ASTM E776-87(2004)

(Test Method)Standard Test Method for Forms of Chlorine in Refuse-Derived Fuel

Standard Test Method for Forms of Chlorine in Refuse-Derived Fuel

SIGNIFICANCE AND USE

The standard is available to producers and users of RDF for determining the content and forms of chlorine present in the fuel.

SCOPE

1.1 This test method covers the determination of the forms of chlorine in refuse-derived fuel-three (RDF): total chlorine, water-soluble chloride, and water-insoluble chlorine.

1.2 This test method may be applicable to any waste material from which a laboratory analysis sample can be prepared.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precaution statements see Section 6 and 11.2.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E776–87 (Reapproved 2004)

Standard Test Method for

Forms of Chlorine in Refuse-Derived Fuel

This standard is issued under the fixed designation E 776; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope RDF-1—Wastes used as a fuel in as-discarded form with

only bulky wastes removed.

1.1 This test method covers the determination of the forms

RDF-2—Wastes processed to coarse particle size with or

of chlorine in refuse-derived fuel-three (RDF): total chlorine,

without ferrous metal separation.

water-soluble chloride, and water-insoluble chlorine.

RDF-3—Combustible waste fraction processed to particle

1.2 This test method may be applicable to any waste

sizes, 95 % passing 2-in. square screening.

material from which a laboratory analysis sample can be

RDF-4—Combustible waste fraction processed into powder

prepared.

form, 95 % passing 10-mesh screening.

1.3 This standard does not purport to address all of the

RDF-5—Combustible waste fraction densified (compressed)

safety concerns, if any, associated with its use. It is the

into the form of pellets, slugs, cubettes, or briquettes.

responsibility of the user of this standard to establish appro-

3.1.2 total chlorine—all chlorine as determined in the

priate safety and health practices and determine the applica-

refuse-derived fuel.

bility of regulatory limitations prior to use. For specific

3.1.3 water-insoluble chlorine—water-insoluble chlorides

precaution statements see Section 6 and 11.2.1.

and chlorine in the refuse-derived fuel.

2. Referenced Documents

3.1.4 water-soluble chloride—those chlorides which are

water-solubilized by water extraction as determined in the

2.1 ASTM Standards:

refuse-derived fuel.

D 1193 Specification for Reagent Water

E 144 Practice for Safe Use of Oxygen Combustion Bombs

4. Summary of Test Method

E 180 Practice for Determining the Precision of ASTM

4.1 The forms of chloride and chlorine are determined. The

Methods for Analysis and Testing of Industrial Chemicals

various procedures in the method convert the forms of chlorine

E 287 Specification for Burets

into a water-soluble chloride form that can be quantitated by

E711 Test Method for Gross Calorific Value of Refuse-

titration.

Derived Fuel by the Bomb Calorimeter

4.1.1 Total Chlorine—The sample is combusted in an oxy-

E 829 Practice for Preparing Refuse-Derived Fuel (RDF)

gen atmosphere. The chlorine is converted to chloride and

Laboratory Samples for Analysis

absorbed in an alkaline solution.

3. Terminology

4.1.2 Water-Soluble Chlorides—A portion of the analysis

sample is successively extracted with hot chloride-free water.

3.1 Definitions of Terms Specific to This Standard:

4.1.3 Water-Insoluble Chlorine—Water-insoluble chlorine

3.1.1 refuse-derived fuels—solid forms of refuse-derived

is calculated from the results of the total chlorine and the

fuels from which appropriate analytical samples may be

water-soluble chloride determination where:

prepared are defined as follows in ASTM STP 832:

water2insoluble chlorine 5 total chlorine 2 water2soluble chlorides

(1)

This test method is under the jurisdiction of ASTM Committee D34 on Waste

4.2 The chlorides contained in the alkaline solution (4.1.1)

Management and is the direct responsibility of Subcommittee D34.03.02 on

Municipal Recovery and Reuse.

and the extraction solution (4.1.2) are determined by potentio-

Current edition approved Aug. 28, 1987. Published October 1987. Originally

metric (see Section 13) or modified Volhard titration (see

published as E 776 – 81. Last previous edition E 776 – 81.

Section 14).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Thesaurus on Resource Recovery Terminology, ASTM STP 832, ASTM, 1983,

p. 72.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E776–87 (2004)

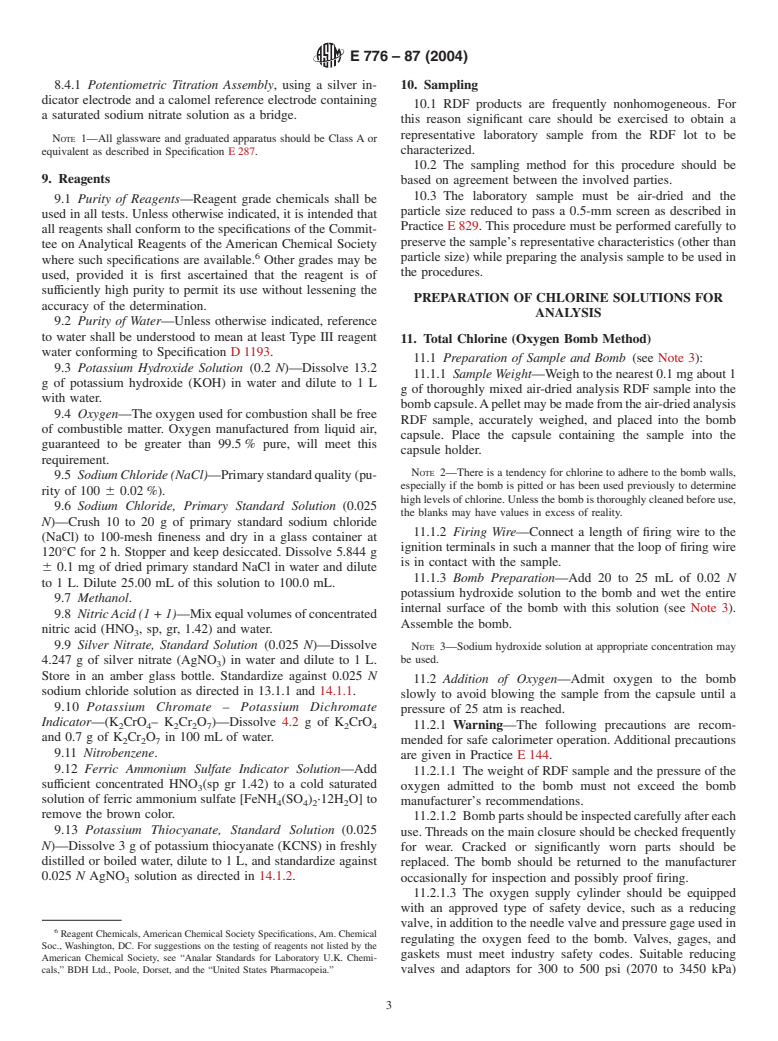

FIG. 1 Graph From a Potentiometric Titration of Chloride

5. Significance and Use excess of sulfide is easily removed by gently boiling the acid

solution for a few minutes. Sulfite can be eliminated in the

5.1 The standard is available to producers and users of RDF

same way.

fordeterminingthecontentandformsofchlorinepresentinthe

7.2.3 Cyanide is also precipitated by silver nitrate. It is

fuel.

usually determined separately by the Liebig-Deniges method

and a correction is applied to the results of the Volhard

6. Precautions

titration.

6.1 Due to the origins of RDF in municipal waste, common

7.2.4 The Volhard method, as with the potentiometric

sense dictates that some precautions should be observed when

method, directly applied to a mixture of halides can determine

conducting tests on the samples. Recommended hygienic

only total halide content excluding fluoride. Preliminary treat-

practices include use of gloves when handling RDF; wearing

ment is necessary for the determination of chloride alone in a

dust masks (NIOSH-approved type), especially while milling

mixture.

RDF samples; conducting tests under negative pressure hood

when possible; and washing hands before eating or smoking.

8. Apparatus

7. Interferences 8.1 Balance, having a sensitivity of 0.1 mg.

8.2 Apparatus for Bomb Combustion of the Sample.

7.1 Potentiometric Titration Method A:

8.2.1 Oxygen Bomb, similar to that used in the determina-

7.1.1 Iodide and bromide are also titrated as chloride.

tion of the calorific value of refuse-derived fuels as described

Ferricyanide causes high results and must be removed. Chro-

in Test MethodE711.

mate and dichromate interfere and should be reduced to the

8.2.2 Capsule, for holding the sample, approximately 25

chromic state or be removed. Ferric iron interferes if present in

mm in diameter at the top, approximately 12 mm deep, and

an amount substantially higher than the amount of chloride.

conforming to Test MethodE711.

Chromic ions, ferrous ions, and phosphates do not interfere.

8.2.3 Firing Wire, as specified in Test MethodE711.

7.1.2 Grossly contaminated sample solutions usually re-

8.2.4 Firing Circuit, as specified in Test MethodE711.

quire pretreatment. Where contamination is minor, some con-

8.2.5 Metal Vessel, cylindrical, such that the bomb will be

taminants can be destroyed simply by the addition of nitric

fully immersed when approximately 2 L of water are added.

acid.

8.3 Magnetic Stirrer and Stirring Bars.

7.2 Volhard Titration Method B:

8.4 Apparatus for Potentiometric Titration:

7.2.1 Compounds that have a strong oxidizing action inter-

fere by reacting with thiocyanate. These compounds should be

reduced beforehand by treatment with ferrous sulfate or a

similar reducing agent.

Scott’s Standard Method of Chemical Analysis, edited by M. H. Furman, D.

7.2.2 Salts of mercury and palladium interfere by reacting

Van Nostrand Co., Inc., New York, NY.

with thiocyanate. They may be removed by precipitation with

Koltoff, I. M., and Stenger, V. A., Volumetric Analysis II, Interscience

hydrogen sulfide before the addition of silver nitrate. The Publishers, Inc., New York, NY.

E776–87 (2004)

8.4.1 Potentiometric Titration Assembly, using a silver in- 10. Sampling

dicator electrode and a calomel reference electrode containing

10.1 RDF products are frequently nonhomogeneous. For

a saturated sodium nitrate solution as a bridge.

this reason significant care should be exercised to obtain a

representative laboratory sample from the RDF lot to be

NOTE 1—All glassware and graduated apparatus should be Class A or

characterized.

equivalent as described in Specification E 287.

10.2 The sampling method for this procedure should be

9. Reagents

based on agreement between the involved parties.

10.3 The laboratory sample must be air-dried and the

9.1 Purity of Reagents—Reagent grade chemicals shall be

particle size reduced to pass a 0.5-mm screen as described in

used in all tests. Unless otherwise indicated, it is intended that

Practice E 829. This procedure must be performed carefully to

all reagents shall conform to the specifications of the Commit-

preserve the sample’s representative characteristics (other than

tee on Analytical Reagents of the American Chemical Society

particle size) while preparing the analysis sample to be used in

where such specifications are available. Other grades may be

the procedures.

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

PREPARATION OF CHLORINE SOLUTIONS FOR

accuracy of the determination.

ANALYSIS

9.2 Purity of Water—Unless otherwise indicated, reference

to water shall be understood to mean at least Type III reagent

11. Total Chlorine (Oxygen Bomb Method)

water conforming to Specification D 1193.

11.1 Preparation of Sample and Bomb (see Note 3):

9.3 Potassium Hydroxide Solution (0.2 N)—Dissolve 13.2

11.1.1 Sample Weight—Weigh to the nearest 0.1 mg about 1

g of potassium hydroxide (KOH) in water and dilute to 1 L

g of thoroughly mixed air-dried analysis RDF sample into the

with water.

bombcapsule.Apelletmaybemadefromtheair-driedanalysis

9.4 Oxygen—The oxygen used for combustion shall be free

RDF sample, accurately weighed, and placed into the bomb

of combustible matter. Oxygen manufactured from liquid air,

capsule. Place the capsule containing the sample into the

guaranteed to be greater than 99.5 % pure, will meet this

capsule holder.

requirement.

NOTE 2—There is a tendency for chlorine to adhere to the bomb walls,

9.5 Sodium Chloride (NaCl)—Primarystandardquality(pu-

especially if the bomb is pitted or has been used previously to determine

rity of 100 6 0.02 %).

high levels of chlorine. Unless the bomb is thoroughly cleaned before use,

9.6 Sodium Chloride, Primary Standard Solution (0.025

the blanks may have values in excess of reality.

N)—Crush 10 to 20 g of primary standard sodium chloride

11.1.2 Firing Wire—Connect a length of firing wire to the

(NaCl) to 100-mesh fineness and dry in a glass container at

ignition terminals in such a manner that the loop of firing wire

120°C for 2 h. Stopper and keep desiccated. Dissolve 5.844 g

is in contact with the sample.

6 0.1 mg of dried primary standard NaCl in water and dilute

11.1.3 Bomb Preparation—Add 20 to 25 mL of 0.02 N

to 1 L. Dilute 25.00 mL of this solution to 100.0 mL.

potassium hydroxide solution to the bomb and wet the entire

9.7 Methanol.

internal surface of the bomb with this solution (see Note 3).

9.8 NitricAcid (1 + 1)—Mixequalvolumesofconcentrated

Assemble the bomb.

nitric acid (HNO , sp, gr, 1.42) and water.

9.9 Silver Nitrate, Standard Solution (0.025 N)—Dissolve NOTE 3—Sodium hydroxide solution at appropriate concentration may

be used.

4.247 g of silver nitrate (AgNO ) in water and dilute to 1 L.

Store in an amber glass bottle. Standardize against 0.025 N

11.2 Addition of Oxygen—Admit oxygen to the bomb

sodium chloride solution as directed in 13.1.1 and 14.1.1.

slowly to avoid blowing the sample from the capsule until a

9.10 Potassium Chromate – Potassium Dichromate

pressure of 25 atm is reached.

Indicator—(K CrO–K Cr O )—Dissolve 4.2gofK CrO

2 4 2 2 7 2 4 11.2.1 Warning—The following precautions are recom-

and 0.7 g of K Cr O in 100 mL of water.

2 2 7 mended for safe calorimeter operation. Additional precautions

9.11 Nitrobenzene.

are given in Practice E 144.

9.12 Ferric Ammonium Sulfate Indicator Solution—Add

11.2.1.1 The weight of RDF sample and the pressure of the

sufficient concentrated HNO (sp gr 1.42) to a cold saturated

oxygen admitted to the bomb must not exceed the bomb

solution of ferric ammonium sulfate [FeNH (SO ) ·12H O] to

manufacturer’s recommendations.

4 4 2 2

remove the brown color.

11.2.1.2 Bombpartsshouldbeinspectedcarefullyaftereach

9.13 Potassium Thiocyanate, Standard Solution (0.025

use. Threads on the main closure should be checked frequently

N)—Dissolve3gof potassium thiocyanate (KCNS) in freshly

for wear. Cracked or significantly worn parts should be

distilled or boiled water, dilute to 1 L, and standardize against

replaced. The bomb should be returned to the manufacturer

0.025 N AgNO solution as directed in 14.1.2.

occasionally for inspection and possibly proof firing.

11.2.1.3 The oxygen supply cylinder should be equipped

with an approved type of safety device, such as a reducing

valve, in addition to the needle valve and pressure gage used in

Reagent Chemicals,American Chemical Society Specifications,Am. Chemical

regulating the oxygen feed to the bomb. Valves, gages, and

Soc., Washington, DC. For suggestions on the testing of reagents not listed by the

gaskets must meet industry safety codes. Suitable reducing

American Chemical Society, see “Analar Standards for Laboratory U.K. Chemi-

cals,” BDH Ltd., Poole, Dorset, and the “United States Pharmacopeia.” valves and adaptors for 300 to 500 psi (2070 to 3450 kPa)

E776–87 (2004)

method of turbidity or color removal without interfering with the chloride

discharge pressures are obtainable from commercial sources of

content of the solution.

compressedgasequipment.Thepressuregageshallbechecked

periodically for accuracy.

ALTERNATIVE PROCEDURES

11.2.1.4 During ignition of a sample, the operator must not

permit any portion of his body to extend over the calorimeter.

13. Potentiometric Titration (Method A)

11.3 Preparation of the Chlorine Solution—Immerse the

13.1 Standardization of Reagents—Prepare a standard solu-

bomb in a cold-water bath, connect it to the firing circuit, and

tion of silver nitrate by adding 10.0 mL of standard 0.025 N

close the circuit to ignite the sample.Allow the bomb to stand

NaCl solution to a 250-mL beaker. Add 40 to 50 mL of water

in the water bath for not less than 10 min after firing. Remove

and 50 mL of methanol (Note 9). Add 2 mL of HNO (1+1)

the bomb from the water bath, invert the bomb and shake for

and titrate potentiometrically with the AgNO solution as

about 10 min (Note 4). Release the pressure at a slow, uniform

directedin13.3.CalculatethenormalityoftheAgNO solution

rate so that the pressure is reduced to atmospheric in not less

as follows:

than 1 min. Open the bomb and examine the inside for traces

Normality of AgNO 5 mL of NaCl solution used

of unburned material or sooty deposits. If any are found,

3 normality of NaCl solution/mL of AgNO solution required (2)

discard the determination and thoroughly was

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.