ASTM D7090-04(2010)

(Test Method)Standard Test Method for Purity of Isophorone by Capillary Gas Chromatography

Standard Test Method for Purity of Isophorone by Capillary Gas Chromatography

SIGNIFICANCE AND USE

This test method determines the purity of isophorone, as well as the concentration of various potential impurities, several of which are critical in the application of these solvents.

SCOPE

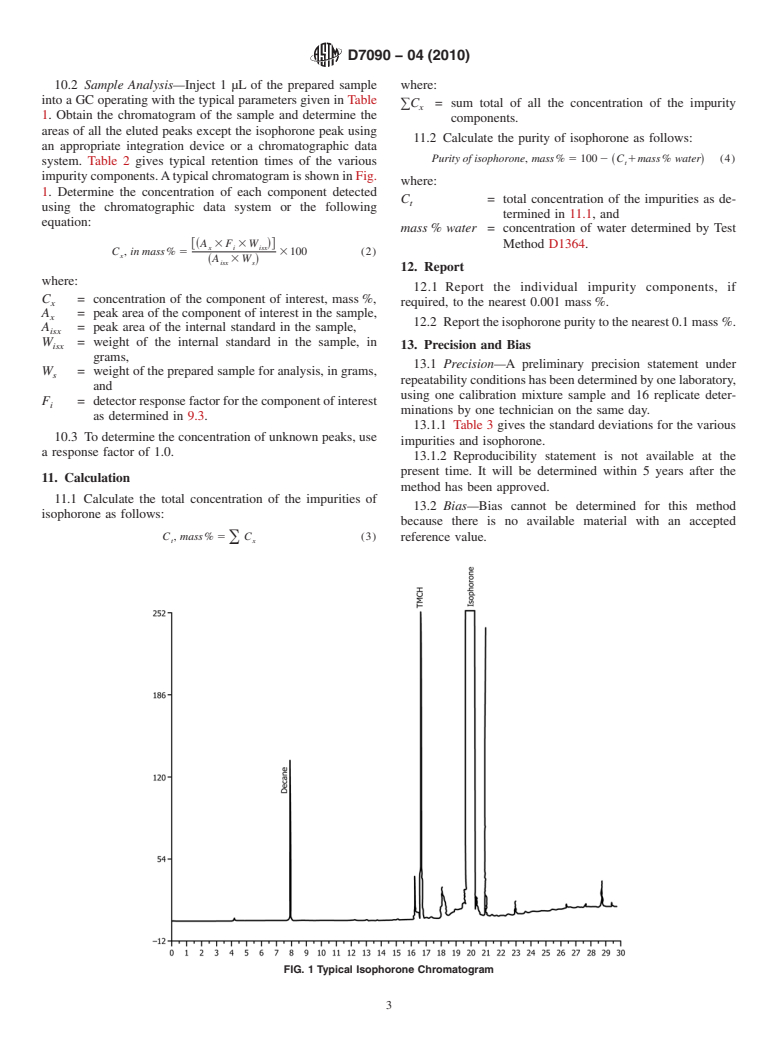

1.1 This test method covers the determination of the purity of isophorone. This method also determines the impurities of the material in concentration level less than 0.5 mass %, which may include mesityl oxide (MSO), mesityl oxide-isomer, mesitylene, trimethyl cyclohexenone (TMCH), phorone, phorone-isomer, xylitone, and tetralone.

1.2 Water cannot be determined by this test method and shall be measured by other appropriate ASTM procedure. The result is used to normalize the chromatographic data determined by this test method.

1.3 For purposes of determining conformance of an observed or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification limit, in accordance with the rounding - off method of Practice E29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7090 − 04 (Reapproved 2010)

Standard Test Method for

Purity of Isophorone by Capillary Gas Chromatography

This standard is issued under the fixed designation D7090; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope column using temperature programming and a flame ionization

detector. The concentrations of the sample components are

1.1 This test method covers the determination of the purity

calculated from the integrated component peaks using internal

of isophorone. This method also determines the impurities of

standardization technique with response factors. Water is

the material in concentration level less than 0.5 mass %, which

measured in accordance with Test Method D1364 and the

may include mesityl oxide (MSO), mesityl oxide-isomer,

result is used to normalize the values obtained by gas chroma-

mesitylene, trimethyl cyclohexenone (TMCH), phorone,

tography.

phorone-isomer, xylitone, and tetralone.

4. Significance and Use

1.2 Water cannot be determined by this test method and

shall be measured by other appropriate ASTM procedure. The

4.1 This test method determines the purity of isophorone, as

result is used to normalize the chromatographic data deter-

well as the concentration of various potential impurities,

mined by this test method.

severalofwhicharecriticalintheapplicationofthesesolvents.

1.3 For purposes of determining conformance of an ob-

5. Apparatus

served or a calculated value using this test method to relevant

5.1 Chromatograph—Any gas chromatograph utilizing a

specifications, test result(s) shall be rounded off “to the nearest

capillary column and has the following characteristics (see

unit” in the last right-hand digit used in expressing the

Table 1 for typical GC parameters):

specification limit, in accordance with the rounding-off method

5.1.1 Detector—A flame ionization detector (FID) capable

of Practice E29.

of continuous operation at a temperature equivalent to the

1.4 This standard does not purport to address all of the

maximum column temperature employed. The detector shall

safety concerns, if any, associated with its use. It is the

havesufficientsensitivitytodetect0.001mass %ofimpurityin

responsibility of the user of this standard to establish appro-

the specimen at a peak height 3 times the noise level.

priate safety and health practices and to determine the

5.1.2 Column—fused silica capillary column with bonded

applicability of regulatory limitations prior to use.

polyethylene (see Table 1 for details).

5.1.3 Column Temperature Programming—The chromato-

2. Referenced Documents

2 graph shall be capable of reproducible linear temperature

2.1 ASTM Standards:

programming.

D1364 Test Method for Water in Volatile Solvents (Karl

5.1.4 Sample Inlet System—The sample inlet system shall

Fischer Reagent Titration Method)

be capable of split injection, typically at a 100:1 split ratio.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications NOTE 1—An autoinjector is recommended. Manual injection with a

syringe is acceptable, however the observed precision may not apply.

E300 Practice for Sampling Industrial Chemicals

5.1.5 Integrator—Means shall be provided for determining

3. Summary of Test Method

the area of the observed chromatographic peaks. This can be

3.1 A representative specimen is introduced into a gas

done by means of an electronic integrator or a computer based

chromatograph with a bonded polyethylene glycol capillary

chromatography data system. The integrator/computer system

shall have standard chromatographic software for determining

This test method is under the jurisdiction of ASTM Committee D01 on Paint

the retention times and quantification of eluting peaks.

and Related Coatings, Materials, andApplications and is the direct responsibility of

5.1.6 Flow Controller—The chromatograph shall be

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

equipped with a constant flow device capable of maintaining

Current edition approved Dec. 1, 2010. Published December 2010. Originally

the carrier gas at a constant flow rate throughout the tempera-

approved in 2004. Last previous edition approved in 2004 as D7090 – 04. DOI:

10.1520/D7090-04R10.

ture program.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.7 Microsyringe—A microsyringe of appropriate capac-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ity is required for injection of the specimen into the chromato-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. graph. Typically,a5µL syringe is used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7090 − 04 (2010)

TABLE 1 Typical GC Parameters

9. Calibration and Standardization

Parameters Values

9.1 Prepare a calibration mixture containing approximately

Column 30m×0.32mmfused silica capillary column

0.1 mass % of each of the components of interest and the

with 0.5 micron bonded phase polyethylene

glycol

decane internal standard in pure isophorone. The total weight

Column Temperature 50°C for 5 min., programmed to 210°C at 10°C/

of the calibration mixture solution should be 100 g. If pure

min. Hold for 10 min.

isophorone is not available, then isophorone containing rela-

Injector Temperature 230°C

Sample size 1 µL

tively low concentration of the components of interest can be

Split ratio 100:1

used, and the composition of the calibration mixture corrected

Detector Flame Ionization

for components already present. Typical components suitable

Detector Temperature 250°C

Carrier Gas (Helium) 30 cm/s

for the calibration mixture are: MSO, MSO-isomer,

Hydrogen Gas 30 mL/min.

mesitylene, TMCH, phorone, phorone isomer, xylitone, and

Air 300 mL/min.

tetralone (see 6.2).

9.2 Record the actual weight of each added component, the

6. Reagents and Materials internal standard, and the total weight of the calibration

mixture.

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in the preparation of the calibration mixture. 9.3 Determine the detector response factor of the various

components of interest, by injecting 1 µL of the calibration

6.2 Calibration Mixture Components:

mixture into a GC using the typical chromatographic param-

6.2.1 Isophorone—solvent used in the preparation of the

eters given in Table 1, and using the equation:

calibration mixture, and shall be free of the components of

interest. If pure isophorone is not available, then isophorone W 3A

~ !

i is

F 5 (1)

i

containing relatively low concentration of the components of

~W 3A !

is i

interest can be used, and the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.