ASTM E604-15

(Test Method)Standard Test Method for Dynamic Tear Testing of Metallic Materials

Standard Test Method for Dynamic Tear Testing of Metallic Materials

SIGNIFICANCE AND USE

5.1 The DT energy value is a measure of resistance to rapid progressive fracturing. In a number of applications, the enhanced resistance that may develop during about one plate thickness of crack extension from a sharp notch is of major interest. In the test method, a sufficiently long fracture path is provided so that the results serve as a measure of this property.

5.2 Fracture surfaces of nonaustenitic steels tested in their temperature transition region have areas that appear bright and areas that appear dull. The bright, faceted appearing areas are termed “cleavage” fracture, and the dull appearing areas are termed “shear” fracture after their respective mode of fracture on a micro scale.

5.3 This test method can serve the following purposes:

5.3.1 In research and development, to evaluate the effects of metallurgical variables such as composition, processing, or heat treatment, or of fabricating operations such as forming and welding on the dynamic tear fracture resistance of new or existing materials.

5.3.2 In service evaluation, to establish the suitability of a material for a specific application only where a correlation between DT energy and service performance has been established.3

5.3.3 For information, specifications of acceptance, and manufacturing quality control when a minimum DT energy is requested. Detailed discussion of the basis for determining such minimum values in a particular case is beyond the scope of this test method.

SCOPE

1.1 This test method covers the dynamic tear (DT) test using specimens that are 3/16 in. to 5/8 in. (5 mm to 16 mm) inclusive in thickness.

1.2 This test method is applicable to materials with a minimum thickness of 3/16 in. (5 mm).

1.3 The pressed-knife procedure described for sharpening the notch tip generally limits this test method to materials with a hardness level less than 36 HRC.

Note 1: The designation 36 HRC is a Rockwell hardness number of 36 on Rockwell C scale as defined in Test Methods E18.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E604 − 15

Standard Test Method for

1

Dynamic Tear Testing of Metallic Materials

This standard is issued under the fixed designation E604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

3.1 Definitions of Terms Common in Mechanical Testing:

1.1 Thistestmethodcoversthedynamictear(DT)testusing

3 5

3.1.1 The definitions of mechanical testing terms that ap-

specimens that are ⁄16 in. to ⁄8 in. (5 mm to 16 mm) inclusive

pear in Terminology E6 apply to this test method.

in thickness.

3.2 Definitions of Terms Specific to This Standard:

1.2 This test method is applicable to materials with a

3

3.2.1 dynamic tear (DT) energy—the total energy required

minimum thickness of ⁄16 in. (5 mm).

to fracture DT specimens tested in accordance with the

1.3 The pressed-knife procedure described for sharpening

provisions of this test method.

the notch tip generally limits this test method to materials with

3.2.1.1 Discussion—With pendulum-type machines, the DT

a hardness level less than 36 HRC.

energy is the difference between the initial and the final

NOTE1—Thedesignation36HRCisaRockwellhardnessnumberof36 potential energies of the pendulum or pendulums.

on Rockwell C scale as defined in Test Methods E18.

3.2.1.2 Discussion—With drop-weight machines, the DT

energy is the difference between the initial potential energy of

1.4 The values stated in inch-pound units are to be regarded

the hammer and the final energy of the hammer as determined

as standard. The values given in parentheses are mathematical

by a calibrated energy measurement system.

conversions to SI units that are provided for information only

and are not considered standard.

3.2.2 percent shear fracture appearance—the percent of the

net section that fractured in a shear mode.

1.5 This standard does not purport to address all of the

3.2.2.1 Discussion—Net section may be either the net sec-

safety concerns, if any, associated with its use. It is the

tion area before fracture or the area of the projected plane of

responsibility of the user of this standard to establish appro-

the fracture surface.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

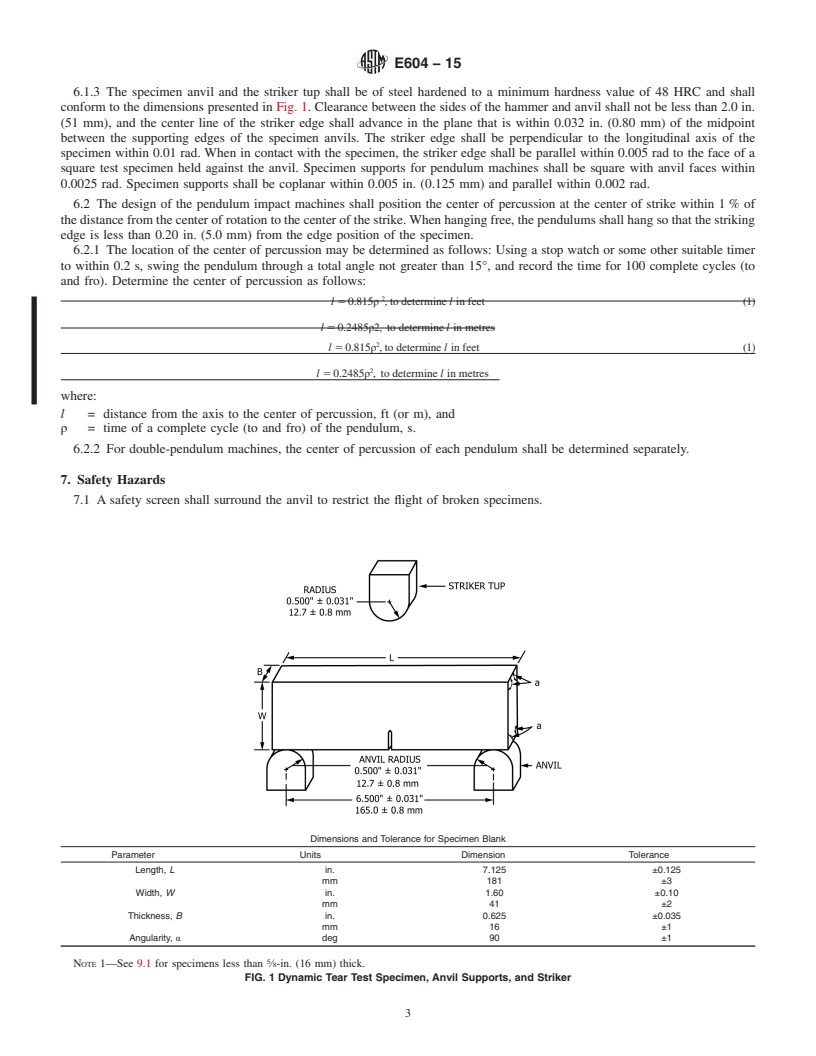

2. Referenced Documents 4.1 TheDTtestinvolvesasingle-edgenotchedbeamthatis

impact loaded in three-point bending, and the total energy loss

2

2.1 ASTM Standards:

during separation is recorded.

B221Specification forAluminum andAluminum-Alloy Ex-

4.2 The DT specimens are fractured with pendulum or

truded Bars, Rods, Wire, Profiles, and Tubes

drop-weight machines.

E6Terminology Relating to Methods of Mechanical Testing

E18Test Methods for Rockwell Hardness of Metallic Ma-

5. Significance and Use

terials

E399Test Method for Linear-Elastic Plane-Strain Fracture

5.1 The DTenergy value is a measure of resistance to rapid

Toughness K of Metallic Materials

progressive fracturing. In a number of applications, the en-

Ic

hanced resistance that may develop during about one plate

thickness of crack extension from a sharp notch is of major

interest. In the test method, a sufficiently long fracture path is

1

This test method is under the jurisdiction of ASTM Committee E28 on

provided so that the results serve as a measure of this property.

Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on

Impact Testing.

5.2 Fracture surfaces of nonaustenitic steels tested in their

Current edition approved Dec. 1, 2015. Published February 2016. Originally

temperature transition region have areas that appear bright and

approvedasaproposedtestmethodin1975.Lastpreviouseditionapprovedin2008

as E604–83(2008). DOI: 10.1520/E0604-15.

areas that appear dull. The bright, faceted appearing areas are

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

termed “cleavage” fracture, and the dull appearing areas are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

termed “shear” fracture after their respective mode of fracture

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. on a micro scale.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E604 − 15

5.3 This test method can serve the following purposes:

5.3.1 Inresearchanddevelopment,toevaluatetheeffectsof

metallu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E604 − 83 (Reapproved 2008) E604 − 15

Standard Test Method for

1

Dynamic Tear Testing of Metallic Materials

This standard is issued under the fixed designation E604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

3 5

1.1 This test method covers the dynamic tear (DT) test using specimens that are ⁄16 in. to ⁄8 in. (5 mm to 16 mm) inclusive

in thickness.

3

1.2 This test method is applicable to materials with a minimum thickness of ⁄16 in. (5 mm).

1.3 The pressed-knife procedure described for sharpening the notch tip generally limits this test method to materials with a

hardness level less than 36 HRC.

NOTE 1—The designation 36 HRC is a Rockwell hardness number of 36 on Rockwell C scale as defined in Test Methods E18.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B221 Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

E6 Terminology Relating to Methods of Mechanical Testing

E18 Test Methods for Rockwell Hardness of Metallic Materials

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

3. Terminology

3.1 Description of Terms Specific to this StandardDefinitions of Terms Common in Mechanical Testing:

3.1.1 The definitions of mechanical testing terms that appear in Terminology E6 apply to this test method.

3.2 Dynamic Tear (DT) Energy—the total energy required to fracture DT specimens tested in accordance with the provisions

of this test method.

NOTE 2—With pendulum-type machines, the DT energy is the difference between the initial and the final potential energies of the pendulum or

pendulums.

NOTE 3—With drop-weight machines, the DT energy is the difference between the initial potential energy of the hammer and the final energy of the

hammer as determined by a calibrated energy measurement system.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 dynamic tear (DT) energy—the total energy required to fracture DT specimens tested in accordance with the provisions

of this test method.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on Impact Testing.

Current edition approved Sept. 1, 2008Dec. 1, 2015. Published January 2009February 2016. Originally approved as a proposed test method in 1975. Last previous edition

approved in 20022008 as E604 –83(2002). –83(2008). DOI: 10.1520/E0604-83R08.10.1520/E0604-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.2.1.1 Discussion—

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E604 − 15

With pendulum-type machines, the DT energy is the difference between the initial and the final potential energies of the pendulum

or pendulums.

3.2.1.2 Discussion—

With drop-weight machines, the DT energy is the difference between the initial potential energy of the hammer and the final energy

of the hammer as determined by a calibrated energy measurement system.

3.2.2 percent shear fracture appearance—the percent of the net section that fractured in a shear mode.

3.2.2.1 Discussion—

Net section may be either the net section area before fracture or the area of the projected plane of the fracture surface.

3.3 Percent Shear Fracture Appearance—Percent shear fracture appearance is the percent of the net section that fractured in a

shear mode.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.