ASTM D3236-88(2004)

(Test Method)Standard Test Method for Apparent Viscosity of Hot Melt Adhesives and Coating Materials

Standard Test Method for Apparent Viscosity of Hot Melt Adhesives and Coating Materials

SIGNIFICANCE AND USE

This test method distinguishes between hot melts having different apparent viscosities. It is believed that apparent viscosity determined by this procedure is related to flow performance in application machinery operating under conditions of low shear rate. Apparent viscosity as determined by this test method may not correlate well with end-use applications where high shear rates are encountered.

Materials of the type described in this procedure may be quite non-Newtonian and as such, the apparent viscosity will be a function of shear rate under the conditions of test. Although the viscometer described in this test method generally operates under conditions of relatively low shear rate, differences in shear effect can exist depending upon the spindle and rotational speed conditions selected for the test program. Maximum correlation between laboratories, therefore, depends upon testing under conditions of equivalent shear.

Approximate shear rates using various spindles are shown in Table A1.1 in the Annex to this test method.

SCOPE

1.1 This test method covers the determination of the apparent viscosity of hot melt adhesives and coating materials compounded with additives and having apparent viscosities up to 200 000 millipascal second (mPa·s) (Note 3) at temperatures up to 175°C (347°F).

Note 1—Although precision has not been studied, this procedure may be adaptable to viscosities higher than the present 200 000-mPa·s limit and temperatures above 175°C (347°F). Equipment described in this test method permits testing of materials having viscosities as high as 16 x 106 mPa·s and provides temperatures up to 260°C (500°F).

Note 2—For petroleum waxes and their blends having apparent viscosities below 15 mPa·s, Test Method D 445 is especially applicable.

Note 3—One pascal second (Pa·s) = 1000 centipoise (CP); one millipascal second = one centipoise.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3236–88(Reapproved2004)

Standard Test Method for

Apparent Viscosity of Hot Melt Adhesives and Coating

Materials

This standard is issued under the fixed designation D3236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 apparent viscosity—the viscosity determined by this

test method and expressed in millipascal seconds. Its value

1.1 This test method covers the determination of the appar-

may vary with the spindle and rotational speed selected

ent viscosity of hot melt adhesives and coating materials

because many hot melts are non-Newtonian.

compounded with additives and having apparent viscosities up

3.1.2 viscosity—the ratio of shear stress to shear rate. The

to 200 000 millipascal second (mPa·s) (Note 3) at temperatures

viscosity of a liquid is a measure of the internal friction of the

up to 175°C (347°F).

liquid in motion. The unit of dynamic viscosity is the pascal

NOTE 1—Although precision has not been studied, this procedure may

second. For a Newtonian liquid, the viscosity is constant at all

beadaptabletoviscositieshigherthanthepresent200 000-mPa·slimitand

shear rates. For a non-Newtonian liquid, viscosity will vary

temperatures above 175°C (347°F). Equipment described in this test

6 depending on shear rate.

method permits testing of materials having viscosities as high as 16 3 10

mPa·s and provides temperatures up to 260°C (500°F).

4. Summary of Test Method

NOTE 2—For petroleum waxes and their blends having apparent vis-

cosities below 15 mPa·s, Test Method D445 is especially applicable. 4.1 A representative sample of the molten material to be

NOTE 3—One pascal second (Pa·s) = 1000 centipoise (CP); one milli-

tested is maintained in a thermally controlled sample chamber.

pascal second = one centipoise.

Apparent viscosity is determined under temperature equilib-

1.2 The values stated in SI units are to be regarded as the rium conditions using a precision rotating spindle type viscom-

standard. The values in parentheses are for information only. eter. Data obtained at several temperatures can be plotted on

1.3 This standard does not purport to address all of the appropriate semi-logarithmic graph paper and apparent viscos-

safety concerns, if any, associated with its use. It is the ity at intermediate temperatures can be estimated.

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5.1 Thistestmethoddistinguishesbetweenhotmeltshaving

different apparent viscosities. It is believed that apparent

2. Referenced Documents

viscosity determined by this procedure is related to flow

2.1 ASTM Standards: performance in application machinery operating under condi-

D445 Test Method for Kinematic Viscosity of Transparent tions of low shear rate. Apparent viscosity as determined by

and Opaque Liquids (and Calculation of Dynamic Viscos- this test method may not correlate well with end-use applica-

ity) tions where high shear rates are encountered.

5.2 Materials of the type described in this procedure may be

3. Terminology

quite non-Newtonian and as such, the apparent viscosity will

3.1 Definitions: be a function of shear rate under the conditions of test.

Although the viscometer described in this test method gener-

ally operates under conditions of relatively low shear rate,

This test method is under the jurisdiction of ASTM Committee D02 on

differences in shear effect can exist depending upon the spindle

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

and rotational speed conditions selected for the test program.

D02.10 on Properties of Petroleum Wax.

Current edition approved May 1, 2004. Published June 2004. Originally

Maximum correlation between laboratories, therefore, depends

approved in 1973. Last previous edition approved in 1999 as D3236–88 (1999).

upon testing under conditions of equivalent shear.

DOI: 10.1520/D3236-88R04.

5.3 Approximate shear rates using various spindles are

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM shown in Table A1.1 in the Annex to this test method.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3236–88 (2004)

TABLE 1 Suitable ASTM Thermometers

6. Apparatus

Scale

6.1 Viscometer, rotating spindle type with leveling stand.

Immersion, ASTM Thermometer

Temperature Range Error,

mm Number

6.2 Viscometer Spindles, stainless steel.

max

6.3 Sample Chamber, with precision proportional tempera-

90°C to 170°C 51 0.2°C 35C-62

,

3 4

ture controller that provides control accuracy of 61.0°C

194°F to 338°F 51 0.5°F 35F-62

145°C to 205°C 76 0.4°C 100C-68

(1.8°F) or better through the range from 100 to 200°C (212 to

392°F).

6.4 Graph Paper, semi-logarithmic.

during temperature reading to minimize the effect of thermal

7. Calibration

gradients in the sample. Continue temperature readings and

7.1 The viscometer is precalibrated using Newtonian fluids controller adjustment until minimum deviation from test tem-

by the manufacturer. No zero adjustment is provided, since perature is obtained. Minimum deviation may vary between

experience has shown that the zero point will not vary due to laboratories, depending upon the controller, but should in no

changes in the spring. The viscometer and spindles are preci- case exceed 60.5°C (0.9°F). Repeat this procedure for any test

sion equipment and should be kept from undue shock and temperature desired within the scope of this test method.

mishandling. Physical damage to the instrument will often

8. Procedure

reveal itself as erratic or no oscillation of the pointer when the

instrument, with or without the spindle in place, is operated in

8.1 Selection of Spindle—From the estimated viscosity of

air. When operating normally, the pointer will be stable and

the sample and Table A1.1 in the Annex, select a viscometer

have free oscillation about the zero point in air.

and spindle combination that will produce readings in the

7.2 The instrument may be further calibrated using standard

desired range.

reference fluids. Suitable fluids are available in nominal

NOTE 5—Use only the spindle shown to be appropriate for the

viscosities up to 15 000 mPa·s at 149°C (300°F). The proce-

viscometer to be used.

dure for instrument calibration using standard reference fluids

8.1.1 Wheremorethanonespindleisavailablefortherange

isthatencompassedbythistestmethod.Resultsobtainedusing

selected, choose the spindle that produces results nearest the

standard reference fluids should not deviate from the nominal

midpoint of the measurable viscosity range. Viscometer scale

viscosity by more than 2 %.

readings must be within the 10 to 95 range.

7.3 The temperature controller of the type recommended for

this procedure is factory calibrated and has control capability

NOTE 6—Care must be taken in the storage and handling of spindles

of 60.5 % of the control point (61.0°C at 175°C). To further and assemblies. Protect them from dust, corrosive deposits, and mechani-

cal abuse. Avoid touching the calibrated section of the spindle with the

check the controller and further establish controller settings,

hands. Clean the spindle and sample chamber thoroughly after each use.

use the following procedure: Place a sufficient quantity of low

A recommended cleaning procedure is included in Annex A2.

viscosity (500 mPa·s or less) hot melt in the sample container

8.2 Preparation of Sample—Place the required amount of

to permit immersion of the appropriateASTM thermometer to

representative sample (see Table 2) measured to the nearest

theproperdepth.Donotpermitthethermometerbulbtoreston

0.005 g (or 0.05 mL if handled in the molten state) in the

the bottom of the sample container. Suitable thermometers are

sample chamber. Melt the sample in an oven set at the desired

shown in Table 1.

test temperature or in the thermo-container preheated to the

NOTE 4—Particular care must be taken not to overflow the sample

desired test temperature.Avoid excessive or prolonged heating

chamber when using the 100°C, 76-mm immersion thermometer.

of the sample to minimize thermal and oxidative effects. Use a

7.3.1 Insert the thermometer through the insulating cover of

fresh sample for each temperature for which a determination is

the sample container and hold it in place at the point required

to be made.

for proper immersion depth. Adjust the thermal controller to

8.3 System Alignment and Spindle Insertion—After the

provide the desired test temperature. Rotate the thermometer

sample is completely melted, lower the properly aligned and

leveled viscometer until the tips of the alignment bracket just

touch the top of the thermo-container, making contact directly

The sole source of supply of the viscometers and accessories known to the

committee at this time is Brookfield Engineering Laboratories, Inc., Stoughton, MA

02072. If you are aware of alternative suppliers, please provide this information to

TABLE 2 Sample Size Requirement

ASTM International Headquarters. Your comments will receive careful consider-

Approximate Approximate Sample

ation at a meeting of the responsible technical committee , which you may attend.

Spindle

A

Volume, mL Weight, g

Thesolesourceofsupplyofthetemperaturecontrollerknowntothecommittee

at this time isAthena Controls, Inc., 2 Union Road,West Conshohocken, PA19428. SC 4-18 8.00 6.40

If you are aware of alternative suppliers, please provide this information to ASTM SC 4-21 8.00 6.40

SC 4-27 10.50 8.40

International Headquarters. Your comments will receive careful consideration at a

SC 4-28 11.50 9.20

meeting of the responsible technical committee , which you may attend.

SC 4-29 13.00 10.40

The sole source of supply of the calibration fluids known to the committee at

SC 4-31 10.00 8.00

this time is Brookfield Engineering Laboratories, Inc., Stoughton, MA 02072 or

SC 4-34 9.50 7.60

Cannon Instrument Co., P. O. Box 16, State College, PA16801. If you are aware of

A

alternative suppliers, please provide this information to ASTM International

Based on typical molten specific gravity of 0.800. If the specific gravity of the

Headquarters.Your comments will receive careful consideration at a meeting of the

material to be tested varies greatly from this value, sample size must be adjusted

responsible technical committee , which you may attend. to ensure proper liquid level on the spindle shaft.

D3236–88 (2004)

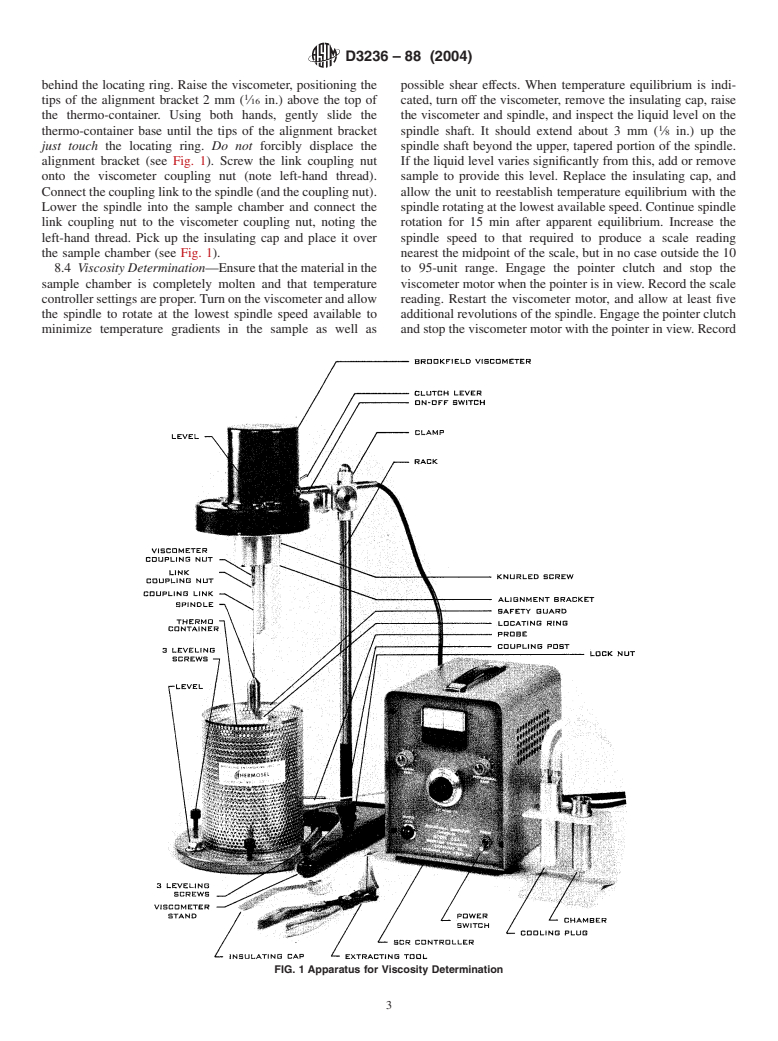

behind the locating ring. Raise the viscometer, positioning the possible shear effects. When temperature equilibrium is indi-

tips of the alignment bracket 2 mm ( ⁄16 in.) above the top of cated, turn off the viscometer, remove the insulating cap, raise

the thermo-container. Using both hands, gently slide the the viscometer and spindle, and inspect the liquid level on the

thermo-container base until the tips of the alignment bracket spindle shaft. It should extend about 3 mm ( ⁄8 in.) up the

just touch the locating ring. Do not forcibly displace the spindle shaft beyond the upper, tapered portion of the spindle.

alignment bracket (see Fig. 1). Screw the link coupling nut If the liquid level varies significantly from this, add or remove

onto the viscometer coupling nut (note left-hand thread). sample to provide this level. Replace the insulating cap, and

Connectthecouplinglinktothespindle(andthecouplingnut). allow the unit to reestablish temperature equilibrium with the

Lower the spindle into the sample chamber and connect the spindle rotating at the lowest available speed. Continue spindle

link coupling nut to the viscometer coupling nut, noting the rotation for 15 min after apparent equilibrium. Increase the

left-hand thread. Pick up the insulating cap and place it over spindle speed to that required to produce a scale reading

the sample chamber (see Fig. 1). nearest the midpoint of the scale, but in no case outside the 10

8.4 Viscosity Determination—Ensurethatthematerialinthe to 95-unit range. Engage the pointer clutch and stop the

sample chamber is completely molten and that temperature viscometer motor when the pointer is in view. Record the scale

controllersettingsareproper.Turnontheviscometerandallow reading. Restart the viscometer motor, and allow at least five

the spindle to rotate at the lowest spindle speed available to additional revolutions of the spindle. Engage the pointer clutch

minimize temperature gradients in the sample as well as and stop the viscometer motor with the pointer in view. Record

FIG. 1 Apparatus for Viscosity Determination

D3236–88 (2004)

the second dial reading. Repeat the above operation until three under constant operating conditions on identical test material

consecutive scale readings are obtained that differ by no more would, in the normal and correct operation of the test method,

than 0.5 unit. exceed the following values in one case in twenty:

8.8 % of the mean of the two results. (1)

9. Calculation

11.1.2 Reproducibility—The difference between two single

9.1 Determine the average of the three consecutive scale

and independent results obtained by different operators work-

readings which differ by no more than 0.5 scale unit. To

ing in different laboratories in identical test material would, in

convert to millipascal seconds, multiply this value by the

the long run, exceed the following value only in one case in

appropriate factor taken from either the instrument instruction

twenty:

manual or Table A1.2 in the Annex. Repeat this for each

25.4 % of the mean of the two results. (2)

temperature.

NOTE 9—The precision of this test method is based on a round-robin

NOTE 7—If it is necessary to interpolate for viscosity values at

conducted using six wax-based hot melt materials that are believed to be

intermediate temperatures, plot a series of observed apparent viscosity

representative of the class. Tests were conducted at three temperatures by

valuesonthelogarithmicscaleandthecorrespondingtesttemperatureson

seven to eleven laboratories using the Brookfield viscometer model and

the linear scale of appropriate semi-logarithmic paper, using a series of at

spindle combination available to that laboratory.This encompassed a tot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.