel-copper-chromium-molybdenum-columbium

alloy steel forgings for pressure vessel components.

1.2 Forgings under this specification are available as Grades A or B. Grade A may be ordered in one or two classes as follows:

1.2.1 Grade A Class 1—Normalized-and-precipitation-heat-treated, providing a minimum yield strength of 55 ksi [380 MPa]

[380 MPa] and a minimum tensile strength of 65 ksi [450 MPa].[450 MPa].

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat-treated, providing a minimum yield strength of 65 ksi [450 MPa]

[450 MPa] and a minimum tensile strength of 75 ksi [MPa].[515 MPa].

1.2.3 Grade A was the original steel composition in this specification.

1.3 Although the material is readily weldable, welding procedures are of fundamental importance and must be such as not to

affect adversely the properties of the material, especially in the heat-affected zone. It is presupposed that welding procedures will

be suitable for the material being welded.

1.4 Supplementary requirements, including those applicable in Specification A788/A788M, are provided for use when

additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other. Combiningother and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.6 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M”

specification designation [SI units], the material shall be furnished to inch-pound units.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

A788/A788M Specification for Steel Forgings, General Requirements

E208 Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

E604 Test Method for Dynamic Tear Testing of Metallic Materials

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved Oct. 1, 2014March 1, 2019. Published October 2014April 2019. Originally approved in 1986. Last previous edition approved in 20092014 as

A859/A859M – 04A859/A859M(2009). DOI:10.1520/A0859_A0859M-04R14.–04 (2014). DOI:10.1520/A0859_A0859M–04R19E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A859/A859M − 04 (2019)

2.2 ASME Standard:

ASME Boiler and Pressure Vessel Code—Section IX

3. Ordering Information and General Requirements

3.1 In addition to the ordering information required by Specification A788/A788M, the purchaser shall include with the inquiry

and order a detailed drawing, sketch, or written description of the forging and the method of selecting test location (see 6.3). When

appropriate, the areas of significant loading in the forging shall be designated.

3.2 Material supplied to this specification shall conform to the requirements of Specification A788/A788M, which outlines

additional ordering information, manufacturing requirements, testing and retesting methods and procedures, marking, certification,

product analysis variations, and additional supplementary requirements.

3.3 If the requirements of this specification are in conflict with the requirements of Specification A788/A788M, the

requirements of this specification shall prevail.

4. Manufacture

4.1 Melting Practice—The steel shall be made to a killed, fine austenitic grain size, practice.

4.1.1 Vacuum degassing in accordance with Specification A788/A788M is highly recommended.

4.2 Heat Treatment:

4.2.1 Normalizing may, at the manufacturer’smanufacturer’s option, precede the prescribed heat treatment cycle.

4.2.2 Grade A Class 1 forgings shall be normalized at a temperature in the range from 1600 to 1725°F1725 °F [870 to

940°C]940 °C] and then precipitation hardened in the range from 1000 to 1225°F1225 °F [540 to 665°C]665 °C] for a time to be

determined by the material manufacturer.

4.2.3 Grade A Class 2 forgings shall be liquid quenched from a temperature in the range from 1600 to 1725°F1725 °F [870 to

940°C]940 °C] and then precipitation hardened in the range from 1000 to 1225°F1225 °F [540 to 665°C]665 °C] for a time to be

determined by the material manufacturer.

4.2.4 Grade B forgings shall be double quenched and tempered (liquid quenched twice) by austenitizing twice at a temperature

in the range of 1600 to 1725°F1725 °F [870 to 940°C],940 °C], and then precipitation hardened at a temperature in the range of

1000 to 1300°F1300 °F [540 to 700°C]700 °C] for a time to be determined by the manufacturer.

5. Chemical Composition

5.1 Heat Analysis—The heat analysis obtained from sampling in accordance with Specification A788/A788M shall comply with

Table 1.

5.2 Product Analysis—The purchaser may use the product analysis provision of Specification A788/A788M to obtain a product

analysis from a forging representing each heat or multiple heat.

TABLE 1 Chemical Requirements

Composition, %

Element Grade A Grade B

Carbon 0.07 max 0.02–0.04

Manganese 0.40–0.70 0.75–1.05

Phosphorus, max 0.025 0.015

Sulfur, max 0.025 0.002

Silicon, max 0.40 0.40

Chromium 0.60–0.90 0.45–0.75

Nickel 0.70–1.00 3.35–3.85

Molybdenum 0.15–0.25 0.55–0.65

Copper 1.00–1.30 1.15–1.75

Columbium 0.02 min 0.02–0.06

Columbium 0.02 min 0.02–0.06

Vanadium max . 0.008

Aluminum max . 0.03

Titanium max . 0.003

Tin max . 0.03

Arsenic max . 0.025

Antimony max . 0.025

Nitrogen . report

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

´1

A859/A859M − 04 (2019)

6. Mechanical Requirements

6.1 Tensile Requirements—The forgings, as represented by the tension test specimens, shall conform to the requirements of

Table 2. The largest obtainable tension test specimen as specified in Test Methods and Definitions A370 shall be used.

6.2 Notch Toughness Requirements:

6.2.1 For Grade A, Class 1 or 2 forgings, unless Supplementary Requirement S6 is specified, the Charpy impact test results shall

conform to the requirements of Table 3. One set of three specimens shall be removed from each specimen location as specified

in 6.3. The supplier may select a test temperature colder than that specified in the order, but in any case, the actual test temperature

shall be reported with the test results.

6.2.2 For Grade B forgings two sets of Charpy impact specimens shall be removed from each test specimen location as specified

in and shall conform to the requirements of Table 3.

6.2.3 Full-size, 10 by 10 mm, Charpy V-notch specimens shall be used unless the material thickness or configuration makes it

impossible to obtain full-size specimens. If the use of sub-size specimens is necessary, the largest standard sub-size specimen it

is possible to obtain shall be used.

6.2.4 The acceptance values for sub-size specimens shall be reduced in direct ratio to the reduction of specimen width.

6.3 Sampling—The longitudinal axis and the mid-length of tension and impact test specimens shall be positioned in accordance

with one of the following methods as specified by the purchaser:

6.3.1 Method 1—This method shall always be used when the maximum as-heat-treated thickness does not exceed 2 in. [50 mm].

Specimens shall be located in the production forging or test forging (as described in Method 4) at mid-thickness and at least 2 in.

[50 mm] from other as-heat-treated surfaces.

6.3.2 Method 2—T by 2T, where T is the distance from the area of significant loading (see 3.1) to the nearest as-heat-treated

3 1

surface. However, the specimen shall not be nearer to one as-heat-treated surface than ⁄4 in. [20 mm] and not nearer than 1 ⁄2 in.

[40 mm] to a second as-heat-treated surface. When this method of testing is employed, forgings are usually manufactured in

accordance with a purchaser-approved drawing showing pre-heat-treatment dimensions and the location of test specimens.

6.3.3 Method 3— ⁄4T by T, where T is the maximum thickness of the forging as-heat-treated. When this method of testing is

employed for Class 2, the maximum as-heat-treated thickness shall not exceed 8 in. [200 mm] unless otherwise agreed.

6.3.4 Method 4—Test specimens shall be taken from a representative separate test forging or bar made from the same heat of

steel that shall receive substantially the same reduction and type of hot working as the production forgings which it represents;

except that a longitudinally forged bar may be used to represent a rolled ring of similar cross section. It shall be of the same

nominal thickness as the as-heat-treated production forgings and shall be heat treated in the same furnace charge and under the

same conditions as the production forgings. Test specimens shall be removed using the ⁄4T by T procedure referenced in Method

3 with the same limitation on forging thickness as in 6.3.3. This method shall be limited to forgings with a rough machined weight

of not more than 1000 lb [500 kg]. [500 kg].

6.4 Metal Buffers—The required distances from as-heat-treated surfaces may be obtained with metal buffers instead of integral

extensions. Buffer material may be carbon or low-alloy steel and shall be joined to the forging with a partial penetration weld that

seals the buffered surface. Specimens shall be located at least ⁄2 in. [13 mm] from the buffered surface of the forging. Buffers shall

be removed and the welded areas subjected to magnetic particle test to ensure freedom from cracks unless the welded areas are

completely removed by subsequent machining.

6.5 Samples shall be removed from forgings after heat treatment. The sample material shall be subjected to a simulated

post-weld heat-treatment if Supplementary Requirement S1 is specified.

6.6 Orientation—For upset disk forgings, the longitudinal axis of all test specimens shall be oriented in the tangential direction.

For all other forgings, the longitudinal axis of the specimens shall be oriented in the direction of maximum working of the forging

unless Supplementary Requirements S11 or S14 are imposed.

6.7 Number of Tests:

6.7.1 Forgings Under 500 lb [250 kg] As-Heat-Treated—For duplicate forgings weighing less than 500 lb [250 kg]

as-heat-treated, one tension test and one impact test (three specimens) shall be made to represent each heat in each heat-treatment

charge. When heat-treatment is performed in continuous-type furnaces with suitable temperature control and equipped with

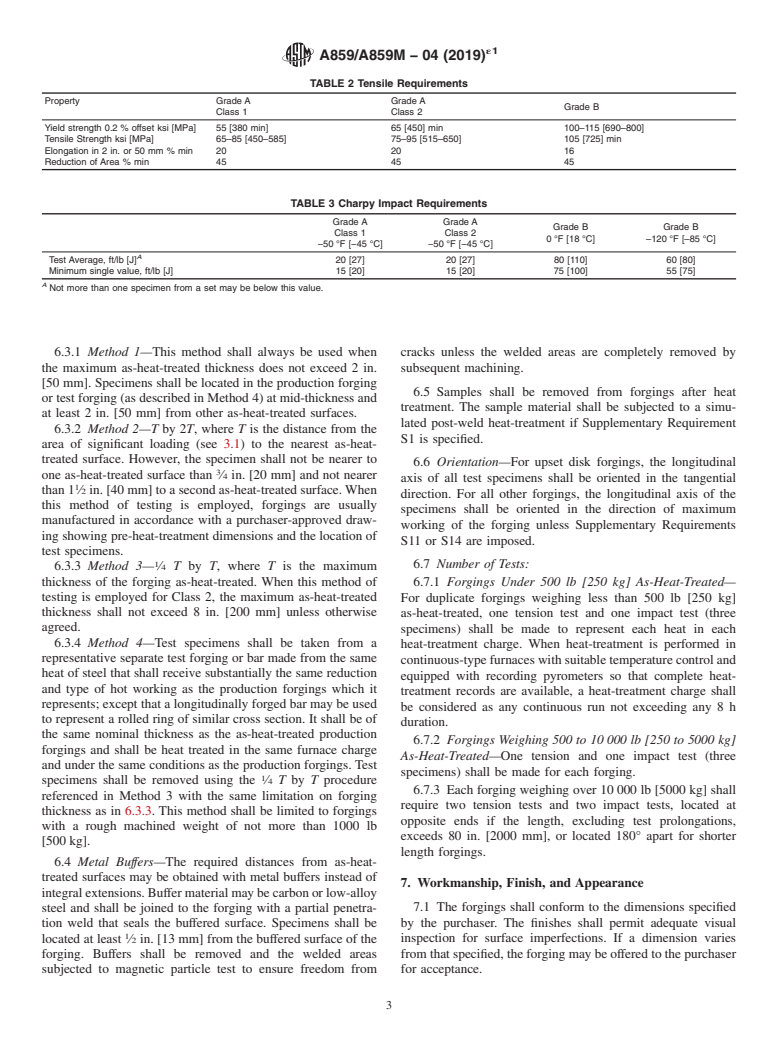

TABLE 2 Tensile Requirements

Property Grade A Grade A

Grade B

Class 1 Class 2

Property Grade A Grade A Grade B

Class 1 Class 2

Yield strength 0.2% offset ksi [MPa] 55 [380 min] 65 [450] min 100–115 [690–800]

Yield strength 0.2 % offset ksi [MPa] 55 [380 min] 65 [450] min 100–115 [690–800]

Tensile Strength ksi [MPa] 65–85 [450–585] 75–95 [515–650] 105 [725] min

Elongation in 2 in. or 50 mm % min 20 20 16

Reduction of Area % min 45 45 45

´1

A859/A859M − 04 (2019)

TABLE 3 Charpy Impact Requirements

Grade A Grade A Grade B

Class1Class 1 Class2Class 2 Grade B —120°F

−50°F [−45°C]−50 °F −50°F [−45°C]−50 °F 0°F [18°C]0 °F [18 °C] [-85°C]–120 °F

[−45 °C] [−45 °C] [–85 °C]

A

Test Average, ft/lb [J] 20 [27] 20 [27] 80 [110] 60 [80]

Minimum single value, ft/lb [J] 15 [20] 15 [20] 75 [100] 55 [75]

A

Not more than one specimen from a set may be below this value.

recording pyrometers so that complete heat-treatment records are available, a heat-treatment charge shall be considered as any

continuous run not exceeding any 8-h 8 h duration.

6.7.2 Forgings Weighing 500 to 10 000 lb [250 to 5000 kg] As-Heat-Treated—One tension and one impact test (three

specimens) shall be made for each forging.

6.7.3 Each forging weighing over 10 000 lb [5000 kg] shall require two tension tests and two impact tests, located at opposite

ends if the length, excluding test prolongations, exceeds 80 in. [2000 mm], or located 180° apart for shorter length forgings.

7. Workmanship, Finish, and Appearance

7.1 The forgings shall conform to the dimensions specified by the purchaser. The finishes shall permit adequate visual inspection

for surface imperfections. If a dimension varies from that specified, the forging may be offered to the purchaser for acceptance.

8. Repair Welding

8.1 Repair welding of forgings shall be permitted only with the approval of the purchaser.

8.2 Preparation for repair welding shall include inspection to ensure complete removal of the defect.

8.3 Repairs shall be made using welding procedures qualified in accordance with ASME Boiler and Pressure Vessel Code

Section IX and repair weld

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.